Behind every productive and profitable business, there’s effective equipment management.

In the simplest of terms, it ensures that your equipment is being used as efficiently as possible. But what exactly does equipment management involve?

There are several aspects to it, such as equipment acquisition and disposal, tracking equipment utilization, repair, and maintenance.

However, although equipment management is quite a complex process, don’t get discouraged. We’re here to help!

To take your equipment control game to another level, consider the five super-useful strategies we outlined in this article.

In this article...

Stay On Top of Your Equipment Needs

Contractors and construction workers alike know that every construction project is different and therefore requires various tools and machinery for its completion.

Unexpected equipment shortage during a project is the worst-case scenario, so before you even begin the work, you’d want to know you have everything you need.

That’s why you must stay on top of your construction equipment needs, both big and small.

In other words, you need to ensure you have enough equipment of the right type to finish each construction project on time.

How do you do that? By regularly reviewing your equipment needs and going through every piece of equipment you own.

Doing so gives you insight into whether you need to dispose of the old, buy new, or rent additional equipment.

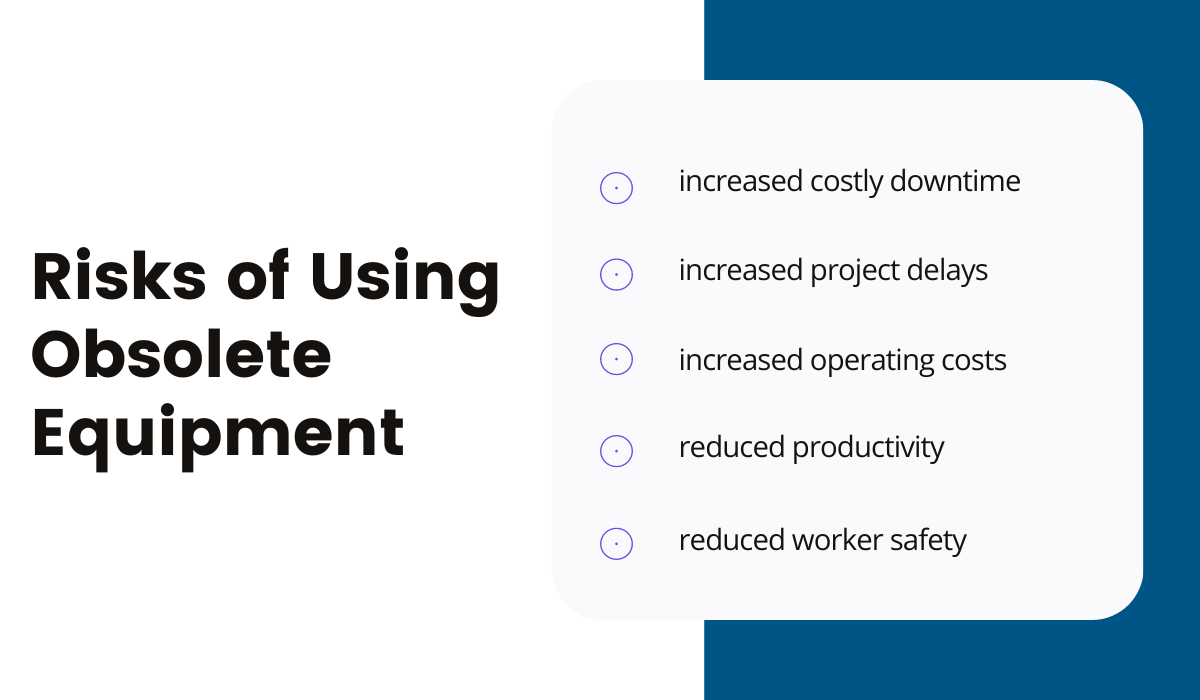

To begin with, disposing of old equipment is just as important a part of equipment management as acquiring new items because once a particular piece becomes obsolete, using it starts incurring substantial risks.

Take a look at how outdated equipment might be harming your business:

Equipment obsolescence is unavoidable, though. It occurs due to technological advancements, aging, and deterioration.

It’s also a huge profitability killer. Keeping it for longer than necessary just makes no sense.

Be careful, however, not to get carried away with buying shiny new equipment, especially if you don’t really need it.

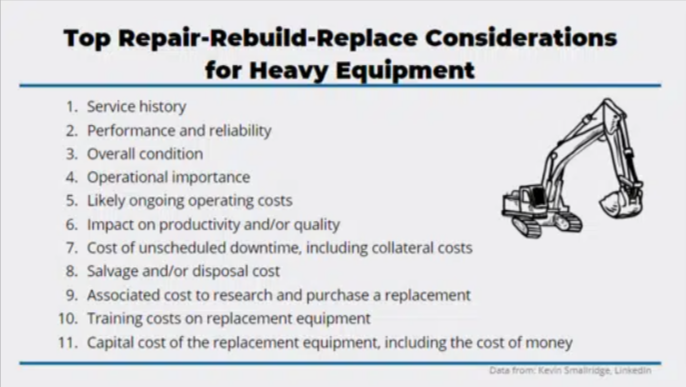

But how can you know when is the right time to replace and when to repair your equipment?

Kevin Smallridge, Managing Director at Medaco considers these factors, along with the cost of repair, to help him make that decision:

To put it simply, if a piece of equipment is in such a bad condition that it no longer operates as it should, and the cost of repairing it is considerably higher than the cost of buying new equipment, it’s time to replace it.

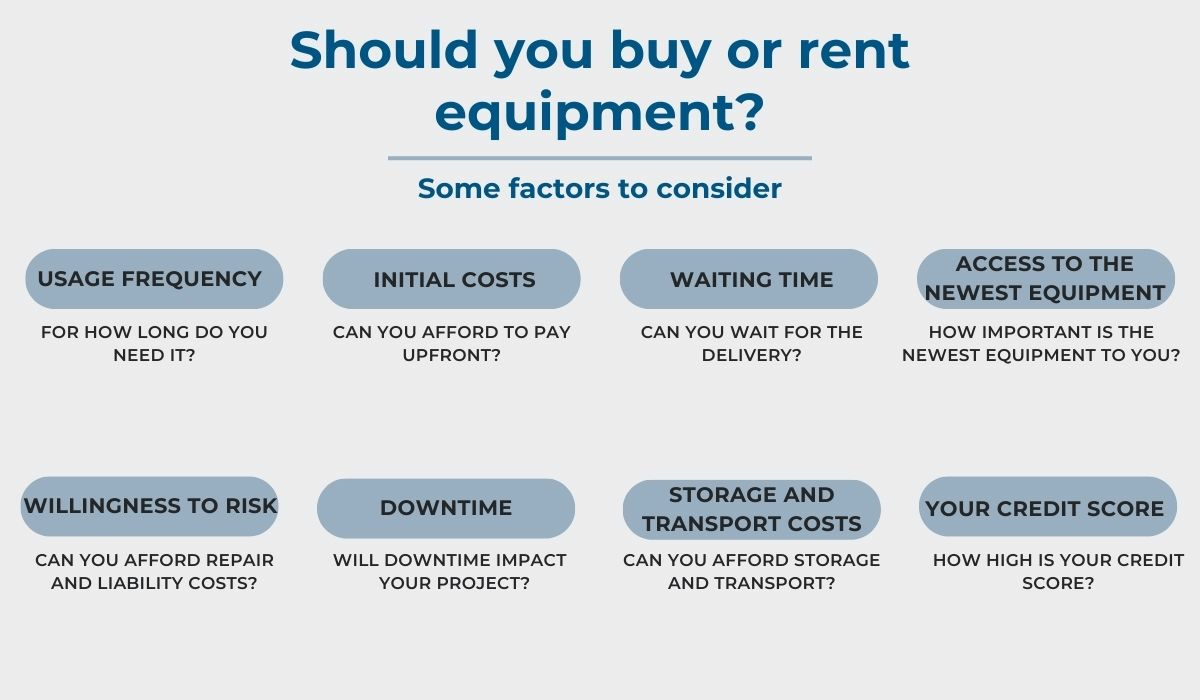

Another big part of equipment management is acquiring new equipment. And when adding equipment to your fleet, there are two choices: buying and renting.

Here’s just a quick overview of some of the factors to consider when deciding whether to rent or buy. You can read in more detail about them here.

As you can see, there are many factors to consider. Naturally, no business is the same, and you need to figure out what makes the most sense for you, profitability and productivity-wise.

All in all, keeping an eye on your equipment during every phase of its lifecycle will greatly impact the quality of your equipment management style.

Maximize Your Equipment Utilization

Having enough equipment is one thing, but ensuring that equipment is utilized to its full potential is completely different.

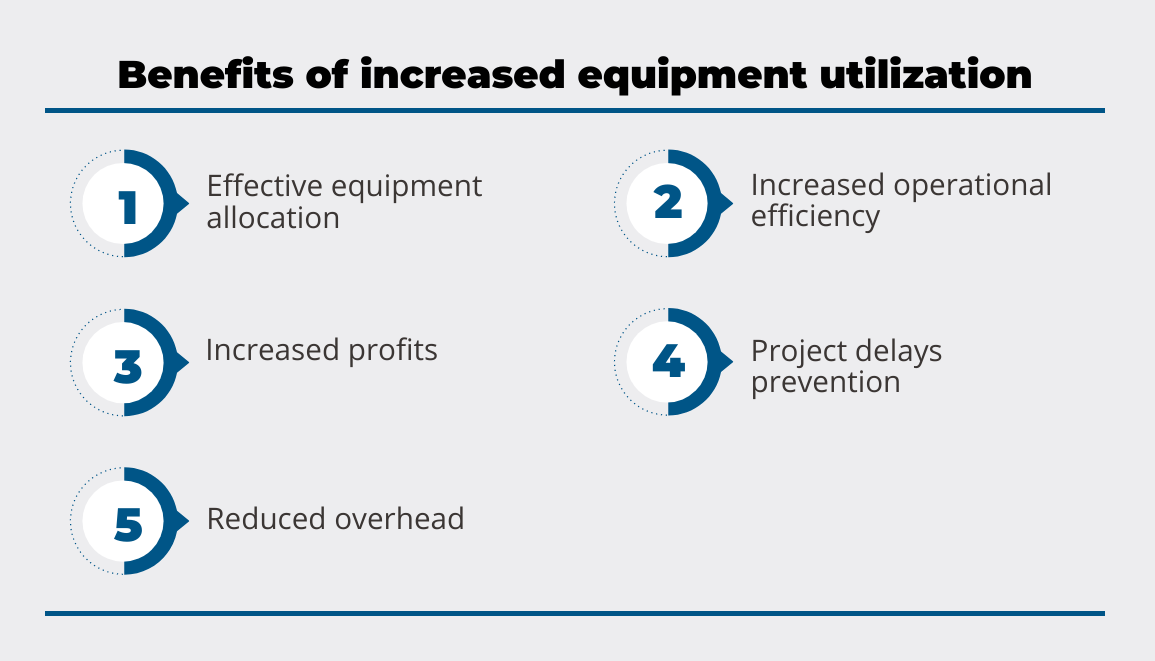

Tracking equipment utilization, i.e., monitoring how, when, and where your equipment is used, will do wonders for your equipment management and significantly improve your operational efficiency, among other benefits you can see below:

In a nutshell, tracking equipment utilization will prevent you from buying duplicate equipment when there’s no need for it, prevent costly project delays, reduce unnecessary downtime, and generally increase productivity.

These four steps will assist you in getting your equipment to reach its peak efficiency:

- Calculate the current equipment utilization rate (EUR)

- Track equipment usage

- Analyze usage trends

- Allocate equipment effectively

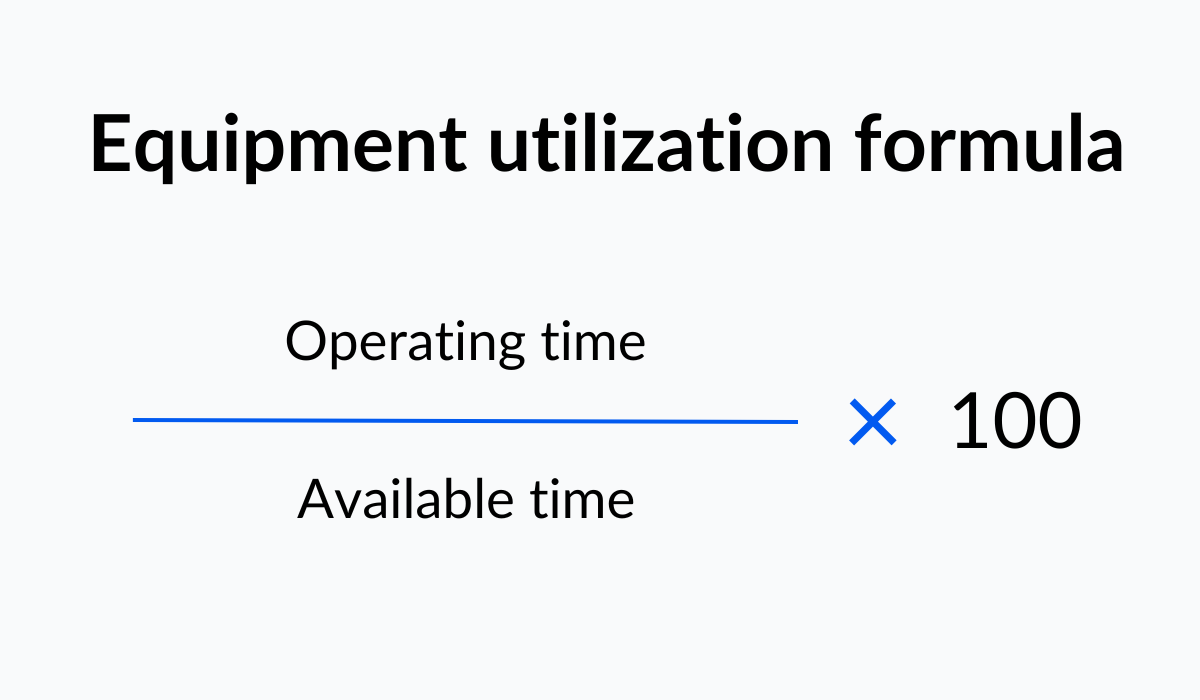

Firstly, to calculate the equipment utilization rate, use this simple formula:

Essentially, EUR is calculated by dividing the operating time by the equipment’s available time, with the planned downtime, such as weekends, public holidays, or nights, excluded.

For example, if your excavator is scheduled to run for 6 hours, five days a week, its available time would be 30 hours a week.

However, suppose the excavator, due to unexpected circumstances, operates for only 25 hours in one week. In that case, we can determine, by using the formula above, that its utilization rate for that week was 83%.

To maximize equipment efficiency, it’s also important to keep tracking equipment utilization and pay attention to the trends in usage.

There are plenty of metrics to consider. Here are some of them:

- Equipment check-in/check-out

- GPS location

- Ignition running time

- Miles

- Machine part action

If you look at patterns in equipment usage, you will quickly notice what areas might need your intervention, and you’ll be able to allocate equipment effectively.

For instance, if you notice that all your excavators across different jobsites are being overutilized, you’ll know it’s time to either rent or buy a new one.

In short, maximizing equipment utilization is a reliable way to improve your equipment management.

Try tracking when, where, and how your equipment is utilized to see how you can improve its productivity.

Keep Your Equipment in Good Condition

An important thing to note is that making the most out of your equipment does not mean running it until it breaks down.

Effective equipment management entails taking the time to ensure your equipment is in good condition.

In other words, timely maintenance directly translates to optimal efficiency and reduces equipment malfunction, which consequently prevents expensive and unnecessary project delays.

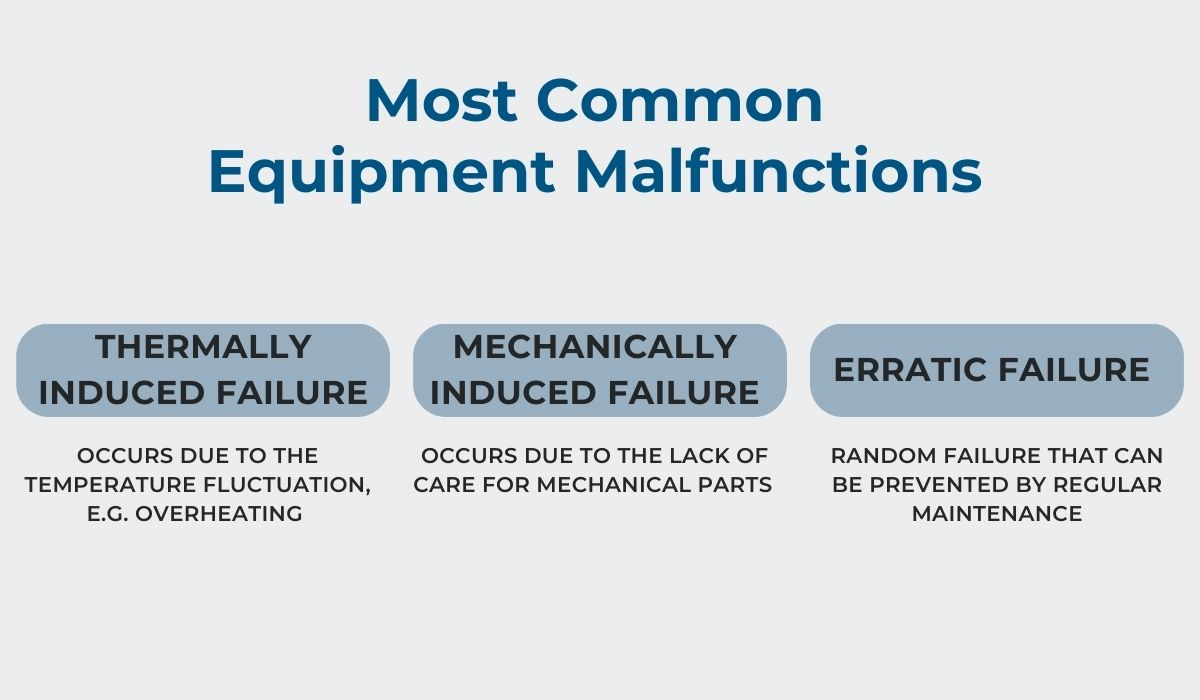

According to Canadian Occupational Safety, here are some of the most common equipment malfunctions:

Keeping your equipment in good condition requires a proactive approach. Waiting for a machine to break simply will not do.

Not only is reactive maintenance less effective, but it also costs more money in the long run.

For instance, if a machine breaks down during a project, it causes a delay as well as makes the paid worker who operates it idle.

Preventive maintenance, therefore, is the way to go.

That type of maintenance entails scheduling maintenance during planned downtime.

This way, you’re not disrupting ongoing projects but allocating specific time dedicated to regular equipment upkeep, which usually involves replacing broken parts as well as filters, batteries, fluids, and tire checkups.

Furthermore, for preventive maintenance to be effective, you need a good maintenance plan. Here’s how you can create yours.

Begin by determining your objective. This can be, for instance, prolonging equipment lifetime by a certain percentage.

The next step would be estimating how much money you would have to put into the process, including new parts and labor costs.

Moreover, if there was any previous maintenance on a particular piece of equipment, reviewing it would be the next step, along with consulting manuals and other important documentation that will help you carry out the maintenance efficiently and safely.

Before moving on to the final step—execution—choosing the right person for the job is essential.

Overall, the keyword when it comes to preventive maintenance is consistency. Therefore, conduct maintenance regularly, and it will surely keep your equipment in good condition for longer.

Protect Your Equipment Against Theft

Unfortunately, theft is quite common in the construction industry, so to improve your equipment management, you need to protect your assets from robbery.

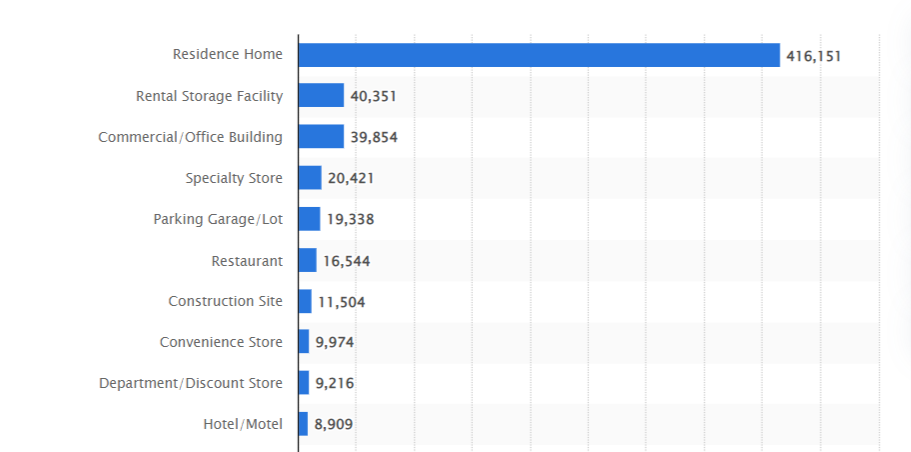

In 2021, more than 11,000 burglaries were reported on construction sites in the United States, which places such jobsites among the top ten locations where this type of felony occurs.

And what is probably an even more alarming fact is that, in 2016, only 21% of the stolen equipment was recovered.

In fact, low recovery rates are one of the many reasons construction equipment gets stolen so often in the first place.

Experienced thieves are able to remove license plates pretty quickly, thus lowering the chances of the machine ever getting found.

One effective way to prevent equipment theft is GPS tracking.

Here’s how it works. By tagging all your equipment with durable asset tags, you get immediate access to your assets’ location on a map in real time. It’s that simple!

This is an excellent method of deterring thieves since the tags are hard to remove.

Moreover, the labels usually contain your company’s name and logo, which further discourages robbers from theft.

To elaborate, seeing that your equipment is being monitored can be a deal-breaker for some robbers, but it also makes the asset easier to find and figure out who it belongs to in case of a robbery.

In essence, GPS tracking is a process that offers insight into an asset’s precise location. Not only that, but the data it provides is available to everyone on the team in real time.

This increases accountability among employees and, at the same time, discourages potential thieves.

Therefore, despite the overwhelming number of burglaries in the construction industry, keeping a closer eye on your equipment by GPS tracking can go a long way when it comes to theft prevention.

Automate Your Equipment Management

Having in mind everything we’ve covered so far, there’s no denying that effective equipment management is a very data-driven process.

It involves tracking and analyzing equipment quantities, utilization rates, maintenance schedules, location, etc.

Therefore, it probably goes without saying that manual data entry using pen and paper, or a digital spreadsheet, might not be the most efficient equipment management method as they are quite time-consuming, labor-intensive, and, not to mention, highly susceptible to human error.

For instance, if a worker needs to wait until the end of the shift to report that a bulldozer needs an oil change, there is a high chance he will forget to do it.

Finding a way of reporting this right away, however, is likely to make a huge difference.

That’s why it’s not a bad idea to embrace new trends and start using equipment management software.

Today, there’s plenty of equipment management software explicitly intended for the construction industry, our own solution, GoCodes Asset Tracking, included.

GoCodes Asset Tracking is a cloud-based software that provides all the data needed for efficient equipment management. It is also very user-friendly.

The solution uses custom durable tags with QR codes that you attach to an asset.

Scanning the code with our smartphone scanner app shows data about that particular asset, such as who has it, the return date, status, etc.

When using GoCodes Asset Tracking, you have an insight into the quantity of your equipment and consumable items, so you always know when to start considering a new purchase.

Moreover, our solution is perfect for monitoring and increasing equipment utilization.

Not only does our software monitor all the metrics we mentioned earlier, such as check-in, check-out, and location, but it also provides analytics and reports to help you make sense of all that data.

With GoCodes Asset Tracking, scheduling service tasks, such as preventive maintenance, is also possible.

And after a task is set up, the software sends notifications to the team in the morning of the scheduled maintenance as a reminder.

To sum up, there’s no more need to use manual data entry when it comes to equipment management. It’s highly ineffective anyway.

Instead, consider using equipment management software to improve your equipment tracking and control considerably.

Conclusion

Effective equipment management can be a game changer when it comes to raising overall operational productivity.

To take your equipment control to another level, ensure you have your equipment needs covered at all times. Don’t let the equipment shortage delay your projects.

Furthermore, the equipment you do have should always be protected, whether from inside factors, such as rapid deterioration due to the lack of preventive maintenance, or outside factors, such as theft.

After all, your equipment is a big investment. You want to make sure you’re utilizing it to its full potential.

While all of this might seem daunting, don’t worry—there’s plenty of equipment management software out there to help you track all your data.