Although oftentimes overlooked and underappreciated, especially in the construction industry, inventory control affects many different business aspects.

In fact, if not done correctly, it’s known to be the cause of many project delays, money loss, and poor productivity.

In other words, inventory control can either make or break your business.

Therefore, looking into how you can improve this part of your business operation might have a significant positive impact on your success.

Keep on reading to find out more about the many benefits of inventory control.

In this article...

Always Knowing How Much Inventory You Have

Knowing exactly how much inventory you have is the most obvious benefit of proper inventory control. And it’s quite an important one at that.

Still, construction companies often overlook this part of their operations and don’t even notice how incorrect data about inventory quantities might be negatively impacting their businesses.

Has it ever happened that one of your workers went to the warehouse to look for a component he needs, only to find out there’s no more left because no one was alerted they needed to be reordered?

Or have you or anyone on your team ever ordered extra supplies of hydraulic fluid only for it to sit unused for too long?

Situations like these are a sign of substandard inventory control.

Stockouts, as well as overstocking, can have serious consequences for your business.

From certain materials or tools becoming unusable due to improper storage over longer periods of time, and high storage costs to unplanned downtime, significant project delays, and decreased profitability overall.

Clearly, not knowing how much inventory you have can have severe repercussions and this issue stems from poor inventory control, but what is the underlying cause of both issues?

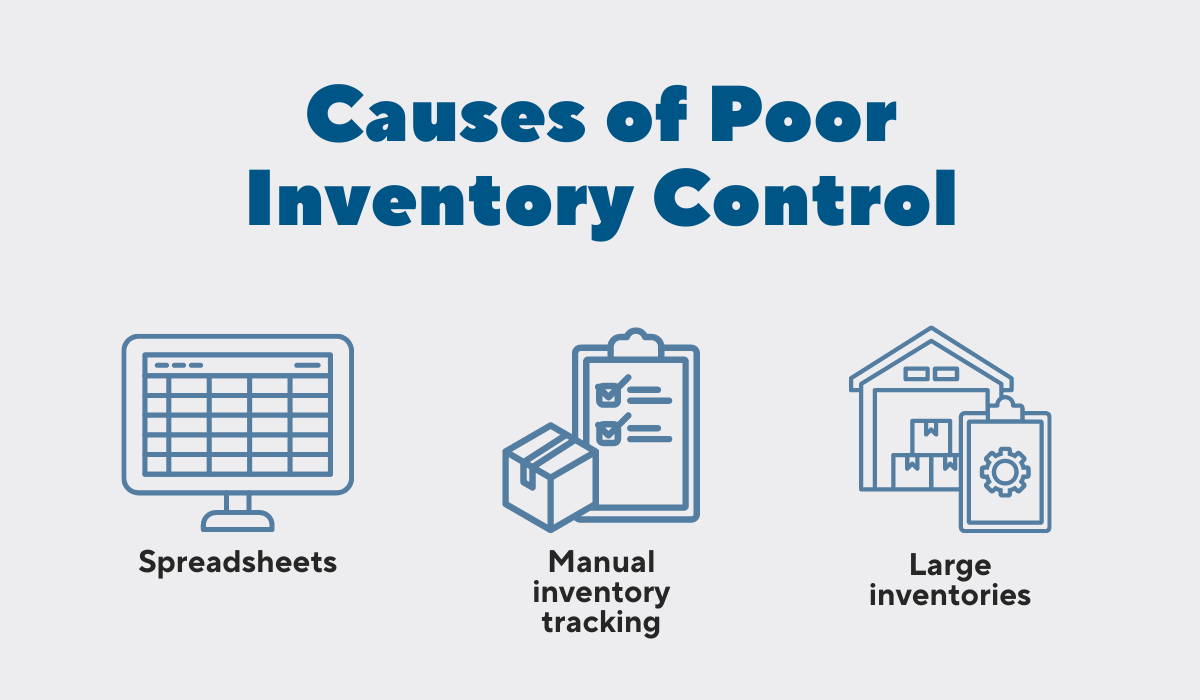

Here are the three most common roots of improper inventory control:

The first step in getting control over your inventory quantities is getting rid of spreadsheets and manual inventory tracking and replacing them with inventory control software, such as GoCodes Asset Tracking.

Such software helps even with very large inventories that can be a challenge to manage.

GoCodes Asset Tracking does wonders for your inventory quantity tracking and management as it lets you update the information about each item on the go.

Not only that, but the software also sends you low inventory quantity notifications when a specific item goes below the minimum quantity you specified.

Overall, getting an insight into your inventory quantities is the first step in increasing your operational efficiency.

Why not rely on technology to help you obtain accurate and up-to-date data regarding your inventory?

Makes It Easier to Effectively Manage Inventory

Managing inventory is no simple task, especially when there’s so much data to track, scattered across different spreadsheets and different software solutions.

Organizing and making sense of it all is truly a nightmare.

However, an inventory control system makes inventory management so much easier because it serves as a centralized database with all the crucial information about your inventory, such as check-in and check-out times, asset location, maintenance schedules, and so much more.

Essentially, a proper inventory control system streamlines and centralizes your inventory data, which has all sorts of benefits for your business.

To begin with, a clear understanding of what you have in your warehouse enables you to make better-informed decisions about asset acquisition, disposal, and allocation.

This way, you’re more able to identify potential problems, such as stockouts, before it’s too late, and not when everyone is already losing their head because a tool is missing.

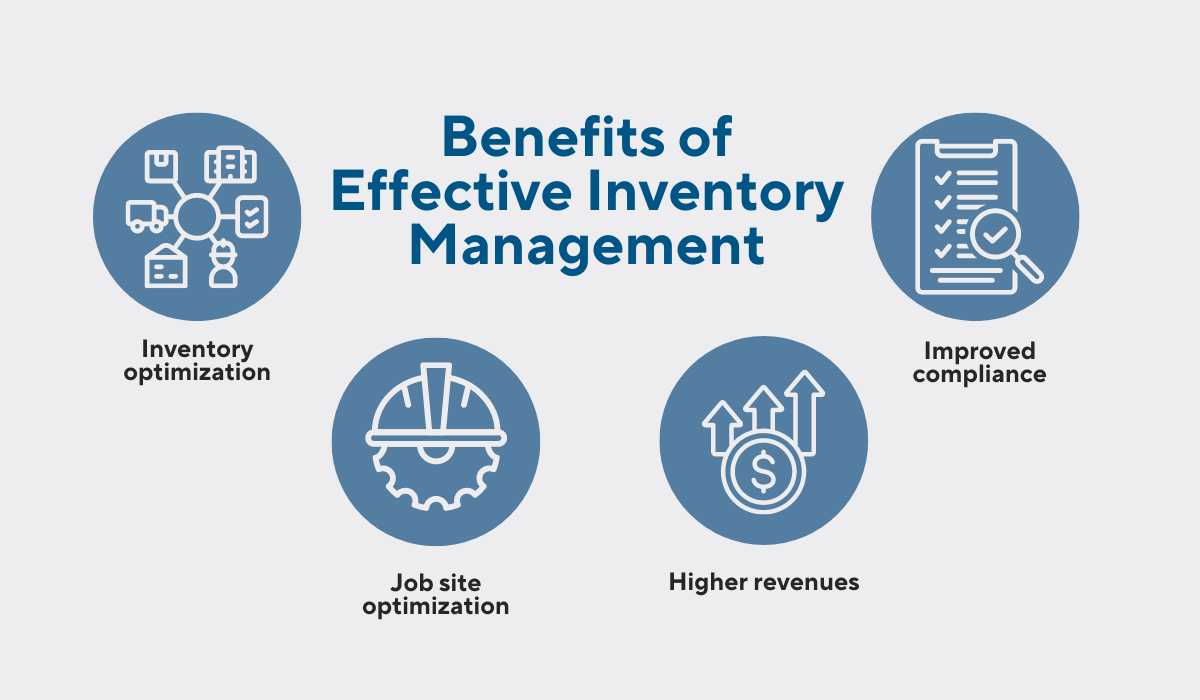

Moreover, optimized inventory often goes hand in hand with a well-organized job site.

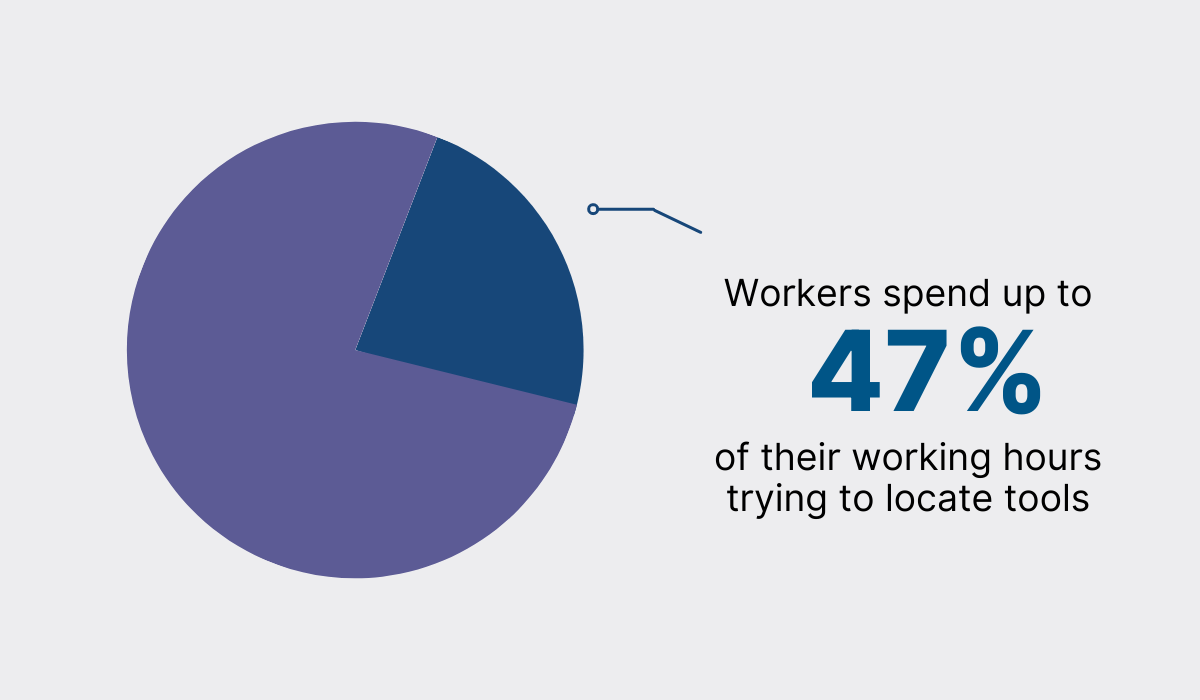

Did you know that workers spend 47% of their working hours looking for tools they need? That is a significant amount of time—time that could be spent on actual project completion.

Proper inventory management mitigates that issue by providing the exact asset location and information about the last person to use that particular item, which significantly increases productivity.

In turn, increased productivity directly translates to higher revenues.

Since inventory management ensures there are just enough tools and materials for all team members, and guarantees that everybody knows where that inventory is, it improves coordination across job sites.

As a result, it decreases unplanned downtime, ensures project deadlines are met, and positively impacts your profitability.

Besides, having a reputation for completing projects on time is not a bad thing at all. In fact, it often leads to more job opportunities.

Finally, with proper inventory management, you’re able to better comply with industry and government standards precisely because you can track your inventory quantities, and access all the necessary information about the items, including asset calibration, testing, and locations.

That way, you’re always ready and can prove your compliance with all the regulations and laws.

All in all, inventory management involves a lot of moving parts, which makes it hard to do it properly.

Luckily, inventory control systems help make this task more streamlined, enabling you to take better care of your inventory.

Allows for More Accurate Inventory Forecasting

Knowing how much inventory you have is one thing, but knowing how much you need is completely different.

Not having enough inventory for project completion, as we already established, has a negative effect on efficiency and productivity.

However, overstocking is no good either. After all, you need storage space for all that extra materials and tools. And storage space costs money.

You need accurate data so you can properly forecast your future inventory needs and avoid overstocking and stockouts, both of which can be pretty expensive in the long run.

Still, not many companies are aware of the importance of accurate inventory forecasting, it seems.

In fact, a US-based consulting company Ernst&Young reported that, when they recently held a webcast on forecasting for recovery scenarios, only 9% of those who took part reported feeling confident in their company’s forecasting abilities.

Moreover, 44% of their participants claimed the biggest impediment to accurate forecasts is a lack of access to meaningful and quality data.

Although the webcast participants were professionals from several different industries, and not just construction, the same rule applies to everyone: accurate data is crucial for accurate short-term and long-term forecasting.

This is where inventory control software comes into play.

Any proper inventory control software should offer analytics and reporting features that are easy to use and provide correct, detailed, and timely data on your inventory.

Furthermore, being able to design your own reports or schedule them to be created automatically allows you to sort, filter, combine, and present information in a way it suits your needs.

Finally, being able to generate graphs and charts helps visualize the data better and even further improves your decision-making.

To conclude, inventory forecasting is an important part of any successful business and, as such, it needs to be accurate.

With the help of an analytics feature that is part of inventory control solutions, you’re going to be able to take your decision-making to new heights!

Saves You Money by Reducing Inventory Costs

As we hinted at throughout this article, proper inventory control can save you quite a bit of money in the long run.

In fact, inventory control reduces inventory costs on three different fronts: inventory purchasing, storing, and managing.

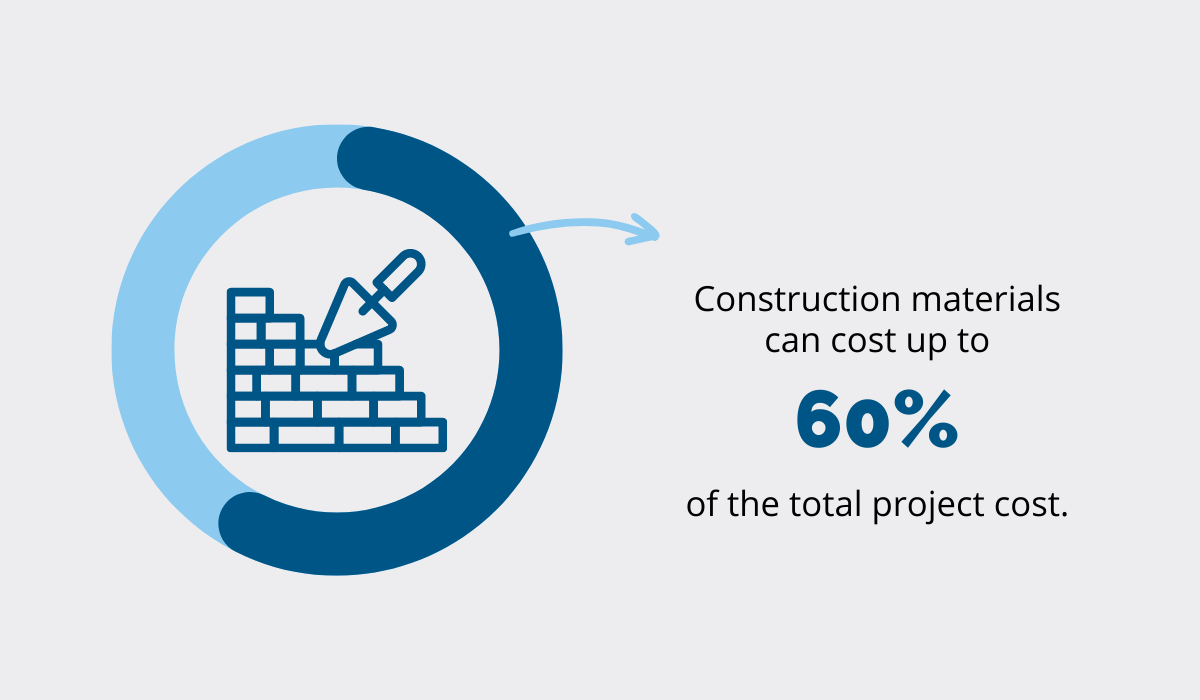

To begin with, it’s important to note that construction materials alone can account for up to 50-60% of the total project costs.

This is a significant sum, and therefore, it’s advisable to be really careful when it comes to inventory acquisition.

Purchasing too much inventory presents a large cost center as the extra supplies are oftentimes left unused in a warehouse until they expire or get misplaced and are therefore never even utilized.

Proper inventory control prevents overstocking and, in turn, reduces storage costs as well.

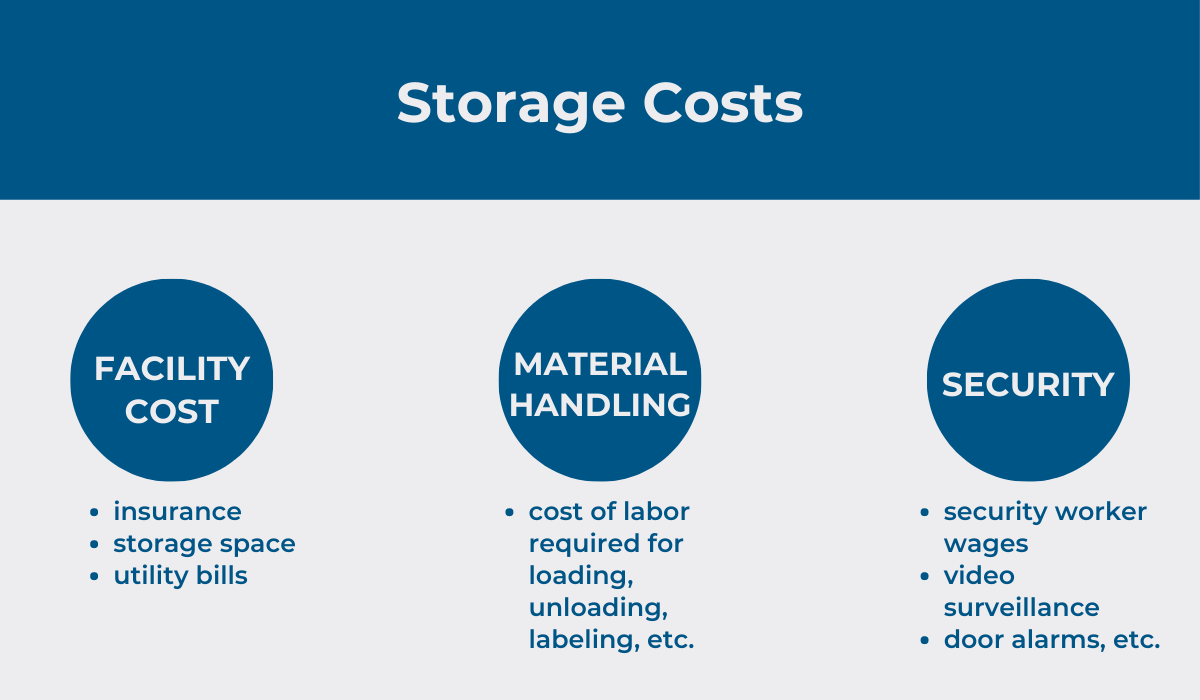

Many businesses don’t even consider storage costs a significant investment, but the expenses can add up pretty quickly.

This is especially due to the fact that storage costs actually have many different components.

In other words, when you’re paying for storage, you’re not only covering the cost of the space itself but of many different elements, all of which are needed for appropriate inventory storage.

Finally, inventory handling consists of many different tasks, such as finding proper materials, tools, and machinery to start with, then acquiring these assets after thorough market research and transporting that inventory.

All of these stages require time, effort, and personnel to be properly executed, and they cost money.

Therefore, the more time and labor these tasks require, the more the price of inventory handling increases.

Overall, inventory control can help you cut unnecessary costs on many fronts.

Some of these costs you might not be even aware of in the beginning, but with the help of inventory control software you’ll detect and eliminate them in no time.

Identifies the Weak Links in Your Supply Chain

Inventory control does not only improve your own overall operational efficiency, but it also helps you identify some of the external factors that might be either helping or hindering your growth.

For example, effective inventory control can help you determine if there are any weak links in your supply chain.

In other words, when you start carefully and meticulously tracking and managing your inventory, you may start noticing that some of your suppliers are underperforming in certain areas.

In fact, there are a few metrics to consider when you want to evaluate supplier performance.

Relying on suppliers that don’t fulfill some of these criteria can actually impact your business in a negative way.

For example, not having goods delivered on time or in full often results in project delays.

And if the delivered goods are defective and experience failures, the quality of your work suffers, which can inflict quite a reputational damage to your company.

Moreover, you also need to ask yourself if your suppliers are working within legal standards and complying with all the regulations, if they’re continuously working on improving, and, probably most importantly, if they’re giving you a fair price compared to the competitors.

You want a strategic partner that will support and enable your growth, and continuing business relationships with suppliers that don’t meet the necessary criteria can be detrimental to your success.

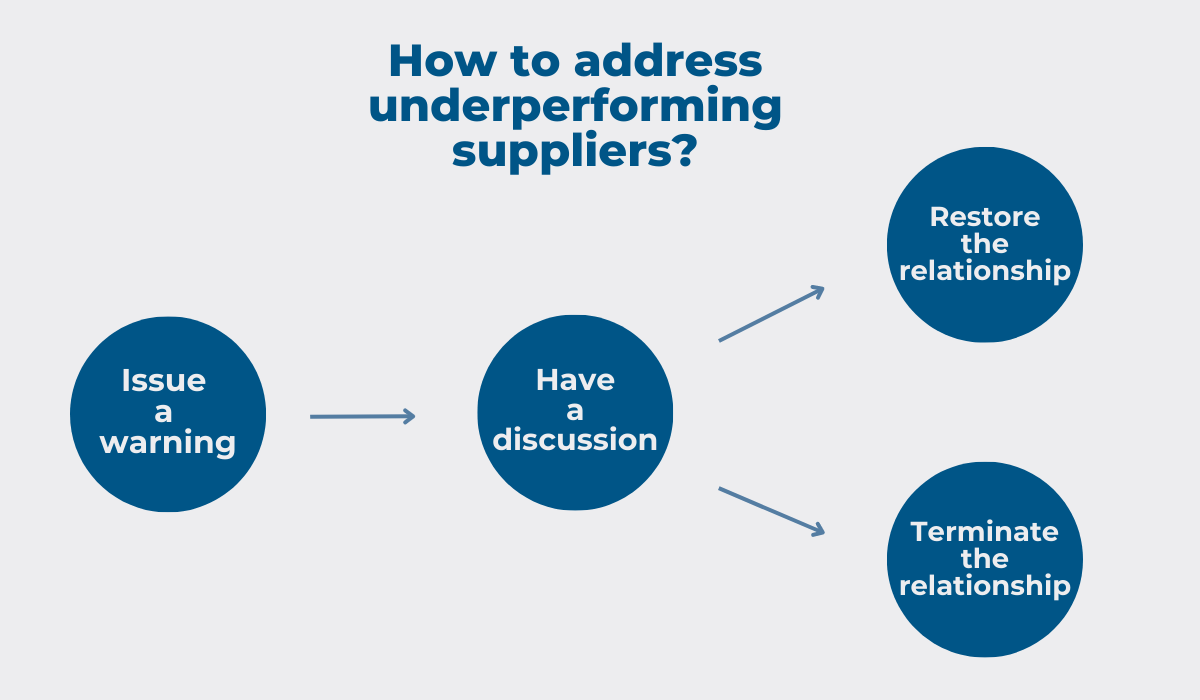

Therefore, when you detect an underperforming supplier, there are several things you can do about it.

Before making any major changes, it’s best to give the suppliers a chance to correct the issue and have an honest, unbiased conversation about your concerns.

Reaching an agreement would be the desirable outcome, but if not, it’s not your obligation to accept bad service. If the supplier isn’t willing to change, consider looking for a new one.

Sometimes, exiting a business relationship is the only thing you can do to protect your own interests.

Conclusion

Proper inventory control has far more benefits than people often realize.

By implementing an inventory control system, construction companies can get accurate knowledge about their inventory quantities, locations, and many other important aspects of their inventory.

Based on that knowledge, it’s far easier to make better-informed decisions concerning asset acquisition, allocation, and disposal, which substantially increases productivity and reduces unnecessary costs in the long run.

And that’s how you stay on top of the game!