Key Takeaways:

- Certain technologies help contractors predict the necessary material types and quantities.

- Sustainable materials are becoming more frequently used in construction.

- Construction material suppliers play a big role in ensuring operational efficiency, minimizing project costs, and mitigating risks.

Just like any other aspect of construction, material management isn’t immune to various changes that are reshaping the industry.

But which trends should you really keep an eye on?

And how exactly are these innovations impacting material management?

In this article, we answer these very questions.

We’ll explore five trends that are currently gaining momentum, show some examples, and outline the benefits they potentially bring to the table.

Let’s get started.

In this article...

The Rise of Digitalization

Although construction has a reputation for being slow to embrace new technology, digitalization is still rapidly transforming the industry—and material management is no exception.

There are three specific technologies worth highlighting in this context.

The first one is Artificial Intelligence.

AI can be particularly valuable during the initial, project planning phase, as it automates, and therefore significantly speeds up material procurement.

Before AI, contractors had to manually sift through design specs and product sheets, tediously matching requirements to available products.

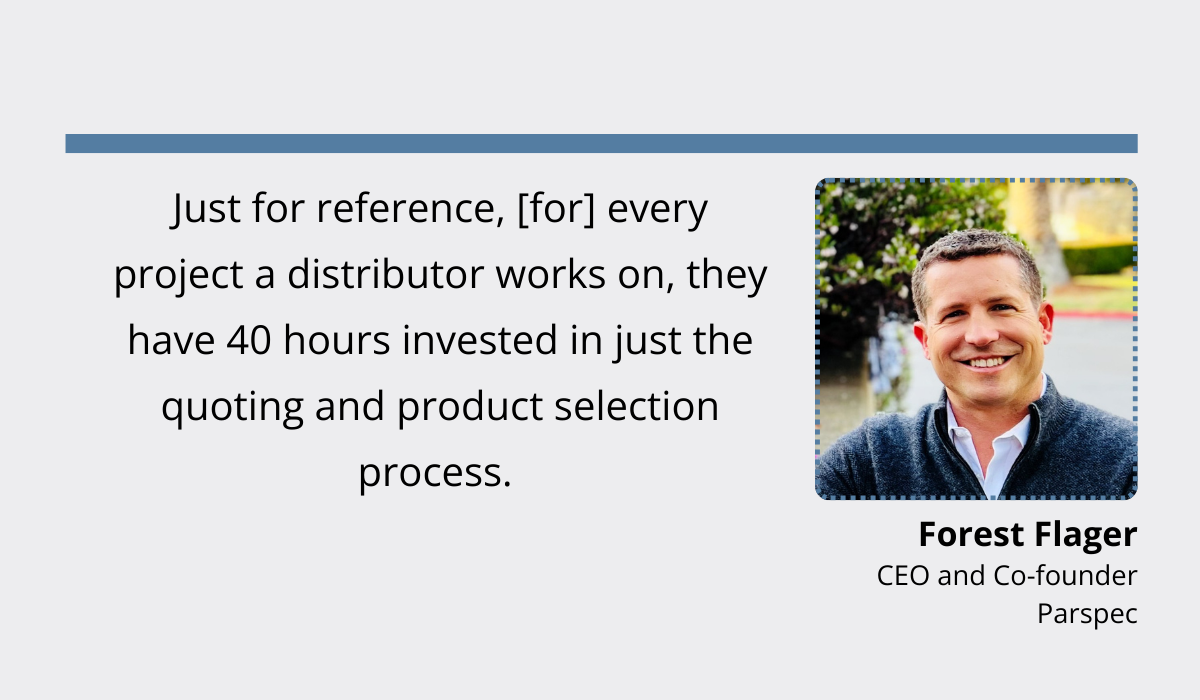

Forest Flager, CEO and Co-founder of the construction material sourcing platform, Parspec, explains just how time-consuming this can be.

AI, on the other hand, can reduce time spent on product selection and quoting by a staggering 80%, he notes.

That’s because AI leverages historical data from past projects and scans the internet for vendors, providing recommendations on what materials to procure, how much to order, and where to source them.

This helps project managers secure the right amount of the right inventory from the get-go.

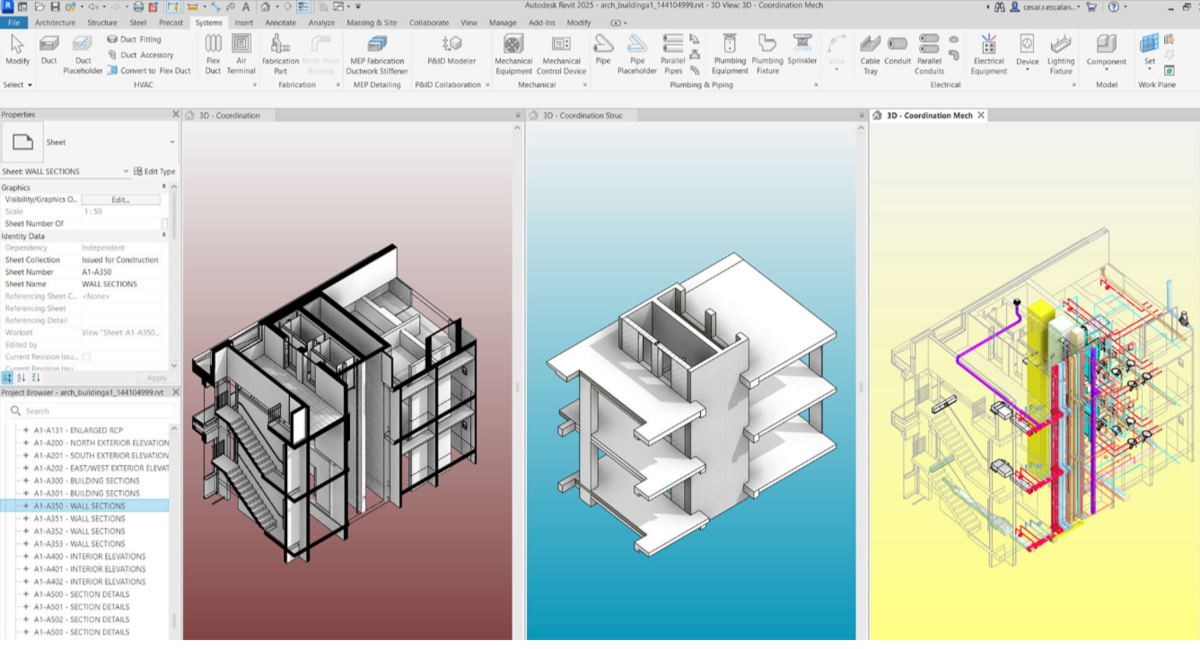

Building Information Modeling (BIM) is another powerful digital tool reshaping material management.

Essentially, this tech enables different stakeholders to create and collaborate on a “digital twin” of a structure before construction even begins.

As you can see below, this digital twin maps out all the details about the building, including materials.

This allows contractors to plan and control their inventories throughout the project life cycle.

It also allows them to simulate and compare the impact of various scenarios, such as poor weather, on material performance or availability.

That way, the risk of wastage or understocking is considerably reduced.

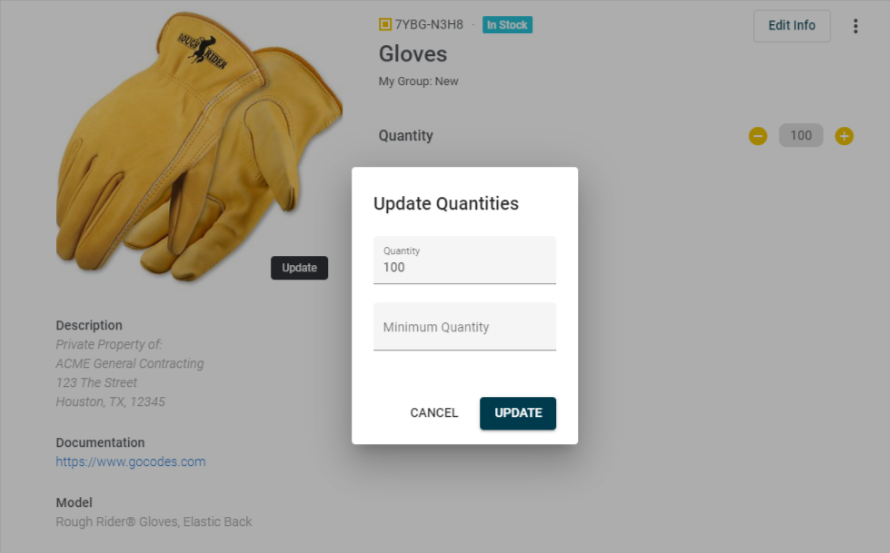

And the last technology making waves in material management we’ll cover is asset management software, like our very own GoCodes Asset Tracking.

GoCodes Asset Tracking, combining QR code asset labels with a user-friendly asset tracking app, provides timely updates on material quantities and helps maintain optimal stock levels during the whole project.

How does it work exactly?

It’s all pretty simple.

First, QR code labels are attached to your inventory.

Then, workers scan these labels using our app when they use certain products to update the stock levels. And that’s all there is to it.

The result?

Up-to-date, accurate inventory lists that can be accessed anytime, anywhere, and from any device with internet connectivity.

Plus, GoCodes Asset Tracking takes it a step further by sending notifications when stock levels dip below the minimum you specify.

With this kind of software, you’re never caught off guard and can reorder on time, keeping your operations smooth and delay-free.

So, what do all these three technologies have in common?

They all make material management smarter, faster, and way more efficient than ever before.

We’re definitely bound to see their adoption continue to grow in the future.

Increased Focus on Sustainability

Achieving sustainability through material management manifests itself in two ways:

- procuring materials that are sustainable themselves, and

- adopting more sustainable inventory management practices.

Sustainable materials are, essentially, greener alternatives to traditional options like wood or concrete, which are notorious for their environmental footprint.

Some examples include:

- engineered cementitious composite (bendable concrete),

- mass timber,

- bamboo,

- mycelium, and

- 3D-printed concrete.

Today, we truly see more and more buildings being constructed with these eco-friendly components.

For instance, bamboo—thanks to its flexibility and durability—is a very popular option for building all sorts of structures, such as yoga studios, badminton courts, and other sports facilities.

Even mud, one of the oldest building materials known to humanity, seems to be making a comeback.

When it comes to sustainable material management practices, the main focus is on reducing waste as much as possible.

And considering that in the UK alone, 62% of waste comes from the construction sector, these changes are more than necessary.

That’s why there’s a greater adoption of circular economy principles in construction, such as recycling and reusing materials.

Digitalization also plays a role in achieving sustainability and reducing waste by helping cut down on paper use and promoting smarter resource allocation.

Ervin Quezada, Senior Project Engineer at a tobacco manufacturing company, Imperial Tobacco La Romana, offers another example of an area for improvement, and that’s material procurement:

“As a personal experience, I once worked on a project where materials were sourced from all over the world, once you factor in all of the effort that was made to source those materials (shipping containers, aviation + other means of transportation), you would come to the conclusion, that indeed that project in particular was very damaging to the environment.”

That’s right: where you get your products from has a great environmental impact, too.

This leads many to try and source materials locally to reduce their carbon footprint.

The bottom line?

Material management represents a massive opportunity for improving sustainability in construction.

Whether through the use of eco-friendly materials or by rethinking how you acquire and manage your inventories, these efforts can have a profound influence on the environment.

It’ll be exciting to see what other innovations and trends emerge in this field—and their impact, too.

More Frequent Use of Prefabricated Components

Prefabricated components refer to construction elements, such as wall panels and floor cassettes, that are manufactured offsite and then transported to the construction site for quick assembly.

They are quite versatile and can be used for exterior structures, interiors, as well as roofing.

One significant impact of this trend on material management is the reduction of on-site waste.

Christine McCorkell, Communications and Design Manager at Arkular, a firm designing modular homes, elaborates:

In short, prefabrication promotes smarter and standardized material use.

These components are all made in a controlled environment with high precision, resulting in fewer mistakes like materials being improperly cut or misshapen.

Besides, manufacturers of such elements order and use exactly the amount of material they need, maximizing usage and minimizing offcuts or scraps.

But, this efficient use of materials brings another advantage: reduced costs.

Since the components are made with minimal waste, there’s less money spent on materials that would otherwise be discarded due to errors, miscalculations, or damage on site.

Moreover, because these elements are mass-produced in factories that leverage economies of scale, they are often cheaper than traditional options.

Mark Glass, principal at a construction industry consultancy, notes that many contractors made the switch to prefabricated elements when material prices soared after the pandemic.

This also helped them speed up some of their processes, he explains.

It’s easy to see why they made this change. It’s simply smarter.

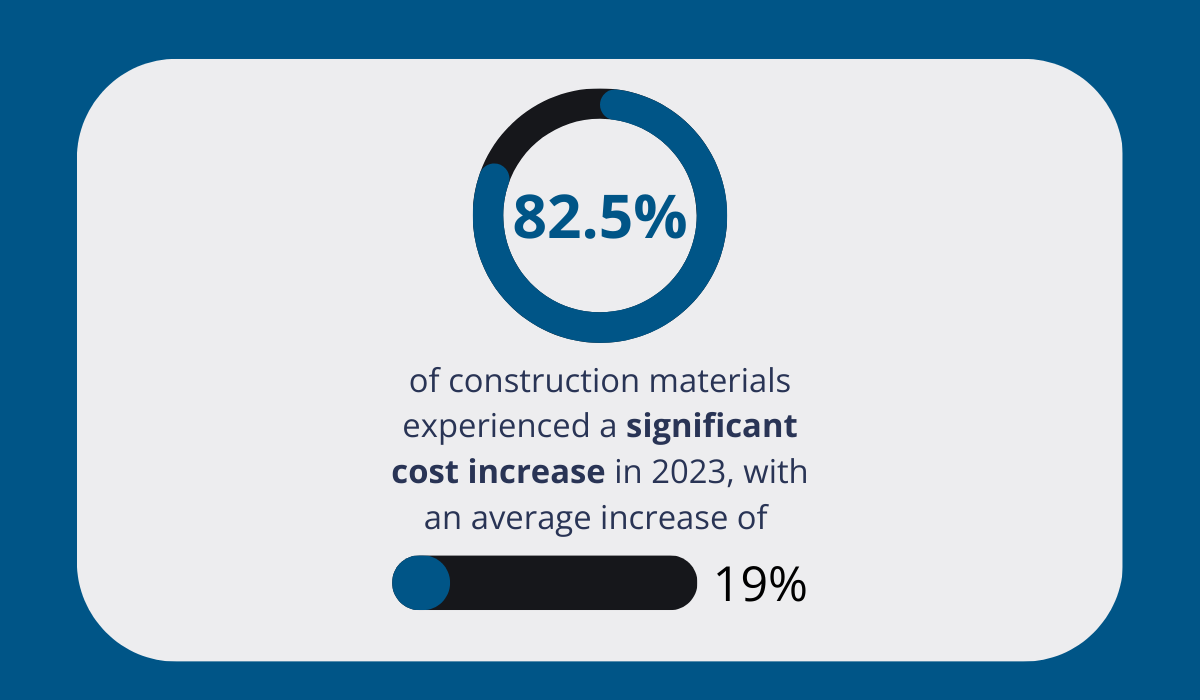

According to Gordian, in 2023 alone, 82.5% of material costs increased, with an average rise of 19%.

Even now, as material prices stabilize, they still represent a hefty chunk of project costs.

Prefabrication helps trim those expenses both directly, by reducing the price of the materials themselves, and indirectly, by cutting down on construction time and labor costs.

At the end of the day, prefabricated components are more sustainable and cost-effective all around.

And the best part?

They are equally, if not more, durable than traditional materials.

With benefits like these, it’s very clear that prefabrication isn’t just a passing trend—it’s here to stay.

Stronger Collaboration with Suppliers

Construction professionals are collaborating with their suppliers more than ever before.

And for good reason, too.

These collaborations unlock a host of benefits within the realm of material management, from securing better quality products and pricing to ensuring more dependable deliveries.

At the core, strong supplier relationships help secure the five Rs of construction materials management:

This, ultimately, means they have a huge role to play in keeping your projects on track, free from delays and budget overruns.

Plus, some vendors might even throw in expert tips and best practices to help you get the most out of your materials.

There are a couple of trends that illustrate this change in the way we work with our suppliers.

The first is a shift toward strategic negotiations.

Nicolas Walden, a Senior Advisor in The Hackett Group’s Procurement Advisory membership program, explains what those are in more detail:

“Strategic negotiations allow both parties to win, and we do this through using facts to understand, then to shift each parties’ interests, to a joint position where each party receives a benefit or gain. This strategic, interest-based approach is preferred over more traditional position-based approaches where one party to the negotiation wins and the other loses as we attempt to shift people to our preferred position.”

Put simply, in strategic negotiations, there are no losers.

The focus is on forging long-term, mutually beneficial partnerships rather than immediate, smaller wins.

These are the kinds of relationships that can land you better material prices and valuable insider knowledge that gives you a competitive edge.

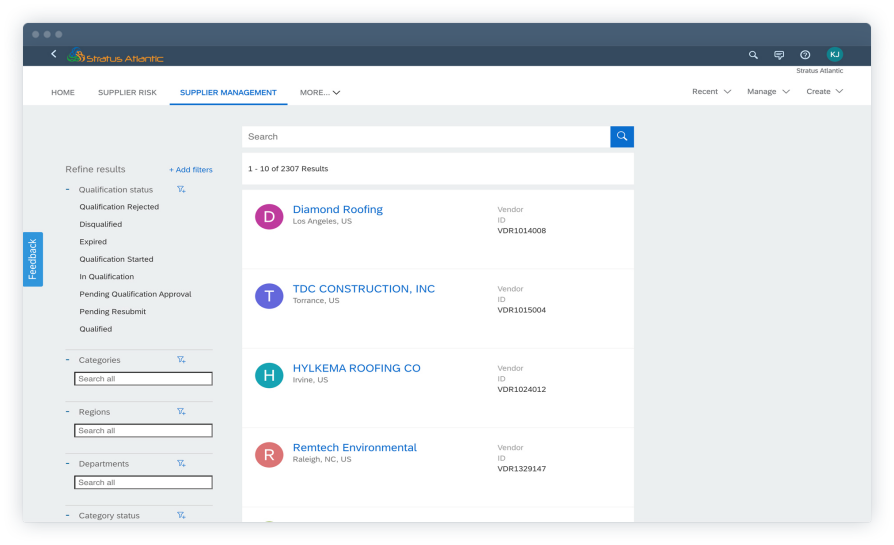

The second trend is the adoption of supplier relationship management (SRM) software, like the one you see below.

These solutions serve as effective communication channels, enabling both parties to share feedback and resolve issues quickly.

They facilitate faster responses, minimize misunderstandings, and create a single source of truth for all your communications.

That way, you ensure everyone’s on the same page, as well as keep your supplier relationships productive and reliable.

All in all, navigating supply chains is more challenging than ever, with fluctuating prices and material shortages posing a constant threat to operational efficiency and budgets.

However, building strong partnerships with suppliers means you don’t have to face these challenges alone.

They lead to dependable service, guidance, preferential treatment, and various other perks that keep your operations safe from risks and disruptions.

Use of Predictive Analytics for Material Demand Forecasting

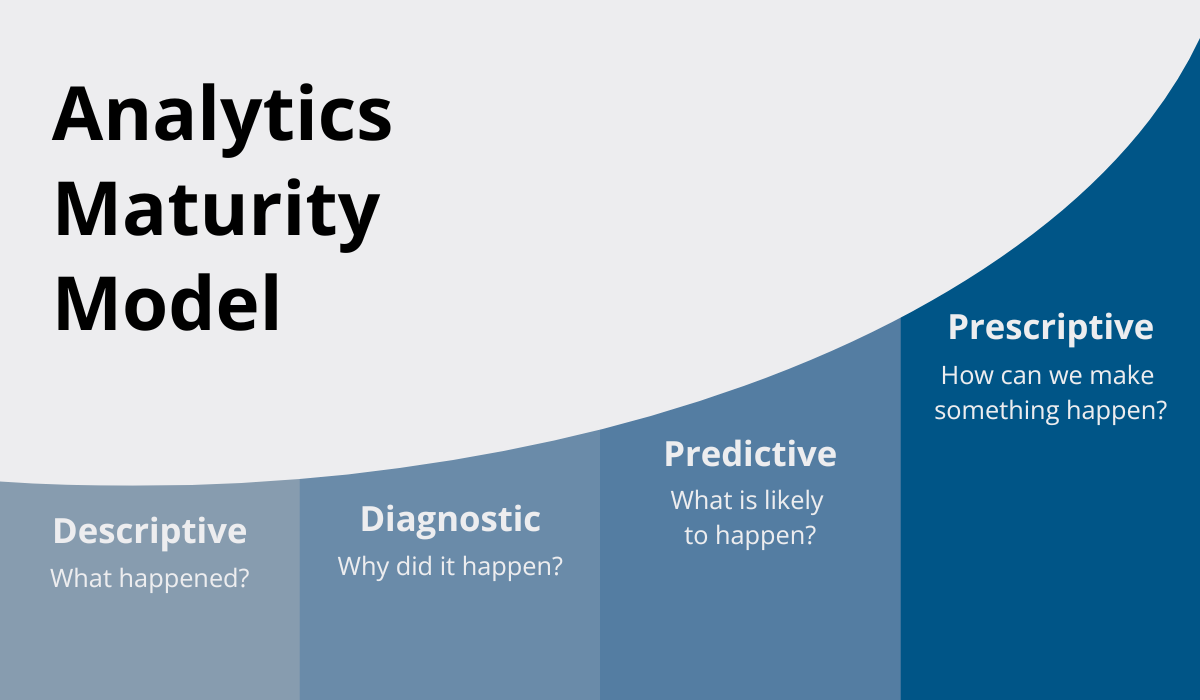

Predictive analytics is an advanced technology that uses statistical algorithms and machine learning to analyze historical and current project data.

Based on that analysis, it can then identify patterns or trends and make predictions about future outcomes and material demand.

As such, it represents the third stage in data analytics maturity.

Obviously, this can be quite a powerful tool in the context of material management.

By analyzing past projects and various market trends, predictive analytics can determine the necessary product types and quantities for upcoming projects.

This makes it easier than ever to secure just the right amount of the right materials.

No more overordering. Also, no more running out of key materials in the middle of a job.

As Stancioiu Alina, Procurement Project Manager at the Southeastern European energy producer OMV Petrom, notes, planning ahead is a must for minimizing risks and budgetary overruns.

Well, predictive analytics is the master of strategic planning.

It pulls from both internal data sources—such as project specifications—and external factors like seasonal changes and economic shifts to give you the most reliable insights.

Besides, it allows you to run “what-if” scenarios, testing different project conditions to see how they might impact material needs.

For example, if a delay occurs in one phase, predictive analytics can show you how this might ripple through the rest of the project, allowing you to better prepare and address risk head-on.

In any case, one thing is clear: the days of relying solely on intuition or guesswork in material management are gone.

Predictive analytics provides data-driven insights that empower construction professionals to make smarter, better-informed decisions.

And as this tech continues to advance, it’s set to become an even bigger part of the toolkit for successful material procurement and control.

Conclusion

Doesn’t the future of construction material management seem exciting?

Keep in mind: these innovations aren’t just fleeting fads or futuristic tech gimmicks without purpose—they’re making a real impact.

From more accurate material demand forecasting to helping projects hit their sustainability targets, these advancements are transforming material management as well as the industry as a whole.

Pretty soon, they won’t be seen as just trends but as the standard, helping companies mitigate risks, avoid budget overruns, navigate supply chain disruptions, and much more.