Tool theft is a real threat to contractors all over the US, and it happens more often than you realize. Up to $1 billion worth of equipment and tools is stolen yearly, stressing the importance of a theft prevention program.

This article will help you understand the four things you can do to secure your tools and make it harder for thieves to get them. That way, you’ll minimize and practically eliminate tool theft at your construction site.

In this article...

Lock Up Your Tools

If you want to deter thieves, the first step is to always keep your tools under lock and key.

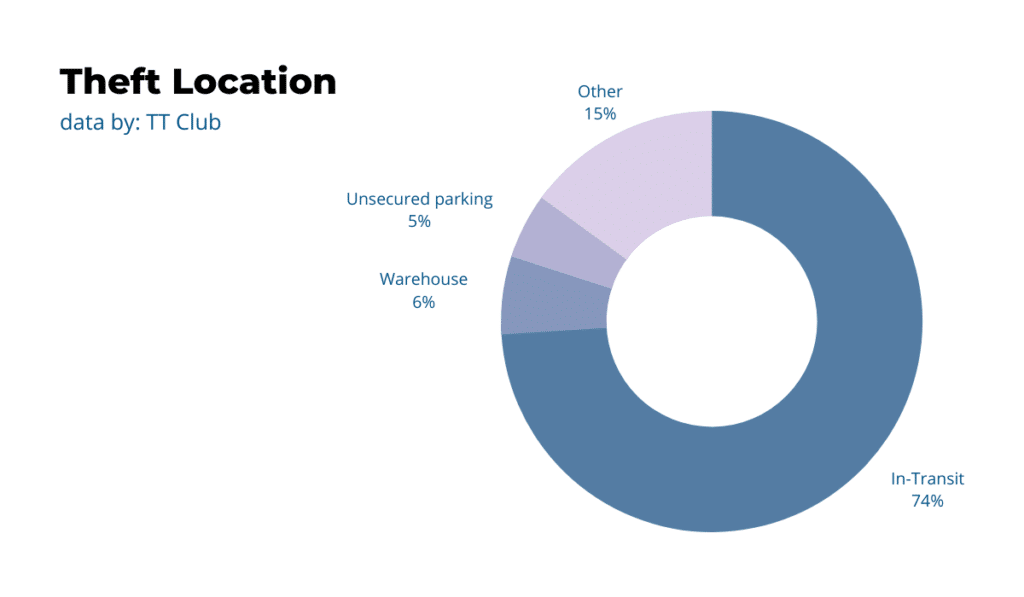

TT Club’s global cargo theft report for 2020 analyzed all cargo thefts in the last year globally and found that most of them happen during transport and from the warehouse.

This means that your tools are at risk even at the warehouse, the place you deem secure. Therefore, you have to invest in keeping your tools locked even when they’re stored somewhere you think is safe.

What makes matters worse is that construction thefts are often inside jobs, meaning that it is your workers who steal your construction tools.

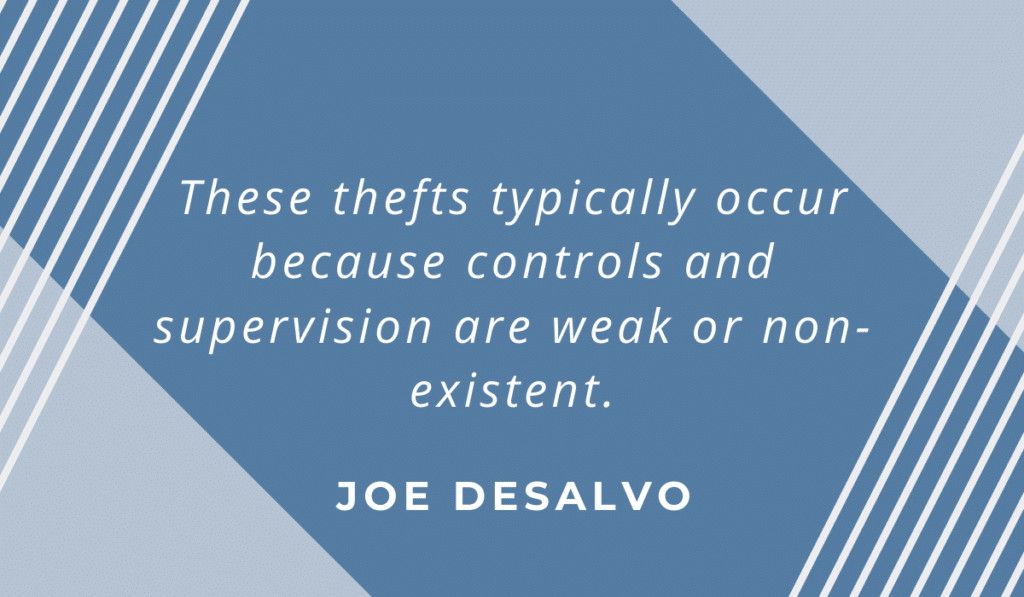

Garda interviewed Joe DeSalvo, a former FBI agent who has investigated many internal thefts during his 20 years at the Bureau, and asked him why employees steal from companies.

DeSalvo didn’t mince words:

“Because they can—a crime of opportunity, if you will. These thefts typically occur because controls and supervision are weak or non-existent.”

So, a large majority of the thefts would never have happened if some form of supervision or theft prevention had been in place.

So, it’s essential to keep your toolbox locked. When your tools are safely stored away, no one can steal one or two and hide them in their pockets or under their coat.

Instead, the thief would have to take the whole box, which is a lot harder to do unnoticed.

You can have smaller, portable toolboxes for your workers to take to the field, while keeping bigger ones in your warehouse. The worker should sign out the toolbox they’re using and guard it at all times to prevent theft.

You may want to look into extra secure toolboxes, such as the KNAACK Jobmaster Chest. Apparently, this chest proved impossible to break into for thieves at Terre Haute in Indiana who left empty-handed after an attempted break-in.

The owners found signs of thieves trying to open the chest, but failing, as all $3,000 worth of tools and equipment was still inside.

When choosing the perfect toolbox for your workplace, don’t skimp. Price doesn’t always guarantee quality, of course, but buying the cheapest thing out there and hoping no one will break into it is wishful thinking.

Find something reliable within your means if you want to keep your tools protected at the worksite.

After all, the toolbox is what separates your tools from the thieves.

Don’t Leave Tools in the Vehicle

Leaving tools unattended in a vehicle is simply a recipe for disaster.

Think about it: anyone could walk by your parked vehicle—especially if it’s unlocked—and grab the tools. Why take that risk?

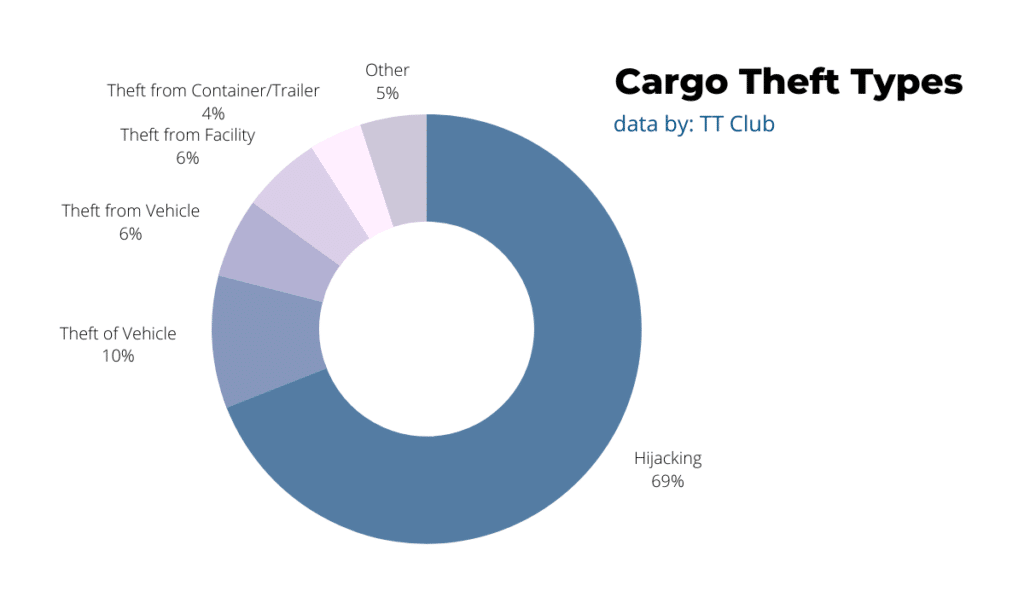

This happens more often than you can imagine, as TT Club’s findings prove. Their report also touched specifically on North America and the types of cargo thefts that happened there.

The number one type of theft was hijacking, followed by the theft of a vehicle.

However, the following three types make up for 16% of tool-related thefts: vehicle, facility, and container/trailer theft.

Such thefts happen when thieves get a chance to gain entrance into and steal from one of the locations listed above. All three theft types can happen on your worksite, to your workers, or at your facilities, so you should be aware of them and look into prevention.

Therefore, one of the things you can do to stop equipment theft from a vehicle is to stop leaving tools unattended.

Of course, many workers forget this as the worksite, so they park their vehicle, leave it unlocked, and go on to finish their task or relay some information. By the time they’re back, the tools they left inside the vehicle could be missing.

Of course, this rings true for your warehouse, facilities, and containers. Whenever you leave a tool unsupervised, you’re risking losing it, so teach your employees to always keep an eye on your tools.

Try to include this point in your onboarding and regular training so everyone knows and understands what’s at stake and how to help prevent these losses.

When your team becomes aware of the dangers, they will start taking more accountability for the tools they use.

However, there might be times when you simply have to leave the tools in the vehicle. In such cases, you should ensure that the tools are stored in a locked toolbox.

That way, you’re creating an additional layer of protection, as thieves might be deterred by a locked chest.

On top of that, you should invest in a security system for your vehicle. Many contractors rely on warning stickers on the vehicle, but they simply don’t work as well as having a sound security system in place.

Jeff Scott, the director of van security specialists at Sussex Installations, agrees. He thinks you should address all the weak spots in the type of vehicle at hand, as well as some standard break-in methods.

On top of that, Scott warns about a potential problem with vehicle alarms:

Many factory-fitted alarms and aftermarket alarms do not offer any cargo area protection for high-level destruction attacks such as door folding—peel and steal—or ‘large hole in the body’ type of attacks.

Since these types of attacks are probable, you should cover these vulnerable areas as well. That way, you’ll guarantee total protection of the vehicle in question.

Get a Contractors Insurance Policy

A bulletproof insurance policy can be another layer of protection from thieves.

Sometimes, you simply can’t stop theft from happening, but you can insure yourself in case it does happen. If you protect yourself and get insurance, you’re covered on all fronts.

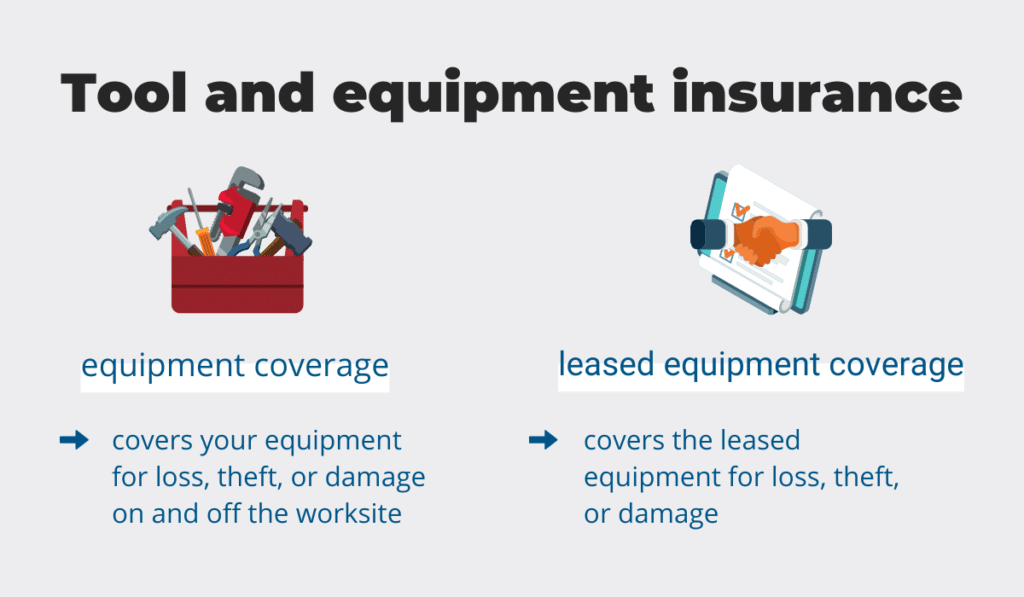

The most important insurance policy you can invest in is equipment coverage, formerly known as inland marine coverage. This form of insurance covers the tools you use to perform your job.

You may think that getting an equipment coverage policy isn’t necessary, as a general insurance policy covers your workers and tools. However, the general insurance policy covers you only at the worksite.

As we’ve already mentioned, your tools can be stolen from places which don’t count as your workplace, such as vehicles and containers. In such cases, general insurance will not be covering your loss, which can burn a huge hole in your pocket.

If the tools you use aren’t your own but are leased, you should get the leased equipment coverage.

By investing in this type of policy, you’ll be covered if someone steals the leased tools, regardless of whether the theft occurs at the worksite or elsewhere, in the off-hours.

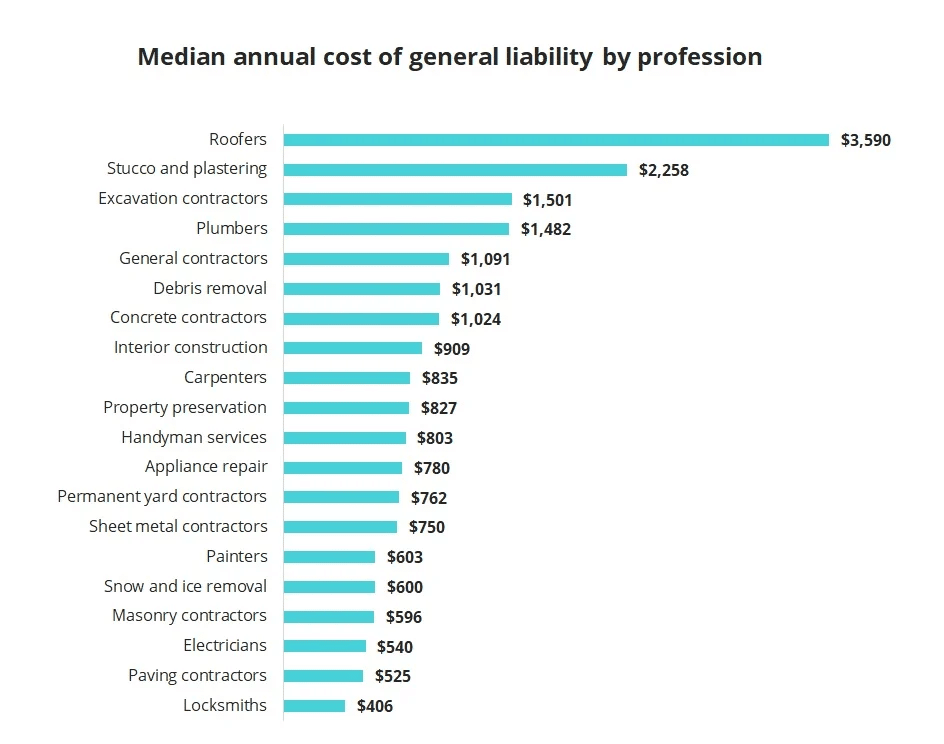

Insureon, a company that offers insurance to contractors, published their data on how much contractors spend on insurance by profession.

Roofers pay up to $3,590, mainly because they must work at heights and falls are the number one cause of death among construction site workers.

In fact, deadly falls occur in this line of work more than in all other professions combined, so it’s clear why insurance companies would charge higher fees to construction companies.

On the other end of the list are locksmiths, who pay around $406 a year for general liability insurance. Therefore, roofing companies have to pay almost 9x the amount locksmith businesses pay.

Still, even if you think this type of insurance is expensive, it is worth it. If someone steals your entire toolbox, the damage incurred can go way above the average policy price.

So, not only would you lose a couple of thousand dollars worth of tools, but you’d have to invest in buying new tools out of pocket, which could set you back significantly.

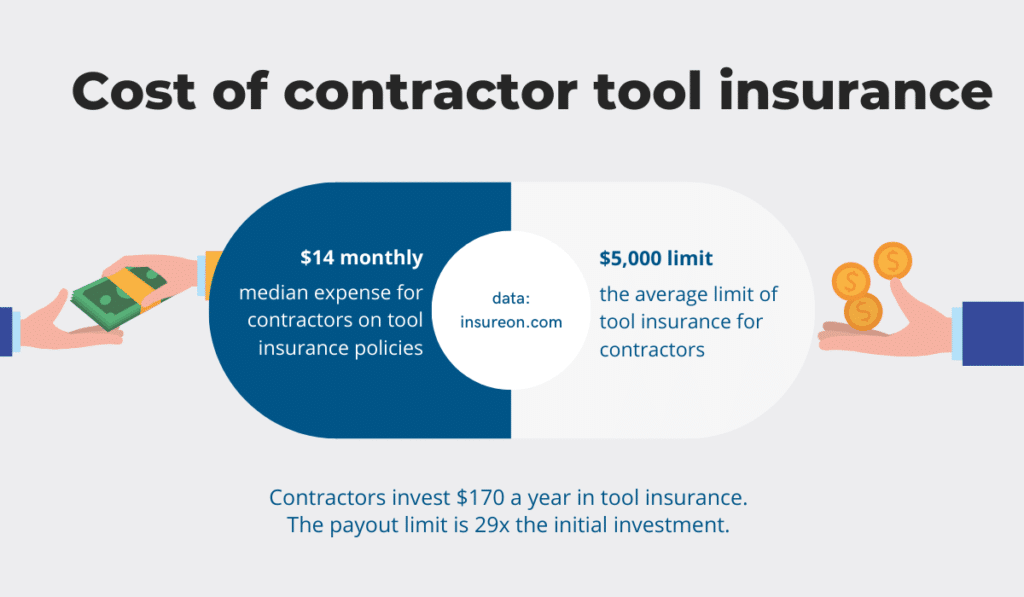

Insureon also reports that most contractors spend around $14 monthly on tool and equipment coverage, making the policy all the more worth it.

Mostly, companies choose to go up to the $5,000 limit. In other words, businesses invest around $170 yearly and will receive up to $5,000 for a claim, which is almost 30 times more than they paid. Therefore, insuring your tools is a wise investment.

Have Proof the Tools Are Yours

In case of theft, you need to have a way to prove that the stolen tools belong to you.

Otherwise, you may never get them back.

Not many companies consider that the investigators will not just take your word for it when you say a retrieved item is yours. You have to have all the necessary documentation and some other way of identifying the tool.

After all, tools are generally not unique, so yours should have some kind of differentiating feature that allows you to easily claim them if needed.

The first thing you should consider is your tool documentation, especially for the more expensive pieces.

You should always have the ownership records to prove when you purchased the tool and how much you paid for it. Any additional documentation, such as insurance and warranties, can help your case.

The second thing you need to do is mark your tools to prove they’re yours. Think about it: even if the police do manage to locate your stolen tool, how can you prove that the particular piece they’ve found belongs to you?

You have to find a way to keep it recognizable.

After you mark your tool with a tag, label, or QR code, remember to take pictures of the tool from all sides. These pictures will serve as proof that you are the person who labeled the asset and will help you claim it as yours.

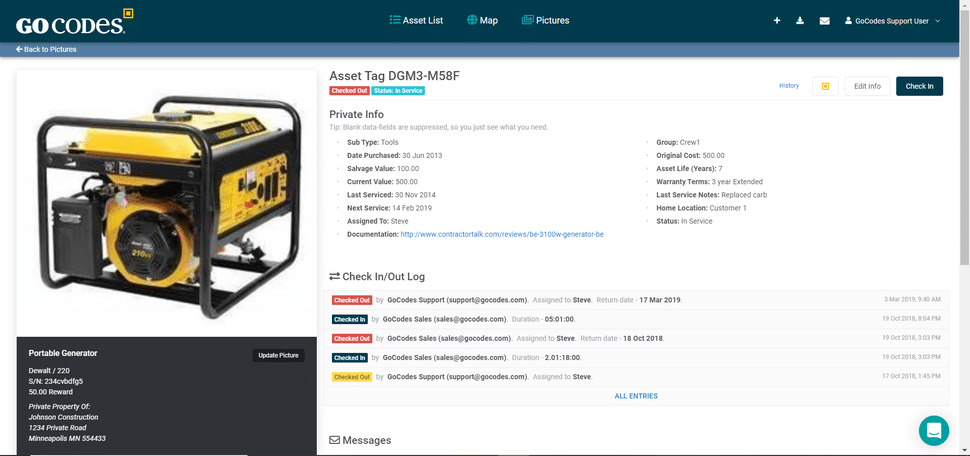

A great way to keep up with both these things is to use tool tracking software that lets you gather all tool data in the same place and label each tool with a tag or a QR code.

When adding all your tools into the cloud, you can link any relevant documents. You can simply scan and upload them online and link them to the tool page.

That way, whenever you look for the asset in the cloud, you’ll have all this documentation in the same place.

You’ll also have to label each tool with a QR code that leads to this page in the cloud. The tools will get a unique global identifier, which means no one else will have the same code.

In other words, no one else who uses this software will be able to claim your tool as theirs.

When scanning the QR code, the software will open the asset’s page, where you’ll be able to see all the data you’ve previously added, including the tool’s pictures and description, making it easier to prove ownership.

Keep Your Equipment Inventory List up to Date

Knowing what you own helps you stay on track with all your tools.

After all, if you don’t know what tools you have, where they are, and if anyone’s using them, you can’t really notice that one of them is missing.

By the time the loss is detected, it might be months since the theft, which brings down your chances of tool recovery.

Instead of risking huge monetary losses this way, do an inventory and keep it updated. Whenever a change occurs, mark it in your inventory list. This can be the addition of a new tool, the removal of an old, useless one, or a change in the tool’s description.

When your database is up to date, you’ll be able to rely on it for accurate and detailed information, especially if one of your tools is stolen.

Tool tracking software will help you keep your database current without doing a lot of manual work.

When you check the equipment in and out, the statuses change automatically, so you always have the latest information on where the tool is, i.e., if someone is using it.

The check-in/-out process takes a couple of seconds: you scan the tag and change the tool’s status from “available” to “in use,” and the system automatically assigns it to you.

The software also helps you track your consumable assets, such as nails, drill bits, or sanding sponges.

Of course, you won’t track each individual piece, but you can track their overall quantity. The system will notify you when you’re running low on a particular item so you can reorder on time and always have consumables in stock.

Conclusion

Being in the construction business is expensive as you have to invest in your tools and equipment out of pocket to get the job done.

So, losing or having your assets stolen can really hurt your bottom line and affect you negatively. Because of this, you should focus on preventing theft from happening in the first place.

This article offered four different methods to help you combat tool theft. Which one will you implement?