Key Takeaways:

- RTLS helps construction companies track equipment, staff, and vehicles in real-time.

- It prevents theft, reduces downtime, and enhances worker safety with geofencing and emergency alerts.

- Choosing the right RTLS depends on accuracy needs, budget, and work environment.

You’ve probably heard about a real-time locating system.

Maybe you’ve even thought about implementing it in your construction company.

However, before you do, there are a few things you need to know.

In this article, we’ll go over what RTLS exactly is, the benefits it brings, the challenges surrounding it, and, if it makes sense for your business, how to choose the right RTLS solution for your specific needs.

Ready? Let’s get into it.

In this article...

What Is a Real-Time Locating System (RTLS)?

A real-time locating system (RTLS) is a set of technologies that allows tracking and locating assets and personnel in real time.

This is incredibly valuable in industries like healthcare, manufacturing, logistics, and construction, where real-time tracking can improve efficiency, reduce costs, and enhance safety.

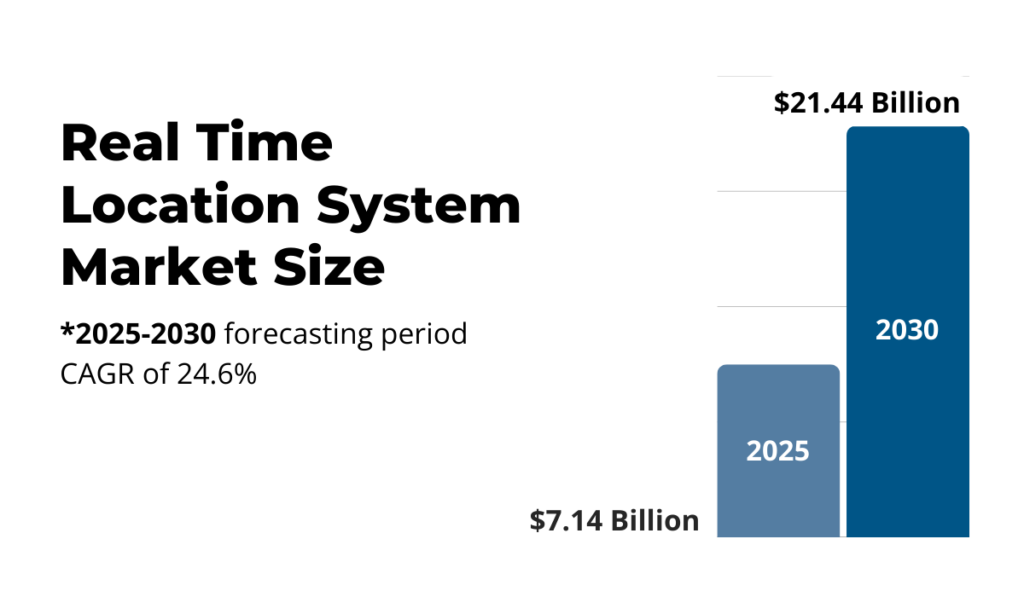

With that in mind, it’s no wonder that the RTLS market size is estimated at USD 7.14 billion in 2025 and is expected to reach USD 21.44 billion by 2030, at a CAGR of 24.6%.

Illustration: GoCodes Asset Tracking / Data: Mordor Intelligence

But to make the definition more specific to the construction industry, let’s put it this way:

A real-time location system (RTLS) is a set of technologies that allows you to track and locate equipment, staff, tools, vehicles, and machinery in real time.

But how does it do that?

Let’s start with the basics.

The real-time locating system usually consists of 3 components:

- Tags

- Receivers

- Software

Tags are attached (or in some cases embedded) to an asset or individual that you want to track.

The receivers are devices that communicate with the tags, collect data from them, and then send that data to software.

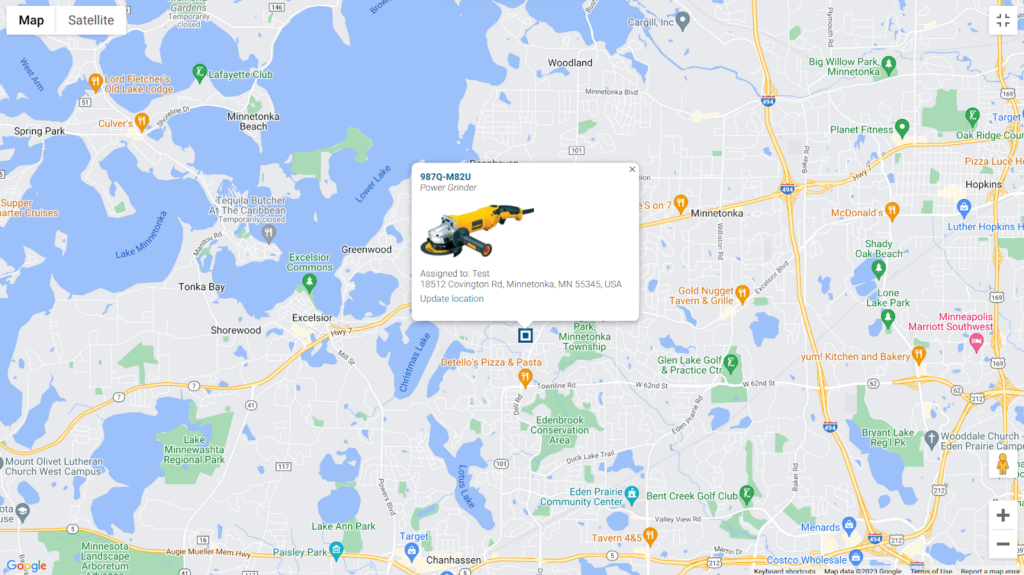

Finally, the software processes this data, transforms it, and ideally presents it in a map format so users can easily see the real-time location of the tracked objects.

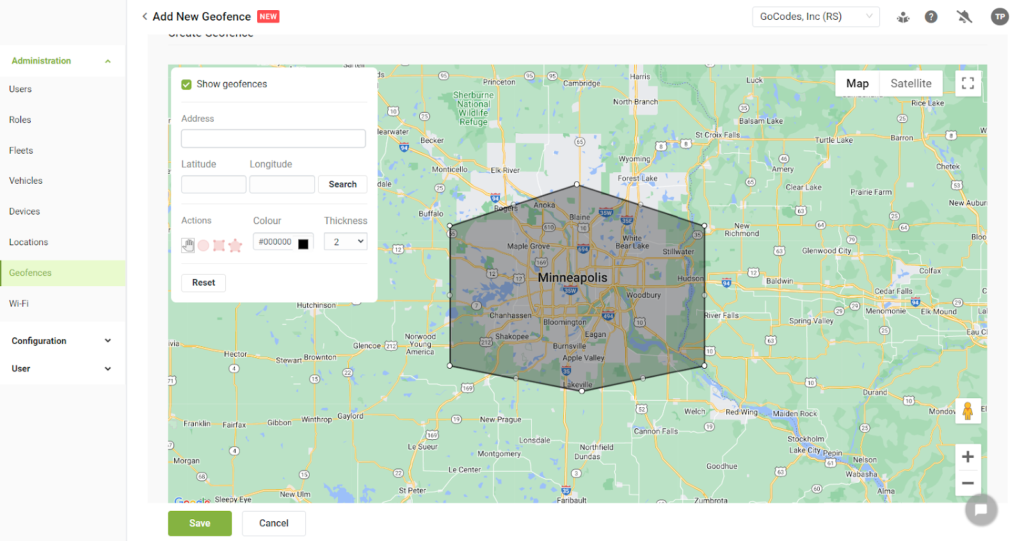

Here’s an example of what that looks like in GoCodes Asset Tracking:

Source: GoCodes Asset Tracking

This is the fundamental principle on which real-time locating systems are built.

Now, there are many different types of RTLS technologies available, each with its own pros and cons.

Here’s a breakdown of the most commonly used ones:

| Technology | How it Works | Pros & Cons | Typical Use-Case | Cost |

|---|---|---|---|---|

| RFID | Uses radio waves and relies on RFID tags attached to assets, with RFID readers capturing their signals. | + Affordable, no power needed for passive tags. – Short range- | Inventory management and tool tracking. | Low |

| UWB | Uses short radio pulses across a wide frequency range, relying on UWB tags and readers. | + High accuracy, resistant to interference. – Higher cost, requires more infrastructure. | Tracking assets in complex environments. | High |

| GPS | Uses satellite signals to track assets. | + Works globally, good for tracking moving assets. – Limited accuracy, doesn’t work well indoors. | Tracking vehicles, heavy machinery, and outdoor assets. | Medium |

| BLE | Employs low-energy Bluetooth beacons to transmit signals to receivers. | + Low power consumption, cost-effective. – Moderate accuracy, susceptible to interference. | Worker monitoring and small tool tracking. | Low |

| Wi-Fi | Leverages existing Wi-Fi networks to determine tracked asset locations. | + Utilizes existing infrastructure, moderate range. – High power consumption, susceptible to interference. | Tracking workers and equipment inside large indoor areas. | Medium |

But which one is the best?

The answer is the same as for the majority of big decisions: it depends.

We know that’s not the most satisfying answer, but every company has different needs, and the right RTLS technology depends on several factors:

- Required accuracy

- Operating environment

- Type of assets being tracked

- Budget

- Specific application needs

The clearer these factors are, the easier it is to determine which solution makes the most sense.

Let’s now take a look at why more and more construction companies are implementing RTLS.

RTLS Benefits for Construction

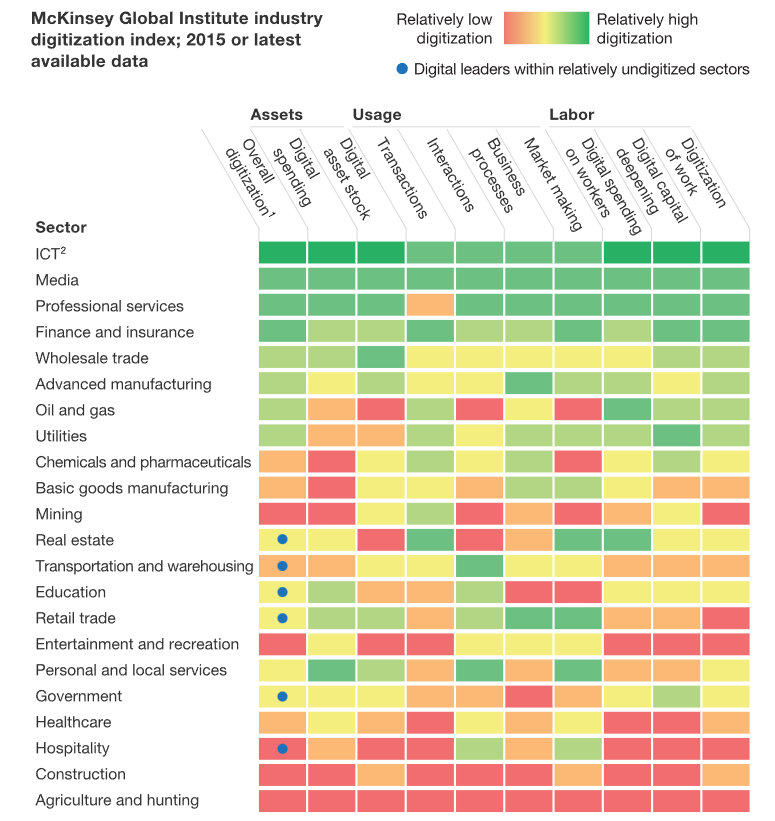

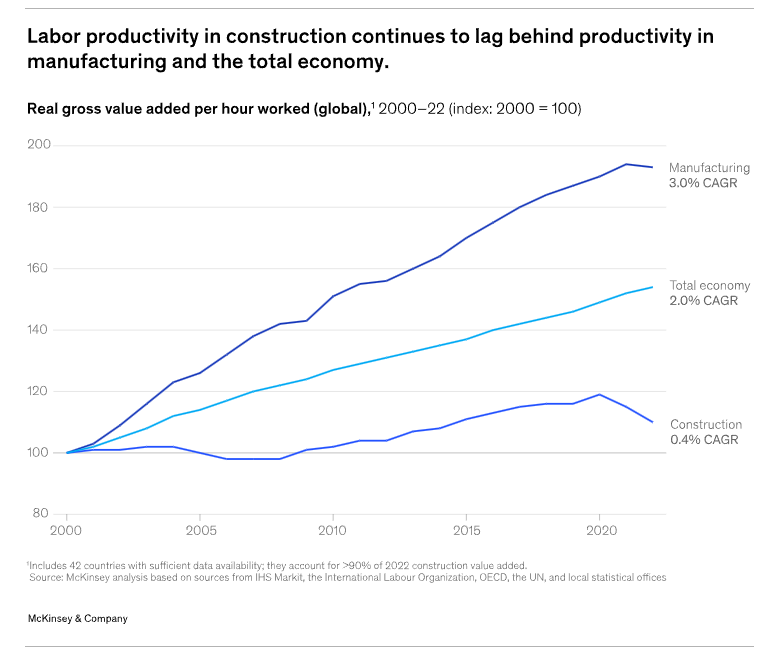

It’s no secret that the construction industry has traditionally been slower to adopt new technologies.

So, it’s not surprising that other sectors—such as healthcare, manufacturing, supply chain, logistics, automotive, and mining—have adopted RTLS at a faster pace.

Source: McKinsey

However, that’s not necessarily a bad thing.

Think about it: implementing it now, while it’s still not as widespread in the construction industry, can give your company a serious competitive advantage.

Why?

Because in construction, there are countless assets to keep track of, and most of them are constantly moving.

Equipment, tools, machines, vehicles, materials, and workers—you need to know where everything is at all times.

This is where RTLS makes a massive difference.

And no, it’s not just because it makes locating them easier and instantaneous.

It’s also because it improves operations, increases productivity, enhances safety, optimizes maintenance, and helps cut costs.

So, let’s cover the 3 biggest benefits of RTLS in more depth and show you exactly how RTLS makes them happen.

Asset Tracking for Security

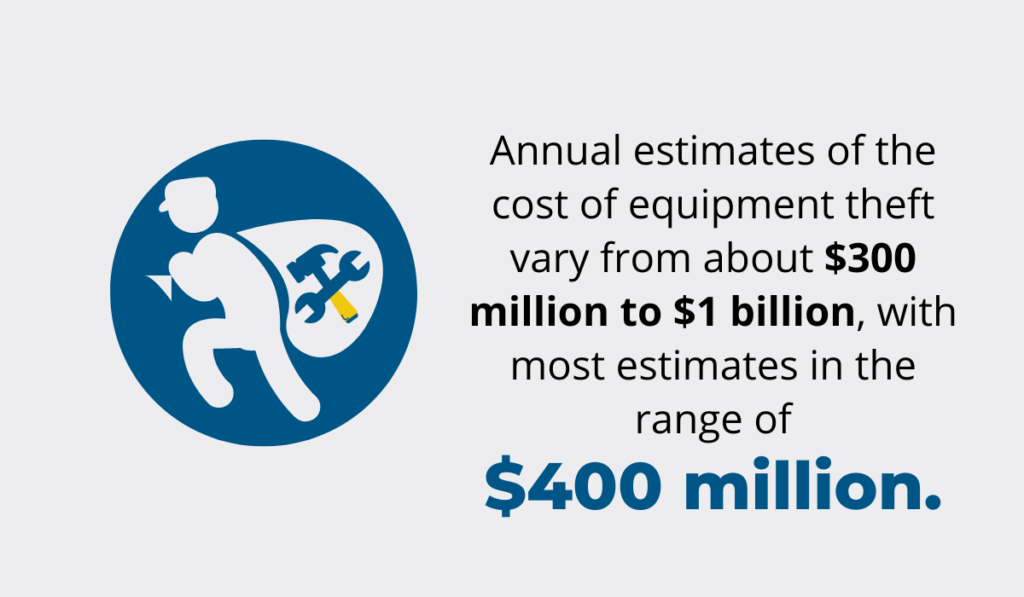

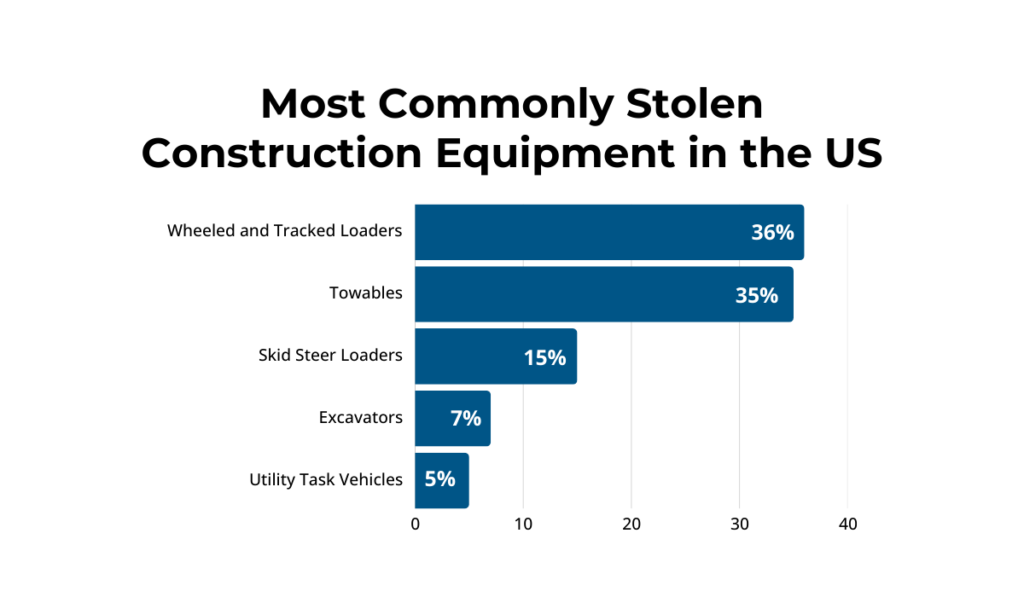

It’s not a secret that the construction industry faces significant challenges with equipment theft.

According to the National Equipment Register (NER), an estimated $300 million to $1 billion worth of construction equipment is stolen annually in the United States alone.

Illustration: GoCodes Asset Tracking / Data: NER

This is a big number, but to really get a sense of how much it can cost you, think about this.

Imagine if someone stole just one of your loaders, which is the most commonly stolen type of equipment, according to LoJack’s research.

Illustration: GoCodes Asset Tracking / Data: LoJack Corporation

That would cost you around $100,000 for one standard wheel loader.

And keep in mind, this staggering figure doesn’t account for indirect costs like project delays and increased insurance premiums.

That’s a huge loss that could easily be prevented with RTLS, because it lets you see where your assets are at all times.

It notifies you when something is moved when it shouldn’t be.

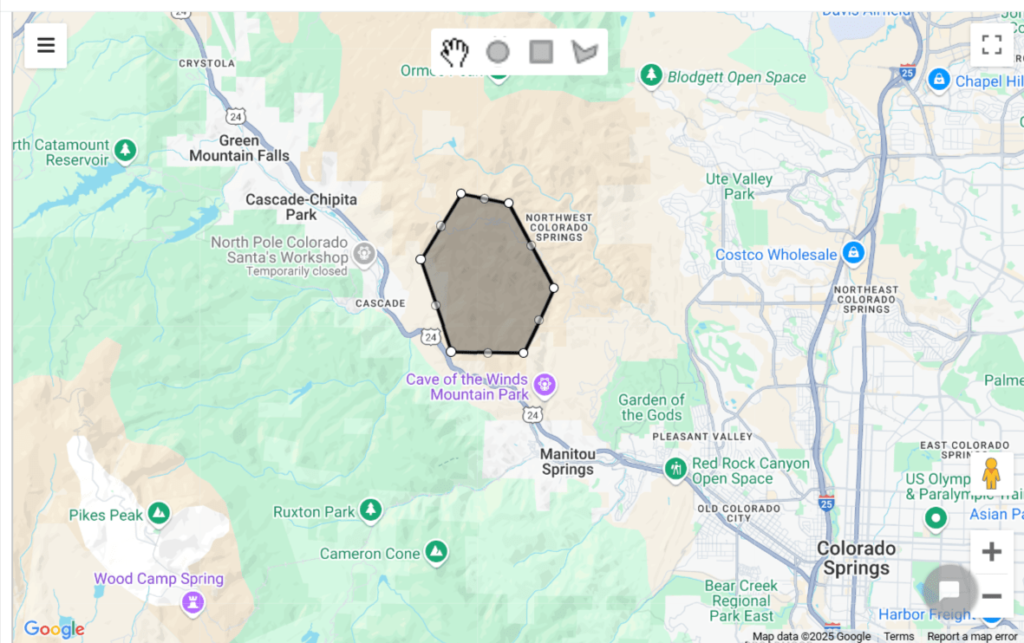

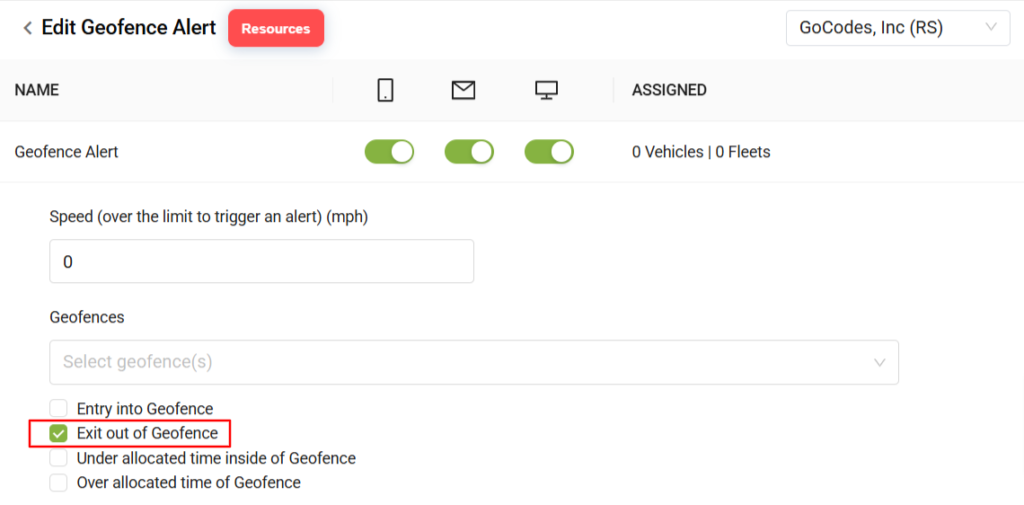

It also allows you to set geofences: virtual boundaries around job sites, storage areas, restricted zones, or other key locations, so if something gets moved outside of those areas, you’ll get an instant alert.

Source: GoCodes Asset Tracking

And if a theft does happen, RTLS helps you track the stolen asset’s last known location, increasing the chances of recovery.

It’s a simple solution to a costly problem.

Worker Safety Monitoring

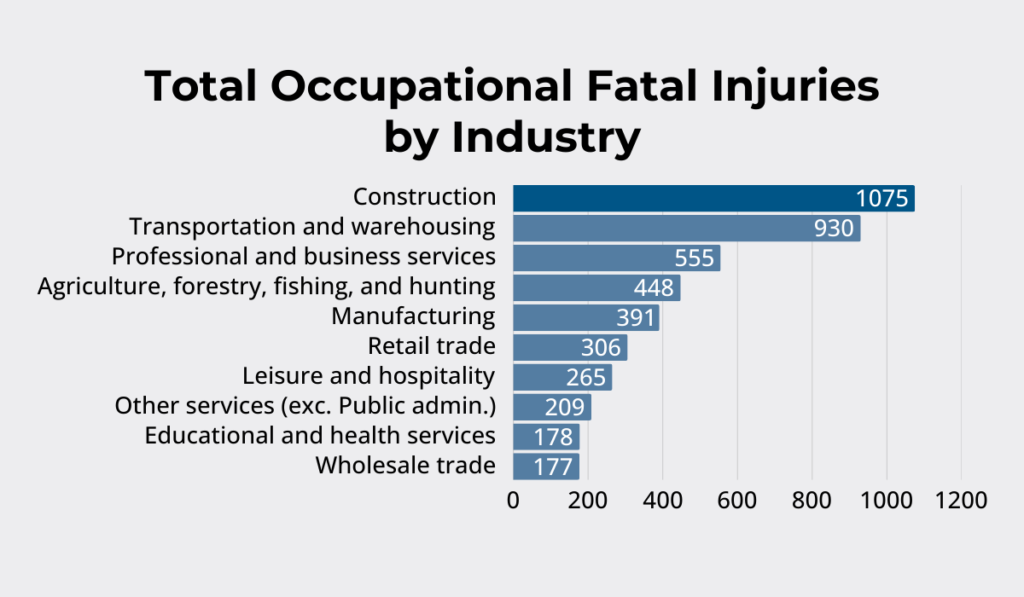

Construction sites are dangerous.

Heavy machinery, high places, and fast-moving equipment create constant risks.

Every year, thousands of workers get injured on job sites, and unfortunately, many of these accidents are fatal.

According to the Bureau of Labor Statistics (BLS), in 2023, the construction industry recorded 1,075 work-related fatalities.

That’s the highest number since 2011 and more than any other industry.

Illustration: GoCodes Asset Tracking / Data: U.S. Bureau of Labor Statistics

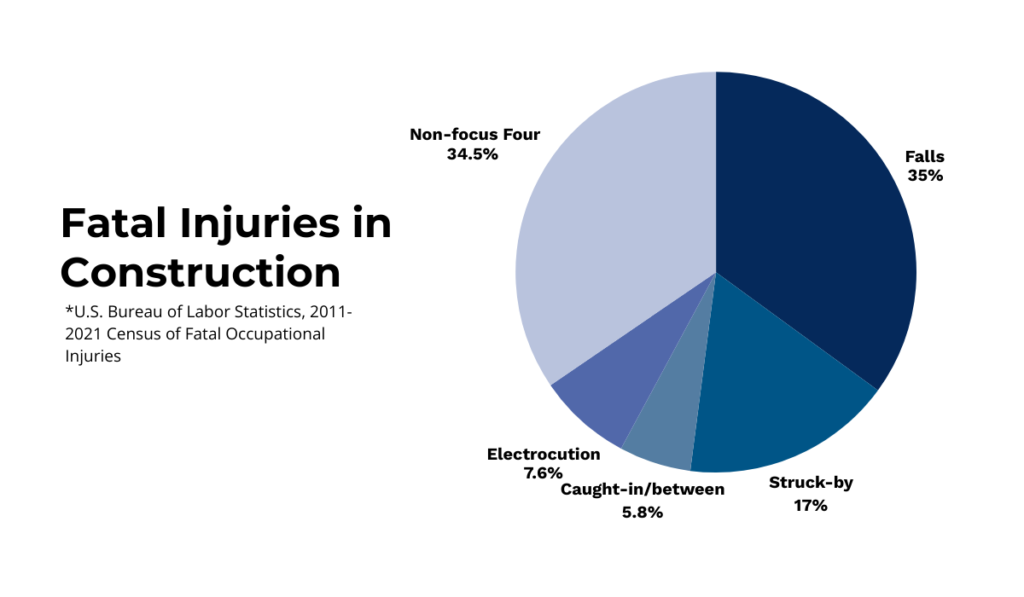

OSHA identifies falls, struck-by accidents, caught-in/between incidents, and electrocution as the four most common and deadly hazards in construction.

In fact, 65% of all fatal accidents are caused by these “focus four”:

Illustration: GoCodes Asset Tracking / Data: U.S. Bureau of Labor Statistics

And while there’s still no way to completely stop accidents from happening, RTLS can significantly reduce them.

When an accident happens, every second counts, and a quick response can be the difference between life and death.

RTLS tracks workers in real-time, so if someone falls, stops moving, or presses a distress button, the system instantly alerts supervisors with their exact location.

This helps emergency responders find them fast and provide help when it matters most.

Here’s how RTLS worker safety usually works:

Source: Wipelot IoT on YouTube

But RTLS doesn’t just help after an accident has happened—it can also prevent them.

Construction sites have high-risk zones, like areas with toxic fumes, heavy machinery, or high noise levels.

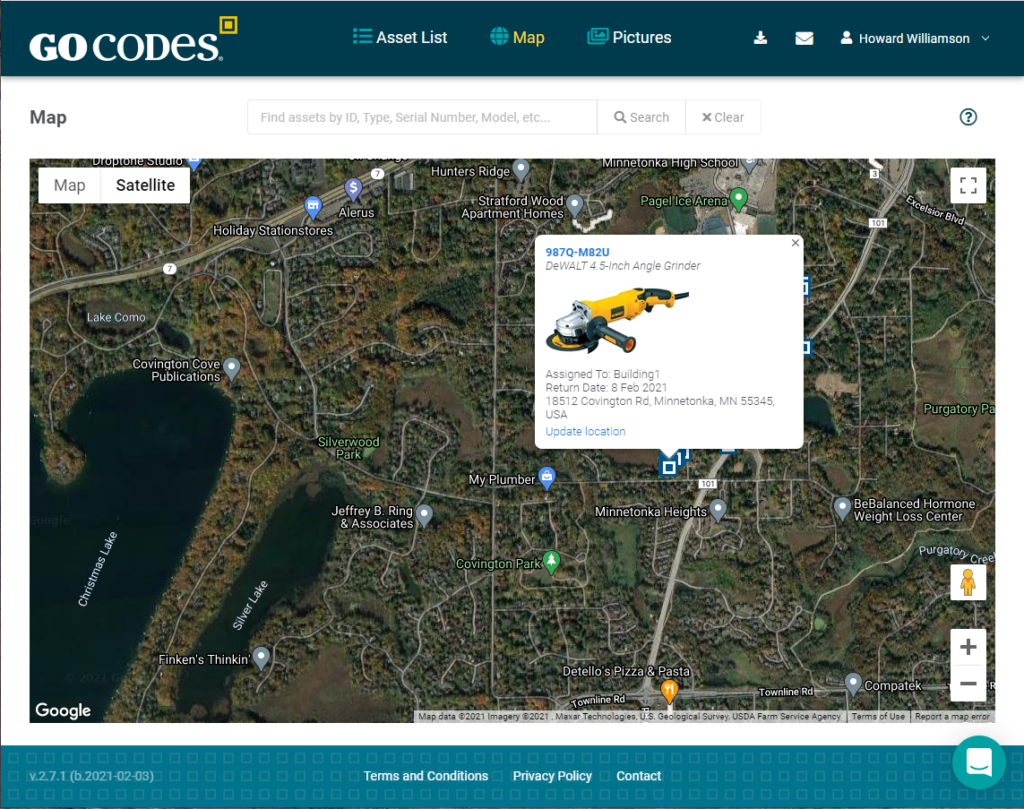

With RTLS, you can geofence these zones and integrate them with sensors that detect dangers.

If a worker enters a restricted area, the system triggers an instant alert, warning them and their supervisor before it’s too late.

With GoCodes Asset Tracking, creating geofences is as simple as drawing boundaries on a map:

Source: GoCodes Asset Tracking

And setting up automated relevant alerts and keeping your team safe is just as easy:

Source: GoCodes Asset Tracking

But there’s also the risk of collisions.

Workers on foot and heavy machinery operators often work close together, which increases the chance of accidents.

RTLS can reduce this risk by sending instant alerts when a worker and a machine get too close to each other, and, in some cases, it can even automatically slow down or stop equipment to prevent a collision.

By making emergency response faster, helping workers stay out of dangerous areas, and preventing collisions, RTLS saves lives and makes construction sites safer for everyone.

Operational Efficiency Improvement

Operational efficiency is all about maximizing productivity and minimizing costs without sacrificing quality or safety.

Given that productivity in the construction sector improved by just 10% between 2000 and 2022—and even declined by 8% globally between 2020 and 2022—it’s evident that significant efficiency challenges persist.

Source: McKinsey

But how does RTLS help increase productivity and minimize costs?

Well, in several ways.

For instance, one of the biggest inefficiencies on construction sites is wasted time looking for misplaced equipment.

Tools, machines, and materials don’t always end up where they should be, and every minute spent looking for them is a minute not spent working.

RTLS eliminates this problem by showing exactly where assets are.

So, instead of running around looking for a lost drill or a misplaced forklift, workers can check the system, find the exact location, and get back to work.

Source: GoCodes Asset Tracking

But that’s just the beginning.

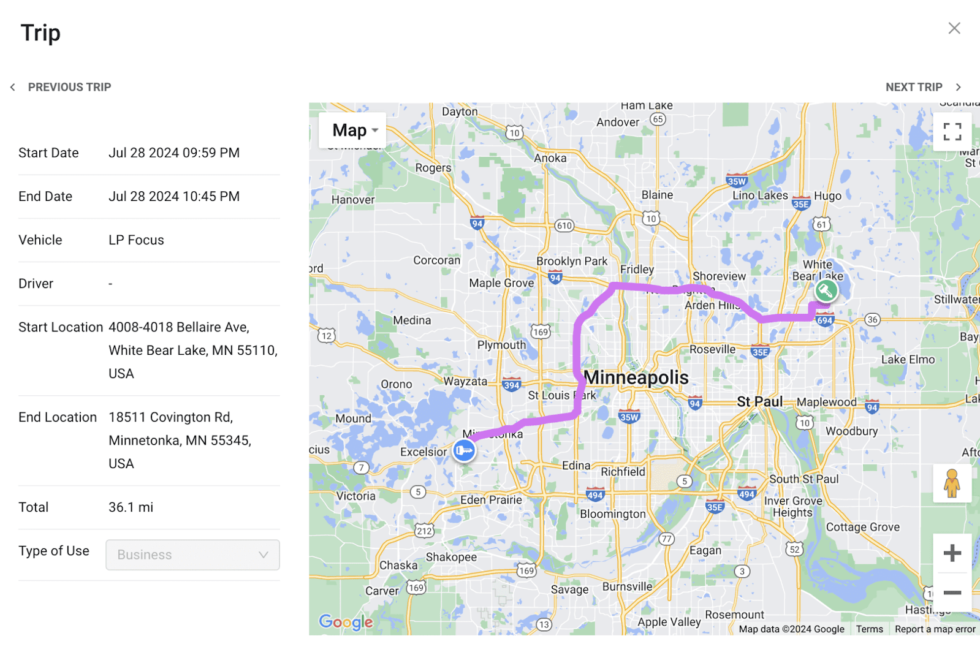

RTLS also improves logistics and transportation efficiency.

It tracks movement patterns, calculates distances traveled, and provides route history, helping managers find better routes, cut fuel costs, and reduce time wasted in transport.

For example, here’s how trip tracking looks in GoCodes Asset Tracking:

Source: GoCodes Asset Tracking

If trucks or equipment are taking inefficient paths or spending too much time idling, RTLS provides the data to fix it.

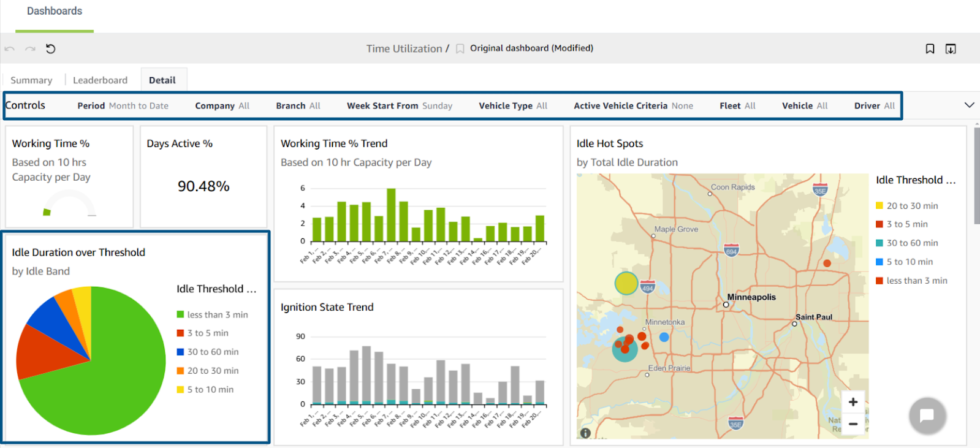

Speaking of idling, idle equipment is another major issue.

Machines sitting unused for long periods still take up space, require maintenance, and rack up costs.

And you don’t want your equipment sitting around gathering dirt and wasting your money.

RTLS tracks how long equipment stays idle, helping you redistribute assets where they’re actually needed, or adjust your fleet size to match your needs.

Source: GoCodes Asset Tracking

It also helps keep maintenance on schedule.

RTLS tracks engine hours, usage patterns, and wear-and-tear, helping teams schedule preventive maintenance before breakdowns happen.

This reduces unexpected downtime and extends the lifespan of expensive machinery.

In short, implementing RTLS means less searching, waiting around, and overall delays, and more work done and money in your pocket.

Challenges of Implementing RTLS in Construction

We’ve covered the benefits, but like any technology, RTLS also comes with its challenges, too.

So, let’s take a look at some of the biggest ones, and more importantly, some strategies you can use to overcome them.

Managing High Initial Costs

Implementing RTLS is not cheap.

Between hardware, software, installation, and training, the initial investment can add up fast.

And for many construction companies, adding another expense to an already tight budget isn’t an easy decision.

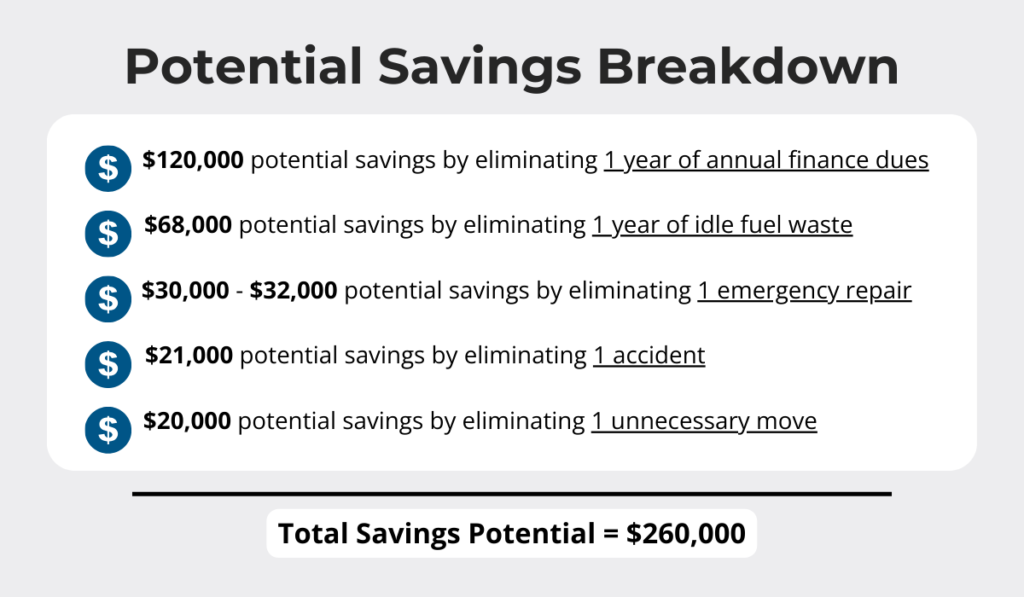

But here’s the thing: The real cost isn’t in implementing RTLS, it’s in not having it.

Think about it:

Theft prevention alone can save hundreds of thousands of dollars in lost equipment.

Add in reduced downtime, fewer delays, better equipment utilization, and lower fuel costs, and suddenly, RTLS starts looking a lot less like an expense and a lot more like a smart financial move.

To put things into an even better perspective, let’s look at how much not implementing RTLS could be costing you:

Illustration: GoCodes Asset Tracking / Data: Tenna

By using logic alone, you can see how improving this just a bit can have a drastic impact on your profits.

Still, that doesn’t mean the initial cost isn’t a challenge.

To make implementation more affordable, many companies start small.

Instead of rolling out RTLS across your entire operation at once, begin with a pilot program.

Choose one job site or a specific type of asset to track.

This keeps costs lower while letting you test the system, measure ROI, and fine-tune the setup before scaling.

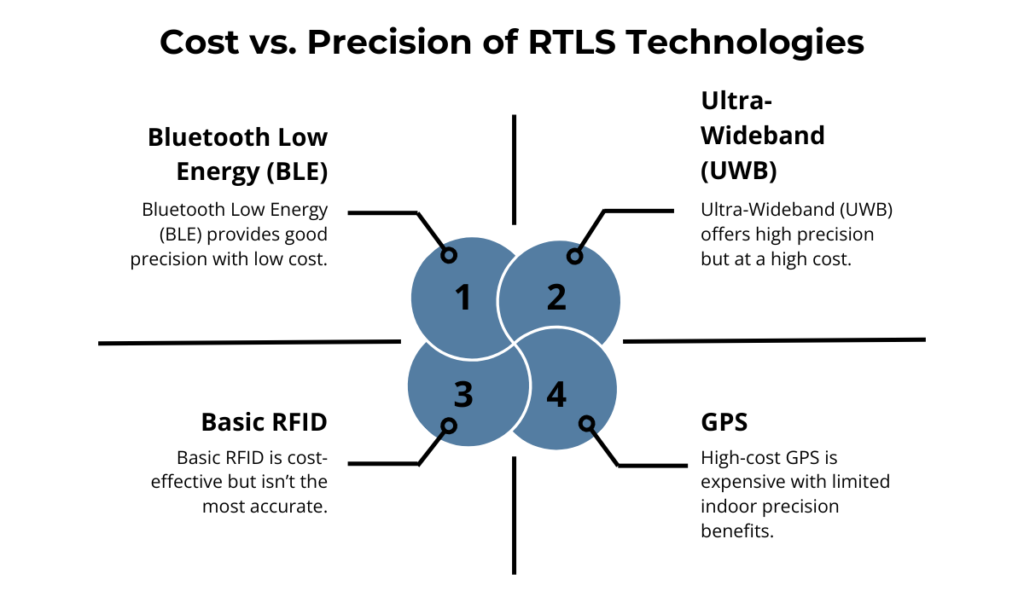

Another way to reduce costs is choosing the right RTLS technology.

Not all tracking systems require expensive infrastructure.

Some solutions, like Bluetooth Low Energy (BLE) or RFID can be more affordable than high-precision Ultra-Wideband (UWB) or GPS while still delivering solid results.

Source: GoCodes Asset Tracking

In some regions, companies investing in technology that improves safety and efficiency may qualify for financial support, so it’s worth checking local programs before dismissing RTLS as too expensive.

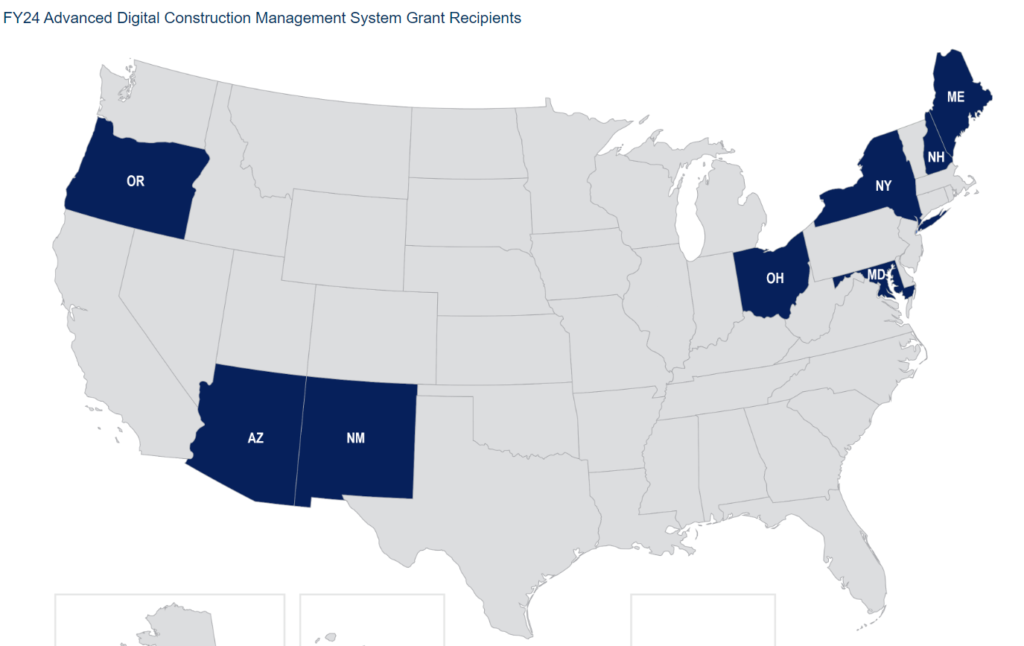

For example, the U.S. Department of Transportation’s Federal Highway Administration (FHWA) launched the Advanced Digital Construction Management Systems (ADCMS) grant program under President Biden’s Bipartisan Infrastructure Law.

With $85 million in funding, the program supports digital construction advancements, including computer modeling, 3D design, and modern project delivery technologies.

As Federal Highway Administrator Shailen Bhatt put it:

“Technology has transformed many facets of life in the modern era, and we want the transportation construction industry to take advantage of these advancements to deliver projects on time and on budget. These technologies, along with funding from President Biden’s Bipartisan Infrastructure Law, will help us more quickly deliver the transportation system of the 21st century.”

In November 2024, FHWA announced $16.6 million in grants for eight projects across eight states.

Source: Federal Highway Administration

The bottom line?

Yes, the initial cost can be high, but when you look at the long-term savings and efficiency gains, it’s not a question of whether it’s worth it or not.

It’s just a matter of when you start seeing the returns.

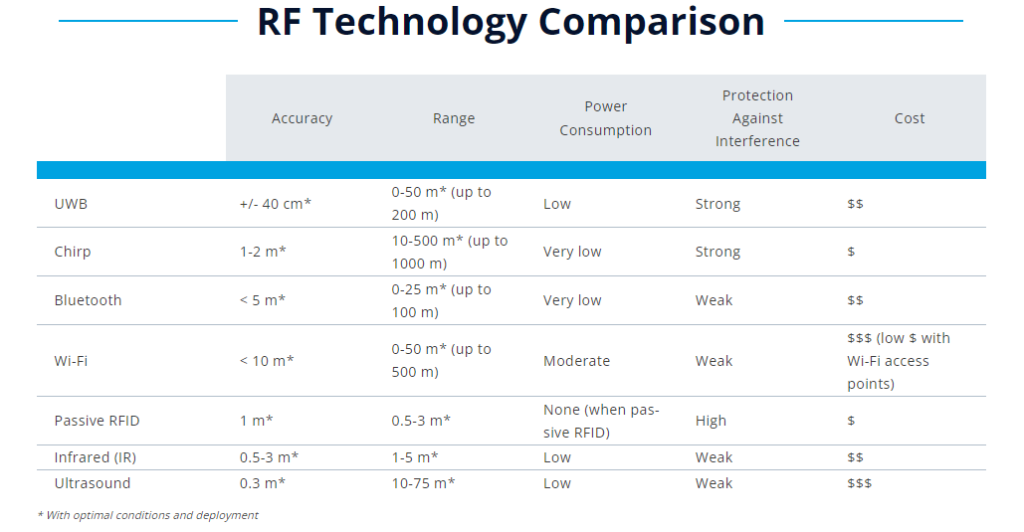

Poor RTLS Signal Strength

RTLS is only as good as its signal.

If the signal is weak or unreliable, tracking becomes inaccurate, updates get delayed, and the system stops being useful.

And in construction, signal interference is a real issue.

Unlike controlled indoor environments like warehouses or hospitals, construction sites are complex, constantly changing, and full of obstacles.

Thick concrete walls, steel structures, large machinery, underground areas, and even bad weather can interfere with signals, making it harder for RTLS to work as it should.

For example, RFID and Bluetooth Low Energy (BLE) can struggle with interference from metal structures, while GPS loses accuracy indoors or in areas with tall buildings.

Ultra-wideband (UWB) is highly precise, but requires a denser infrastructure to maintain strong coverage.

So, how do you deal with this?

First, choose the right RTLS technology for your needs.

Source: Inpixon

If you’re tracking equipment across a large open site, GPS might be the best choice.

And if you need high-precision tracking indoors, UWB could be worth the investment.

Second, optimize the sensor placement.

Spacing them correctly, using signal repeaters, and ensuring coverage in critical areas help eliminate dead zones and keep tracking reliable.

Here are the 4 most common RTLS positioning techniques:

- Two Way Ranging (TWR)

- Time Difference of Arrival (TDoA)

- Angle of Arrival (AoA)

- Received Signal Strength Indicator (RSSI)

Third, consider using a hybrid solution.

Many companies combine multiple technologies to get the best results, like using GPS outdoors and BLE indoors, or mixing RFID with UWB for better accuracy.

This is a good approach, especially if you track different types of assets in different environments.

Heavy machinery, handheld tools, vehicles, and materials all have different tracking needs, so relying on a single technology often won’t cut it.

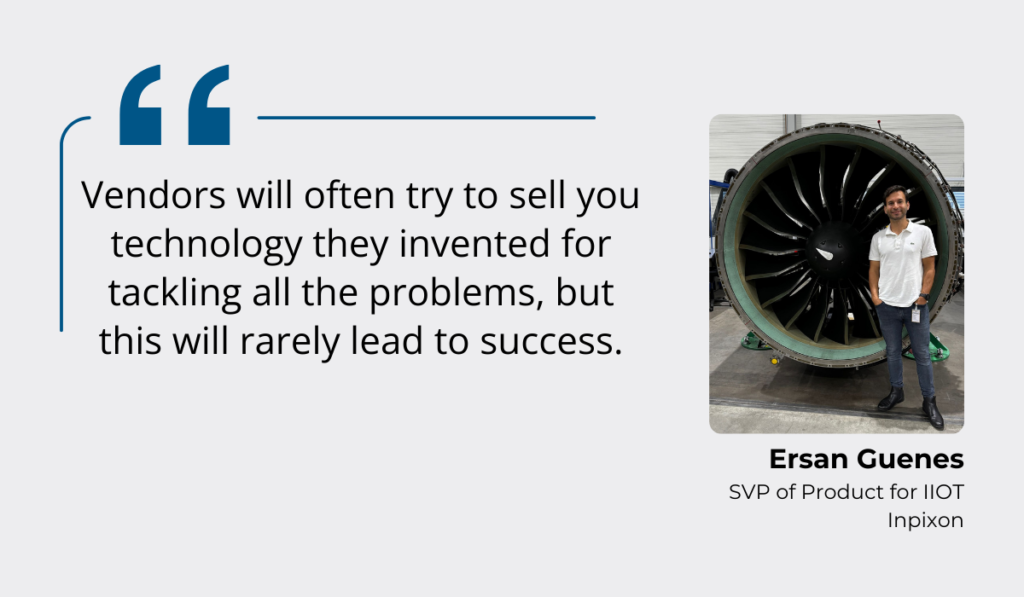

However, Ersan Guenes, SVP of Product for IIOT at Inpixon shares an important thing to keep in mind when looking for the most suitable RTLS solution:

Illustration: GoCodes Asset Tracking / Quote: Inpixon

So while you’ll encounter a lot of vendors trying to convince you that their “perfect” solution is all you need, don’t just take their word for it.

Instead, take the time to evaluate your specific needs, compare different options, and ensure the solution truly aligns with your operational requirements.

Privacy Regulations for Worker Tracking

Tracking assets is one thing. Tracking people is another.

And while RTLS can improve worker safety and efficiency, it also raises privacy concerns, especially when employees feel like they’re constantly being watched.

Many workers don’t like the idea of being tracked, but In many cases, employees have fewer privacy protections at work than they might assume.

As attorney Matt C. Pinker puts it:

Illustration: GoCodes Asset Tracking / Quote: Business News Daily

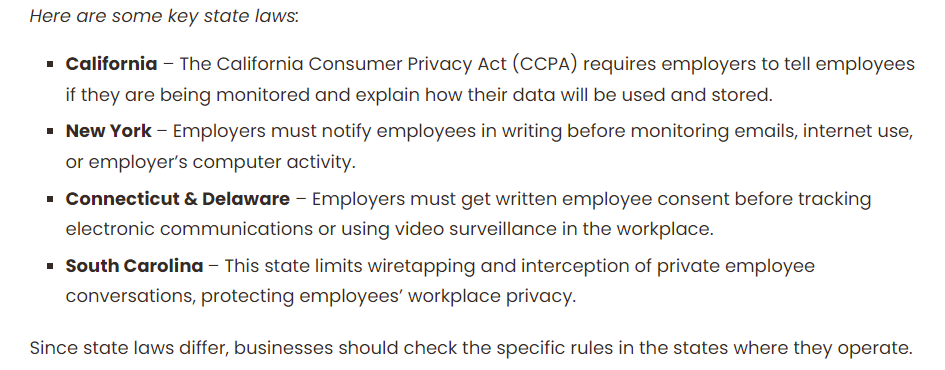

However, that doesn’t mean companies can track workers however they want.

There are privacy laws that strictly regulate employee monitoring.

Regulations like GDPR in Europe and various U.S. labor laws require companies to have clear policies, legitimate reasons, and worker consent before tracking employees.

Ignoring these laws can lead to lawsuits, fines, and serious damage to your company’s reputation.

So, how do you use RTLS to improve safety and efficiency without crossing legal or ethical lines?

First, be transparent.

Clearly explain why RTLS is being used, what data is being collected, and how it will (and won’t) be used.

Workers should never feel like they’re being watched just for the sake of it.

If tracking is meant to improve safety, prevent accidents, and speed up emergency response, make sure they understand that.

Second, set clear policies.

Define who gets tracked, when, and for what purpose. Make sure these policies are written, easy to understand, and legally compliant.

Privacy laws vary across the U.S., and some states have very strict requirements:

Source: Time Doctor

Third, follow legal requirements.

If consent is required, get it in writing. If data must be anonymized or deleted after a certain period, make sure your system follows those rules.

And lastly, limit tracking to what’s absolutely necessary.

RTLS should be used to improve safety and efficiency, not micromanage workers.

Setting up geofencing for hazardous areas or using RTLS for emergency response is one thing.

But tracking bathroom breaks or monitoring every step employees take? That’s a quick way to lose trust and run into legal trouble.

Solicitor Oliver Allanach recommends that employers deploy tactics in ascending order of intrusiveness.

Illustration: GoCodes Asset Tracking / Quote: Compliance Week

At the end of the day, RTLS is a powerful tool, but like any tool, it needs to be used correctly and ethically.

When implemented with clear policies, transparency, and respect for privacy, it becomes a win-win for both companies and workers.

Choosing the Right RTLS Solution

Not all RTLS systems are the same, and choosing the right one isn’t as simple as picking the most advanced or the most expensive option.

Some are built for large outdoor areas, others for high-precision indoor tracking.

Some require expensive infrastructure, while others can be deployed with minimal setup.

So, how do you choose the right one for your construction business?

It all comes down to understanding your:

- Needs

- Budget

- Existing infrastructure

- Long-term goals

The first step is defining what you actually need.

For instance, you can ask yourself questions like:

- Will I be tracking equipment, materials, vehicles, workers, or all of it?

- Do I need real-time precision tracking down to the centimeter, or is a general location good enough?

- Will I be tracking assets indoors, outdoors, or both?

Your needs will determine which technology makes the most sense.

Once you know your goals, budget comes into play.

RTLS systems vary widely in cost.

Some RTLS solutions require expensive sensors, dense infrastructure, and advanced software, while others are more affordable but might lack certain features.

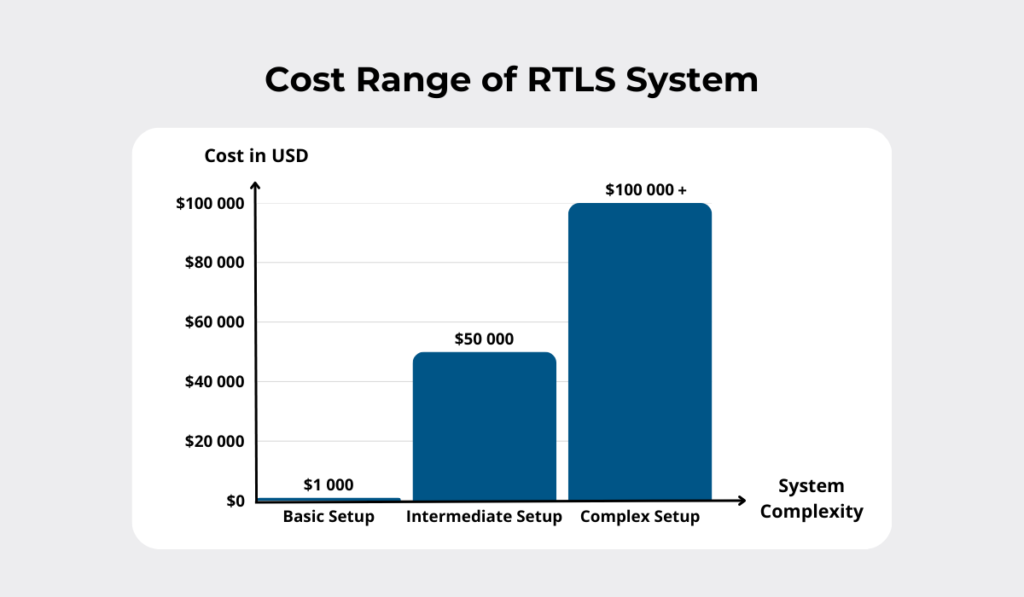

According to ScienceDirect, the cost of an RTLS system, including hardware and software, can range from $1,000 to $50,000, with complex setups exceeding $100,000.

Illustration: GoCodes Asset Tracking / Data: ScienceDirect

That’s why it’s important to balance cost with functionality.

Overspending on a system you don’t fully utilize can be just as bad as choosing one that doesn’t meet your needs.

Next, consider how well the RTLS integrates with your current systems.

The last thing you want is to invest in an RTLS system that doesn’t integrate with your project management platform, inventory software, or asset management systems.

Long-term sustainability matters, too.

A system that works for you now might not be the best fit as your company scales.

After all, construction projects aren’t static.

They change, expand, and move to different locations.

So, a good RTLS should adapt to new job sites, scale with your operations, and remain reliable as your business grows.

Ultimately, the right RTLS solution is the one that fits your specific needs, works within your budget, integrates with your current systems, and can scale as your projects grow.

Conclusion

Construction moves fast. Equipment, tools, materials, and workers are always in motion.

And losing track of them? It costs time, money, and unfortunately, sometimes even lives.

RTLS changes that.

Yes, there is an upfront cost. Yes, there are challenges.

But better visibility leads to better decisions. And better decisions?

They lead to safer job sites, smoother operations, and higher profits.

So the real question is not whether RTLS is worth it.

It is how long you can afford to go without it.