The construction industry isn’t precisely known as the most tech-advanced industry out there. Due to this, construction also lacks productivity.

McKinsey’s study found that construction is the least technologically developed industry, alongside agriculture and hunting.

The study predicts that digitization will help transform construction, which is exactly where technology like the Internet of Things (IoT) steps in.

IoT solves many of the problems the construction industry faces, so you should implement such solutions as soon as possible to reap their benefits.

This article will explain how IoT is changing the industry and translate its features into concrete uses for your company.

In this article...

Skills and Labor Shortage

The first obstacle you can take on by implementing IoT is the shortage of skilled workers.

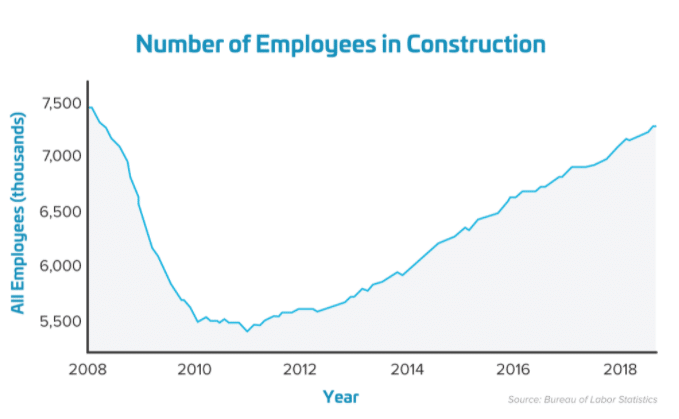

The Bureau of Labor Statistics data shows that the number of construction employees has been steadily rising since 2011, after taking a heavy hit due to the 2008 recession.

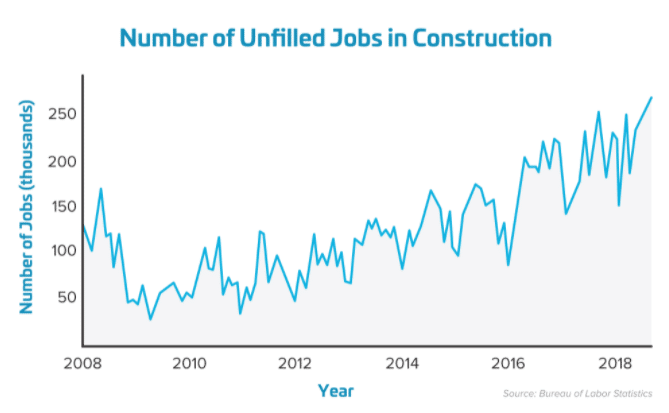

Despite this need for workers in the industry, unfilled jobs are also on the rise.

The reason behind this, according to companies themselves, is the lack of skilled staff. The industry is growing, and so are its labor needs, but there aren’t enough construction professionals on the job market.

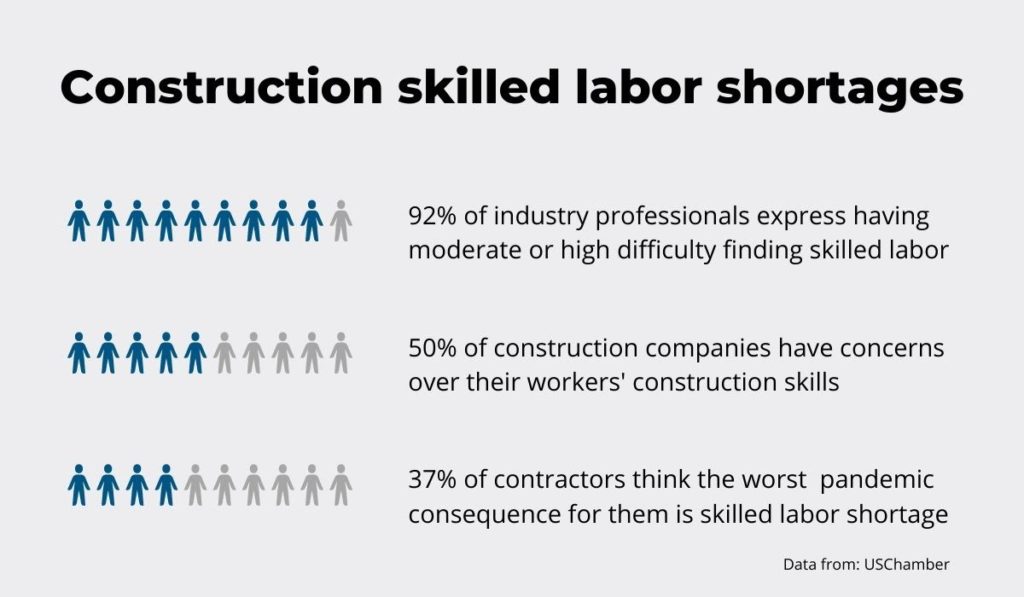

The US Chamber of Commerce reports that 92% of contractors have moderate or high difficulty finding skilled labor, and half of the contractors expressed concern over their staff’s skills.

An additional 37% marked worker shortages as their top concerning consequence of the COVID-19 pandemic.

Clearly, construction companies are struggling with finding the right workers for the job, which means they can’t take on as many projects as they would if they had sufficient staff.

IoT helps you deal with this problem by making the most out of the team you do have.

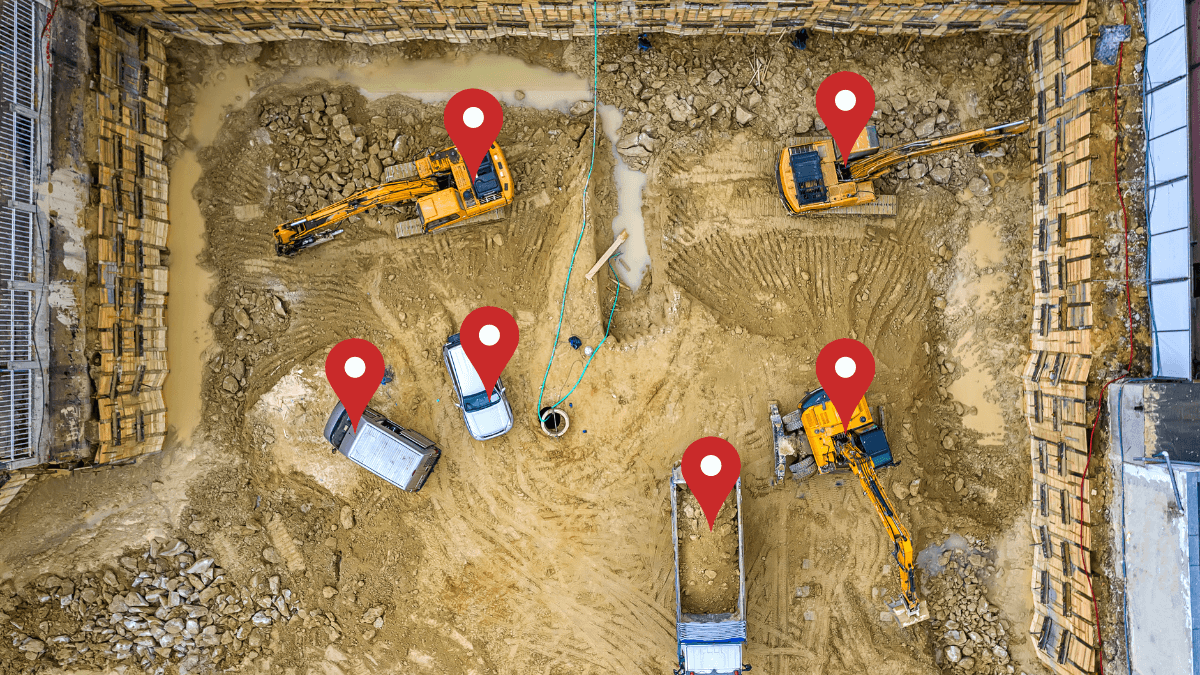

When you use a network of connected devices to track and monitor not just your staff but the entire project, you’ll easily spot when workers are done with their part of the project and can move on to the next one.

That way, you’ll maximize their efficiency and ensure that your team doesn’t idle around the worksite when their skills could come in handy on a different project.

By connecting all your devices and equipment, you’ll be able to collect all project data. If you choose to share this information with your team, you’ll empower them in more ways than one.

First, they’ll be encouraged to look things up independently instead of relying on asking someone else. Then, they’ll also be granted access to data that could help them become more productive by offering them solutions.

Lastly, the team won’t waste as much time locating the information if you share it with them through apps that let you upload asset data and documentation in the cloud.

On-Budget and On-Time Project Delivery

Using IoT in your everyday business can help you meet project deadlines while staying within the budget, which is a massive feat for the industry.

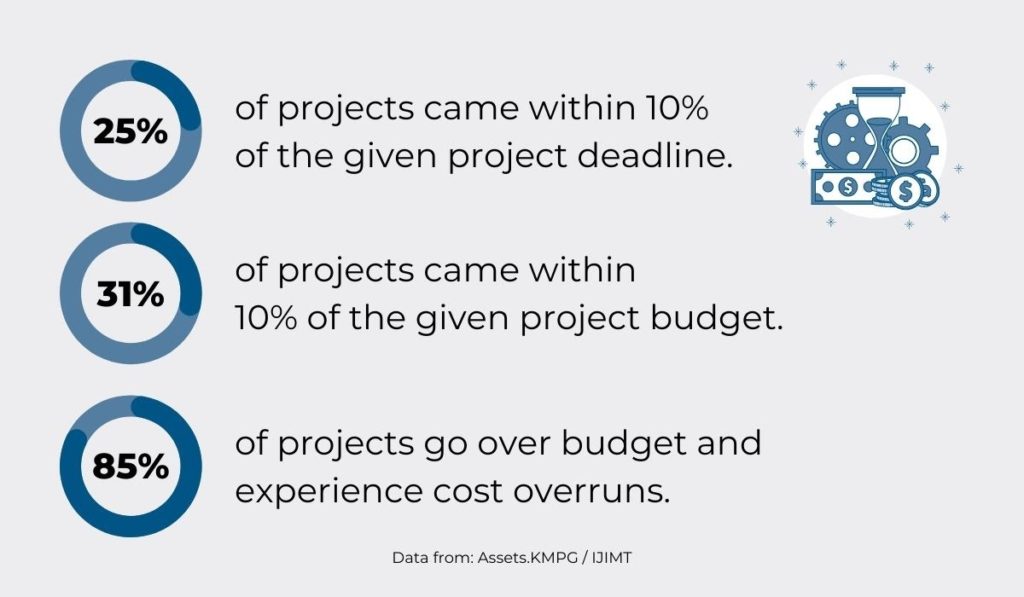

Did you know that just 25% of projects came within 10% of their original time deadlines in three years?

KPMG conducted a survey back in 2015, but it doesn’t seem that the state of the industry is any better nowadays.

In addition to being late, 31% of projects came within 10% of the budget during that same period.

What’s even more concerning is that 85% of projects ran into cost overruns. The industry obviously has to change something, or it will continue wasting time and money on jobs that could be done within schedule and budget.

IoT can come in handy in many ways, including limiting your spending and ensuring that everything is done on time.

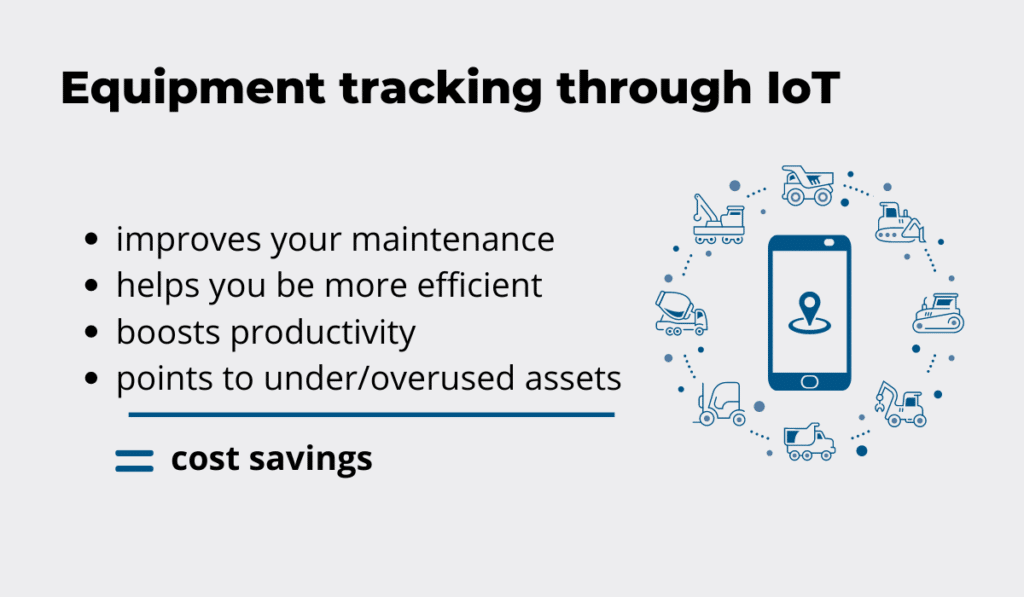

For example, if you connect your equipment to each other and your servers using IoT, you can get data on when it needs repair, maintenance, or a quick fix. This information might not seem like a lot, but it can bring in huge savings.

Roberto Bogdanoff, the director for customer solutions for key accounts at Volvo Construction equipment, agrees with the importance of timely maintenance.

If a machine breaks down in the middle of service, it “can shut down an entire production site, costing thousands and in some cases millions of dollars,” says Bogdanoff.

Since 60% of companies still run their machinery to the point of failure, it’s no wonder that so many projects are simply not done on time and end up costing a lot more than planned.

With IoT, you can minimize machine failures and therefore speed up your project.

Assessing Team Productivity

As a construction company, productivity should be one of your top priorities. After all, the industry isn’t the most tech-developed, and you lack skilled staff, so you have to find a way to boost your efficiency.

Why is productivity such a big deal in the construction world in the first place?

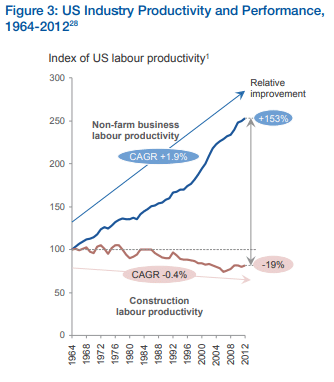

According to the World Economic Forum’s (WEF) report, US business productivity has been rising since 1964, save for the farm industry, and it doesn’t show signs of stopping. Sadly, the construction industry’s productivity didn’t follow the same path.

The industry has constantly had its ups and downs, but productivity has declined since 1992, reaching its low in 2008. However, it showed some improvement but is nowhere near its high.

In fact, the overall labor productivity saw a 153% increase since 1964, while the construction industry’s productivity went down by 19%.

WEF explained that even a 1% rise in productivity could save the industry $100 billion a year, so companies must prioritize efficiency.

By implementing IoT, you can directly affect your team’s productivity and improve their performance. This boost will help you make the most out of your team, their skills, and their knowledge.

Some IoT solutions automate processes, which means you can use your workers to perform the jobs the machines can’t while letting IoT do some of the work for you, thus saving time and energy.

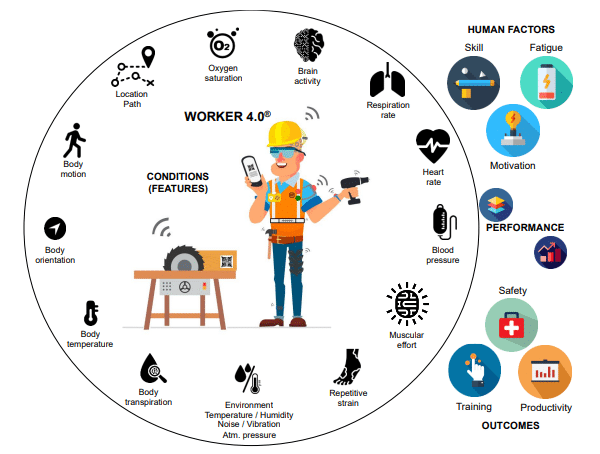

IoT technology also lets you measure worker conditions, human factors, performance, and outcomes.

It sounds like a lot, but the tech does most of the work: wearable devices and sensors placed around the worksite measure your employee’s work and conditions, sending the information to the central system.

You can then quickly tell if the employee spent their time working or idling, if they follow your safety guidelines, and where they are wasting time.

When you analyze their daily movements around the worksite, you can tell which issues your team has experienced.

For example, your employees might waste a lot of time moving around the worksite to get the necessary tools or project data.

This issue is easily preventable with an app that lets your team check tools and equipment in and out while also offering access to project-related information and documents.

Safety Issues

IoT helps companies promote safety in the workplace while bringing awareness to hazards.

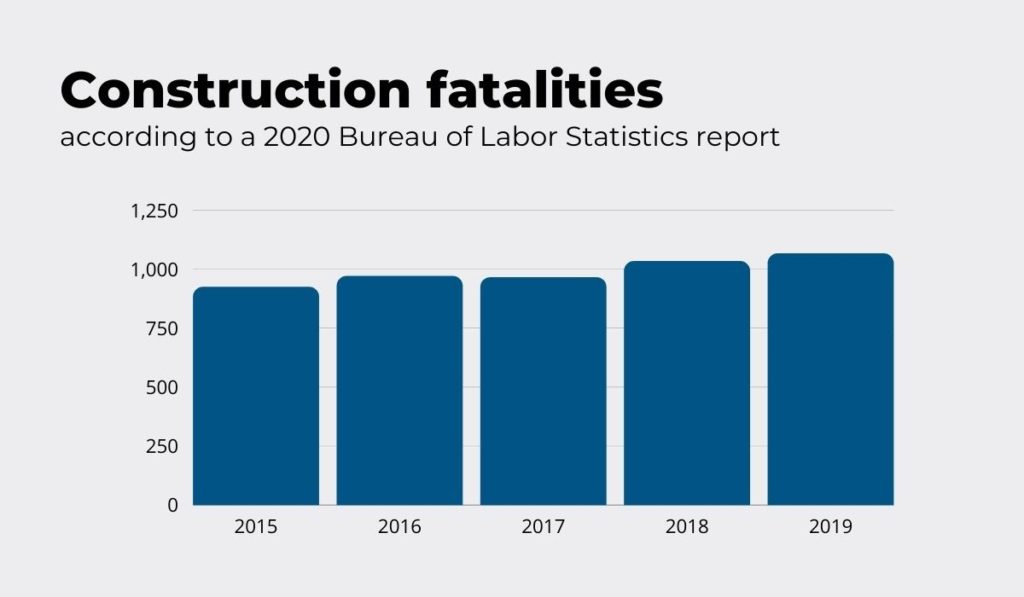

Protecting your workers is one of your primary responsibilities, as the construction industry is a dangerous one. Field employees are in contact with heavy machinery and demanding weather conditions, impacting their visibility and general safety.

The number of fatalities in construction is on the rise and has reached its high in 2019. The Bureau of Labor Statistics reported that 1,066 construction workers lost their lives in 2019, the deadliest year since 2007 for the industry.

Clearly, there’s a pressing need for construction companies to improve their worksite safety and protect their employees. IoT helps you keep your workers safe at the worksite despite all the safety hazards.

With this new technology, you can monitor the workers, their surroundings, and all the equipment, so you have a clear overview of the current situation at the site.

If a heavy machine is approaching a worker, their wearable device can notify them of immediate danger. That way, you’ll minimize workplace injuries and fatalities.

You can also equip your employees with exoskeletons that provide the wearer additional support, protect them when lifting heavy objects, and disperse weight.

The device redistributes weight to make it easier for the worker to move or lift heavier objects, thus preventing straining, fatigue, and injury.

Another excellent example of IoT removing workers from demanding terrain is Komatsu, a company that developed automated bulldozers.

Drones, sensors, and 3D cameras gather data about the surrounding area and terrain and transmit it to the bulldozer. The machine is then able to carry out the pre-foundation work on its own, with human supervision.

Therefore, the tech moves the worker from harm’s way while ensuring that the job gets done.

Waste Management

Through IoT, you’ll get a better understanding of your on-site waste levels and overall waste management.

Waste management is growing as an industry, partially due to an increase in construction activities. In fact, about 40% of US solid waste comes precisely from the construction industry, so it’s no wonder the waste industry is growing alongside it.

According to the WEF report, most construction waste contains “valuable minerals, metals and organic materials,” which you can reuse in the same industry.

IoT technologies assist you in repurposing these materials instead of throwing them away and creating more waste.

A helpful way to use IoT to help with waste is to keep track of the materials and resources you need for a specific project. Doing this will stop you from stocking up on materials you don’t need and that you’ll end up throwing away.

Then, you can also invest in a recycling system since many of the materials can be reused.

WEF suggests that 70-80% of all construction waste is not recovered and then reused, even though we could use it as:

- An additive to fertilizers

- Erosion control

- Reused materials

- Materials for road-building

- Wooden flooring

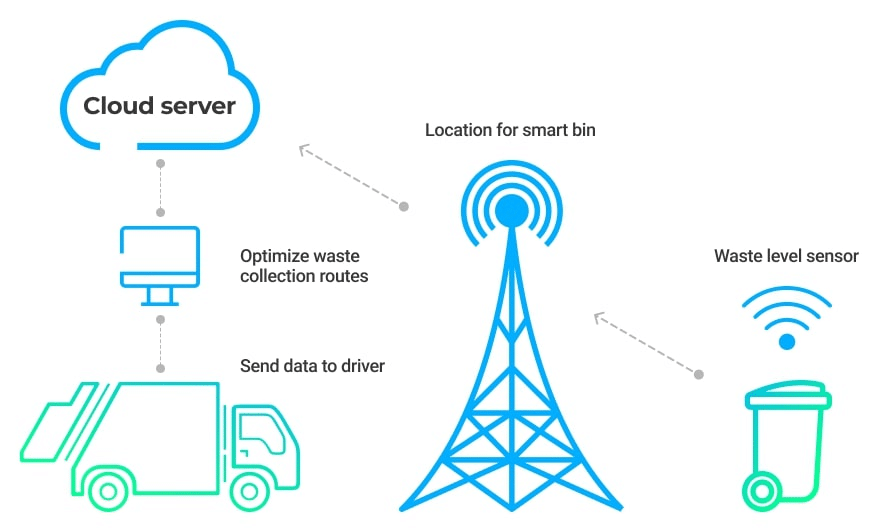

IoT can also help you measure the fill levels of the waste bins around your worksite.

When the containers are full, the sensors can notify the central servers, which alerts waste truck drivers to pick the waste up and avoid too much of it being left around the worksite.

Additionally, the sensors can notify you if a container flips or falls. You’ll also be able to tell whether the drivers are adhering to their pick-up schedule and if you need to adjust the program to fit your actual needs.

Better Control of Tools and Equipment

On top of all that, IoT will help you manage your inventory better.

This aspect of your construction process is essential as you most likely have more than one project going on simultaneously. Each of these projects involves different tools and equipment, materials, and employees.

Instead of tracking all the project-related data manually, you can opt to do it through IoT, digitizing your documentation and allowing your entire team to access it 24/7.

For better coordination between these projects, you must use IoT to connect the devices and employees to the central system.

A great example of this is GoCodes Asset Tracking, which allows you to check equipment in and out and avoid double bookings and machinery being unavailable when needed.

Due to this feature, the app lets you track how often you need the machine and determine what to do with it. If you rarely use it, it may be time to sell the equipment.

If it’s often booked weeks in advance, it might be time to invest in a new piece of the same machinery.

On top of that, you can use such apps to track your maintenance process. How often do specific machines go through repairs and fixes?

If it’s more often than not, you either have a problem with your service team or with the equipment at hand. This type of data lets you make smarter purchasing decisions in the future.

In case of expendable materials, the app will notify you in time for you to purchase more and stock up before you run out.

Conclusion

The construction industry is lagging behind most others, but the introduction of IoT can help it become more efficient and productive.

You can incorporate different IoT devices into everyday construction life that will make your job a lot easier, starting from tracking equipment quantity and maintenance to providing exoskeletons to workers to protect them from strains and injuries.

IoT definitely has a solution for you, no matter which aspect of your work you want to improve. What’s the first thing you will implement?