Construction material handling can be quite stressful and even dangerous for construction workers. They have to deliver, move and control thousands of pounds of construction materials for construction projects to go according to budget and schedule.

So, if you don’t have safety procedures and methods to handle construction materials, accidents and injuries are inevitable. This can result in hefty OSHA fines, loss of productivity, and damaged reputation.

That is why we’ll give you actionable steps you can take today to increase safety for your workers, the local community, and the environment. Read on to find out more.

In this article...

Providing Safety Training for Your Workers

Jesus and Jessica are warehouse material handlers at DOT Foods.

Every day, they operate heavy equipment and work in different temperature conditions while handling materials. They move from 25,000 to 30,000 pounds of materials per day.

That includes lifting boxes and buckets, throwing bags on pallets, and transporting them with forklifts and stackers.

If they’re not careful, they can sustain minor injuries like cuts, bruises, or burns. What is more, improper material handling can also lead to more severe injuries like fractures and, in the worst-case scenario, fatalities.

Luckily, they were properly trained in workplace safety. That means they regularly implement safety procedures, like attaching safety belts and wearing protective clothing.

Even though Jesus and Jessica work in a food industry warehouse, the same applies to construction workers.

You can’t expect employees to comply with safety regulations on your work site without proper training. In fact, it’s your duty as an employer to ensure everyone knows how to handle construction materials safely.

A good safety training program should be tailored to the job duties and site conditions. Still, it should also include general safety guidelines and OSHA’s Focus Four Hazards (fall, caught-in, struck-by, and electrical).

Actually, any quality training program should consist of the following topics:

- Personal protective equipment for material handling

- Correct use of tools and equipment for material handling

- Proper lifting procedures (for manual handling)

- Personal risk factors for sprains and injuries

- Useful warm-up techniques before lifting

Now, the next question is, how do you successfully conduct safety training?

There are numerous options, and you can customize them according to your budget, available time, and the employee’s learning style.

Among others, there are PowerPoint presentations, one-to-one interactions, practical training sessions, YouTube tutorials, and 3D animation.

If you want to take it a step further, you can even enroll your workers in online courses, like eSafety.

They provide basic instructions about material handling, potential hazards, and safety practices for working with cranes, conveyors, and powered industrial trucks.

At the end of a successful safety training program, your workers will be more aware of workplace threats, personal risk factors, and how to handle different types of construction materials properly.

This will create a safer and more productive working environment.

It’s also important to note that safety training should be an ongoing process conducted on an annual or more frequent basis. It’s very easy to become self-assured and ignore safety procedures because you’re in a hurry.

Keep in mind that workplace hazards result from ignorance, complacency, and unsafe working conditions.

So, the only way to ensure everyone actively follows safety measures is to provide adequate instruction on proper construction material handling practices.

Having Safety Procedures for Material Handling

After your workers get adequate safety training about handling construction materials, you have to set additional safety procedures that apply directly to the conditions of your construction site.

For example, have specific safety procedures if you’re frequently working in low-lit areas or at heights. This could mean constructing ramps so employees can access work areas on different levels or ensuring that all aisles and passageways are clear for moving materials.

Additionally, if your workers frequently handle toxic materials, provide facilities so workers can wash up.

These particular health and safety procedures should inform the employees about their shared responsibilities around workplace safety.

More importantly, they should remind workers about the potential hazards they’re exposed to on a daily basis.

It’s important to show your workers that you have their safety and well-being in mind. Putting safety as one of the main priorities in the company will also encourage employees to follow safety measures.

After all, when employees feel safe in a workplace, they’re more motivated, productive, and loyal to their company.

Furthermore, your procedures can cover handling materials of specific shapes and sizes, such as:

Sheet metal | Use leather hand gloves and safety boots because of the sharp edges of the sheet metal. |

Barrel and drum | Use a barrel lifting handle to roll up or down on a ramp. |

Glass panes | Employees must wear hand gloves, long leather sleeves, leg guards, and safety boots. |

Long objects | Pipes, bars, and timber should be carried over the shoulder with the front end raised. To protect from abrasions, all employees must wear shoulder pads. |

Scrap metal | When handling misshaped pieces, employees must wear goggles, leather gloves, an apron, leg guards, and safety boots. |

Gas cylinders | These containers should not be dragged on the floors. |

Boxes, cartons, and bags | The proper way to move boxes and cartons is to grab the opposite top and bottom corners. |

All in all, when you actively implement safety procedures on your construction site, you’re lowering the risk of injuries and accidents and creating a more pleasant working environment.

Safe Storage of Materials

How you store your materials is also important in ensuring on-site safety.

This applies to both materials used in construction and various chemicals that can be toxic or otherwise harmful to your workers.

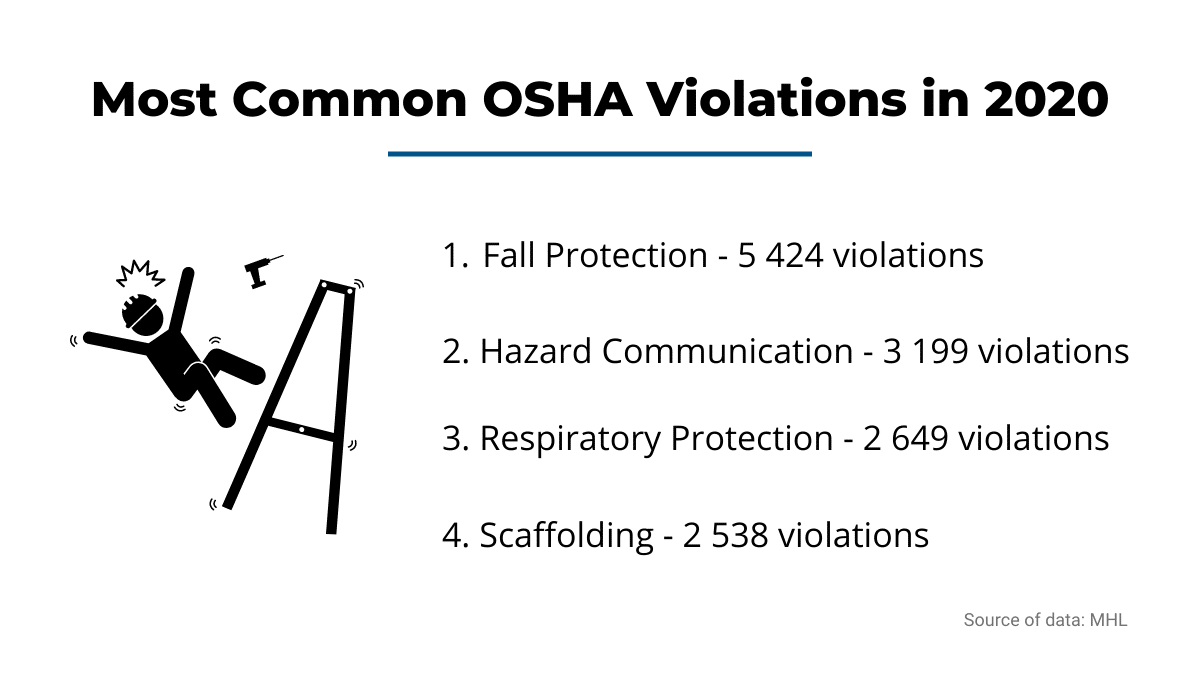

A recent OSHA report showed that one of the biggest safety violations was hazard communication, the set of safety procedures designed to protect workers from the effects of dangerous chemicals.

This means that construction companies failed to properly store and manage toxic, flammable, and explosive materials.

So, let’s briefly cover how you can responsibly handle chemicals on your construction site to guarantee safety and compliance.

Construction sites are full of chemicals and materials that need to be stored carefully, so they don’t come in contact with each other.

Flammable liquids such as paints and adhesives can pose a great fire risk when exposed to heat, oxidizers, and inorganic acids.

On the other hand, cement and plaster additives are corrosive materials that can threaten the environment or workers’ health.

There are also sealers, cleaners, fuel, and lubricants that you need to pay close attention to if you want to avoid hazards.

So, how do you store dangerous construction materials and chemicals?

First, find an area in your storage away from heat sources, smoking areas, and high machinery traffic. This space should be properly labeled to alert people. Keep it well-ventilated to avoid the build-up of toxic vapors.

Then, according to OSHA, you should put all hazardous chemicals in approved storage cans and cabinets.

Consider storing individual chemicals and materials in separate containers that are sealed to prevent spillage or leaks.

When it comes to storage cans, there are many types you can use, but their capacity should not exceed 5 gallons.

They also need to have a leak-proof lid, flame arresters, and pressure relief. Most cans are metallic, but you can also find non-metallic ones for storing corrosive chemicals.

Finally, storage cabinets are specially designed to keep all your dangerous chemicals and materials in one fireproof and spillproof container. Some important safety features include:

- Sloped shelves to prevent spills

- Thick, durable steel construction

- Flush handles that you can lock with keys or padlocks

- 3-point latching system with self-closing doors

- Reflective and legible signage

Remember that properly storing materials has numerous benefits. Apart from complying with federal regulations and preventing on-site accidents and injuries, it also allows you to keep a good stock and maintain pollution control.

In the end, if you want to increase safety on your construction sites, don’t forget about appropriate material storage.

Knowing the OSHA Requirements for Material Handling

In 2013, OSHA fined a Chicago-based company $91,000 for numerous violations that resulted in an accident involving a forklift.

Several years later, OSHA also penalized an Iowa center of the United States Postal Office with $88,000 fines for unsafe working practices used by lift truck operators when handling loads.

When you also consider that OSHA has increased its fines by 80% since 2016, you might think that these punishments are excessive and hurting businesses.

But look at it from OSHA’s perspective. When you continually face negligent companies that jeopardize people’s health and lives, you must implement drastic measures to set an example.

If companies don’t follow OSHA guidelines and, more importantly, instruct their workers to comply with them, the risk of injuries and fatalities increases. This can hurt your reputation, in addition to compelling you to compensate workers financially.

So, if you want to avoid OSHA’s fines, consult with their general guidelines and enforce them on your construction site.

Here are some of them:

- Employees should avoid overloading the equipment when moving materials.

- Employers must display maximum capacity on each piece of equipment.

- If workers pick items with a powered machine, they have to center the load to minimize tipping or load falling.

- Arrange the cargo to the lowest position when traveling.

- Pile and cross-tier all stacked materials.

- Stored materials mustn’t cause tripping, fires, explosions, and cause pest infestation.

- Remove nails from lumber before stacking.

- Ensure stacked materials are well-supported and stable.

Any material and unsafe practice can pose a great risk to people, property, and the environment. As mentioned before, it is your responsibility to follow important regulations to ensure safety on construction sites.

So, what better way than to become familiar with federal guidelines and implement them in your safety procedures?

Disposing Waste Adequately

Construction sites tend to become messy very quickly and piles of debris can pose enormous health and safety risks. Especially if you have to handle hazardous materials.

So, one way to combat large accumulations of construction waste is to have an effective waste management system.

Most commonly, this includes a dedicated area where you’ll keep skips for various materials your employees can sort into recyclable, reusable, and general waste.

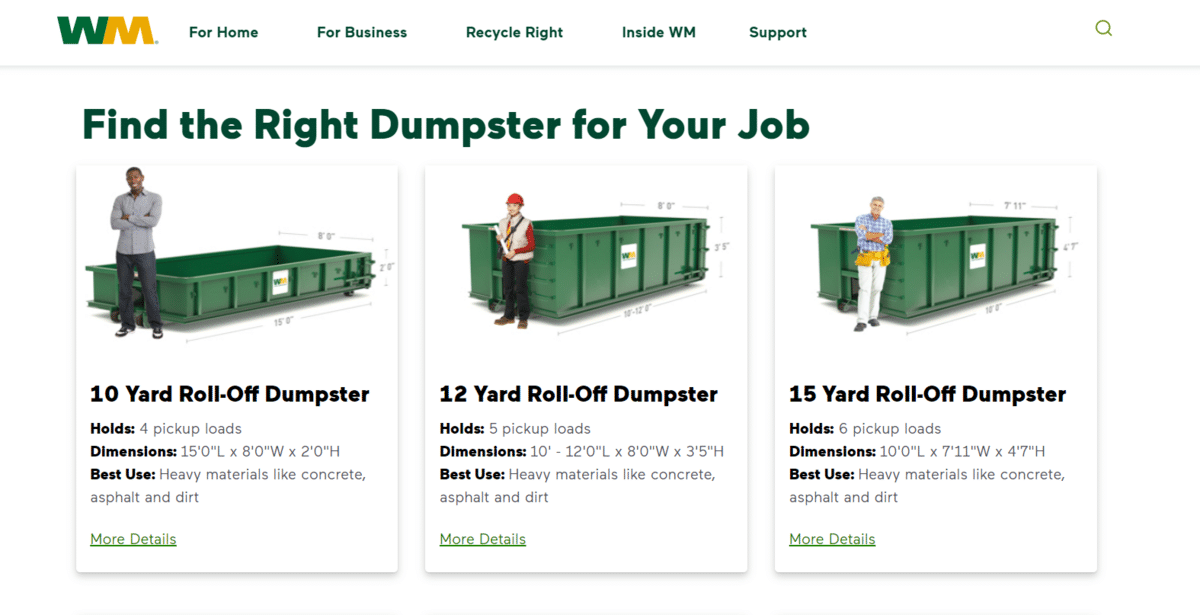

Which skip/bin size you’ll need will depend on the scope of your project and the amount of waste you’ll clear out on the site. Getting the largest one might not be cost-effective if you cannot even fill it halfway.

Following that, run the numbers and plan ahead for on-site waste management.

Apart from saving money by identifying reusable materials, you’re also greatly contributing to creating a safe working environment by properly disposing of materials.

Falls and trips are a huge concern on construction sites, so if you can clear areas regularly, you’ll better protect your workers and site visitors. Not to mention that proper waste disposal significantly reduces air, water, and land pollution.

Here are some other actionable steps you can take:

- Barricade the waste management area to limit access and exposure to hazardous material.

- Use an enclosed chute for workers to drop debris from elevated areas.

- Use separate containers for materials contaminated with oil or flammable liquids.

But if that’s not enough, take advice from Lee County in Florida and their general guidelines for proper construction waste disposal.

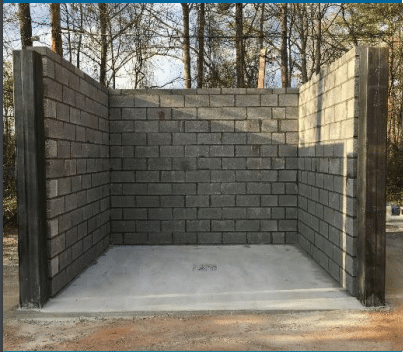

Their advisory document recommends that waste containers be placed on a flat and level concrete surface. Additionally, the containers should be enclosed to limit the contamination of the surrounding area.

Now, to ensure the enclosure is strong enough, the County advises that engineers create a concrete foundation that can endure up to 20,000 lbs. This should require a minimum of 6 inches of concrete in the base.

When it comes to enclosure elements such as gates and walls, the County recommends the following:

- Gates must not obstruct sidewalks, parking spaces, or public right of way.

- Gates should be 2 inches off the ground and hung on the outside.

- The enclosure wall for containers has to be 6 feet in height.

- Acceptable materials for container wall enclosure are masonry and wood.

- Chain link fencing is not acceptable.

If you want to take your waste management to the next level, you can follow the guidelines stated by Lee County. But the most important thing is to have an effective waste management system to protect your workers, adjoining property, and environment.

Conclusion

Proper material handling and storage can have enormous benefits for your company. If you implement proper practices, you can significantly increase safety on your worksites, but also reduce costs and optimize workflows.

Remember that worksite safety is a team effort when handling materials. Once you adequately train your employees, you also need to enforce good safety procedures they can follow and keep everyone accountable.