If you’re a construction business owner or manager wondering what exactly can be tracked with asset tracking software, you’ve come to the right place.

In essence, an asset tracking system allows you to monitor the location, usage, and condition of the assets, such as construction equipment, vehicles, tools, and other items that your business uses in everyday operations.

Armed with the insights gained from automating asset tracking, you can improve asset management processes in your organization, save time and money, and increase overall productivity.

However, since construction businesses typically use a wide range of assets, it can be hard to determine what to track and how.

To help you with that, here are five groups of assets your construction business can track using asset tracking software.

In this article...

Construction Tools

Regardless of how narrowly we define them, construction tools are the largest and most diverse group of assets that can be tracked.

For starters, they include all the traditional, non-powered hand tools like screwdrivers, hammers, pliers, wrenches, trowels, knives, and shovels.

Then there are all the different types of power tools—corded and cordless—like drills, saws, angle grinders, and nail guns.

This is followed by a wide range of smaller equipment like portable power generators and charging stations, measuring instruments like fish tapes, levels, and multimeters, and other items typically used on construction sites, such as ladders, wheelbarrows, and screeds.

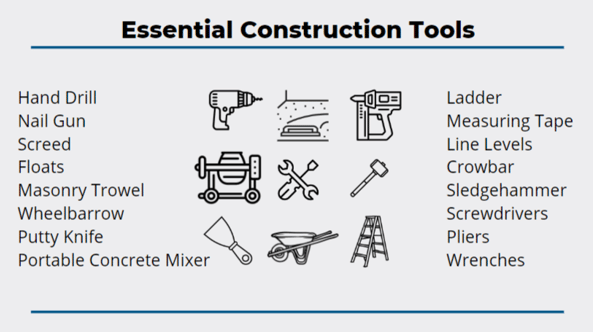

To illustrate all this variety, here’s a list of just some essential construction tools.

Of course, this list could go on to include all general and specialized tool types and subtypes, their attachments, battery packs, extension cords, etc.

Additionally, personal protective equipment (PPE) like hard hats, safety vests and glasses, and other protective gear can also be categorized as construction tools.

So, how can all these construction tools be tracked?

In short, there are many possible tracking solutions, from tagging tools with barcodes, to RFID tags, or active GPS trackers.

However, one solution construction companies find both practical and affordable for tracking their smaller and less valuable construction assets is pairing GPS-enabled QR code tags with tracking software, as GoCodes Asset Tracking does.

Every time an asset’s QR code tag is scanned by a smartphone, tablet, or another compatible device, the GoCodes Asset Tracking app uses its GPS function to update the asset’s location and show it to users on a map.

This technology is practical as it lets you track the GPS location, usage, and maintenance status and view other information about your assets in one place (usually through the mobile app).

At the same time, durable tags and cloud-based software come in an affordable package suitable for tracking large numbers of tools belonging to this diverse group of construction assets.

Heavy Equipment

The construction assets categorized as “heavy equipment” range from mega-cranes to mini excavators, all of which can be tracked using asset tracking software.

Heavy equipment refers to large, heavy-duty machines used for performing various construction tasks, such as excavation, earthmoving, demolition, grading, and material handling.

More specifically, this includes cranes and other lifting equipment, bulldozers, excavators, loaders, motor graders, backhoes, pavers, compactors, and much more.

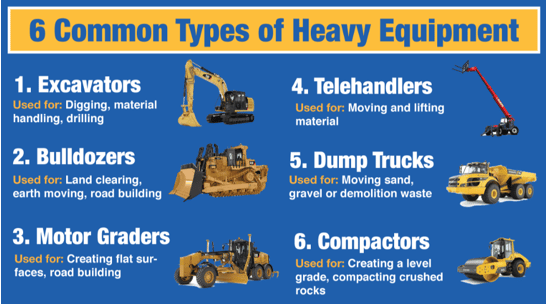

To illustrate all this, here are six common types of heavy equipment and their uses:

As you can see, the distinction between heavy equipment and construction vehicles (covered below) is sometimes blurry and often arbitrary, like in the case of dump trucks.

In other words, some construction managers will say that dump trucks are heavy equipment due to their size, weight, and function, while others may see them as construction vehicles because they transport materials.

In any case, this doesn’t change the fact that all these assets can and should be tracked.

They should be tracked because machines are typically the most valuable assets a construction company owns; they’re large, mobile, and at risk of theft and misuse, while at the same time being critical for project completion.

That’s why heavy equipment is most often tracked with active GPS trackers that read satellite signals to determine the asset’s location and send that info to the asset tracking software in real time.

Finally, when GPS trackers are connected to the asset’s internal or external monitoring sensors, the tracking software can provide a range of other useful information about a specific piece of heavy equipment, such as fuel consumption, idle time, and operating hours.

Vehicles

Just like heavy equipment, vehicles used for construction purposes can and should be tracked using asset-tracking software.

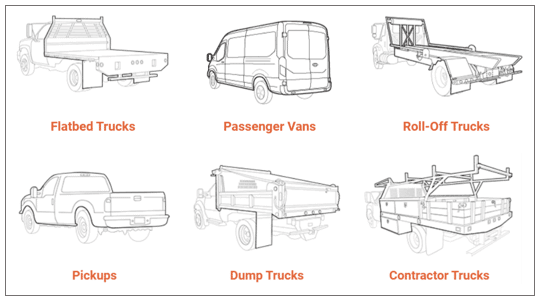

Ignoring possible overlaps with heavy machinery, this group of construction assets includes vehicles used to transport workers, materials, and equipment to and from construction sites.

For example, common vehicles for transporting workers include cars, crew vans, pick-up trucks, buses, and shuttles.

Similarly, vehicles used for transporting materials include concrete mixer trucks, dump trucks, and flatbed trucks.

Finally, tracked (crawler) heavy machinery and other construction equipment are transported on a range of different trucks and trailers.

To illustrate, here are images of some of the abovementioned vehicle types.

As for how these construction assets are tracked, the answer is the same as for heavy equipment—real-time GPS tracking.

In fact, it could be said that the GPS tracking of vehicles allows construction companies to reap major benefits when managing their construction fleet.

These benefits range from navigation and route optimization, and theft protection, to tracking the location, movement, speed, and a range of other data (when combined with sensors).

In other words, when GPS trackers are connected to in-vehicle sensors, asset tracking software allows you to monitor and collect data on idle time, engine performance, and driver behavior.

Armed with these insights, you can improve your construction fleet management, increase efficiency, and reduce costs associated with this group of valuable and critical construction assets.

IT Assets

IT equipment like desktops, monitors, keyboards, laptops, tablets, smartphones, and printers are a quickly growing group of valuable assets that can be tracked.

One reason for this growth in IT assets is that construction companies embraced different construction-specific software, such as Building Information Modeling (BIM), project management, scheduling, cost estimating, and, naturally, asset tracking.

Of course, all these and other software solutions are operated on devices like desktops, laptops, and tablets.

Construction companies are also increasingly using network IT equipment such as servers, routers, and switches.

Moreover, a growing number of items can be classified as a subcategory of IT assets—wearable devices.

Some of this high-tech gear, such as sensors and beacons, are intended for tracking and won’t need to be tracked themselves, while other devices may benefit from having an asset tag.

Similar to construction tools, the most convenient way to track IT assets involves tracking software and scanner apps on smartphones and tablets along with GPS-enabled QR code tags.

These labels and the tracking app allow you to track the GPS location of your IT assets, which is updated every time they’re scanned, and establish an effective check-in/check-out system, meaning you’ll know who is using them at any time.

Furthermore, QR code tags can be made from durable, tamper-proof materials and serve as proof of ownership if, for example, a laptop or tablet is lost or stolen.

Overall, IT assets used by construction companies are growing in number, so the location, usage, and maintenance of these often expensive and fragile items need to be tracked using asset tracking software.

Office Furniture

Upon first glance, office furniture is a straightforward group of assets used by construction companies in their business operations and includes items like office desks and chairs, filing cabinets, and conference tables.

However, there are many more items purchased by construction companies for long-term use that are so valuable or so frequently needed that it makes them worth tracking.

Some examples include lockers, shelving units and racks, workstations, and cubicles.

As in the case of construction tools and IT assets, office furniture is usually tracked using barcodes or QR codes attached to them, which allow the users to scan tags and view and update asset information using tracking software.

If we expand our focus beyond office furniture, there’s still a range of other items construction businesses use in their operations, such as portable restrooms, mobile lighting units, storage containers, tool chests, and carts.

Overall, office furniture and similar items used by construction companies can and often should be tracked to ensure their safety and security, efficient use, and regular maintenance.

Conclusion

Having gone through these five categories of construction assets, it’s clear that construction businesses extensively use various tools, heavy equipment, vehicles, IT assets, and office furniture in their everyday operations.

It’s also clear that most of these items can and should be tracked using asset tracking solutions that best fit the type, value, use, and maintenance requirements of their assets, as well as the company’s specific needs and budget.

The key takeaway?

Tracking the location and status of your construction assets will generate efficiency gains and cost savings across your business, allowing you to improve asset management processes in your organization, enhance overall productivity, and increase profits.