Key Takeaways:

- Using scannable unique identifiers instead of serial numbers avoids duplication and confusion.

- Multi-tagging assets with different trackers improves accuracy and security.

- Proper asset tracking reduces theft, improves compliance, and extends asset lifespan.

- Tracking asset utilization and depreciation prevents underused equipment from draining budgets.

Ever feel like managing your construction assets is a full-time job?

Between misplaced tools, underutilized equipment, and unexpected repair costs, inefficiencies can quickly pile up—draining your time and budget.

But it doesn’t have to be this way.

With the right strategies, asset tracking can become a streamlined process that saves you money and keeps your projects on schedule.

In this article, we’ll give you six tips on how to achieve that, so keep reading.

In this article...

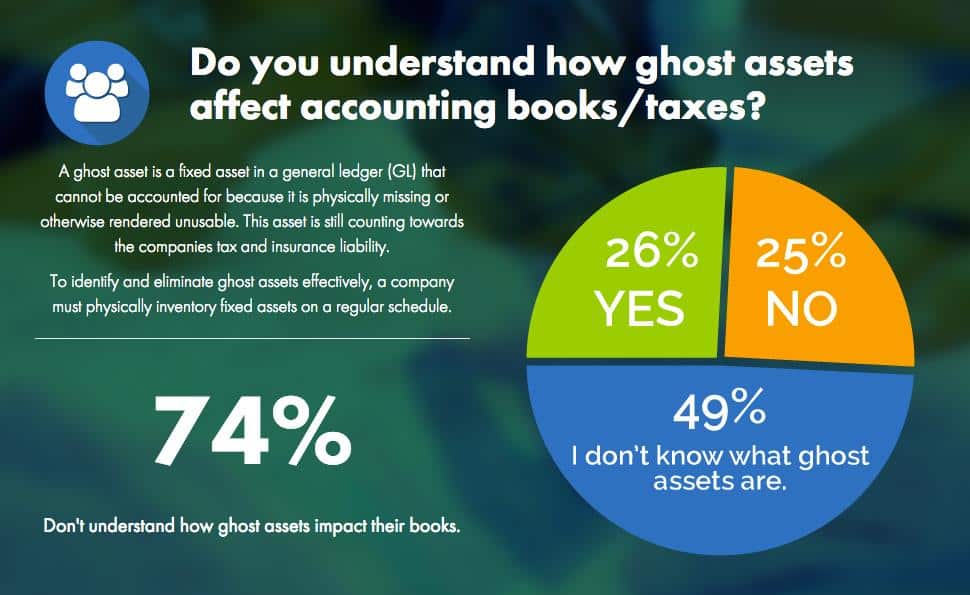

Use Unique Identifiers, Not Serial Numbers

When managing a large inventory of construction tools and equipment, it might seem natural to rely on serial numbers as the foundation of your asset-tracking system.

And while recording each asset’s serial number in your system is important, using it as the sole identifier is impractical, inefficient, and error-prone.

Why?

For starters, not all serial numbers are unique, especially when considering various types of equipment from different manufacturers.

If serial numbers are your only identifiers, you risk duplicates and confusion in your database.

Additionally, many manufacturers don’t provide barcoded serial numbers.

This means you’ll need to locate the serial number on the asset—often in hard-to-reach spots—and manually input it into your system.

This process is far from efficient, especially in challenging environments like construction sites.

Fortunately, there’s a better solution.

As one Reddit user aptly put it:

Source: Reddit

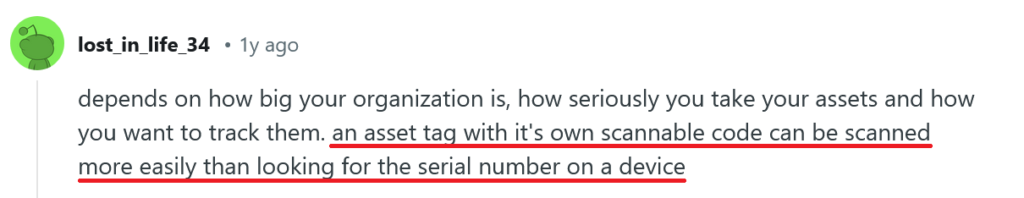

Scannable asset tags with their own unique ID typically use barcodes, QR codes, or RFID labels.

A single scan—whether with a mobile device or handheld scanner—instantly retrieves the asset’s details, but more on that later.

Each tag, once attached to an asset, has a unique ID (a combination of numbers and letters) assigned to it.

This ID becomes the asset’s primary identifier in your tracking system, ensuring every item is easily distinguishable in your system’s database.

Source: GoCodes Asset Tracking

While you can create custom IDs manually, most asset tracking systems generate them automatically, saving time and reducing errors.

Once the digital ID is created, it links directly to the tag placed on the asset.

This tag acts as a bridge between physical equipment and your tracking system, making it easy to retrieve and update asset information.

Ultimately, unique IDs eliminate the need to rely on hard-to-reach, unscannable serial numbers —if the tagged item even has one.

Instead, they provide a scannable, globally unique identifier that simplifies asset management—while still allowing you to keep serial numbers on record.

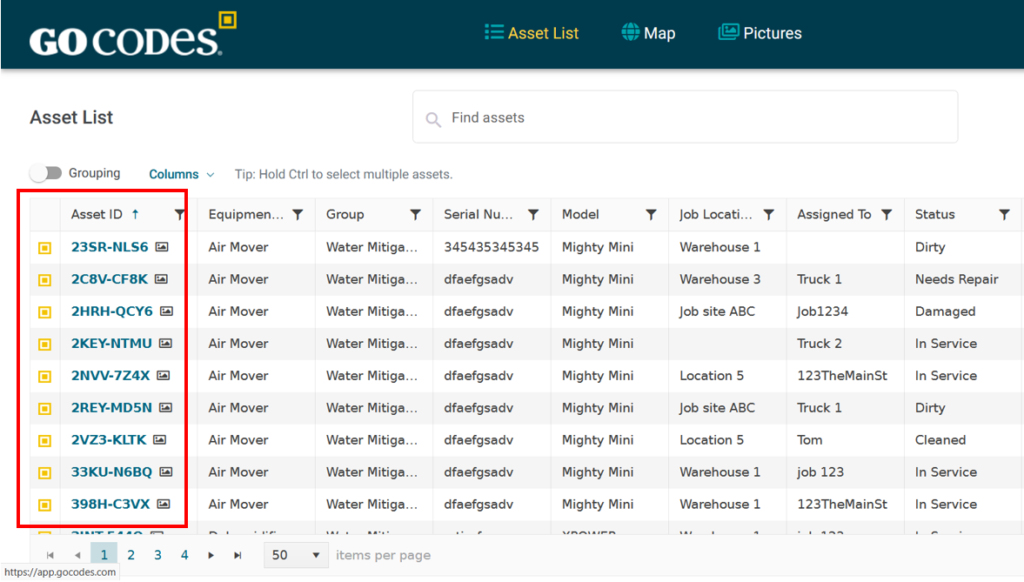

Implement Multi-Tagging for Critical Assets

Not all assets are created equal.

Some construction equipment is worth hundreds or thousands of dollars, while smaller tools might cost only a few dollars.

Similarly, some assets are mobile, frequently used, and critical to your operations.

If these assets go missing—whether due to theft or misplacement—your job site activities could grind to a halt, causing costly delays.

That’s why relying on a single tracking method may not be enough for high-value or mission-critical assets.

Instead, multi-tagging—combining QR codes or RFID with live GPS trackers or Bluetooth beacons—adds an extra layer of security and visibility.

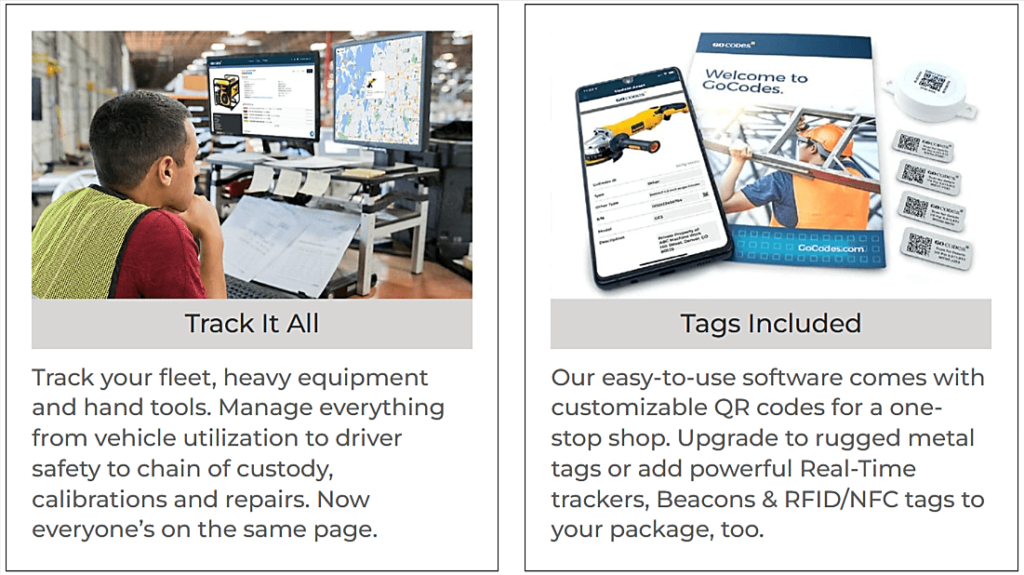

To make multi-tagging as seamless as possible, it’s best to use a tracking system that supports multiple technologies within one platform.

One such multi-tracking solution is our GoCodes Asset Tracking.

Source: GoCodes Asset Tracking

As shown, GoCodes Asset Tracking allows you to pick and choose from a range of the most popular and practical asset-tracking methods.

That way, you can set up your primary QR code-based tracking system for all assets, ranging from the biggest pieces of equipment to the smallest tools, spare parts, and other inventory.

Then, you can expand this basic system with additional tags, typically real-time GPS trackers, to ensure you have more control and better protection for your mobile, high-value assets.

Source: GoCodes Asset Tracking

The advantage of multi-tagging is that it minimizes blind spots in asset tracking.

QR codes and RFID labels excel at logging asset details, but they require someone to scan them.

GPS trackers, on the other hand, provide continuous location updates without manual input, ensuring that assets remain visible even if they are lost or stolen.

Here’s an example of how GPS helped the authorities find a stolen generator along with some other missing equipment worth $200,000.

Source: Fox11

Long story short, the generator had a GPS tracker in it, which led the police to the property where the thief hid it.

This example highlights the power of multi-tagging for critical assets, showing how GPS enhances security and asset recovery.

Additionally, Bluetooth beacons—though shorter in range than GPS—can help track assets indoors, in storage yards, or on job sites where GPS signals may be weak.

Overall, with asset multi-tagging, you improve asset security, create built-in redundancies, and ensure that every asset is exactly where it needs to be when you need it.

Give Employees a Self-Service Asset Portal

Imagine your workers searching for tools and equipment in storage or on a job site with little to no information on where they are or who’s using them.

That’s hardly an efficient way to run construction operations.

What can you do instead?

Give them a self-service asset portal to easily locate assets, and check them in and out—all through a simple dashboard.

This has two big advantages:

- It improves operational efficiency by reducing the time spent searching for tools.

- It increases worker accountability, leading to fewer lost, misplaced, or mishandled assets.

How does it work?

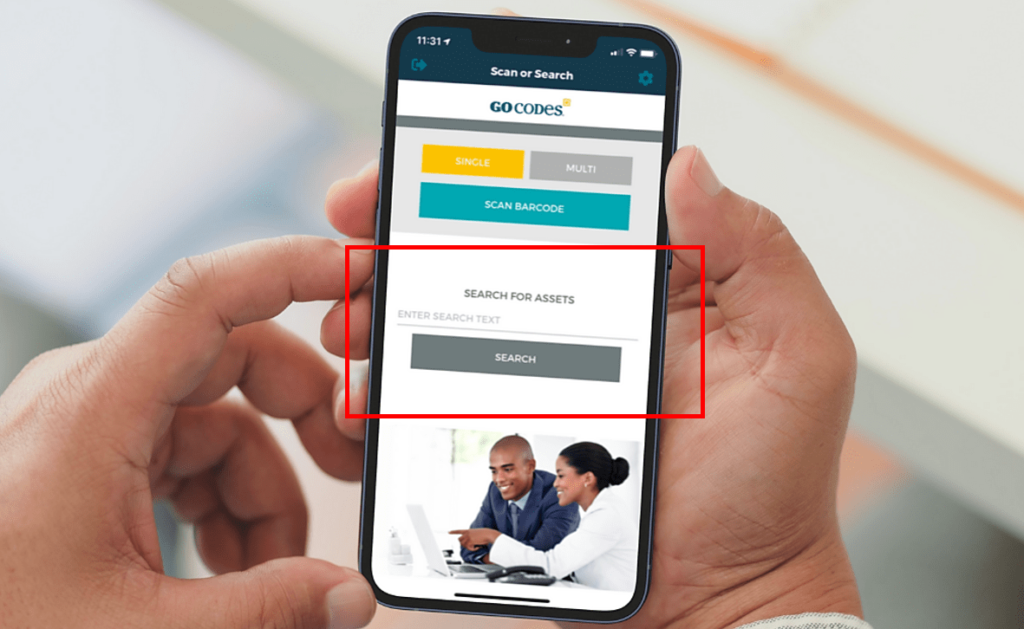

For starters, all employees need to do when looking for a specific tool or equipment is open their smartphone app and enter the name or type of an asset, as you can see below:

Source: GoCodes Asset Tracking

Their tracking app will immediately display how many of those assets the company owns, which are available, and where they are located.

If an asset is currently in use, the app will show who has it, where it is, and when it’s scheduled to be returned.

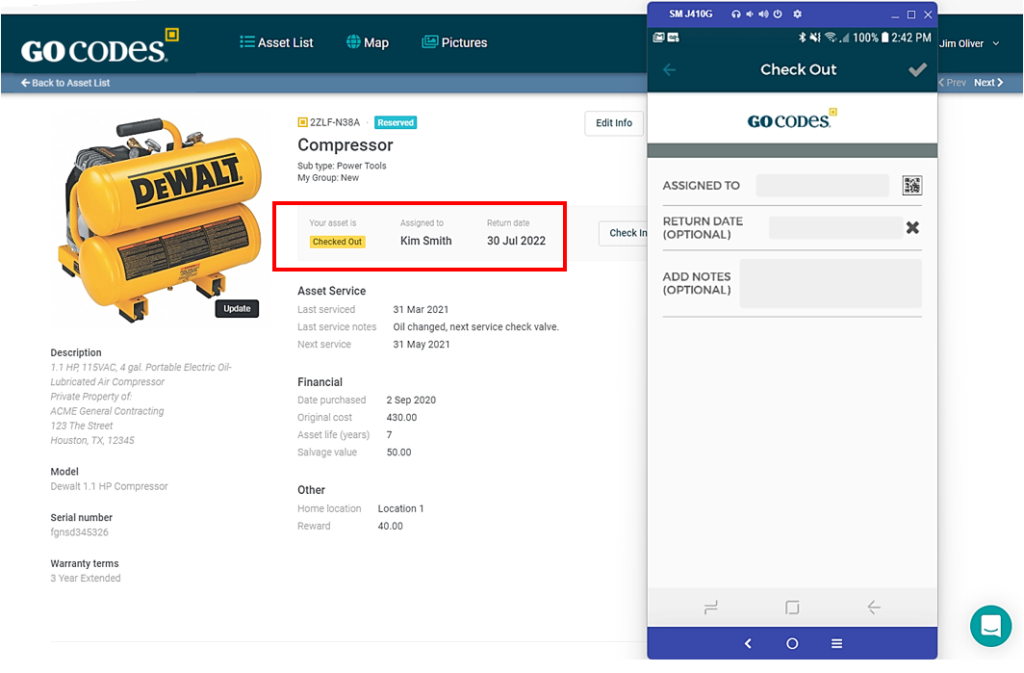

Additionally, whenever a worker takes a tool or piece of equipment, they can scan the tag and mark the asset as “checked out”.

As shown below, the manager can also pre-assign assets, set return dates, and add notes as needed.

Source: GoCodes Asset Tracking

Once the employee is done using the asset, they can check it back in by simply scanning its tag and marking it as “checked in.”

Such a self-service portal allows field workers, service technicians, and managers to instantly access, view, or update the asset’s details.

Some of these details—such as asset description, model, serial number, warranty terms, and maintenance history—are visible in the image above.

However, the possibilities are endless, as you can easily customize data fields to fit your specific asset-tracking needs.

To recap, giving employees an easy-to-use asset management dashboard speeds up operations and improves accountability, reducing the chances of assets being lost or misplaced.

Use Geofencing for High-Value Assets

Geofencing is a valuable tool for protecting high-value assets by setting up virtual boundaries around designated areas.

This feature is typically enabled through real-time GPS trackers and tracking apps that support geofencing.

Bluetooth beacons can also leverage geofences, but they are limited to a smaller detection range—usually around 300 feet (100 meters).

In contrast, geofences created using live GPS trackers offer an unlimited location detection range, making them ideal for large areas.

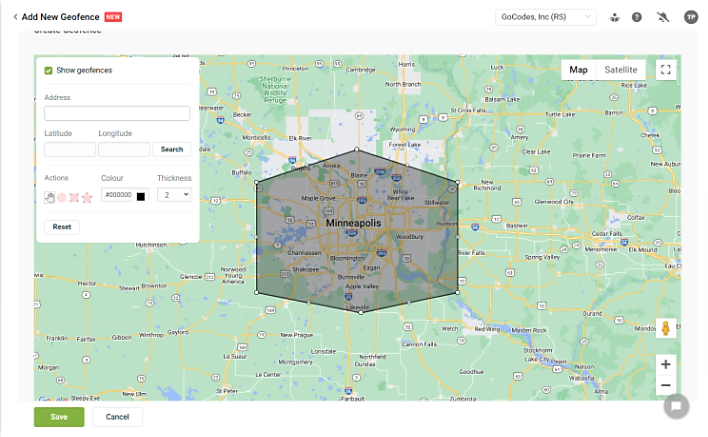

In any case, setting up a geofence is simple.

You select an area such as a job site or storage yard on the map to define the geofenced zone.

Source: GoCodes Asset Tracking

Next, you set the parameters for the geofence and turn on automatic alerts.

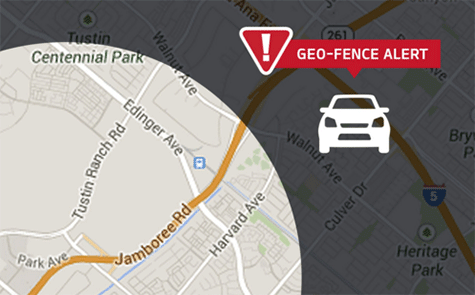

Now, whenever a GPS-wearing asset moves outside the designated area without prior authorization, you’ll receive an instant alert.

Source: Lawrence Kia

These alerts help prevent theft, unauthorized use, or accidental removal of your critical equipment.

Once notified, you can investigate the cause and take the necessary actions, from resolving a simple operator error to contacting authorities in the case of theft.

Ultimately, geofencing provides an extra layer of security on top of GPS tracking, offering peace of mind and enhanced protection for your high-value assets.

Track Asset Utilization, Not Just Location

Knowing where an asset is located is important but understanding how often and how efficiently it’s used is just as critical.

Without tracking asset utilization, you risk:

- Letting expensive assets sit idle.

- Purchasing equipment that’s not needed.

- Missing opportunities for better resource allocation.

Conversely, having asset utilization data at your fingertips allows your managers to make informed purchasing decisions and improve asset allocation.

This reduces unnecessary acquisitions while ensuring essential assets are always available.

So, how can you track asset utilization?

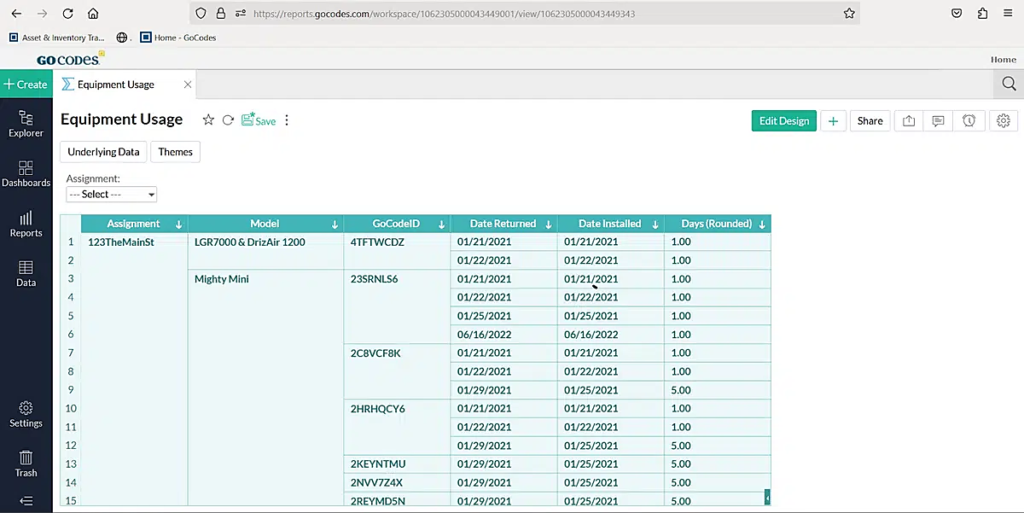

The best way is to collect data in your asset tracking app and take advantage of its reporting features.

Source: GoCodes Asset Tracking

This way, you have all the relevant utilization data, such as check-in/out times, engine hours, and downtime for repairs and maintenance in one place.

As illustrated above, you can use the data in your tracking app to generate equipment usage reports.

For instance, these reports can reveal that a particular piece of equipment is almost always checked out, which means it might be worth purchasing an additional unit.

And if it turns out that assets remain idle for long periods, they could be reassigned to another job site or even sold to free up capital.

So, tracking asset utilization helps you optimize availability, reduce waste, and ensure that every asset contributes to operational efficiency.

Track Depreciation for Financial Insights

Want to make smarter financial decisions about your equipment?

It all starts with tracking asset depreciation.

Every asset loses value over time, and if you’re not monitoring that decline, you could be dealing with inaccurate financial reports, unexpected tax issues, and even unnecessary spending on outdated equipment.

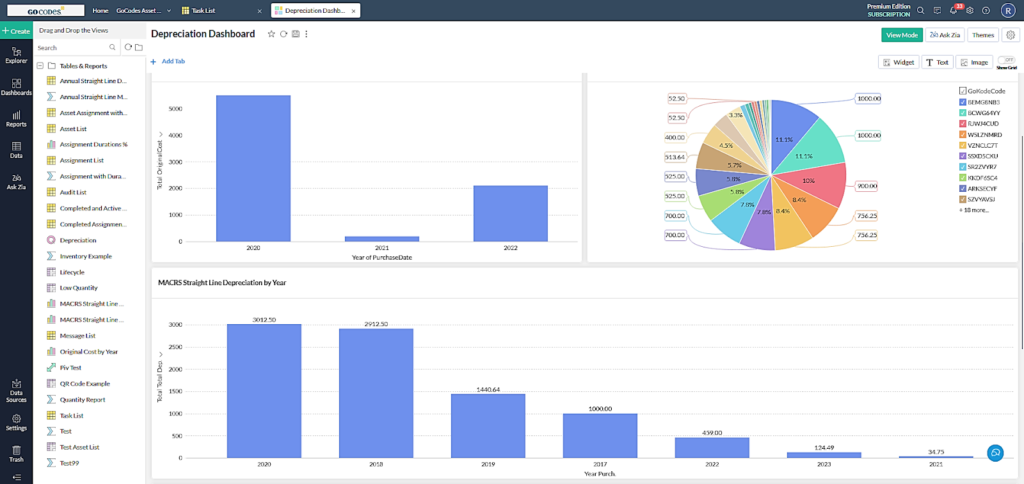

That’s why most asset-tracking systems now include built-in depreciation monitoring.

They let you log depreciation data, calculate rates, and monitor an asset’s value in real time.

With a dedicated depreciation dashboard, you can easily track each asset’s current value and remaining useful life.

Source: GoCodes Asset Tracking

Depreciation monitoring dashboards also help your team determine when an asset is no longer cost-effective to maintain and should be replaced or upgraded.

For instance, if an asset’s repair costs are consistently high and depreciation has significantly reduced its value, replacing it may be a better financial decision than keeping it.

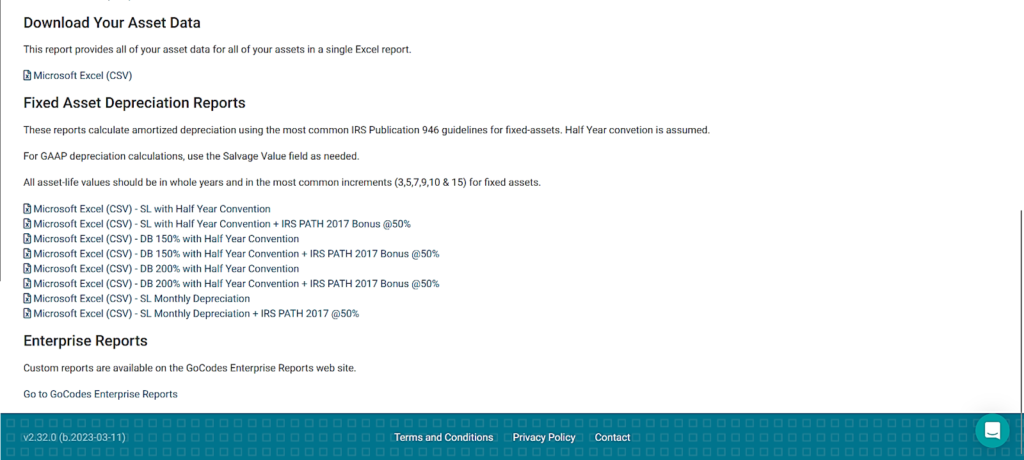

In addition to real-time monitoring, asset-tracking software usually lets you generate and export detailed depreciation reports in Excel or other formats.

Source: GoCodes Asset Tracking

By referencing these reports, your accounting team can accurately calculate depreciation for regulatory compliance, financial reporting, and tax purposes.

Furthermore, they can collaborate with equipment managers and other stakeholders to:

- Assess asset condition and value

- Budget for timely replacements

- Forecast maintenance costs

Ultimately, effective depreciation tracking will give you valuable financial insights, and help you make smarter asset lifecycle decisions.

Needless to say, this saves both time and money.

Conclusion

Effective asset tracking is more than just knowing where your equipment and tools are—it’s about maximizing efficiency, reducing costs, and improving security.

This can be achieved by using scannable unique identifiers, multi-tagging assets, and tracking their utilization and depreciation.

Investing in the right tracking tools that have these capabilities will make your assets work for you—not the other way around.

So, make sure to implement these tips!