The construction industry is expected to generate a whopping $15 trillion revenue in the next three years. This means that the demand for equipment will also grow to keep up with the changes.

Is your construction company prepared for that?

Buying used machinery is a good start. It’s an easy way to get your hands on the equipment you need without breaking the bank.

In this article, we’ll explain some advantages of buying used rather than new machinery. Let us show you how you can get the most for your money and adapt to the growing market.

In this article...

Saving Money Upfront

One of the biggest benefits of opting for used over new equipment is its cost-effectiveness in more ways than one.

Firstly, buying used equipment can save you up to 50% more than buying new machinery. Used equipment costs less even when it is still in optimal condition.

Therefore, it’s often more advisable to invest in used machinery instead of buying new, especially if it’s in good condition.

Secondly, used equipment helps you reap the benefit of better insurance rates. The thing with insurance is that it’s based on the equipment’s replacement value instead of its resale value.

To explain it better, the insurance company will insure your machinery for the amount you’d need to replace it and not to get a new asset. Then, they’ll determine your interest rates based on the total amount—so, the lower the total cost of the equipment, the lower the monthly rates.

Of course, for the insurance company, the cost of replacing a used machine is lower than the cost of doing the same for new equipment, so you’ll fare better with the insurance rates, too.

On top of all that, the equipment market is rapidly growing, and machinery prices are increasing with it. Moreover, because of the expected 70% growth by 2025, companies will need more equipment to deal with the demand.

However, purchasing new pieces of machinery can set you back financially, so it’s often wiser to invest in a used machine.

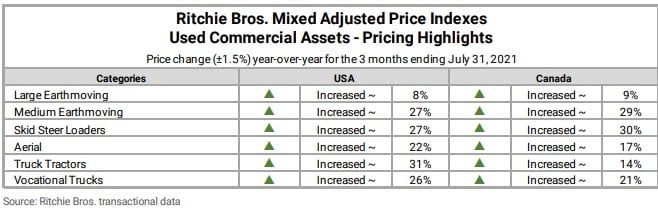

In the table below, you can see how much the prices increased recently for used commercial equipment at one of the long-known US equipment dealers.

A Ritchie Bros. report reveals that large earthmoving equipment has seen an 8% increase in price, while the prices of medium earthmoving machinery and skid steer loaders have risen by an astonishing 27%.

Therefore, you’ll pay a lot more for a new piece of machinery.

Avoiding Costly Initial Depreciation

When you buy used machinery, you’re not the one in charge of its initial depreciation.

Here’s how the savings work: your new equipment loses 20-40% of its original value within a year of purchase. This process is called depreciation, and it helps you figure out how much value your machinery is losing yearly.

The equipment depreciates more in the earlier years and less in the later ones according to the most common depreciation methods, which means that your equipment loses the most value in the very beginning, as explained above.

Usually, you’ll opt for double-digit depreciation after purchasing a new machine, and the rate will slowly go down with time.

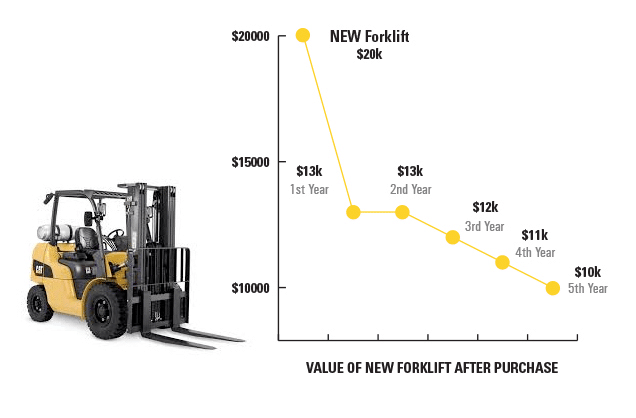

Let’s take a look at the price of a new forklift and how it decreases with time. Depending on the make and model, a new machine would cost you roughly $20,000, which isn’t exactly cheap to buy outright.

In the first year, the value of your investment would quickly drop down by $7,000, after which it would slowly go down to a value of $10,000 in the fifth year.

Notice how the forklift loses almost half its value in the first twelve months? That’s what happens with other new machinery, too, which is why buying used can be a lot wiser.

For example, you may buy a forklift in its fourth year, which means you’d pay around $11,000 for it, which is almost half its original cost.

If you purchase it off of someone who invests in their machinery through preventive maintenance, the forklift should be in optimal condition, which means you get more value for your money.

What do you get out of this? You have to pay a lot less during the rest of the equipment’s useful life.

Just in time Equipment

Maybe the most fantastic benefit of buying used machinery is that you can get whatever you need whenever you need it.

Just think about it: buying new equipment costs more than used machinery and takes a lot more time to obtain. Both time and money are precious in the construction industry.

Let’s say you need an extra bulldozer for a project in ten days. All your others are in use, and you cannot put them into service for the task at hand.

You have a couple of options for acquiring the equipment, such as renting, financing, or buying. In this case, you decide to purchase a bulldozer.

If you opt for a new one, getting it will take time. Nowadays, you can’t walk into a vendor’s store and just leave with the machinery you’ve purchased.

Instead, you have to place an order and wait until the manufacturer makes the product and delivers it, both of which take time, which you don’t have.

In fact, wait time is becoming a major issue in the construction world. Manufacturers aren’t getting parts as quickly as they used to, which prolongs the entire process and leads to customers waiting a lot longer for the equipment to be produced and shipped than is optimal.

To be more precise, manufacturers report the most extended wait times in 34 years, which is concerning. The industry and technology have advanced, but the wait times are currently at the level they were in 1987!

On the other hand, if you decide to go for a used piece of equipment, you can sign a contract that makes it yours virtually right away, which means you’ll have it in time for your new project.

If that isn’t enough to convince you, remember that there will be many more options available within your price range if you decide to go with used machines rather than new ones.

Helping The Environment

Buying used machinery promotes sustainability.

When you buy used, your actions have an immediate positive effect on the environment since the manufacturer doesn’t have to make your machine, waste resources, and increase the carbon footprint.

That way, you get to use equipment that can perform just as well as a new piece while saving money and protecting the environment.

Besides, it’s no secret that sustainability is gaining more relevance as time goes on, especially in construction.

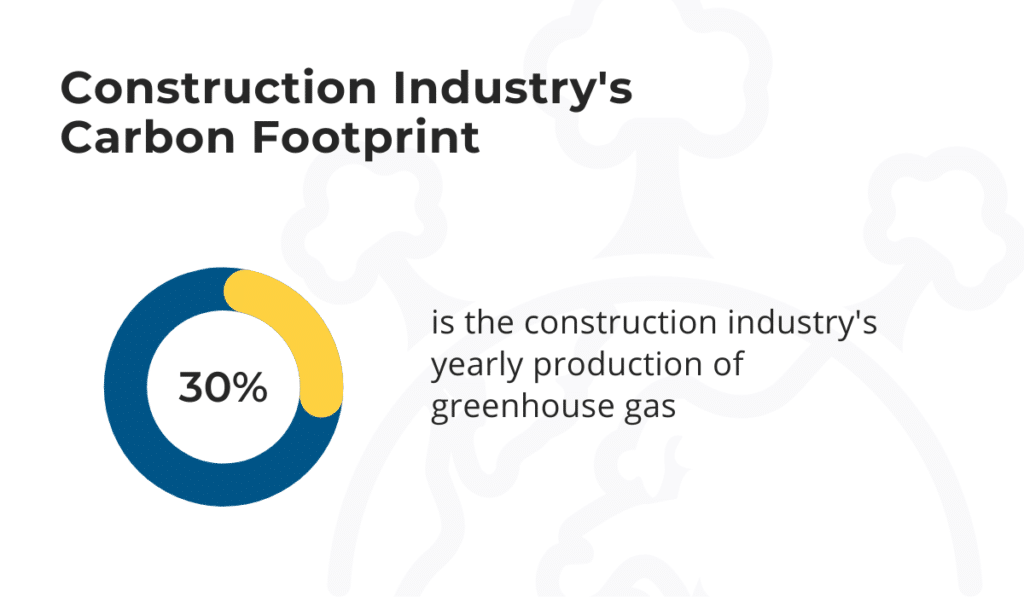

Because construction is a trillion-dollar industry, one of the largest in the world, its carbon footprint is concerning. This industry produces around 30% of the world’s greenhouse gas emissions every year, and since the industry is growing, so does its effect on the environment.

Construction companies are already opting for sustainable building practices. Still, there should also be a shift towards used equipment, reducing the need for machinery production.

Manufacturers are already making more fuel-efficient equipment to reduce fuel consumption and be more sustainable that way. Of course, the newest fuel-efficient models cost quite a bit.

However, if the new models are too expensive for you, why not get a more cost-effective used model and kill two birds with one stone in the process?

Also, keep in mind that preventive maintenance can help you reduce your fuel consumption by 5-10%.

If you buy a used fuel-effective machine and opt for preventive service, you’ll save your own and nature’s resources.

Conclusion

Opting for used machinery can do a lot more for you than just save money.

While that might be your main reason for buying used equipment, there are other important benefits in it for you, like avoiding depreciation and helping the environment.

On top of that, when buying used machines, you can ensure that you get just the machinery you need precisely when you need it, which you can’t count on when purchasing new equipment.

The best part about buying used machinery is that you have a lot more options, so it’s a way of increasing your fleet that you should look into if you want to improve your operational efficiency at a relatively low cost.