Key Takeaways:

- There’s no universal benchmark for construction profitability; average profit margins must be viewed in context.

- To boost profitability, companies must consider various internal and external factors.

- Continuous improvement and adopting the right strategies or technology are essential to achieving profit margin goals.

How do you define the success of one business?

There are several criteria, but most people think along the lines of making a profit.

And with good reason.

Profitability is one of the key metrics of success, which is why construction professionals must keep an eye on their profit margins.

Checking and understanding these numbers helps you stay on top of all the costs and make informed decisions about your business’s future.

Want to get some fresh insights on average profit margins across construction?

The deep dive before you will tell you all this and more, so let’s get started!

In this article...

Average Profit Margins in Construction Projects

Profit margins vary drastically within the construction sector, depending on the type of construction projects companies typically engage in, and a range of other factors.

As such, it can be difficult to draw comparisons and determine where your company is profit-wise.

Profit margin – the percentage of income remaining after you deduct costs from sales revenue.

There are no notable disagreements on the definition, and there’s only slight confusion about the difference between margin and markup.

However, opinions on good, average, and bad profit margins differ significantly.

For example, Zendesk’s guide acknowledges that different industries have different benchmarks, but ultimately puts a good profit margin at 10 percent.

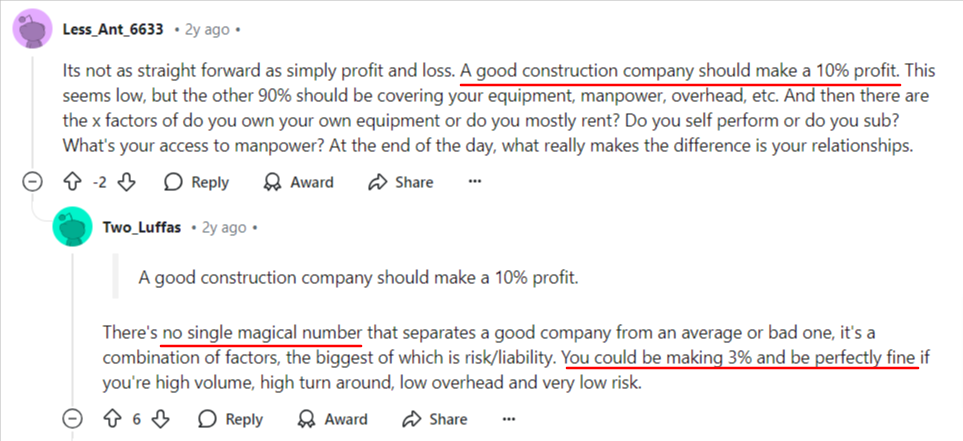

When we zoom into construction profit margins, 10% profit is also mentioned on Reddit, but one user quickly counters the idea of clinging to a “single magical number.”

Indeed, the numbers from construction companies worldwide suggest that good profit is relative and influenced by numerous factors.

Construction Briefing’s recent roundup of profit margins recorded by the biggest construction companies globally lists numbers between 1.8% and 5%.

Naturally, the companies use different financial metrics to report profit, which prevents direct comparison, but it brings us closer to dismantling some preconceptions.

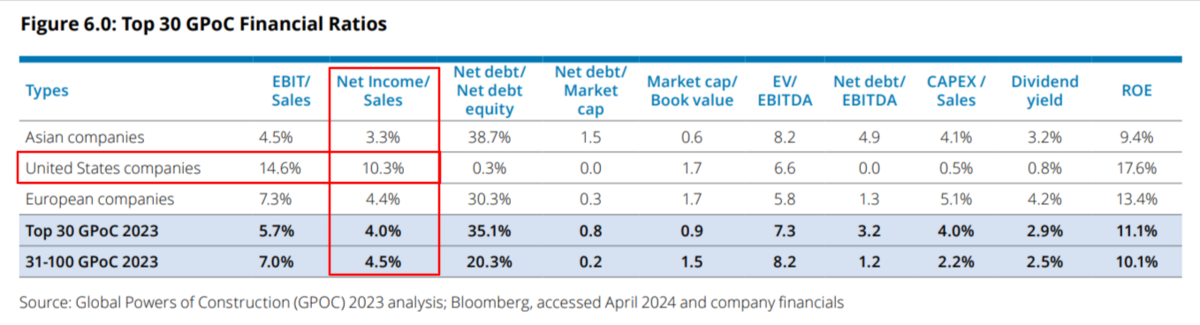

Deloitte’s 2024 report on top-performing companies highlights an additional layer by showing regional variations.

According to the report, the US-based companies achieved notably higher profitability because the sample included the largest number of homebuilders, a traditionally more profitable construction segment.

Delving deeper into this and similar reports is the only way to contextualize insights, but there are some general lessons we can draw on.

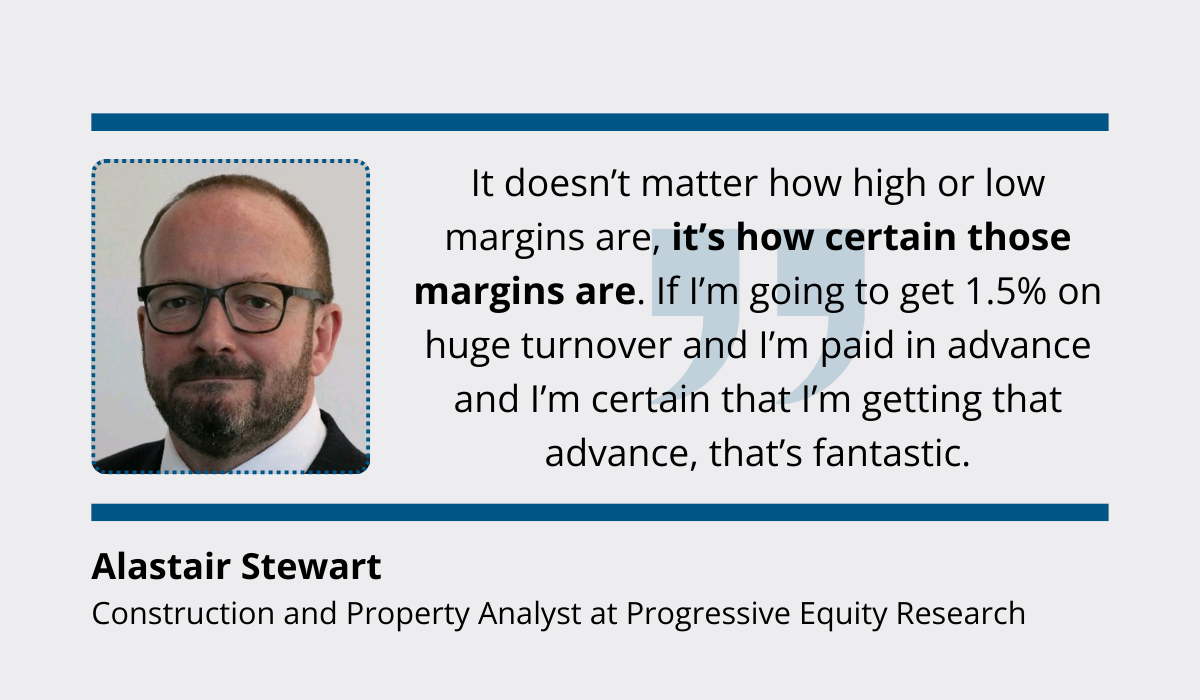

For instance, Alastair Stewart, a Construction and Property Analyst at Progressive Equity Research, reminds companies to also consider the certainty of the margins.

Stewart’s advice also points us in the direction of some core differences between the main types of construction projects.

If we compare residential and commercial construction, the latter is typically more complex in scope, has longer timelines, and requires significant upfront investment.

At the same time, there are more regulatory hurdles that rein in profits.

However, long-term, high-value contracts, associated with commercial and industrial projects, offer more stability and steady cash flow, creating strong foundations for future growth and higher total profits.

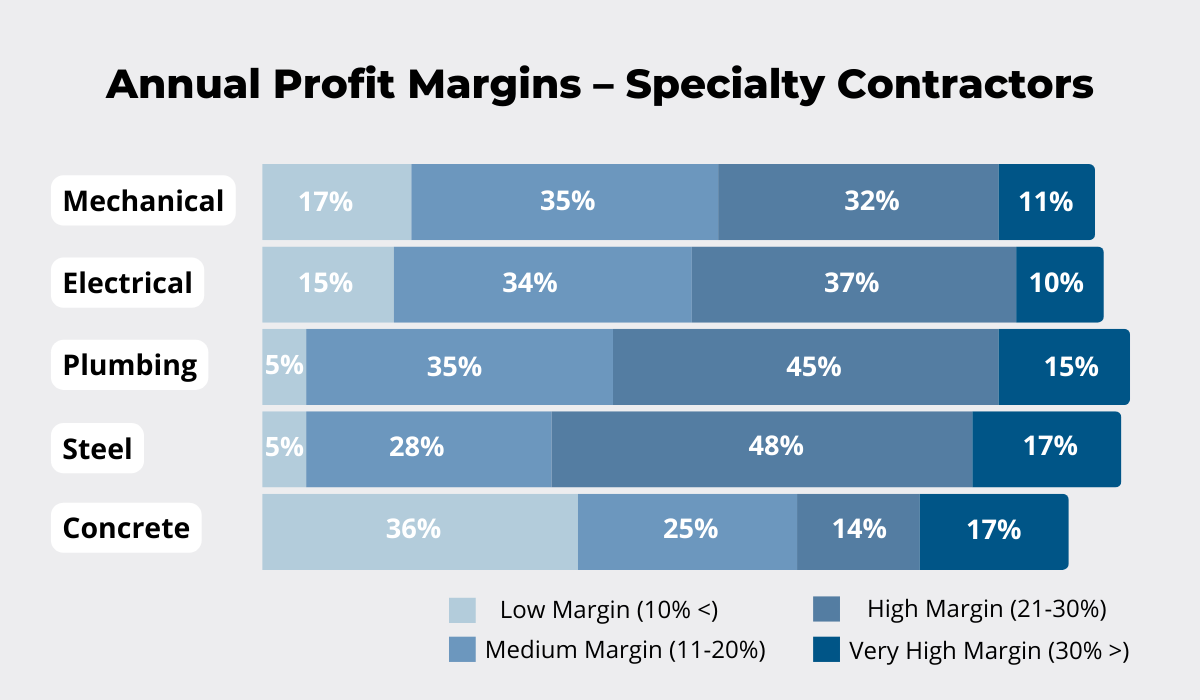

On the other hand, the Dodge Construction Network’s report indicates that the highest profit margins are recorded among the most in-demand specialty contractors, steel and plumbing.

An incredible 65% of surveyed steel contractors had profit margins of over 20%, while one-third of concrete contractors fell under the low-margin group.

Higher margins are also common among homebuilders, especially those who find ways to deliver value-added services and build a niche for themselves.

Such is the example of Vitaliy Pikalov, the owner of VP Homes specializing in building custom homes with astounding 50-70% profit margins.

He attributes these numbers to hard work and several business practices, from long-term relationship building to doing things in-house as much as possible.

However, Pikalov also notes that he doesn’t always aim for the highest profit margins, but that it depends on his stake in the project, which brings us back to our core message.

There’s no single magical number or benchmark for construction profitability.

Your main goal is to identify your ideal profit margins and steer your business in that direction.

And the first step to that is to calculate your current profits.

How to Calculate Your Profit Margins

Calculating your profit margins ensures you’ll have a clear sense of where you are at the moment, and what you should focus on to increase your profitability.

Let’s first break down some key terms.

| REVENUE | The total amount of money generated by the project, including payments received for materials, labor, and services. |

| COST | The total amount of money spent on project resources, including materials, labor, equipment, subcontractor fees, etc. |

| PROFIT | The amount you’re left with after deducting all project-related costs and expenses from the revenue. |

| MARGIN | The difference between the project’s contract or selling price and the total cost of completing it. It’s important to differentiate between gross margin and net margin. |

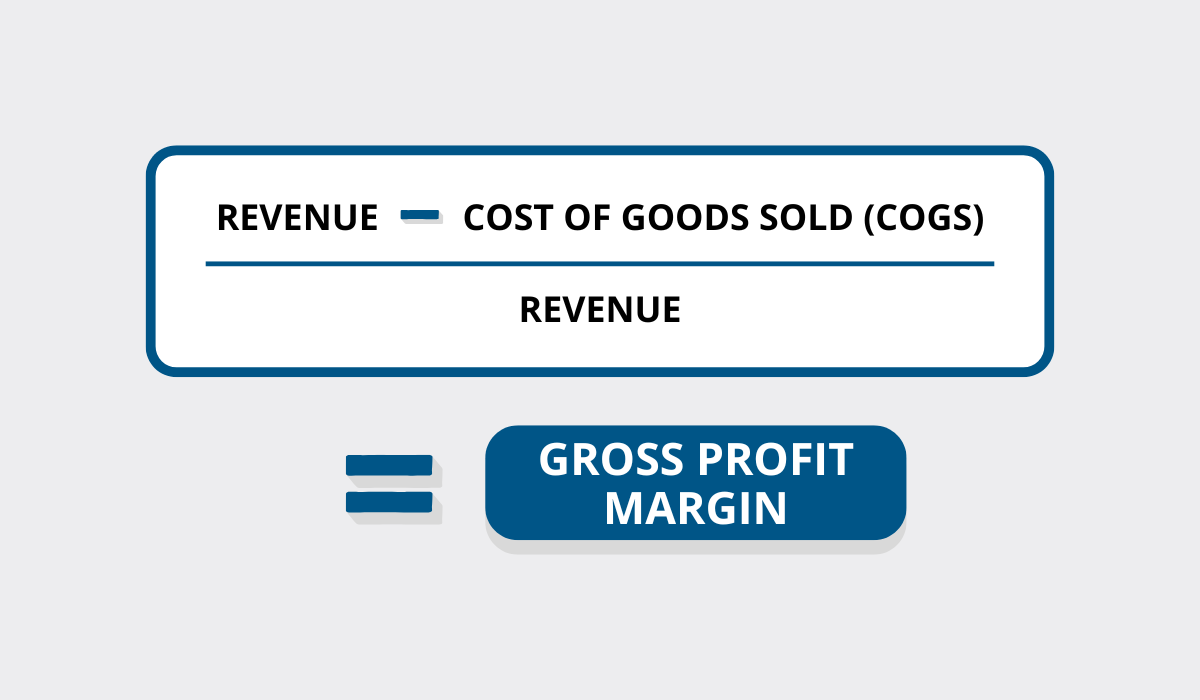

To get the profit insights you need, deduct the cost of goods sold (COGS) from your revenue, and divide that number by the revenue.

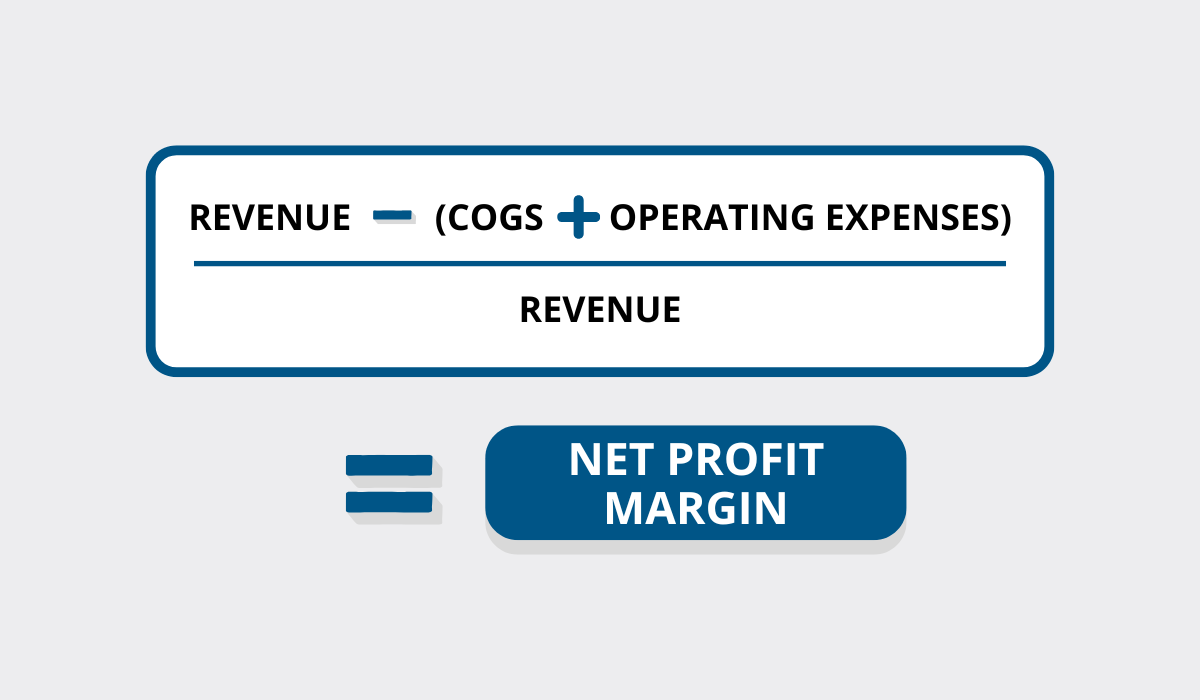

One thing you should keep in mind is that there’s a significant difference between gross profit and net profit margins.

How significant, you ask?

Based on the overview of average profit margins by industry, the gross profit in E&C is 18.4% while the net profit is hovering at around 3.8%.

The gross profit margin is the raw amount of money you’ve made.

In other words, you’re looking at your profit without accounting for all the other expenses.

To get a clearer picture, with all the expenses covered, you need to deduct the expenses like rent, wages, and taxes, and then divide that number by revenue.

So, a revised formula would look like this.

Now you can tell whether you’ve succeeded in covering the costs, and how much money you’re making.

Moreover, if you want to get the numbers quickly, you can always use profit margin calculators.

For example, Omni Calculator has the necessary features and requires no sign-in to use. These features helped earn it praise from thousands of users, including those from the construction sector.

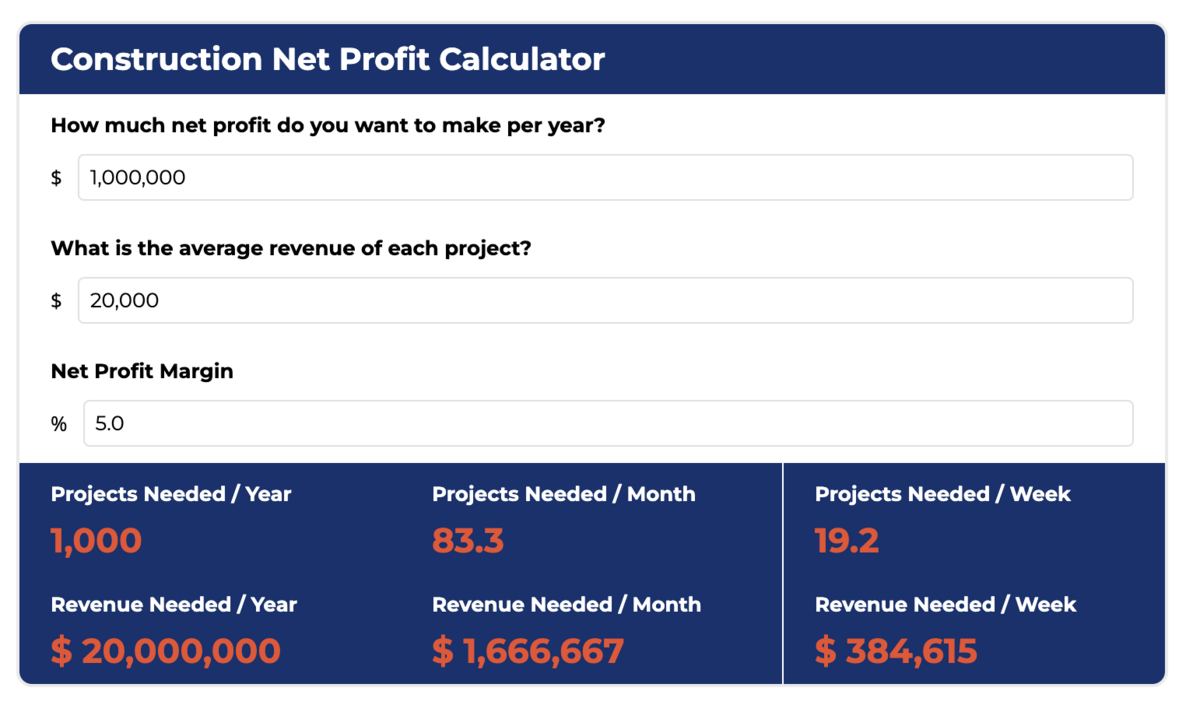

On the other hand, Buildbook’s calculator helps home builders determine how much revenue they need to generate to reach their desired net profit margin, and at which pace.

No matter the number that comes up, and how satisfied you are with it, it’s important to understand the factors influencing your construction profit margins.

They will help you improve your situation.

Key Factors Affecting Profit Margins in Construction

Construction profit margins are affected by different factors that you need to keep in mind if you want to start improving your profitability.

If we put aside project complexity and scope, fluctuating material prices emerge as a major factor.

One example is copper. In mid-2024, construction businesses witnessed a record-high boom in copper prices.

Due to its electrical conductivity and central role in the push toward renewable energy sources, copper is continuously in high demand.

With the mining industry unable to keep up, the prices of copper were particularly volatile over the last couple of years, as shown by Macrotrends data.

Copper is essential in construction for wiring, plumbing, and roofing, among others, so even slight fluctuations can throw a wrench in the initial project cost estimates.

But what about renewable energy projects that depend on copper for their entire infrastructure?

With the price of copper jumping 20% over one year and no mechanisms to prevent it, many companies were heavily affected.

Simarpreet Singh, Hartek Group’s Executive Director and CEO, explains that such volatility goes beyond timeline disruptions and directly erodes profit margins.

But here’s another point of view.

Even when resources are available, their inefficient use can lead to cost overruns and impact profit.

Equipment is an integral part of securing project success, and businesses often struggle with deciding between equipment ownership or renting.

After all, both ownership and renting have their pros and cons, but choosing the wrong option at the wrong moment can inflate operational costs and impact your bottom line.

Equipment ownership enables you to quickly access and deploy machinery wherever you need it, in exchange for steep upfront expenses.

Meanwhile, renting is more accessible to businesses of different sizes, but it’s riskier. Should you not be able to obtain a piece of equipment, you’ll face project delays and erode your profitability in another way.

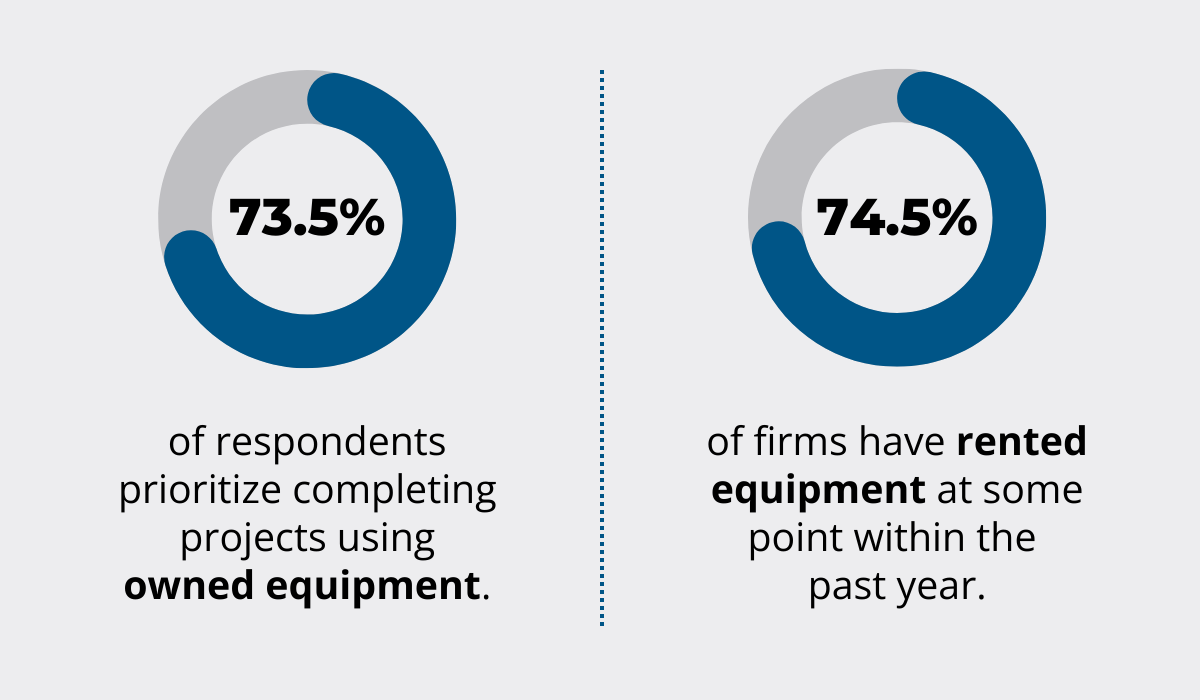

A recent report by Equipment Watch shows that while the majority of companies prefer completing projects with owned equipment, more and more businesses are also renting when needed.

This shows that construction businesses are well aware of the benefits of several strategies, and are carefully assessing all factors to make the right call that will actually boost their profits, not harm them.

Strategies for Improving Your Profitability

Now that we’ve covered the ins and outs of construction profit margins, the question is what can you do to improve your profitability?

You can explore a number of tips, but the following three strategies are a good starting point.

Increase Productivity

High productivity directly impacts the bottom line by removing inefficiencies and improving project timelines.

In simplest terms, improved construction productivity means more work gets done in less time, and at a fraction of the cost.

One surefire way of improving both is using technology.

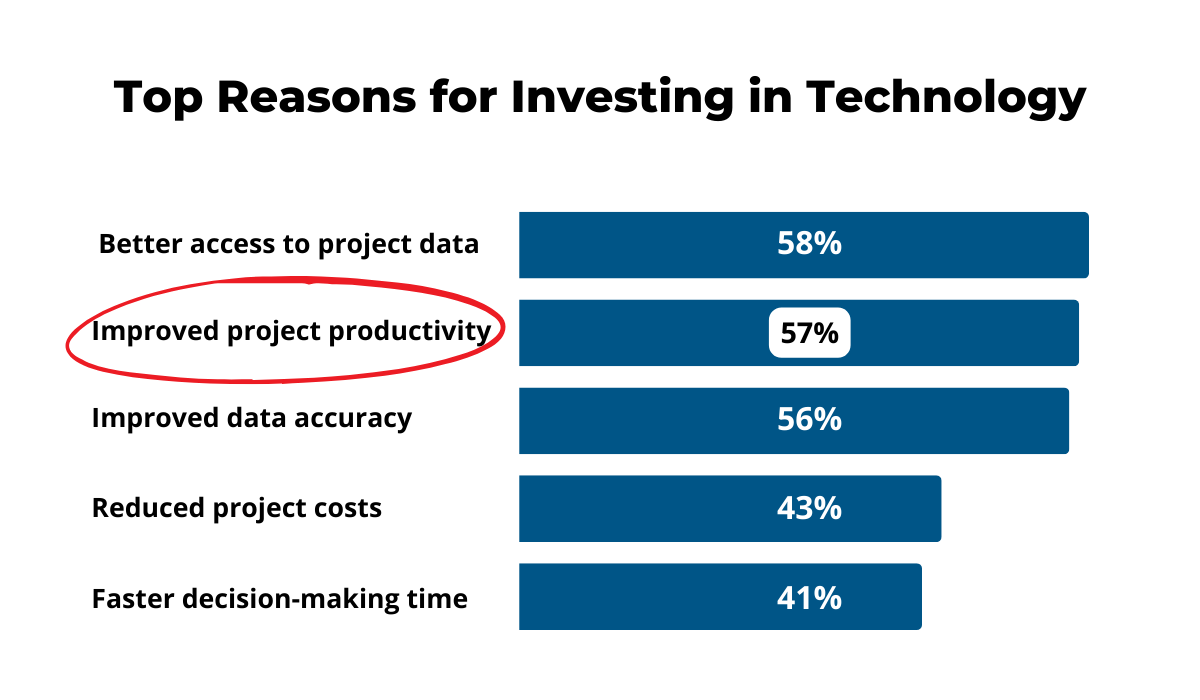

According to Autodesk’s 2018 report, increased productivity was the second most cited reason for investing in technology.

Construction professionals prioritize and embrace different technologies to increase productivity, from design collaboration and field productivity platforms to project management software.

Most of these solutions drive productivity by streamlining workflows, and one such example is drone technology.

In construction, drones are used for aerial surveys of entire construction sites, helping workers map largely inaccessible zones and enhance visibility and safety in record time.

Typically coupled with BIM modeling for the design phase, drones ensure greater efficiency and accurate progress tracking throughout the project.

Keeping an eye on the site minimizes mistakes and the risk of expensive rework, resulting in a significant boost in productivity which is reflected in the profit margins.

Increasing productivity unlocks multiple benefits and improves your project margins, and leveraging the right solutions will get you there even faster.

Enhance Equipment Management

Proper and efficient equipment management ensures the assets you need are available when you need them.

At the same time, proper management reduces repair and replacement costs that would otherwise erode your profit margins.

Did you know that keeping maintenance costs in check is one of the biggest challenges of equipment management?

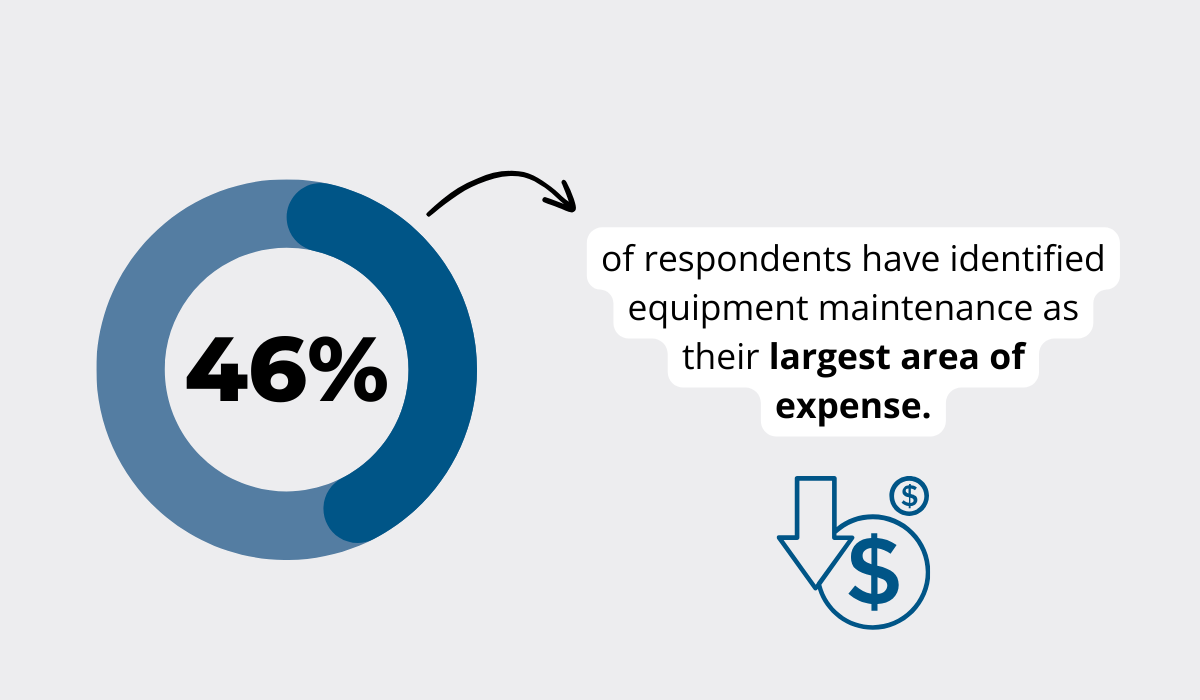

Teletrac Navman’s recent report shows that 46% of respondents recognize equipment maintenance as their largest area of expense.

Construction companies invest in maintenance to optimize equipment use and extend its useful life.

However, if you’re not managing your equipment in the best way, you’re still leaving plenty of room for errors and mounting expenses.

On the other hand, asset management tools have features that will make every penny you invest in maintenance count.

Some of the best asset management solutions combine a cloud-based platform with different tracking devices and scheduling features, enabling you to optimize usage, manage maintenance, and gain total control over your fleet.

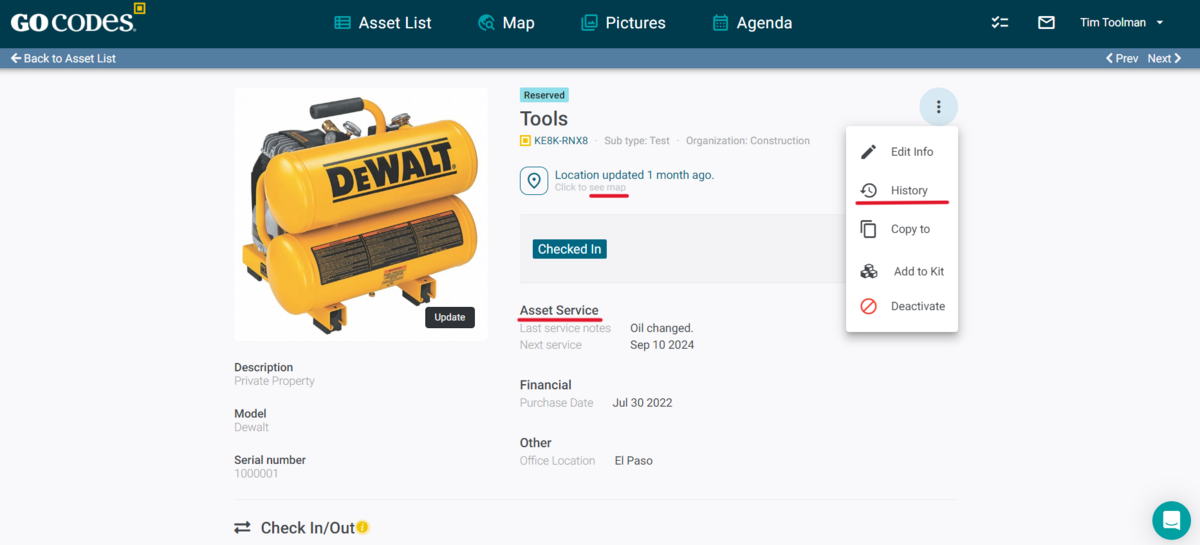

For instance, our GoCodes Asset Tracking solution goes well beyond asset tracking, allowing you to collect a bulk of data on your equipment in a single source of truth accessible from anywhere.

The dashboard gives you the most important information at a glance, including location, ownership, and maintenance history.

To make sure that all your assets are available and in peak condition, you can easily configure service notifications and be reminded of upcoming maintenance and other relevant information.

With this and other mechanisms in place, you won’t have to worry about unplanned downtime and creeping costs.

When done right, equipment management saves money and drives profitability in more ways than one.

Invest in Quality Talent

Investing in quality talent creates a continued positive impact on multiple levels, including overall profitability.

Robust education programs, upskilling initiatives, and better hiring practices enable construction companies to fill their workforce with high-performing employees.

Besides essential construction skills, these workers have higher quality output, resulting in fewer errors and rework, a significant productivity boost, and better project execution.

But does this translate into higher profitability?

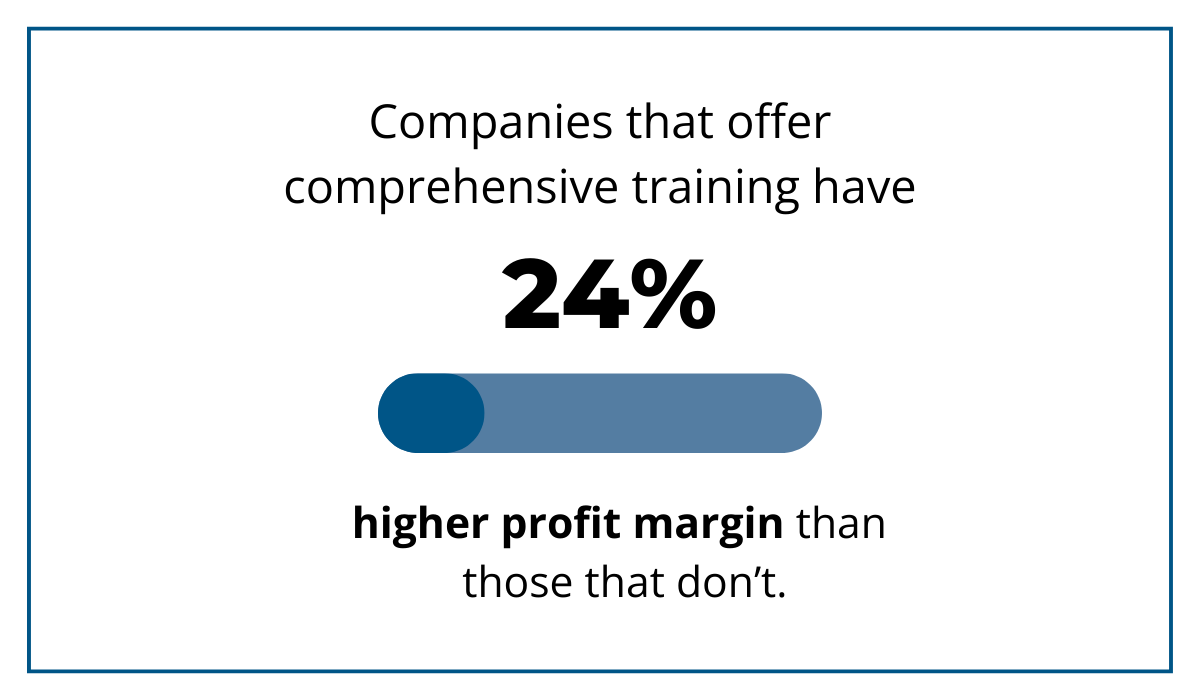

Research proves so.

A study conducted by Business Training Experts shows that construction companies with comprehensive training programs also boast higher profit margins.

So if your workers learn advanced skills or an entirely new trade through cross-training initiatives, you’re automatically increasing your company’s adaptability in the face of unforeseen circumstances.

Upskilling and multi-skilling are also vital for retention efforts.

The Associated Builders and Contractors Association (ABC) recently released a survey showing its members invested $1.6 billion in different education efforts.

These investments are one way of countering severe labor shortages, but also holding on to the talent you have.

Investing in your employees helps boost their morale and inspire loyalty, explains Corey Simpson, Manager at the Life Cycle Institute specializing in performance improvement.

In other words, access to education helps motivate your workers and renew their commitment to the company while helping you minimize the tangible and hidden costs of employee turnover.

One thing’s certain: new learning opportunities bring efficiency and quality that protect and improve your profit margins.

Conclusion

Maintaining a healthy profit margin is an enduring question in construction and any business.

It is an ongoing effort, but it can be made easier by exploring industry insights, noting patterns, and conducting a thorough assessment of your business practices and strategies.

Remember to be careful when drawing comparisons and set clear goals for reaching your ideal profit margin.

With that, and a little bit of luck, you’ll boost your company’s profitability in no time!