Key Takeaways:

- Spreadsheets fail when tracking hundreds of tools across sites.

- Real-time tool tracking cuts tool loss, theft, and confusion.

- Technology adoption fails when workers aren’t trained or included early.

Spreadsheets might have worked when you had 20 tools and one job site.

But as your business scales, manually tracking tool inventory becomes a major source of lost time, equipment, and money.

Construction companies that rely on manual records often struggle with inaccurate data, poor visibility, and theft that goes undetected until it’s too late.

If you’re ready to modernize, here’s how to move from spreadsheets to a smarter, more scalable tool management system—step by step.

In this article...

1. Define Requirements

Before diving into demos or pricing pages, take a step back and figure out exactly what you need from a tool management system.

Do you just want to know where your tools are, or do you also need to assign them to employees, get maintenance reminders, and sync with your project management or payroll software?

The clearer your goals, the better your chances of choosing the right platform the first time.

Yet, skipping this step is a common and costly mistake.

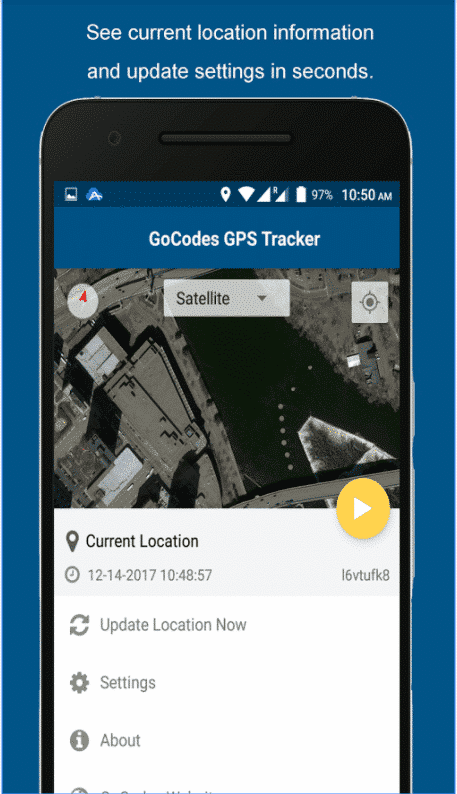

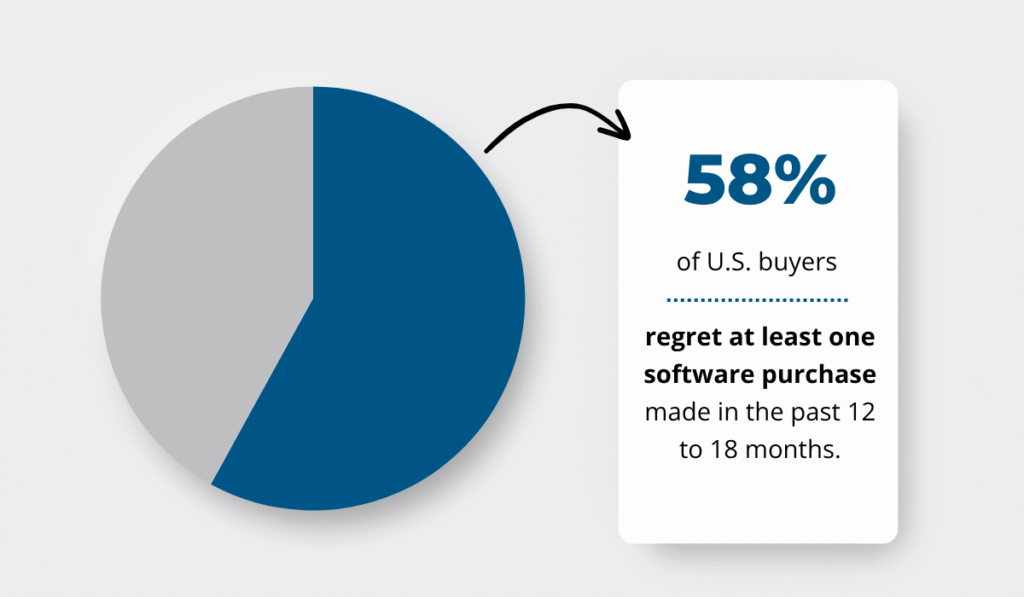

According to Capterra’s 2024 Tech Trends Report, 58% of U.S. buyers regret at least one software purchase, and a major reason is a lack of clarity at the start.

Illustration: GoCodes Asset Tracking / Data: Capterra

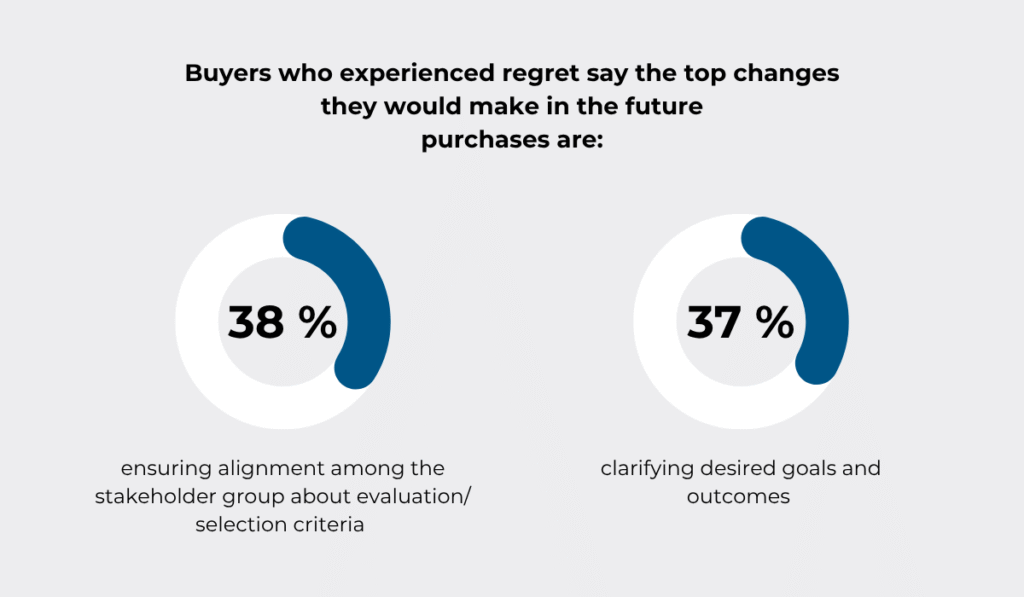

Of those with buyer’s remorse, 38% would align stakeholders on evaluation/selection criteria better in future purchases, and 37% would define their goals upfront.

Illustration: GoCodes Asset Tracking / Data: Capterra

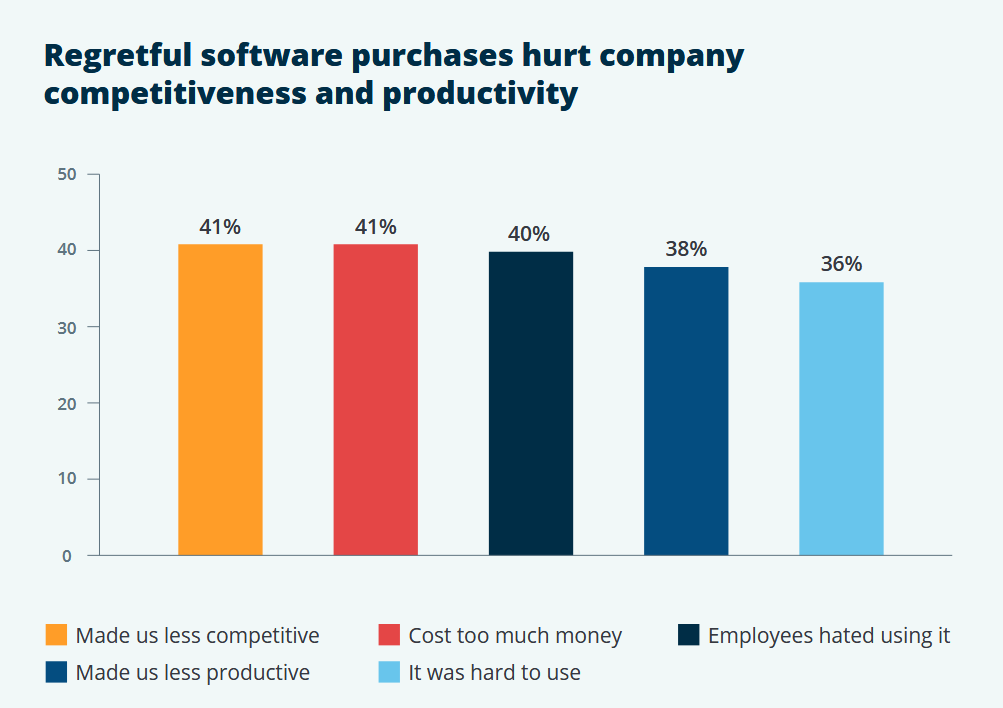

The worst of all is that such purchases cost more than just money.

They harm businesses in several ways, as you can see below:

Source: Capterra

So don’t treat this like a solo decision.

Involve foremen, project managers, field supervisors, and accounting staff early in the process.

Ask each of them:

- What’s not working with our current system?

- What would make your job easier?

The answers may surprise you, and they’ll definitely help you narrow down your must-have features.

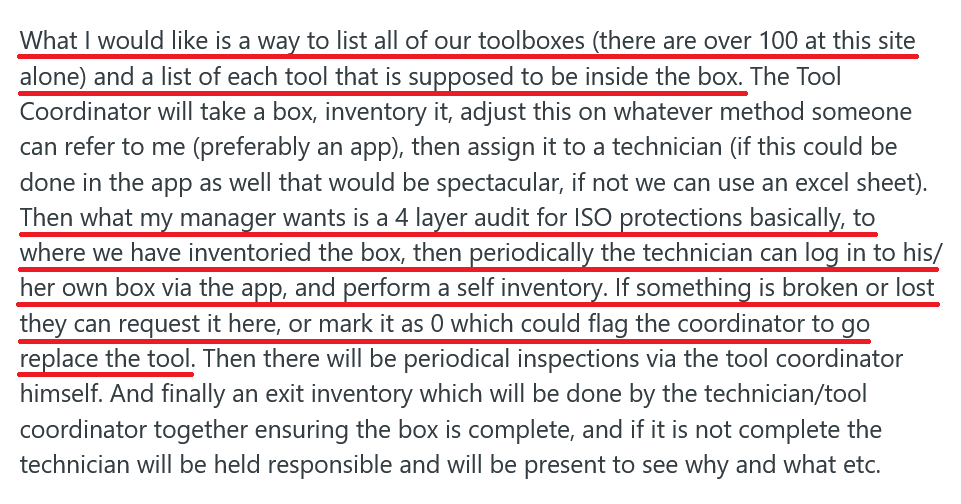

Take the example of one Redditor asking for help finding the right solution.

The manager wanted an audit trail that could stand up to ISO requirements, with multi-level access, so that technicians could log in, do self-checks, and flag missing or broken tools through the app.

Source: Reddit

That’s a lot more than just “tool location tracking.”

But it’s also exactly the kind of use case a good tool management platform can handle—if you pick the right one.

So, take the time to define your requirements clearly and get buy-in from the people who’ll actually use the system.

That way, you avoid wasting money on software that looks good on paper but doesn’t solve your inventory tracking problems.

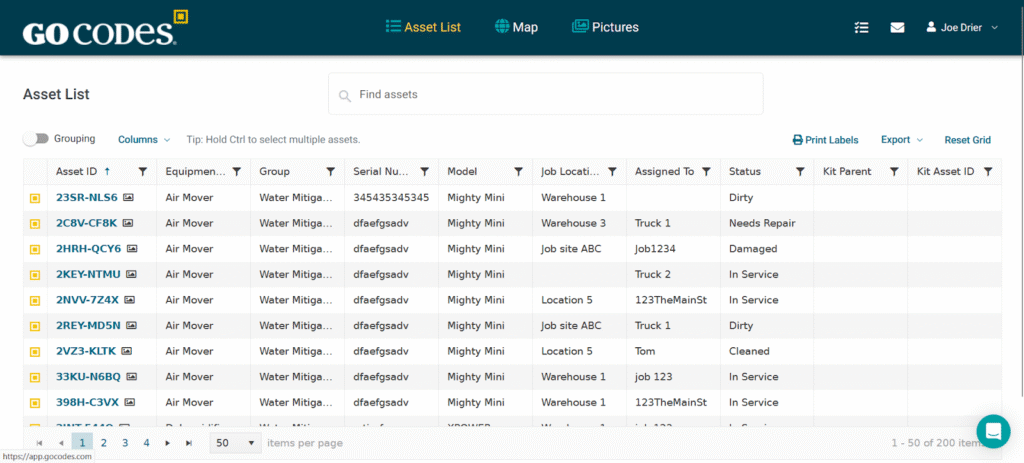

2. Research Tool Management Software Options

With your requirements defined, it’s time to start comparing actual tool management solutions.

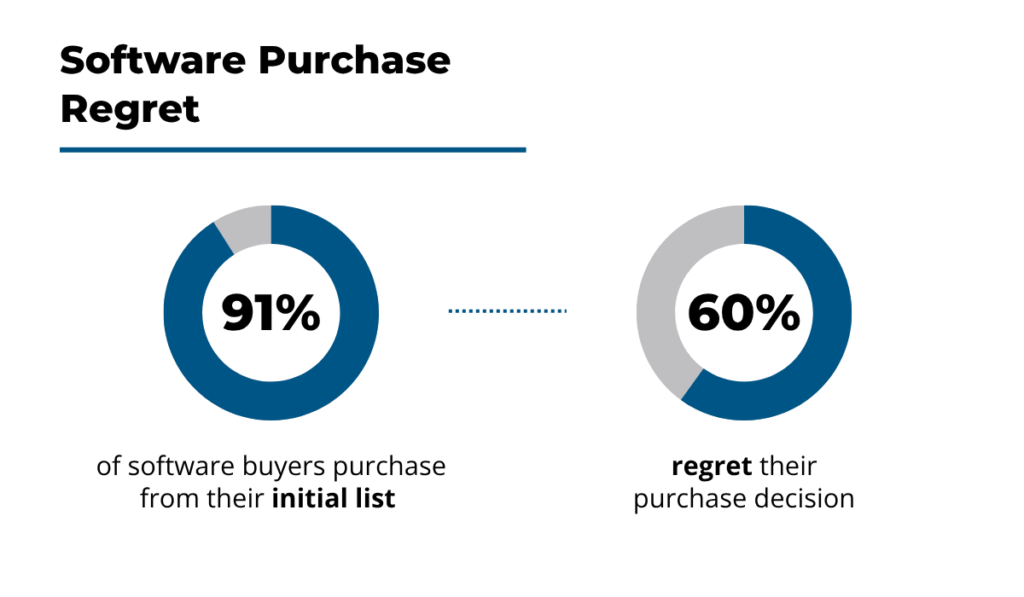

But be careful, as many companies rush through this step and end up regretting it.

According to the same report by Capterra, 91% of software buyers stick to their initial vendor list, and regret their purchase decision 60% of the time.

Illustration: GoCodes Asset Tracking / Data: Capterra

Often, that regret comes from overlooking better-fit solutions that weren’t on their radar early on.

So, don’t stop at the first few names that pop up in your search.

Instead, cast a wider net.

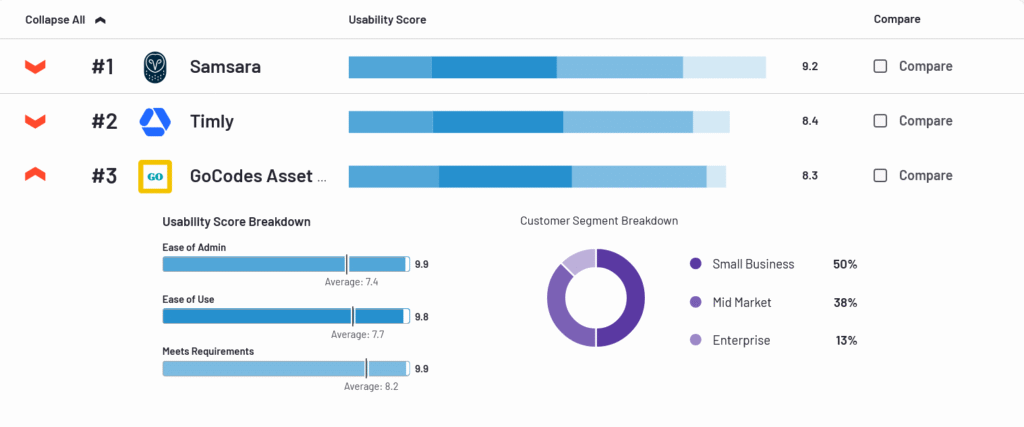

For starters, check platforms like Capterra and G2 to compare tools such as GoCodes Asset Tracking, GigaTrack, ToolWatch, and ShareMyToolbox.

Source: G2

Each of these has its strengths, and depending on your needs, one may be a much better match than the others.

For another solid starting point, check out our comparison of the best tool management systems.

It breaks down top options by features, pricing, and ease of use.

When it comes to features, here are the key ones to look for:

- Mobile-friendly check-in/check-out system for fast updates from the field

- QR code, barcode, or RFID support to eliminate manual data entry

- Tagging and tracking capabilities, ideally integrated with GPS

- Real-time visibility into tool location and usage

- Integrations with payroll, project management, or invoicing tools

- Audit trails and user access controls to support accountability

- Ease of use for field workers with limited digital skills

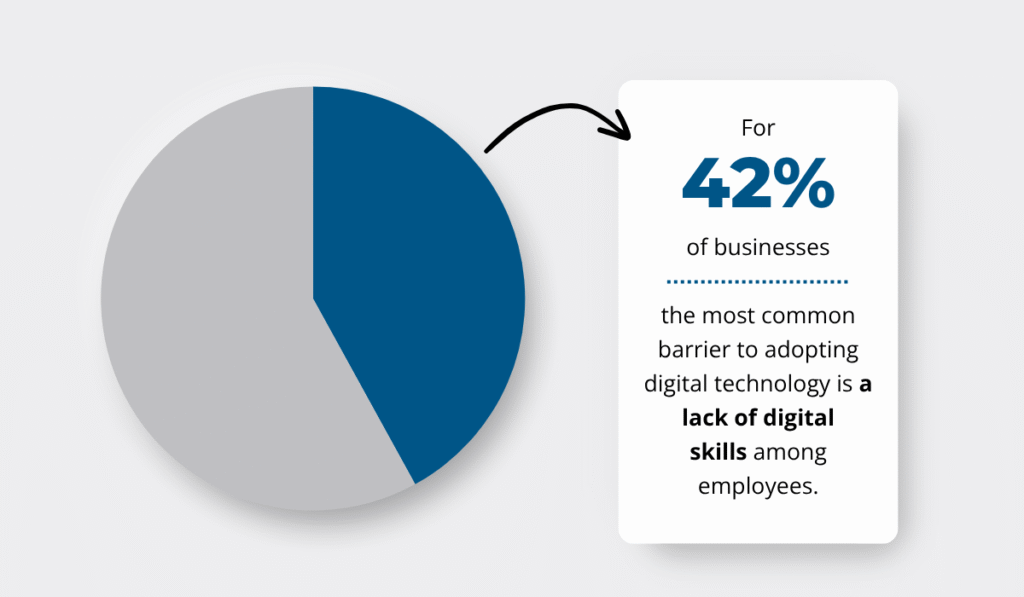

That last point is especially critical.

Deloitte reports that 42% of construction firms cite a lack of digital skills as the top barrier to adopting new technologies.

Illustration: GoCodes Asset Tracking / Data: Deloitte

A good system should be intuitive for crews in the field.

If it’s too complicated, it won’t get used, and you’ll end up back in spreadsheets.

To get a full picture of how well a tool works in practice, watch demos with both decision-makers and end users, and ask for a trial to test it with your real workflow.

Finally, search Reddit, forums, or trade groups to see what users are actually saying.

Here’s a good example of people sharing real experiences.

One Reddit commenter, for example, noted that the ideal system would tie into invoicing so quotes and billing happen in one place.

Source: Reddit

That’s a good reminder that your tool tracker can (and should) work as part of a broader ecosystem, not a standalone app.

Doing this homework may take a little time, but it’s what separates a smart investment from an expensive misfire.

The right platform will make it easier to ditch spreadsheets for good, because it’s actually built for how you work.

3. Clean Up Your Current Tool Inventory

Before importing anything into your new tool tracking system, take time to clean up your existing data.

If your current inventory spreadsheet is messy, outdated, or full of inconsistencies, you’ll just be dragging those problems into a new system.

Start by auditing your current list:

- Standardize tool names and categories (e.g., avoid having “cordless drill,” “Cordless Drill,” and “drill–cordless” as separate items)

- Verify tool location and condition

- Remove duplicates or entries for tools that no longer exist

- Fix obvious typos, broken formulas, or misaligned data columns

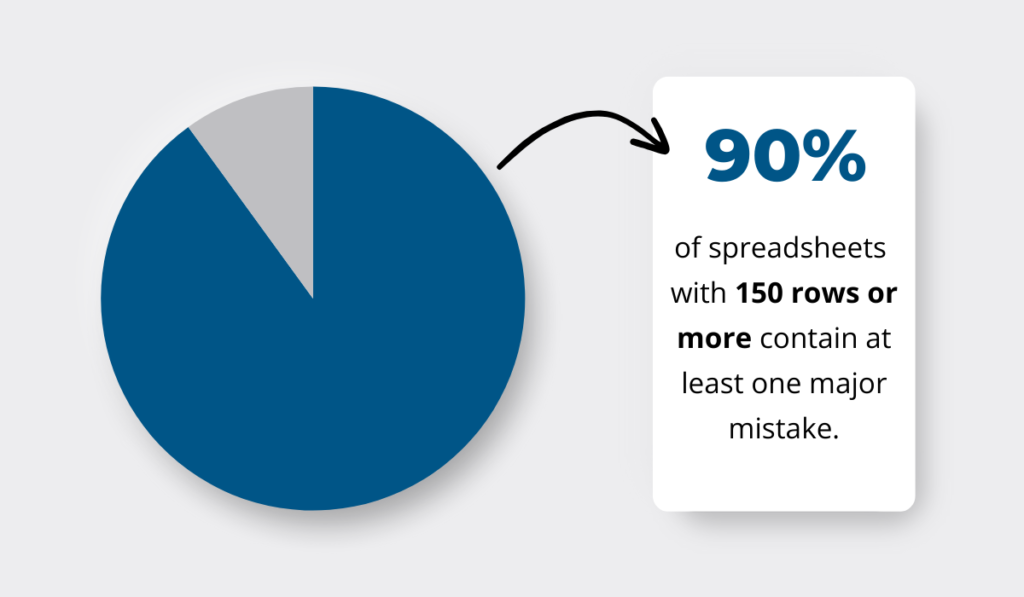

This step may seem tedious, but it will help you avoid costly mistakes.

Especially when we know that 90% of spreadsheets with over 150 rows contain at least one major error.

Illustration: GoCodes Asset Tracking / Data: IGI

You’re about to move to a system that gives you real-time, accurate visibility into your tools.

But that only works if the data going in is reliable.

Once everything has been cleaned up and verified, you’ll be ready to import the data into the new platform.

Most tool management systems support CSV imports or can even help you map the fields correctly during setup.

Some, like GoCodes Asset Tracking, will also walk you through data migration or provide import templates to simplify the process.

4. Use Barcode, QR Code, or RFID Tagging

Now that your tool data is clean and imported into the new system, it’s time to build your live, digital inventory by tagging your tools.

Every tool should be labeled with a scannable tag—barcode, QR code, or RFID—that links directly to its digital profile in your inventory system.

Source: GoCodes Asset Tracking

This step is what transforms a static spreadsheet into a dynamic, automated tool tracking system.

The best tool management platforms provide everything you need in one package: tags, software, a mobile app, and cloud-based inventory.

Source: GoCodes Asset Tracking

GoCodes Asset Tracking, for example, is an all-in-one solution that includes:

- A range of tag options (QR codes, RFID/NFC, Bluetooth beacons, and even GPS trackers)

- Durable labels designed for different environments (indoor, outdoor, heavy-duty use)

- A mobile app that lets field workers scan tools, check them in or out, and log updates

- A cloud-based system that stores and updates all tool data in real time

Here’s how it works:

You create a digital profile for each tool, attach a tag, and from then on, every scan automatically updates the tool’s location, status, who scanned it, and when.

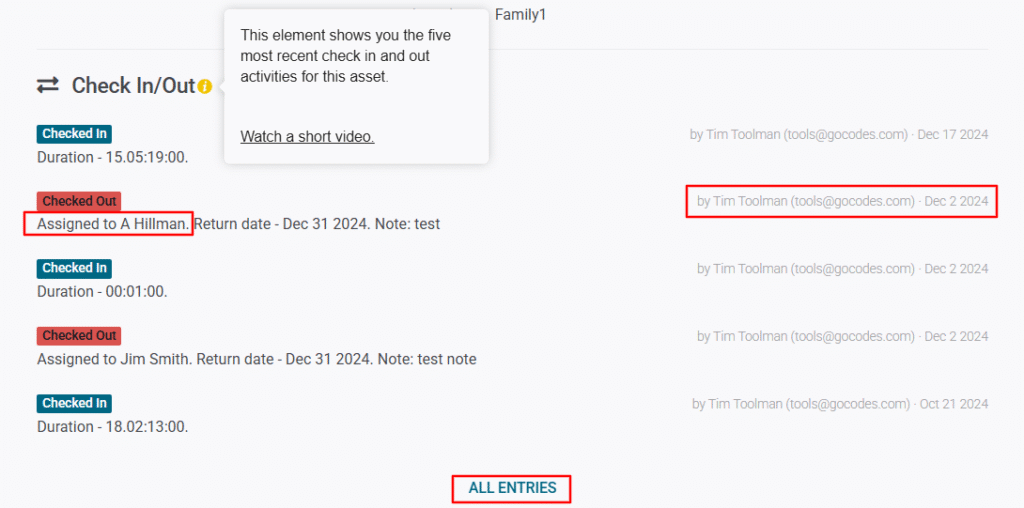

You can also assign tools to workers and view their full history, as shown below:

Source: GoCodes Asset Tracking

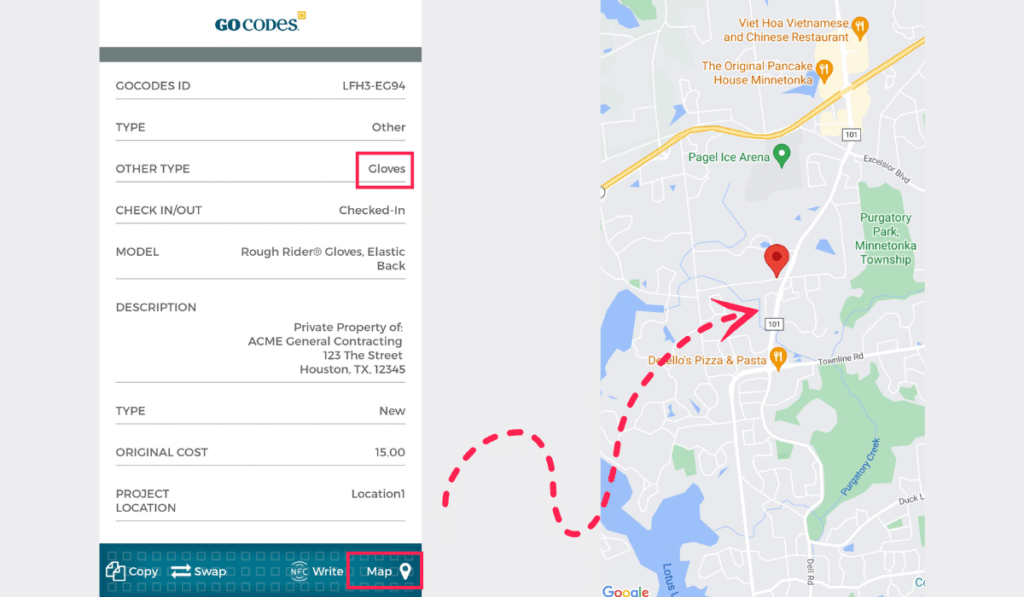

On top of that, you get real-time map visibility, so you always know where your gear is and who’s using it.

Source: GoCodes Asset Tracking

Which tag type you use depends on your needs.

QR codes are simple and affordable, and work well for most tools.

Source: GoCodes Asset Tracking

For higher-value assets, you can add GPS trackers and even enable geofencing—set a virtual boundary around your job site or storage area to detect unauthorized movement.

When it comes to tool inventory audits, it’s just as simple.

Scan tags on-site using the mobile app, and the system instantly verifies tool location and user.

Check out the video below to see how it works:

Source: GoCodes Asset Tracking

With this system, your inventory is always current.

You don’t have to hunt down missing tools, second-guess spreadsheet rows, or chase updates from different crews.

Once your tagging system is in place, you’ve got a live, searchable, and shareable tool inventory, without touching a spreadsheet again.

5. Train Your Staff

One of the biggest reasons digital tool management systems don’t deliver results isn’t the technology: it’s the people using it.

A common mistake is assuming your crew will figure it out on their own, or that a quick walkthrough will do.

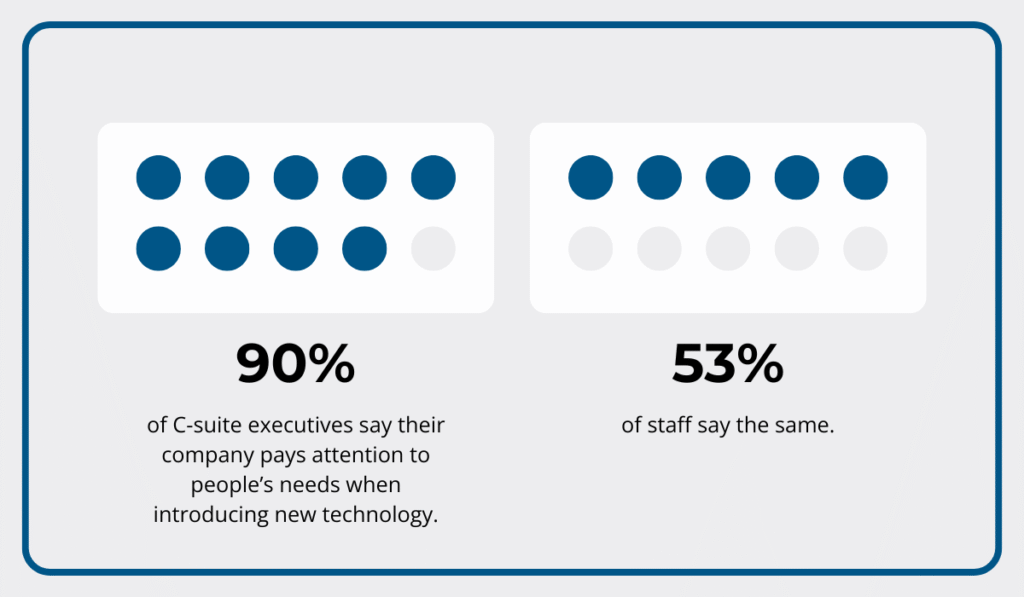

But the reality is, there’s often a gap between leadership’s expectations and frontline adoption.

According to PwC’s Tech at Work report, 90% of C-suite leaders believe they take employee needs into account when rolling out new technology.

Yet, only 53% of employees agree.

Illustration: GoCodes Asset Tracking / Data: PwC

Even if your new tool management platform is intuitive, dedicated training is essential.

Without it, old habits, like updating spreadsheets manually or writing tool transfers on paper, tend to stick around.

To avoid this, offer hands-on training sessions tailored to different roles:

| For office staff | How to assign tools, track usage history, run audits, and access reports |

| For field workers | How to scan tools in/out, check tool info, and flag missing items |

Make sure they understand how the system works and help them see how it saves time, prevents disputes, and eliminates the hassle of chasing down missing gear.

This matters more than you might think.

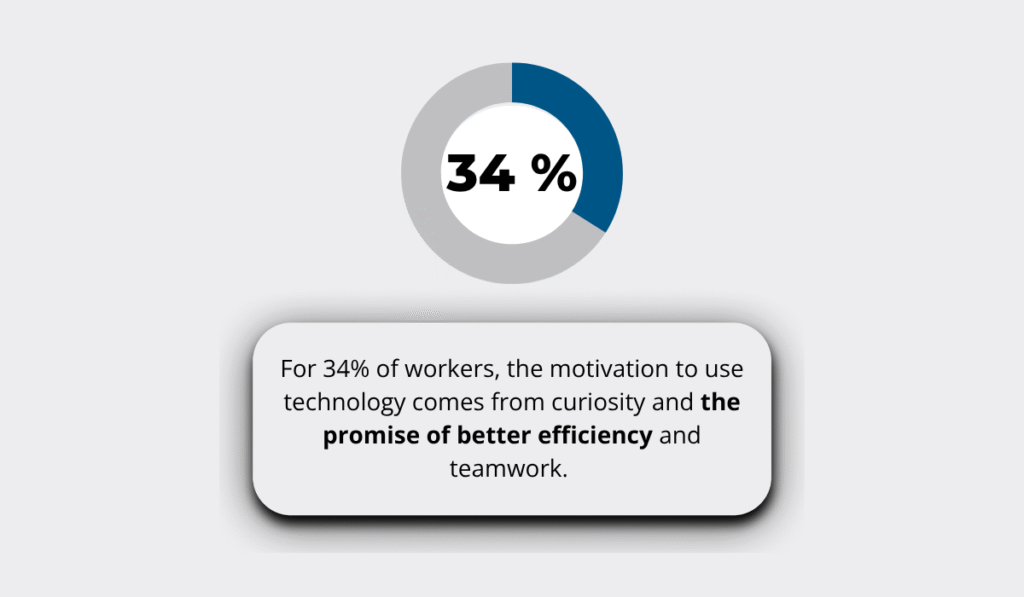

According to the same PwC report, 34% of workers say they’re more motivated to adopt new technology when they believe it helps them work more efficiently.

Illustration: GoCodes Asset Tracking / Data: PwC

By showing your team how digital inventory works in practice and how much easier it makes their jobs, you’ll ensure the system is actually used.

And once that happens, the spreadsheet is truly a thing of the past.

6. Phase Out Spreadsheets Gradually

However, switching to a digital system doesn’t mean you have to pull the plug on spreadsheets overnight.

In fact, the smartest approach is to run both systems side by side for a short period.

This parallel phase serves several important purposes:

- It gives your team time to adjust to the new workflow.

- It allows you to validate the accuracy of your imported data.

- It creates a safety net while you build confidence in the new system.

During this time, keep a close eye on the numbers.

Are tools getting checked in and out faster? Are fewer items going missing? Are field teams spending less time calling around to locate shared equipment?

Chances are, you’ll start seeing results quickly, especially if you’re using scannable tags like QR codes or RFID.

These technologies dramatically reduce manual errors and improve real-time visibility.

McKinsey estimates that RFID alone can cut inventory-related labor hours by 10–15%, freeing up time for more productive work.

Illustration: GoCodes Asset Tracking / Data: McKinsey

More importantly, this stage helps turn skeptics into advocates.

When foremen and field staff see that scanning a tag takes seconds, yet gives everyone instant visibility into where a tool is, who used it last, and whether it’s available, they’ll stop thinking of it as “more work” and start recognizing it as a smarter way to work.

And as confidence in the system grows, the spreadsheets you once relied on will start to feel clunky, outdated, and unnecessary.

That’s when you’ll know it’s time to leave manual tracking behind for good.

Conclusion

If you’re still using spreadsheets to manage tool inventory, you’re not alone.

But you’re also not set up to scale.

Moving to a modern tool tracking system improves accountability, reduces theft, and saves hours every week.

Just take it step by step: define your needs, choose the right tools, and make it easy for your team to succeed.

Do that, and you’ll stop losing tools, time, and money.