Key Takeaways:

- Construction businesses that create detailed roadmaps can reduce delays and improve efficiency.

- Innovative methods like prefabrication and 3D printing help speed up construction while reducing costs and waste.

- Investing in worker training and cross-training enhances speed and quality on-site.

Construction businesses often face the looming threat of unexpected disruptions and project delays.

When such setbacks occur, it’s natural to want to speed things up to still meet deadlines and minimize impact.

However, accelerating project timelines may seem daunting or even impossible.

But, with the right strategies, it’s entirely within your reach!

In this article, we’ll share six actionable tips to help you speed up your construction projects without compromising quality or safety.

Ready to boost your project efficiency? Let’s get started!

In this article...

Create a Thorough Plan First

Delivering construction projects on time and within budget requires thorough planning.

You’ve surely heard the phrase “well planned is half done.”

Well, it certainly rings true in this industry!

Construction businesses that create detailed project roadmaps outline every task and milestone and know their timelines and resources inside and out.

Thanks to proper project planning, they can reduce the risk of bottlenecks and delays and achieve remarkable efficiency.

Of course, there will always be surprises, but if you do some planning first, you can anticipate and deal with any issue more effectively.

On the other hand, rushing through the planning stages can have serious consequences.

For example, did you know that obtaining a building permit takes 6 to 12 months on average?

Even when the process isn’t that time-consuming, a lack of foresight and a simple miscalculation can disrupt your timelines in the blink of an eye.

So, what can you do to avoid this?

Keeping track of everything—especially when you’re handling multiple projects simultaneously—can be very tricky, but it isn’t impossible.

Successful construction managers organize tasks, assign responsibilities, and track progress thanks to different project management tools and features.

These tools can help you organize and align project tasks with the overall timeline phase by phase.

And if anything gets out of hand, instant insights into the project’s progress enable quick adjustments and informed decision-making.

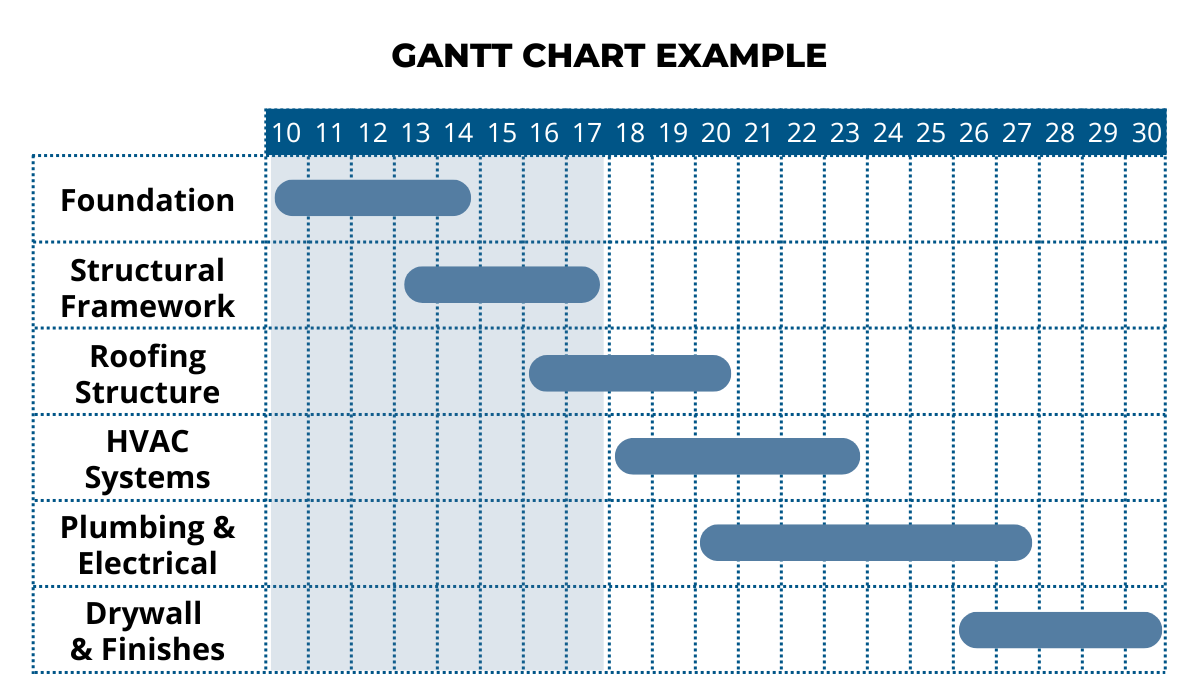

Take scheduling for example.

Construction project management solutions are equipped with tools for tracking deliverables and visualizing task dependencies.

Gantt charts are a prime example of this, helping you monitor task progress, compare actual performance against the original project plan, and adjust schedules as needed.

Gantt charts are a popular construction scheduling method because they’re easy to use while enabling you to visualize and manage complex interdependent tasks.

There are lots of different project management software tools for the construction industry that can help you streamline and optimize different construction processes.

The important thing is to start with a solid game plan, and take it from there!

Adopt Modern Construction Techniques

Adopting modern construction techniques makes a world of difference when you need to speed up project completion.

Simply put, companies that keep up with different construction trends are poised to make the most of the benefits they deliver.

This typically means greater efficiency, flexibility, and durability, as well as less waste.

Don’t forget that innovative methods like prefabrication propelled the construction of the world-renowned Sydney Opera House.

Currently, such methods are essential for the ongoing construction of equally stunning Sagrada Familia, explains Tristram Carfrae, structural designer and Deputy Chair of global consultancy Arup.

In essence, modern construction methods speed things up while cutting down expenses, which is why they aren’t used just on monumental architectural feats.

Techniques like prefabrication and modular building allow parts of the structure, such as walls, roofs, or floors, to be built off-site in a controlled environment.

The main advantage here is that parts assembled in the factory or a similar setting typically have better quality.

In these cases, you don’t have to worry about weather conditions halting construction or damaging a delicate component.

Some construction methods like 3D printing enable companies to either complete the design on-site or prefabricate different components off-site.

It all depends on the project design and workflows, but in the case of one 3D-printed concrete bridge, the final assembly took part at the project’s location.

The bridge’s construction was speedy and efficient, but this method had other benefits, too.

Jeroen Nuijten, formerly an Innovation Manager of a Dutch construction company BAM Infra Nederland, explains how 3D printing helped reduce material waste and the carbon footprint:

“The idea came about when a customer asked us to reduce our impact on the environment […] With 3D-printing, we use less material and [produce] less CO2, so we thought we would 3D-print a concrete bridge for cyclists.”

Whether it’s environmental concerns or overall efficiency, more and more companies are adopting some of the transformative construction techniques and trends.

And you should give them a go, too!

Improve the Way You Manage Equipment

Effective equipment management ensures that all your machinery and tools are well-maintained and ready to use whenever needed on-site.

Plus, keeping track of your equipment and doing regular maintenance has a tremendous impact on your on-site productivity.

Construction businesses that invest in their equipment’s lifespan and seek to optimize utilization also find it easier to bring their projects to a close on time.

Conversely, poor equipment management is bound to erode productivity, often leading to equipment breakdown and costly delays.

However, you have the power to decide which route to take.

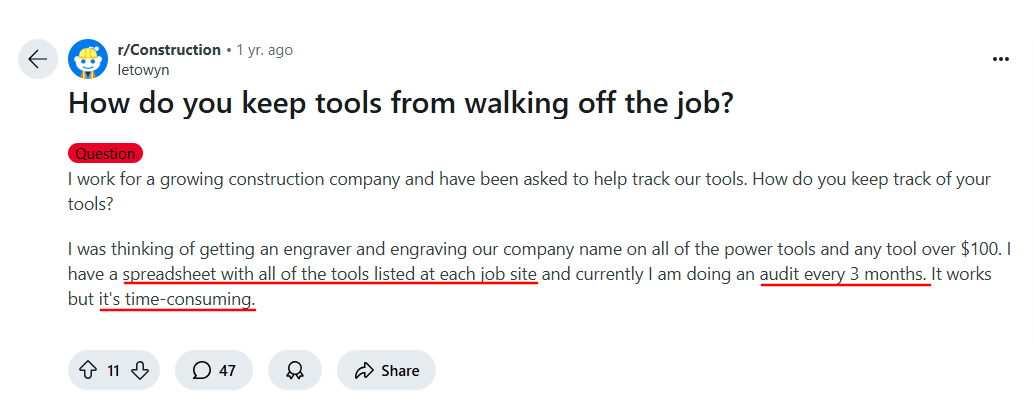

For example, many construction companies still rely on Excel spreadsheets to manage their equipment.

Faced with costly equipment loss and time-consuming manual audits, one Reddit user decided to ask about potential tool-tracking solutions.

Many who replied on the thread suggested adopting an equipment management tool, and for good reason!

These software solutions are superior to spreadsheets in every way because they:

- capture relevant data,

- help you manage maintenance, and

- ensure equipment availability and accountability.

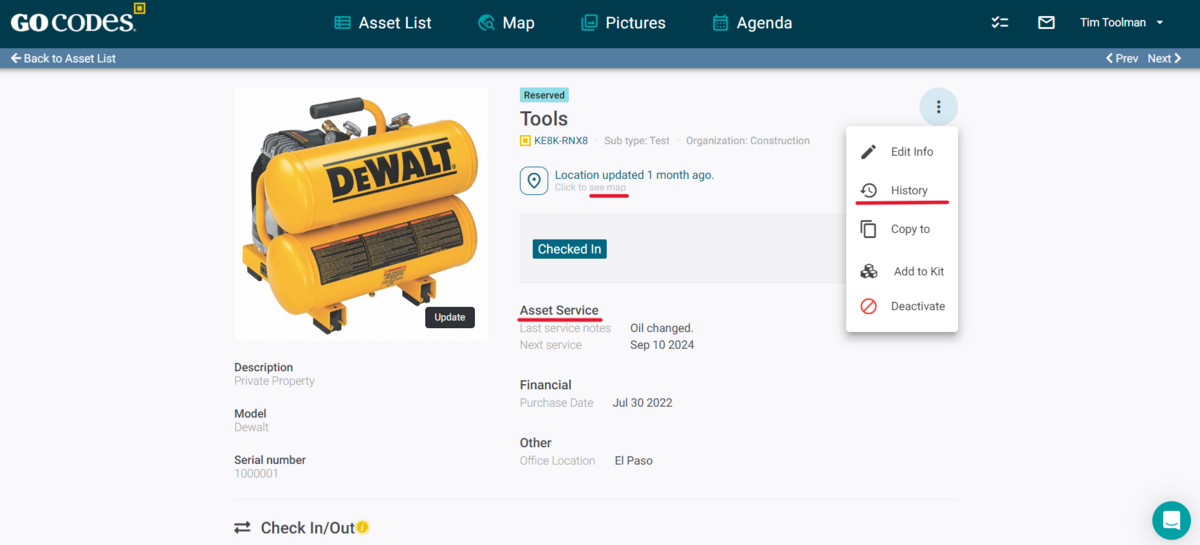

The best equipment management tools offer total visibility and minute-by-minute updates on each asset’s current and past locations and overall condition.

Plus, a centralized, intuitive database keeps all this data—and more—in the palm of your hand.

Here’s what this looks like with our GoCodes Asset Tracking.

As you can see, users on the field or in the office can quickly check where each tool is and access maintenance and other records, such as last known users.

On top of that, detailed check-in/check-out logs help promote company-wide accountability, reducing the chances of workers misplacing or taking off with tools.

Simply put, having your equipment accounted for at all times delivers a significant efficiency boost while saving you money.

How is this possible, you ask?

GoCodes Asset Tracking goes beyond equipment monitoring, enabling you to schedule and assign maintenance tasks to the right personnel.

Needless to say, regular servicing is pivotal in keeping equipment-related costs at bay, helping you minimize unplanned downtime and costly delays.

GoCodes Asset Tracking’ telematics feature mitigates this risk further.

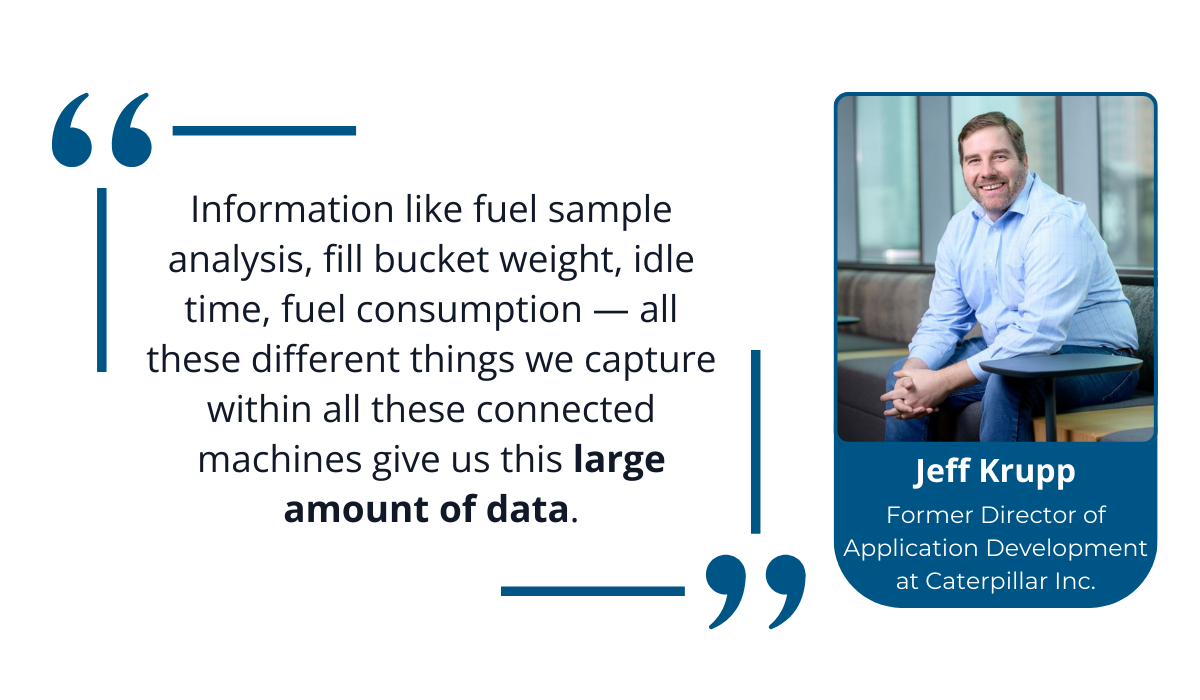

Former Director of Application Development at Caterpillar Inc., Jeff Krupp explains that telematics gives you a wealth of data on all your machines, from idle time to fuel consumption.

In this way, you can spot early signs of trouble and make better decisions concerning your equipment, but also the project as a whole.

Sounds tempting?

If so, it’s high time you turned to technology and improved the way you manage your equipment.

Ensure Easy Communication

Easy communication between project stakeholders is crucial for unlocking greater efficiency without sacrificing quality, as it keeps everyone aligned on project goals.

And with everyone in the loop, it’s easier to navigate communication hiccups and prevent misunderstandings.

Poor communication, on the other hand, is a notable speed bump.

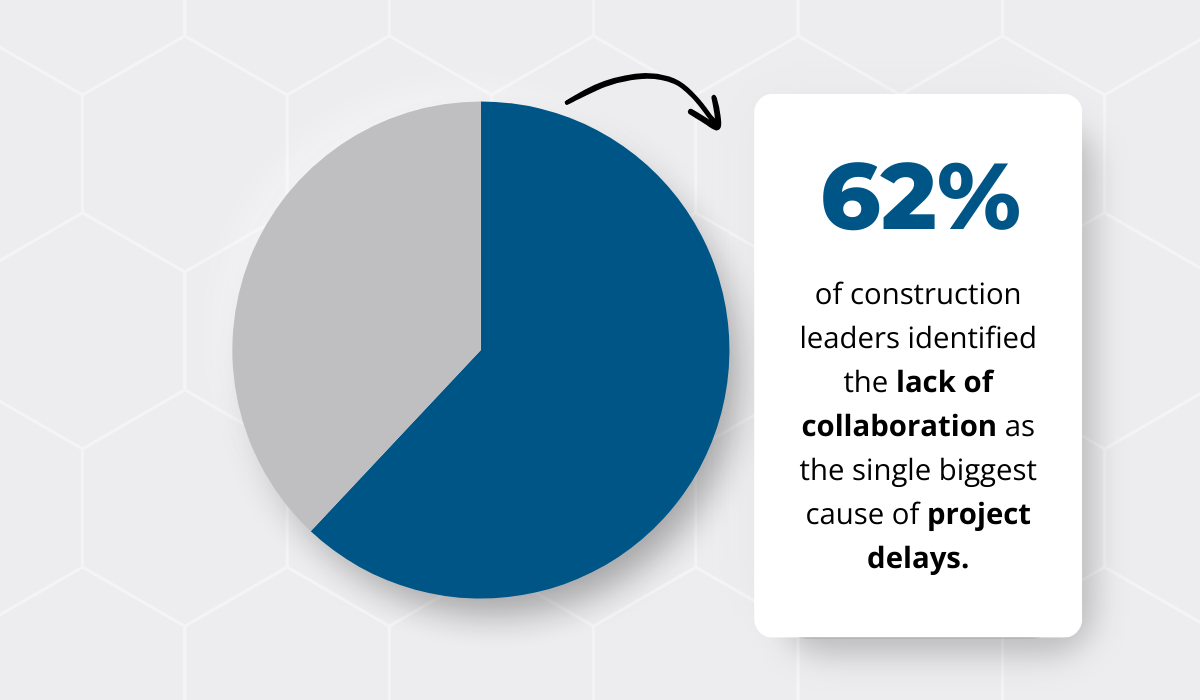

According to Finalcad’s research, 62% percent of 400 surveyed construction leaders see lack of collaboration as the biggest cause of project delays.

Since construction projects depend on the collaboration of multiple parties, poor communication can easily unravel your work.

Unclear goals and expectations can lead to errors, rework, delays, and ultimately client dissatisfaction—the exact opposite of what you need if you’re trying to speed up your project.

The million-dollar question is: How do you improve communication?

For starters, you need to make communication a habit.

That’s right—across the company, from every individual worker to the owner.

Of course, some roles carry greater responsibility for this than others.

Construction project managers hold the project reins, so they need to be exceptionally clear, concise, and skilled at conveying their ideas and instructions.

It’s often the only way to keep the on-site complexities from turning into chaos.

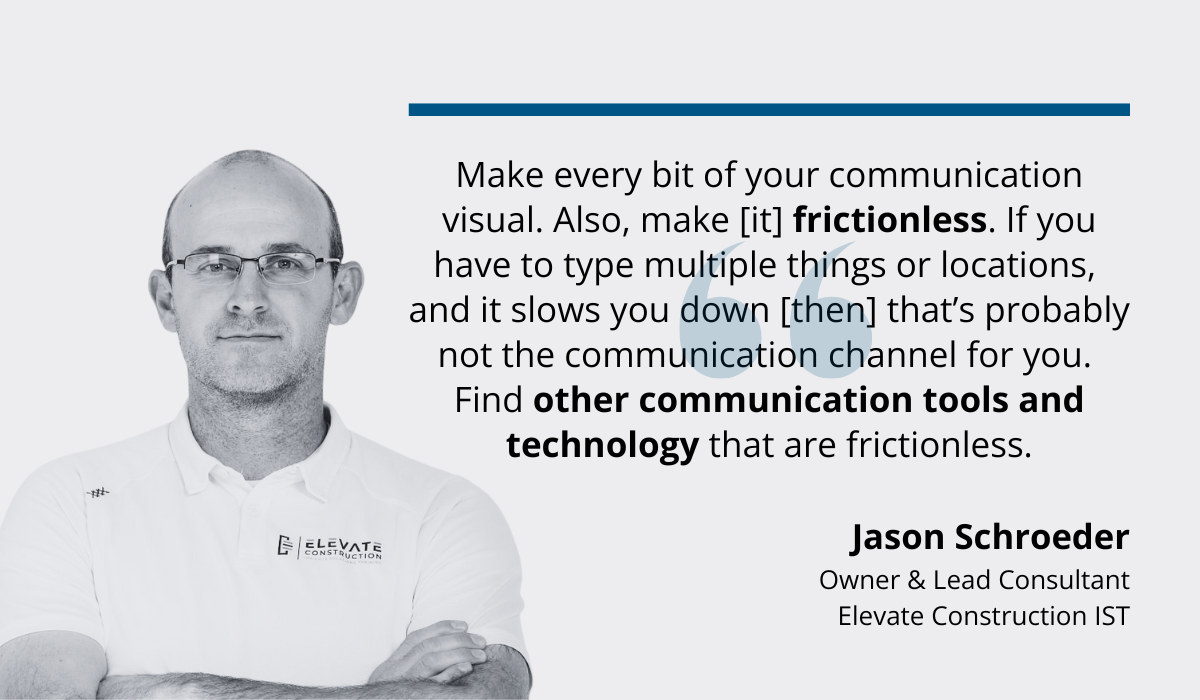

Jason Schroeder, former Field Operations and Project Director and now the owner of Elevate Construction IST, has a couple of tips for project managers.

Technology enhances collaboration in several ways, with different software tools increasing efficiency through real-time collaboration features that enhance workflows and data sharing.

Cloud-based collaboration platforms mitigate the risk of miscommunication because they enable all parties instant access to the latest changes or feedback.

By using these solutions, project managers can easily ask for and analyze input from different stakeholders, making communication a two-way process.

Building this kind of company culture takes time, but the sooner you start, the sooner you’ll get the speed boost you need to see results!

Make Sure Your Workers Are Skilled

Skilled labor elevates the quality of construction work while increasing speed.

The math is simple—the more you invest in your workers, the bigger the gains for the project and your business as a whole.

For starters, having experienced workers on-site accelerates construction work through their sheer expertise.

In other words, skilled workers know how to get the job done.

They’re more likely to pick up advanced skills over time, and they’re less likely to make expensive errors that would need fixing later on and push back the timelines.

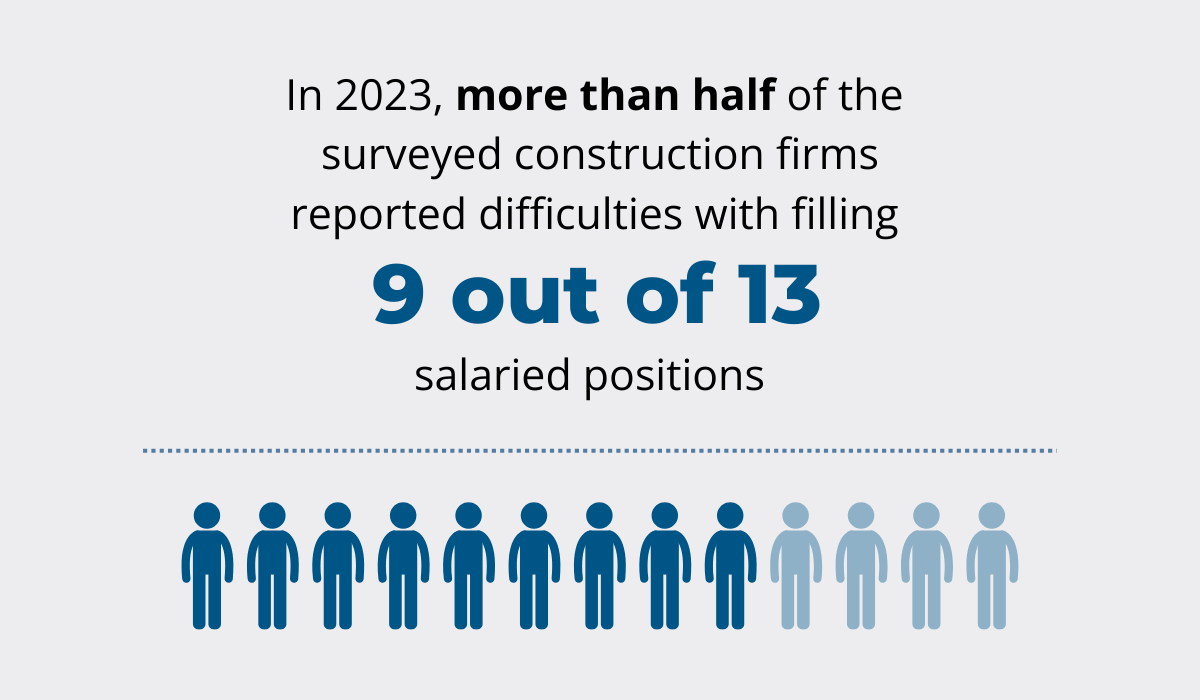

But getting these workers on board is becoming more and more difficult.

The absence of skilled labor has been a long-standing issue in the construction industry, and recent findings aren’t promising.

Namely, over half of 1,400 surveyed construction professionals struggled to fill open positions.

In light of this, companies are scrambling to improve their hiring strategies, offer incentive programs, and increase retention efforts in general.

One surefire way of overcoming labor shortages is by turning to your existing talent pool and providing training.

Regular training sessions are always welcome because they help keep the entire crew updated on the latest construction techniques and technologies.

Raising the bar higher for everyone means immediate and visible changes on-site, and more effective project execution overall.

When you take into account that opportunities for professional growth have a huge impact on your workers’ motivation, it’s clear that this should be one of your go-to strategies.

But what can you offer to the workers who are already skilled?

These workers are more likely to pick up advanced skills over time and take leadership roles, so you can either:

- provide in-depth, specialized training in their field, or

- enable them to learn an entirely new skill through cross-training.

Cross-training, and multi-skilling in general, has multiple benefits.

Once an employee can fulfill two different roles or trades, your company is more equipped to deal with unforeseen situations and minimize project disruptions.

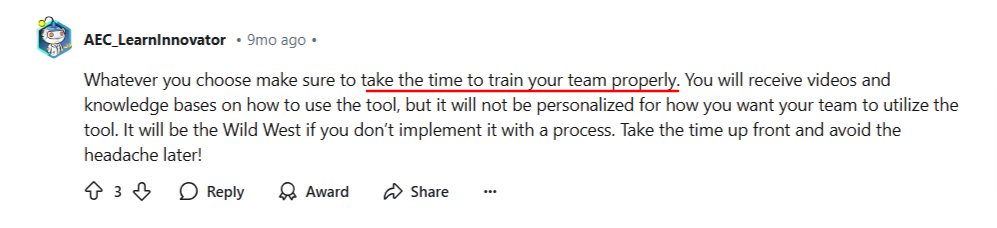

But don’t forget that you need to plan a reasonable amount of time for these trainings to take place!

The broader community of construction professionals agrees, especially if you’re preparing to introduce new technology.

If you set the course right from the start, you’ll save yourself a lot of frustration and come one step closer to meeting your objectives.

Remember that fostering professional growth creates a foundation for higher efficiency and long-term success, so be sure to take action on time!

Use Lean Construction Principles

Relying on lean construction principles is another way you can improve both speed and quality on the construction site.

Lean has been around for quite a while now, but it’s best known as a production method perfected and pioneered by Toyota.

When applied to construction, the goal of lean is building better, faster, safer, and cheaper by focusing on these key principles:

- Value definition

- Waste minimization

- Continuous improvement

- Pull planning and just-in-time delivery

- Collaboration and team integration

- Standardization and visual management

You’re likely already familiar with some of them.

For instance, Just-in-Time (JIT) delivery is both a lean principle and a widespread construction strategy that enables you to get key materials, equipment, and labor only when and where needed.

This optimizes resource allocation and utilization and helps you avoid excess inventory.

Nevertheless, there’s an entire 5S mindset behind lean construction.

The core idea is to streamline operations and maximize efficiency by eliminating activities that don’t add value.

Once you straighten your workplace and make it shine, you can put different systems and procedures in place.

However, you must never treat them as set in stone—they must be refined continuously to deliver the best possible results.

Keep in mind that you can start small.

For example, KHS&S Contractors have used 5S practices to enhance workflows, improve coordination, and reduce waste on site.

In this video, the company’s General Foreman, Ernie Carbajal, explains how their lean boards keep the entire project team in the loop.

This simple but powerful visual management tool helps align everyone on weekly work plans and daily production goals, ensuring greater efficiency and less downtime.

With all that said, where and how do you start?

One of the world’s leading lean construction experts and a higher education professor, Lauri Koskela, says you need a top-down approach in this case.

And it makes perfect sense because it’s all about process improvements and consistency.

Embracing lean construction takes time, but it will transform your business, helping you build smarter and complete each project faster.

Conclusion

Construction projects can be crippled by inefficiencies, but there are proven ways to speed things up.

The tips we’ve shared are part of a larger construction playbook designed to help you prevent delays and bring your projects to a timely close.

Ultimately, success lies in detailed planning, clear communication, and a continuous drive for improvement.

Embrace these principles, and you’ll see faster project completion, reduced costs, and consistently high standards.

Take the first step today, and watch as your construction projects soar to new levels of success!