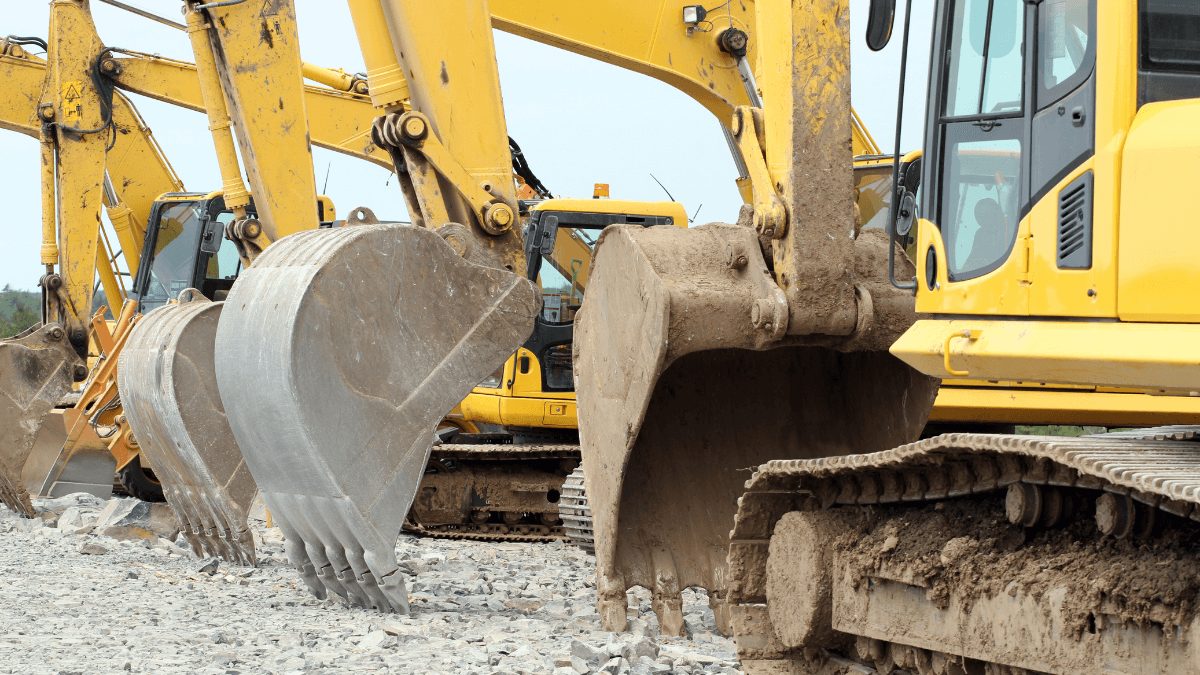

Having a fleet of construction vehicles comes with a lot of costs.

You have to invest in purchasing the machinery, insuring it, and paying taxes for it, and that’s only the beginning. Don’t forget that you have to service your fleet regularly or face costly fines.

Because of this, construction fleet owners often look for ways to hold onto their money while still making sure their equipment is in good working condition.

This article will explain six ways to save money on maintaining your construction fleet while keeping it in excellent condition.

Let’s start saving!

In this article...

Eliminate Excess Fuel Costs

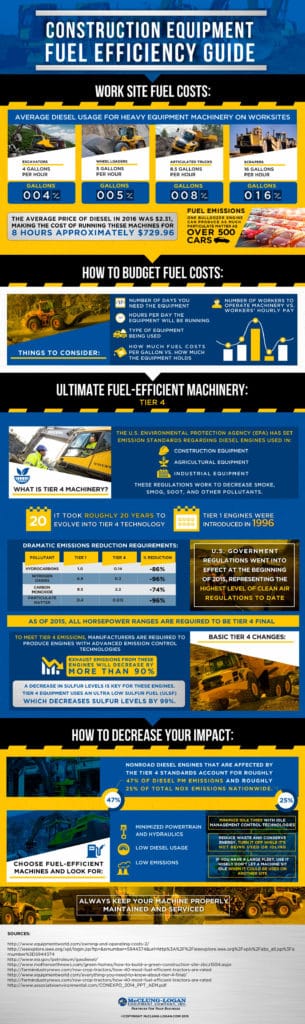

The first thing you can do to save money on your construction fleet is to examine your fuel consumption.

You probably aren’t aware of how much you’re spending on fuel. Some reports even claim that fuel accounts for up to 60% of a fleet’s operating budget. As you can see, it is an expensive necessity.

Still, there are ways to save money on it, and we’ll explain some of them.

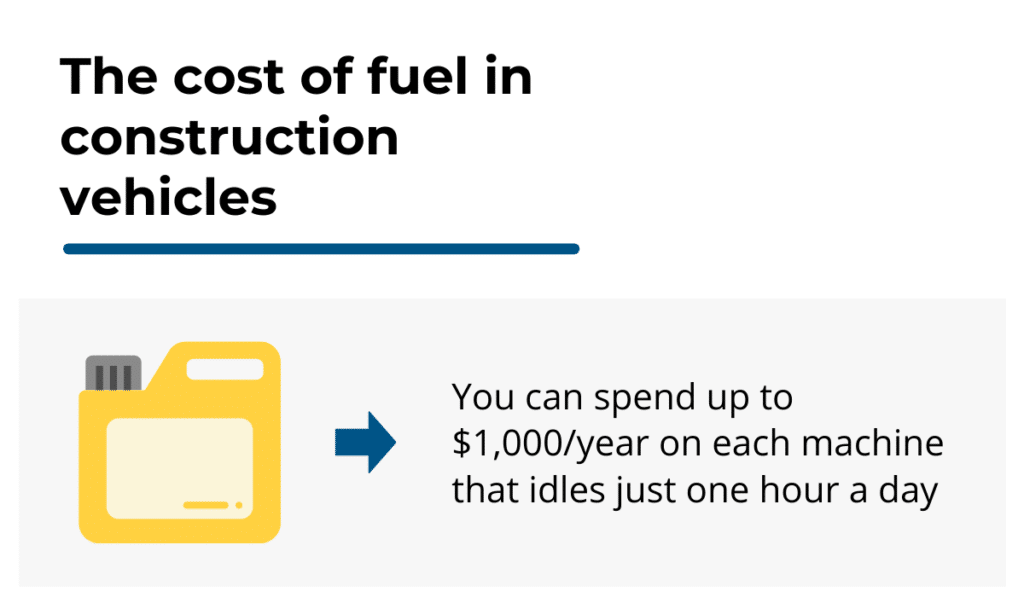

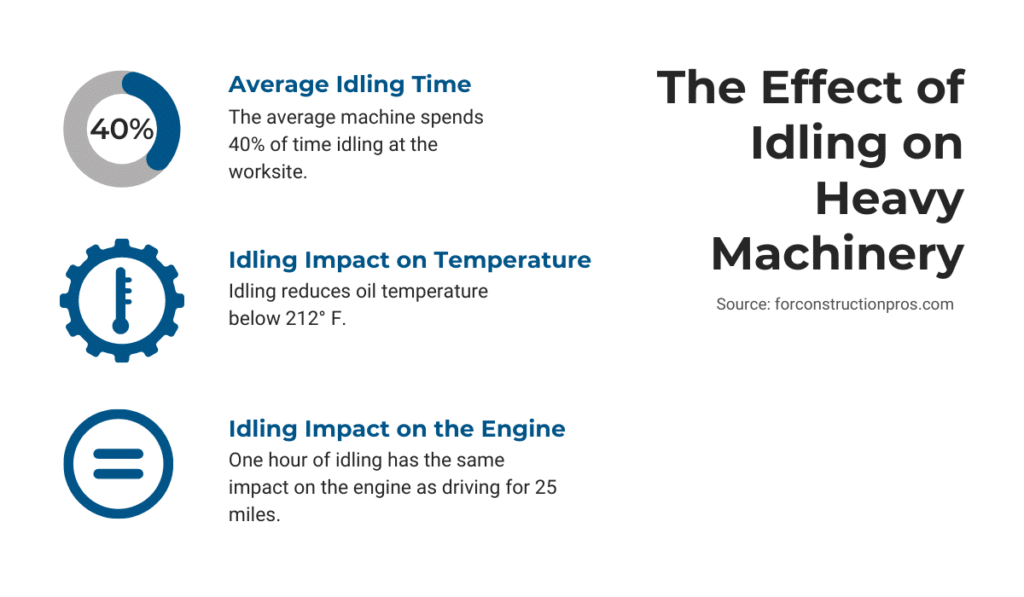

The first thing you should look into is your equipment’s idle time. Idling is harmful to your engine, but you might not be aware of just how much it costs you in terms of fuel consumption.

You can waste a gallon of fuel per hour, which means that you spend up to $1,000 yearly on each machine that idles just one hour a day.

When you own a construction fleet, your expenses are a lot higher than that simply because you have to account for more than one vehicle.

On top of that, excessive idling and fuel consumption lead to more wear.

These issues constitute extra expenses, meaning that they cause you even more monetary losses than initially planned. For example, premature engine failure that results from leaving the machine running without using it for too long will cost you anywhere from $20,000 to $40,000 to fix.

Surprisingly, your tires can also affect how much you spend on fuel. Studies show that even minimal tire underinflation leads to a 3% increase in fuel consumption.

If you’re trying to save money on fuel, make sure to add tire inspection to your checklists and instruct your team to always check how inflated the tires are before using machinery.

You can also reduce your idle time by letting your team know they should turn the engine off when not using the machine. Make this point an integral part of training so the operators never forget how damaging idling can be for your business. After all, the less time the equipment spends idling, the higher your savings will be.

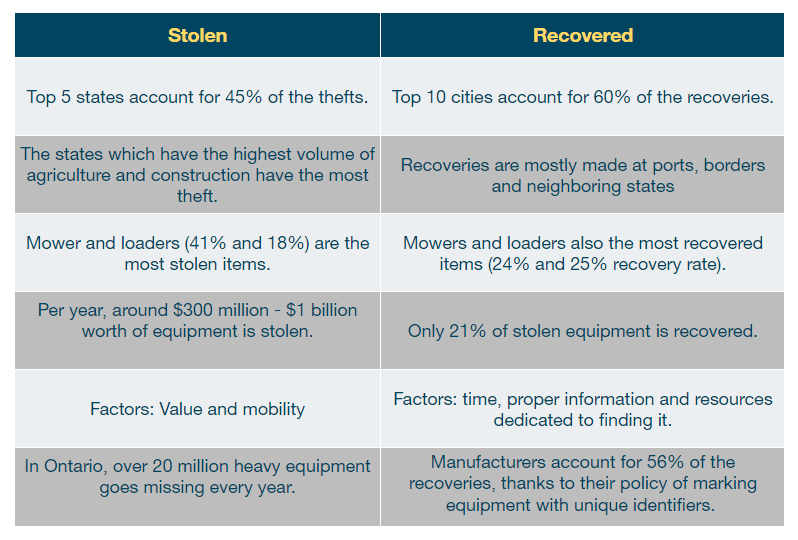

Work on Preventing Equipment Theft

Purchasing heavy machinery is expensive on its own, but when it gets stolen, you’re looking at possible debt. Because of this, you must have a bulletproof way of preventing theft at your worksites.

After all, companies lose anywhere from $300 million to $1 billion yearly on stolen heavy equipment. Sadly, less than a quarter of it is recovered, which means that thefts cost businesses a lot of money.

But that’s not all you’re losing when you lose a piece of equipment this way. If the theft happens during a project, you’ll also face unplanned downtime and costly delays. You’ll have to find a replacement piece of machinery as soon as possible, which can cost a lot at such short notice.

Companies that can’t afford losses of that kind focus on deterring thefts from happening at their worksites.

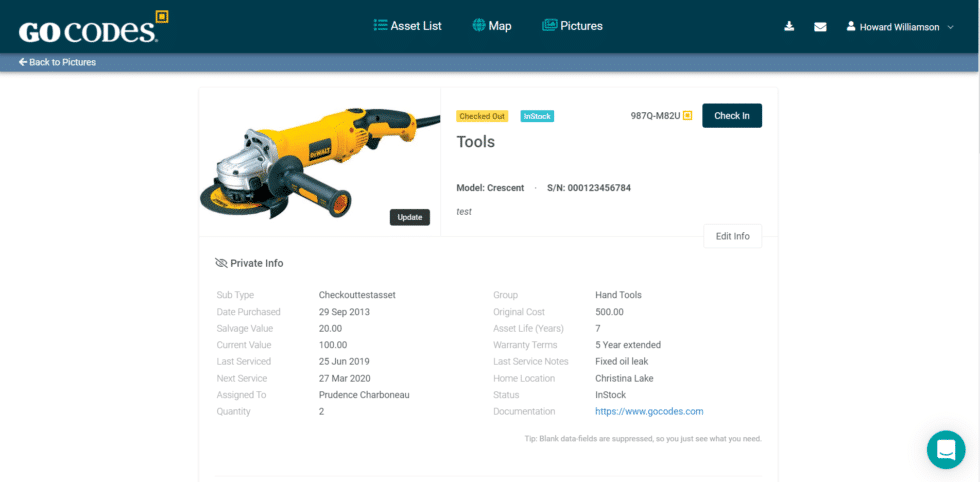

You can do that too if you choose to track your equipment using QR code technology. It lets you tag a piece of equipment and enter the machine’s data into the software, saving it in the cloud.

When anyone with access to the database scans the code with their phone or looks for the machine using the search bar, they will see all the available data on it.

This option also means that you have a globally unique identifier for each piece of machinery, making it easier to prove that the equipment belongs to you if it is ever located.

Such software also allows you to introduce a check-in/check-out system for all your machinery. When someone wants to take the machine for the day, they have to check it out, which links the user to the equipment until it’s checked in again.

Through this system, you see the machine’s last known GPS location and current user, which promotes responsibility and helps you pinpoint exactly where the equipment is and who is using it.

If theft or loss happens, you will be able to go through the equipment’s history and determine who was responsible for the machine at the time.

Monitor the Driver’s Safety Habits

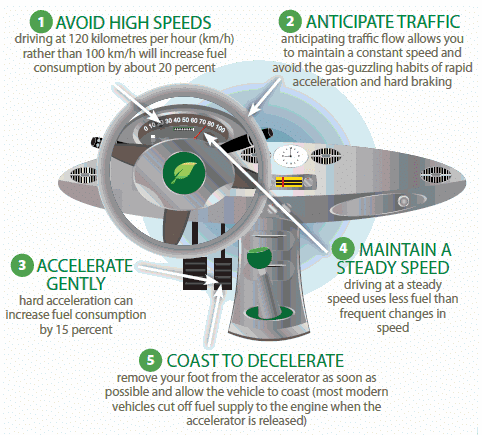

Monitoring your driver’s safety habits can help you save up more than you know.

Think of it like this: when your driver isn’t using the equipment properly, they’re causing more wear and tear, which means you’ll have to resort to more frequent maintenance and, therefore, increase your planned downtime, all of which cost you extra.

The equipment operator can also cause an accident and endanger themselves and others, which you will pay for. On average, vehicle accident settlements amount to $21,000, but that’s nothing compared to Occupational Safety and Health Administration’s (OSHA) operator fines.

In one case, OSHA found that the operator was responsible for an accident that injured another worker, resulting in a $91,000 fine to the company. Do you really want to take on those costs?

On top of that, the driving itself can be careless and not geared towards saving resources, as it should be. For example, a lot of speeding and braking can result in a 25% increase in fuel consumption, leading to rising costs, as mentioned earlier.

If you want to take control of this aspect of your fleet as well, start with quality training. The driver should always be aware of the laws and regulations for the type of machinery they’re using and some general ways to help the company save money.

These include:

- Maintaining the correct tire pressure, as under-inflation increases fuel consumption

- Focusing on the task at hand since this can help prevent accidents

- Being aware of their surroundings to keep themselves and others safe

- Never leaving the machine idle to save money on fuel and avoid engine failure

- Insisting on the safe and proper use of machinery to prevent accidents, injuries, and unnecessary costs

If you train the driver to prioritize these, you will inevitably save money as there will be fewer accidents, and the operator will be more focused on proper machinery use.

You can also use telematics to monitor the driver’s habits. Telematics helps you track your fleet and give you detailed information on its movement.

You can use this technology to determine how much fuel your machine uses, how fast the driver was going during their trip, as well as whether they were using a seatbelt, and how much time the equipment spent idling.

If you analyze this data, you can see which drivers need more training to prevent them from causing an accident or racking up your fleet costs.

Therefore, telematics can help you understand where you’re spending too much money, so you can cut down on those unnecessary costs.

Stick to a Maintenance Schedule

One of the best ways to save money as a construction company is to implement a strict servicing schedule.

The truth is, if you don’t service your equipment regularly, you risk huge losses.

Not maintaining your vehicles regularly means that you will have to replace them at least 50,000 miles before the one you’ve correctly serviced. In other words, you’re wasting money by not maintaining equipment.

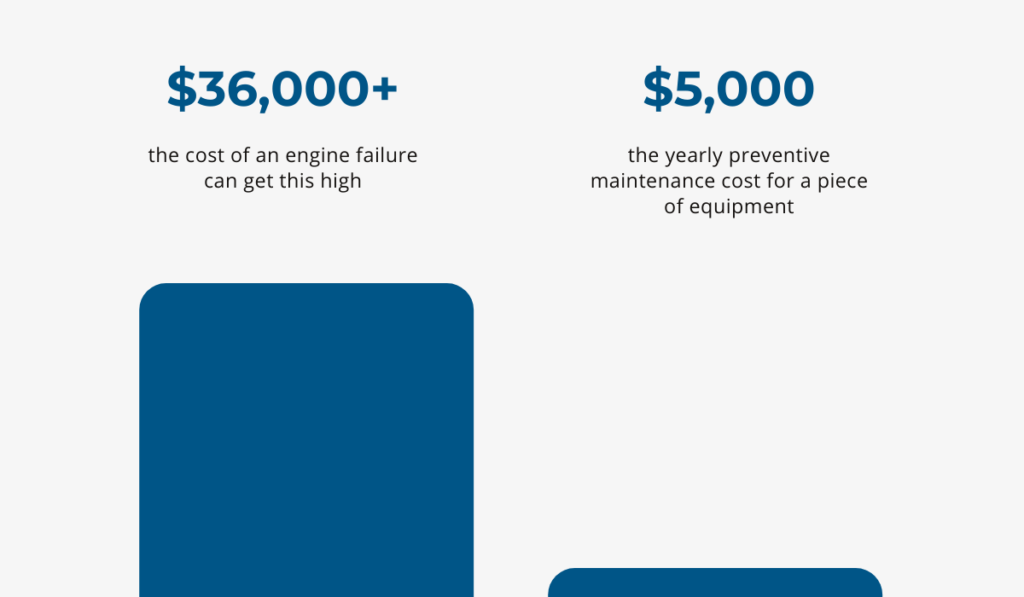

If you’re still not convinced, think of this: an engine failure can cost more than $36,000. At the same time, preventive maintenance of a piece of equipment will cost you, on average, only $5,000 per year.

Therefore, it’s a lot more profitable to spend money on maintenance than waste that much money on urgent repairs, unplanned downtime, and project delays.

Because of all this, it’s essential that you set up a servicing schedule and stick to it.

To determine the perfect intervals between maintenance for each piece of equipment, consult the manufacturer’s manuals and your service team, who regularly inspect the machinery.

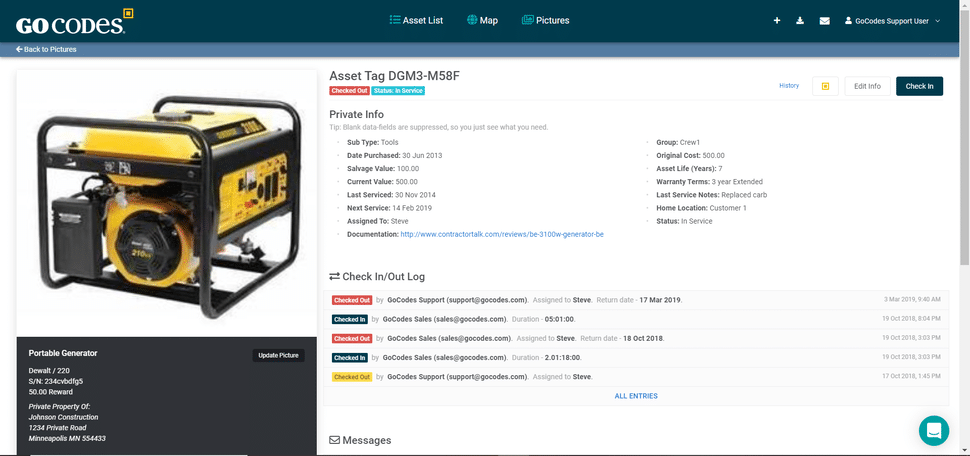

Armed with this knowledge, you’ll be able to schedule maintenance so your team can find and fix possible equipment problems, thus preventing more substantial damage leading to eventual failure. If you use equipment tracking software, opt for the kind that lets you track its maintenance as well.

GoCodes Asset Tracking lets you see the last service date, next service date, and service notes all from one central location

This option will allow your entire team insight into the machine’s previous and current condition.

When all the necessary information is available on their phones, the field workers won’t have to go to the main office or the maintenance team’s area to inquire about previous servicing records. Instead, they’ll access this information in a couple of clicks.

Sell Unused Machinery

Another way to save some money is to get rid of the machinery you don’t use.

If you have equipment lying around your storage room, you’re either saving it for a rainy day, or you’ve forgotten about it. Either way, you’re wasting money on something you’re not actively using.

Firstly, the cost of ownership doesn’t include just the purchase price, so you continue paying for the equipment even after it becomes yours.

If you’re a responsible equipment owner, you will invest in inspection and regular maintenance, in addition to handling insurance and taxes. This means you’ll spend a lot just on owning the machinery.

So, if you don’t really need the equipment, why pay for all these expenses month after month?

Instead, you could sell the machinery you don’t use and thus eliminate the ownership costs while earning some money. Selling the asset means that you no longer have to keep it in your books, or spend money on maintenance.

Of course, you may be worried about needing that piece of machinery down the line. However, there’s a solution for that, too. When the need arises, you can look into rental options.

Renting is often the better option if you only need a machine for a certain period instead of daily, as it ends up costing a lot less and gives you more options.

You can save the extra cash you get from selling the equipment for a time when you might need to rent that piece of equipment for a project, ensuring that you have a plan B.

On the other hand, if you don’t even know you have equipment that no one uses, it’s time for you to do an inventory and use equipment tracking software to create a database.

Having a clear overview of what machinery you own and how useful it is for you will help you keep things under control.

Also, it will allow you to easily spot the machinery that doesn’t get checked out, thus helping you form an informed decision on whether you need this machine in your fleet.

Perform Regular Equipment Inspections

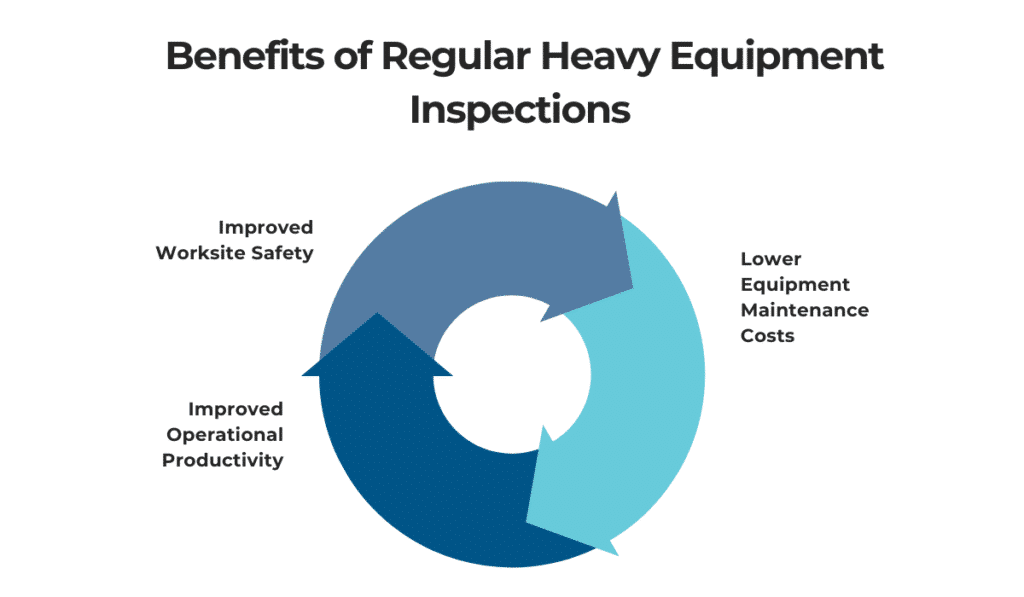

Inspecting your machinery often helps you save lots of money.

Here’s how.

Equipment downtime is a direct consequence of your failure to inspect the machinery before use. When you check the machine before operating it, you’ll quickly notice something is off and report the issue to the maintenance team.

On the other hand, if you don’t perform an inspection and there is an issue you fail to resolve before using the equipment, you can cause a costly failure that might take a while to fix.

As a result, you waste time and money on something very preventable.

Without regular inspections, you’re running the risk of the problem getting worse over time. If you leave the problem unaddressed and keep using the machinery daily, it slowly deteriorates.

In those circumstances, it will undoubtedly take a lot more time and money to fix the problem than it would have if you had conducted the checks in regular intervals and discovered the issue in its early stages.

This is in part because skipping vehicle and equipment inspections can result in asset downtime, costing you from $488 to $760 per machine daily.

To avoid these expenses and complications, make sure your team members check the equipment before and after every use. Doing this will guarantee that they spot any anomalies before they result in equipment failure.

So, how can you ensure that your team carries out daily inspections?

An excellent way to go about this is to make it obligatory for the operators to inspect the machinery using predefined checklists and share the inspection data in real-time, using the equipment tracking software.

If you take the time to ensure regular equipment inspections, you’ll end up saving a lot of time and money.

Conclusion

The most important aspect of cutting costs is to know what to save on.

If you start skimping on maintenance, things can take a turn for the worse, and you could end up with a lot more equipment downtime than expected. What’s even worse, this type of negligence could result in worksite accidents.

So, decide which aspects of your fleet you can save on without risking its effectiveness.

Our suggestions include investing in regular equipment maintenance and conducting obligatory machine inspections before and after each use.

It’s also a good idea to monitor your operators’ safety habits, as well as keep an eye on how much fuel they go through while using the equipment.

Finally, use equipment tracking software, both to prevent theft and determine whether there’s any underused machinery that you own. If you discover there are pieces you neither use nor need, consider selling them, and then renting as needed.

If you invest in implementing one or more of these points, you’ll see the results in no time!