Construction projects are so complex that it’s important to choose a delivery method with which your team is comfortable.

The right delivery method encourages useful data collection and efficiency rather than causing frustration.

Moreover, before entering into a project, it’s best to openly discuss experience levels and expectations with the clients, as well as the subcontractors.

Mutual understanding and knowing the difference between, for example, an integrated project delivery and multi-prime construction management is essential.

While each method offers benefits and potential challenges, remaining flexible no matter the project structure can help you and your team adjust if the project takes an unexpected turn.

In this article...

Design-Build (DB)

Design-build construction is a popular configuration for delivery—of all construction projects in the United States up until 2025, design-build will likely act as the delivery method for 47% of all projects.

This model is suitable for projects in which creativity is not necessarily a priority, and the general contractor agrees to hold more liability for the project.

In this method, the owner signs just one contract to address not only the design of the project but also its construction.

There is a single company responsible for each phase. This avoids the inefficiency and potential communication problems that might arise otherwise.

Even though a design-build is generally a more streamlined process, it still almost always involves subcontractors.

That means labor forces and specialty work will probably get done by third parties. The owner of the venture must remain on watch for possible conflicts of interest.

However, this formation could reduce overhead costs, even though this design might result in template-style work from designers.

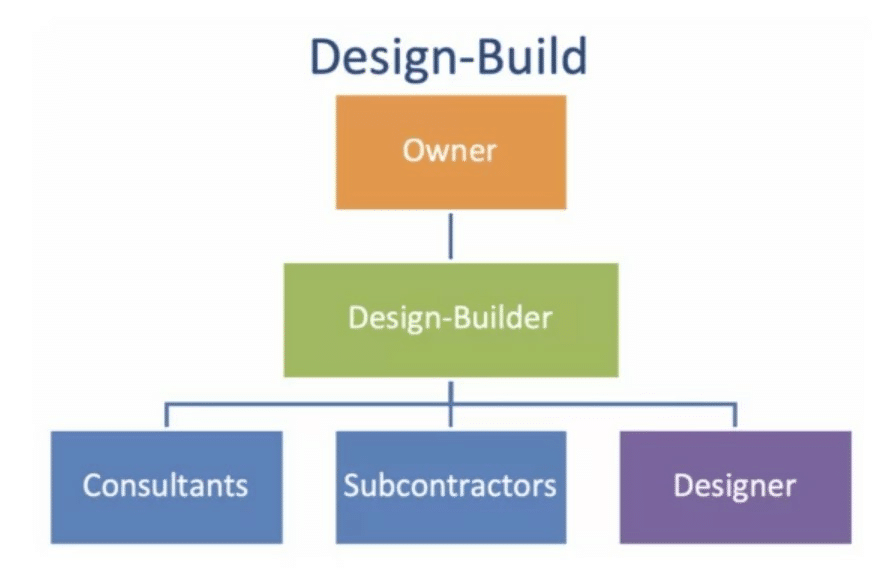

Here’s a look at the responsibility flow of a design-build project:

As you can see, the design-builder oversees those who carry out the project.

That means the owner has a single manager to confer with on all details during the design and building phases.

However, the design-builder isn’t always a construction company or contractor. Sometimes, an architect acts as the head of the team.

This is more common in public or community-oriented projects such as street installations or improvements, shopping malls, schools, or hospitals.

Design-Bid-Build (DBB)

The DBB format is also referred to as the traditional method or design-tender.

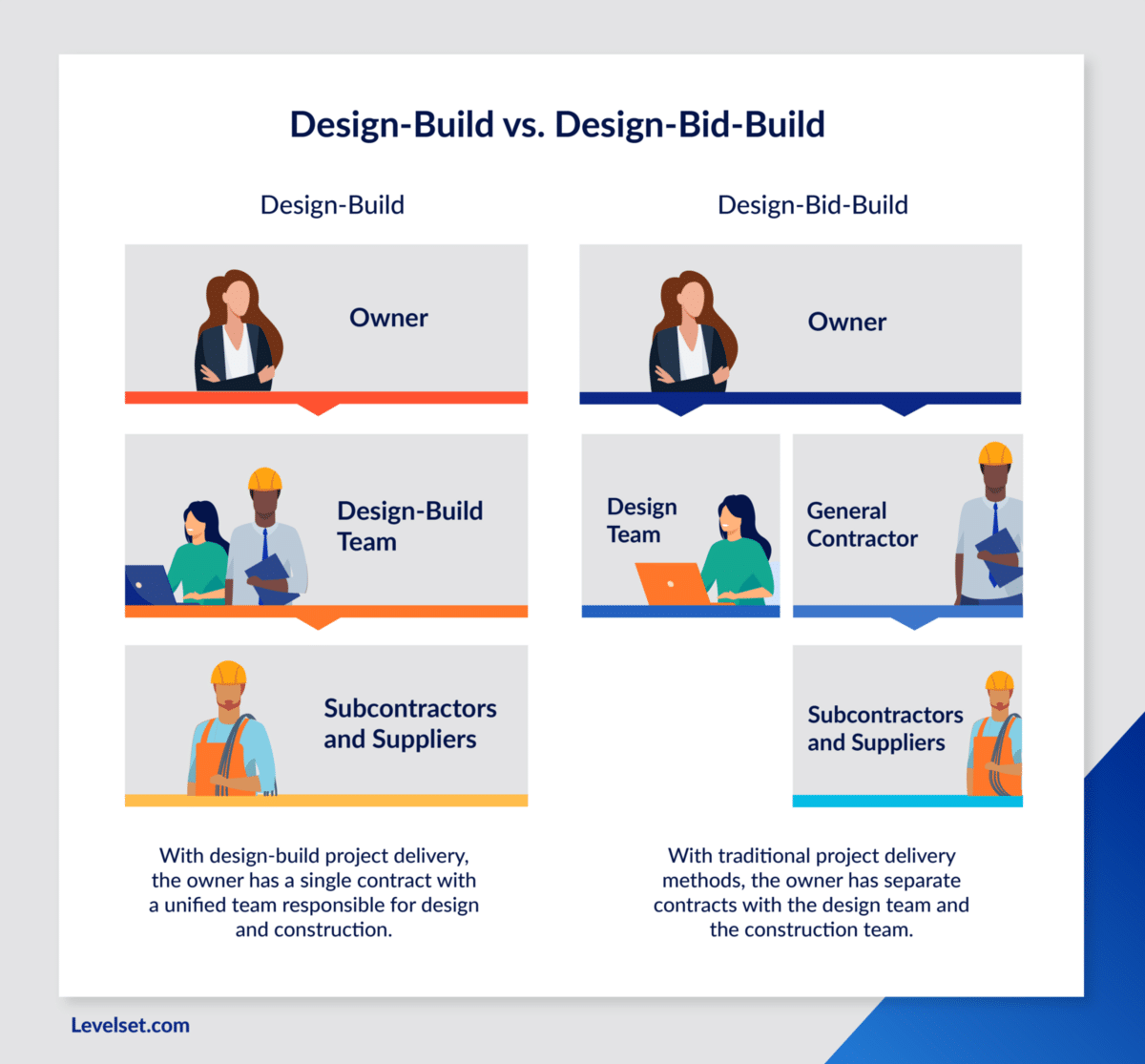

It might help you to better understand the design-bid-build model by comparing and contrasting it to how the method you’re already familiar with, design-build, works:

As you can see, in DBB, the owner works on separate contracts with the design team and the general contractor. The general contractor then arranges for suppliers and subcontractors.

This method is usually best suited for owners who don’t have a great deal of experience with construction projects.

The timeline for a DBB project is different from that of design-build. In this scenario, the owner sets the budget.

He or she then approaches the designer, who plans the project and creates documents to seal its contracts.

Only after this preliminary phase is complete does the contractor enter the picture.

The job is put up for bid for contractors, who read the plans and estimate the costs of labor, construction, and overhead.

Since this step encourages competition, it could result in lower overall cost of construction. Once the owner chooses a construction company, the project is built.

In addition to the owner and the contractor or builder, the consultant plays an elevated role. He or she is usually an architect or an engineer and works closely with the owner.

Unlike DB, in DBB, the consultant is the agent for the owner during the build.

One of the advantages of a DBB method is the use of fixed costs, which means that as long as the owner doesn’t make any voluntary changes to the plans, the cost remains the same throughout.

That means prices and budgets are known. This is possible because the design phase is usually extended and detailed, which means contractor bids are usually accurate.

Finally, because work can’t start until the plans and contracts aren’t finished, each party’s responsibilities are clearly defined, and budget-related upheaval is usually less of a factor than in other projects.

However, owners should know that in a DBB project, design costs are presented upfront, and they cannot resort to a pay-as-you-go plan.

In addition, owners must remember that changing plans increases costs.

The fact that each phase is clearly delineated may make for fewer communication issues, but a delay in one part means slipping milestones for the rest.

Integrated Project Delivery

In integrated project delivery (IPD), collaboration leads the way. The owner, contractor, and architect/designer share responsibility and liability.

Like design-build, the design and construction are united in one contract. The goal of IPD projects is a concentrated effort to increase productivity and cooperation.

It is also thought to increase efficiency and encourage a horizontal approach to the project, in the sense that team members other than the designer, contractor, and owner tend to have more of an opportunity to contribute experience, ideas, and knowledge.

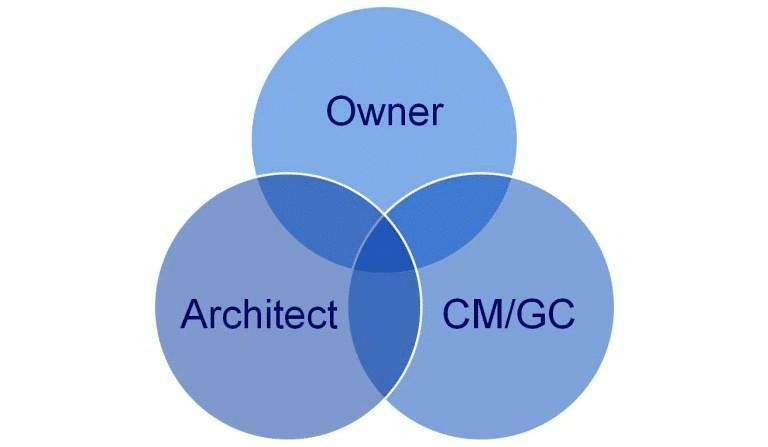

Below is a simplified Venn diagram of how the various parties in IPD work together (keep in mind that CM stands for construction manager, and GC means general contractor):

:

The typical IDP project contains four phases:

- Conceptualization: All project participants are chosen and make suggestions

- Design: Goals are discussed with consideration of waste reduction and efficiency

- Implementation: Computer modeling is used to predict outcomes

- Construction: Physical building begins

As you can see, the bulk of effort and investment in an IPP venture is front-loaded, in the sense that the design and implementation of these designs are deeply pondered and analyzed before ground is ever broken.

This combination of compartmentalization and collaboration tends to help every member of the team focus on lower costs, better safety, and a good balance of innovation and proven methods.

Since the risk as well as the reward in this system are shared, participants are less apt to look to their own benefit.

IPD is relationship-based and more reliant on technology than other methods.

However, it requires a high amount of trust and responsibility, and it might be difficult to find entrenched partners willing to take this approach.

Construction Management at Risk

The construction management at risk (CMAR) method, like integrated project delivery, is a relatively recent format for construction.

This delivery format is flexible and looks at the design and construction process as individual blocks or elements.

Elements include part of the building process that aren’t usually discussed in more traditional methods.

These involve:

- Financing

- Planning

- Schedule

- Milestones

- Design

- Analysis of cash flow

- Construction

In CMAR, a construction management firm, not the designer, acts as the owner’s consultant before the design is finalized and construction begins.

Subcontractors bid for various roles and are responsible for a single element of the project, and the construction manager functions as their leader.

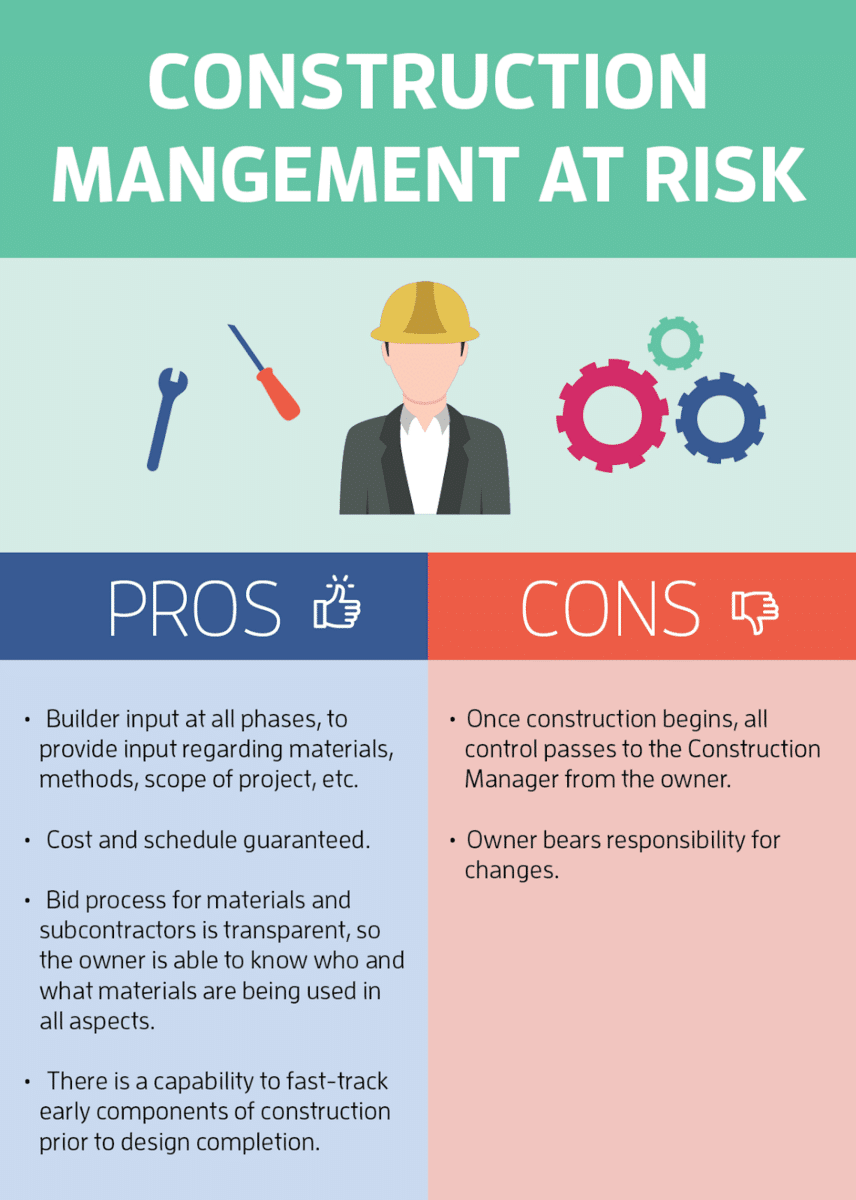

This graphic discusses the some of the pros and cons associated with CMAR:

CMAR carries the benefit of reducing risk to the owner, since overrun costs are passed to the CMAR as a separate entity.

As with the other methods, however, the cost for alterations stemming from change of mind remains the responsibility of the owner, who might also become liable for contract exclusions.

CMAR might not function well for small projects or those working with architects or designers who are not comfortable working closely with CMs.

Multi-Prime Construction Management

Usually abbreviated as multi-prime (MP) or construction manager multi-prime (CMMP), this delivery form focuses on design, engineering, and construction.

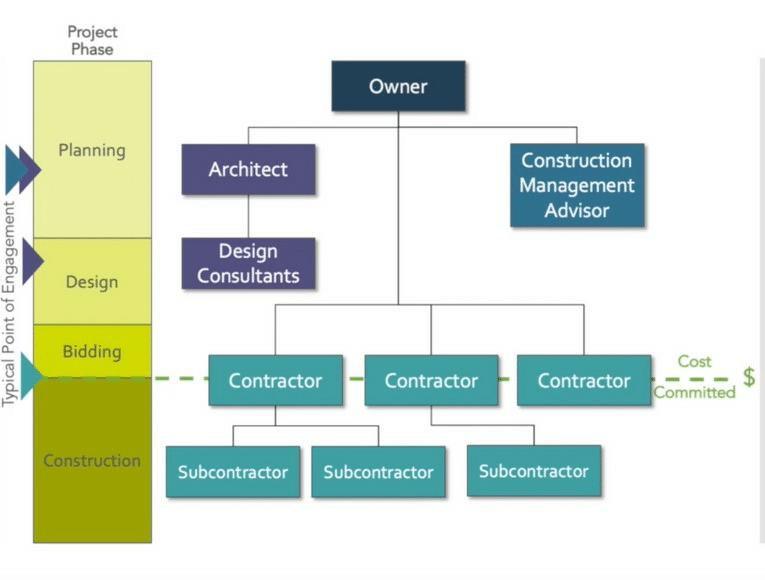

In the MP model, the owner uses a construction management advisor throughout the process:

The name for MP comes from multiple prime players.

The owner fills the role of the general contractor, which means that this probably isn’t a good choice for owners without a great deal of knowledge in the field of construction.

At the same time, the owner can oversee all costs and therefore keep an eye on safety gaps or potential inefficiencies.

Several separate contracts are the hallmark of CM. This allows for bidding competition, provides room for innovation, and facilitates the spread of responsibility.

Since the owner is in control of the project, he or she is limited only by the abilities of the subcontractors and such variables as weather delays.

Experienced owners eager to oversee most details of the project and who are willing to take on a great deal of involvement and cost control are a good fit for MP.

Conclusion

Each construction delivery method offers benefits and potential drawbacks.

Design-build is a streamlined format that might result in a lack of innovation.

On the other hand, design-bid-build is a good choice for owners who aren’t familiar with the design and construction process.

Those who are interested in innovation and collaborative working might thrive in an Integrated Project Delivery environment.

Large projects reliant on builder input are a good format for construction management at risk.

Finally, multi-prime construction management is an advanced form of delivery in which the owner also acts as the general contractor.

Owners should consider their construction experience and priorities before deciding which kind to use.