Most construction companies don’t excel at every aspect of the construction process. Instead, they’re great at some tasks and less skilled at others.

In the construction industry, you don’t necessarily have to be a jack of all trades. When their teams lack expertise in certain aspects of the job, companies simply turn to subcontractors.

That way, the company’s employees can focus on what they do best, while those other tasks get outsourced to experts, creating a win-win situation.

So, if you’re looking to hire someone specialized in an activity you’re not sufficiently skilled at or simply don’t have enough staff for, you’ve come to the right place.

We’ll go through the hiring process and explain some best practices to help you find the best subcontractors out there.

In this article...

Define the Scope of the Project Before Hiring Subcontractors

Before even deciding you need subcontractors, clearly determine the scope of work for the job at hand.

Go through the project plan with your team and understand which parts of the job you can handle yourself.

Once you plan out the project in detail and assign responsibilities within your company accordingly, you can assign the rest of them to subcontractors of your choice.

Keep in mind that you have to know exactly what you expect from your subcontractor before you start thinking of the right person for the job.

Otherwise, you won’t be able to properly consider your options.

For instance, you have to determine the technical aspects of the task, how long it will take to do it, and the roles you’ll have to fill for it to be completed.

For instance, you may want to hire someone specialized in plumbing if that’s the job you’re not trained for, but if you have another unassigned task like electric work, it would be better to hire a subcontractor that can cover both.

When thinking of the scope, always consider the time necessary to finish the project. Research shows that 66% of contractors experienced cost overruns due to scheduling issues and half of them had to extend the deadline on their projects.

If possible, when setting the deadlines, always ask for a bit more time than you think you’ll need.

In other words, if you expect the project to last five weeks, it would be wise to add at least a couple more days to your original estimation, just in case of scheduling issues.

Then, look for a subcontractor who can take on work in that period.

This is also important because if you hire someone to work for you for a week and the deadline keeps moving, the person might not be available after the period you originally planned for.

In that case, you could be forced to hire someone completely new, which might harm consistency and, therefore, the quality of the work done.

Know Where to Look For Good Subcontractors

Once you understand what tasks you need to outsource and for how long, you can start looking for the best people to tackle them.

Be warned—you’ll probably have a hard time finding someone skilled.

After all, almost all construction companies report having difficulty finding qualified workers, which causes significant problems in delivering the right quality, meeting deadlines, and limiting costs.

A further 42% of construction businesses had to turn down work because they just couldn’t find the people to do it.

Because of this, 71% of such companies ask the skilled workers they can find to do more work, which puts them under additional stress.

Construction companies have also reported that their projects often underperform due to poor results delivered by contractors, so keep that in mind when looking for your next subcontractor.

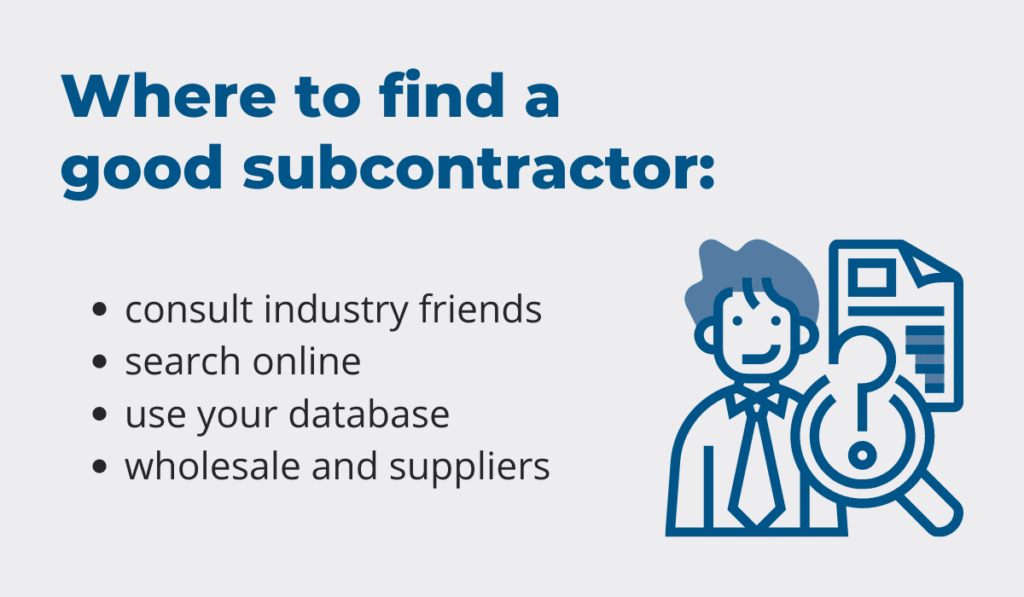

A great way to find someone skilled and reliable is to consult others. If you’ve been in the construction industry for a while, you’ll have at least a couple of contacts who can recommend quality subcontractors with proven experience and good results.

You can also use the internet to your advantage and find someone specialized for the job you need done online.

The best part about sites like LinkedIn is that they show you the subcontractor’s previous employers, so you can consult them and see how well your worker of choice did and if they’re a good hire.

Other times, you don’t have to go to such great lengths to find someone. You can simply check your database and see if any of your current or past subcontractors fit the bill.

The bonus here is that you’ll already be familiar with the person, and you know whether you were happy with their performance.

If you can’t find any great subcontractors that way, turn to wholesalers and suppliers for the materials connected to the task at hand.

They will surely be able to name at least a couple of reliable specialists that buy materials from them, and you can take it from there.

The key takeaway is that you should ask for a recommendation from someone who has experience with the subcontractor to avoid any underperformance issues.

Conduct Detailed Pre-Hiring Evaluations

When you think you’ve found a good match, do some digging on their qualifications and past work.

When hiring a subcontractor, many companies jump at the cheapest offer, but that’s not the right way to go. It’s vital to determine whether they would be a good fit for your company and the specific project you have in mind.

After all, poor performance can cause project delays and rework, which means additional costs, so you don’t end up saving at all.

Another indicator of the subcontractor’s professionalism is their adherence to proper safety regulations.

Of course, safety is a priority concern in the industry due to the many hazards on construction sites that lead to a high amount of fatal and non-fatal injuries.

When sharing some advice concerning the pre-hiring evaluation process, AECOM’s Roger W. George highlighted safety and quality are the key aspects you should be focusing on in your search for a subcontractor.

According to George, “performance is a byproduct of safety and quality”, which means that, if a subcontractor shows that they care about safety on top of demonstrating skill, you can expect great results from them.

A great way to check how safely your candidate works is to check the Occupational Safety and Hazard Administration’s (OSHA) inspection list.

Search for the candidate using a keyword or company name to check whether they’ve received an OSHA citation in the past. If they have, you should be wary of working with them, or you risk a safety hazard on your worksite.

When it comes to the quality of their work, as mentioned earlier, you can contact previous employers and inquire about their satisfaction with the worker’s performance.

However, there’s always a chance that the worker won’t list a contract they’ve had an issue with, so be sure to check if they were involved in any lawsuits or if there are bad reviews online.

Also, don’t forget to check whether the worker has insurance and a valid working license. A license is not required in certain states, but make sure your subcontractor has it if your state calls for one.

Additionally, you can use the license number your potential subcontractor gives you to look them up on your state’s Construction Contractor Board and check whether any company or contractor has filed a complaint against them.

Finally, don’t forget to inquire about the subcontractor’s team. Who are the people they plan to get on board?

If these workers are beginners, inexperienced, or lack the necessary knowledge, the subcontractor’s qualifications won’t matter as much. After all, it’s the workers who will be performing the job.

Create a Written Contract

When hiring a subcontractor, create a bulletproof contract that clearly states the conditions and requirements of each party.

This type of contract will protect both parties if anything goes wrong during the project. Of course, your contract should clearly state the scope of work and the given deadline.

It’s also important to include the agreed milestones for the subtasks, so it’s clear when you expect certain goals to be met.

Then, you should explain the required insurance amount and be named the additional insured.

If you’re afraid of costly delays, explain the penalties if the work is late due to the subcontractor’s poor performance.

To protect the contractor, you can also explain how much more you would pay in case there’s a need for extra work because of your team’s mistake. That way, your contract will be fair and protect both parties.

When it comes to your obligations, make sure to explain the payment terms in detail. You may have trouble getting great subcontractors if you’re known to be late with payments.

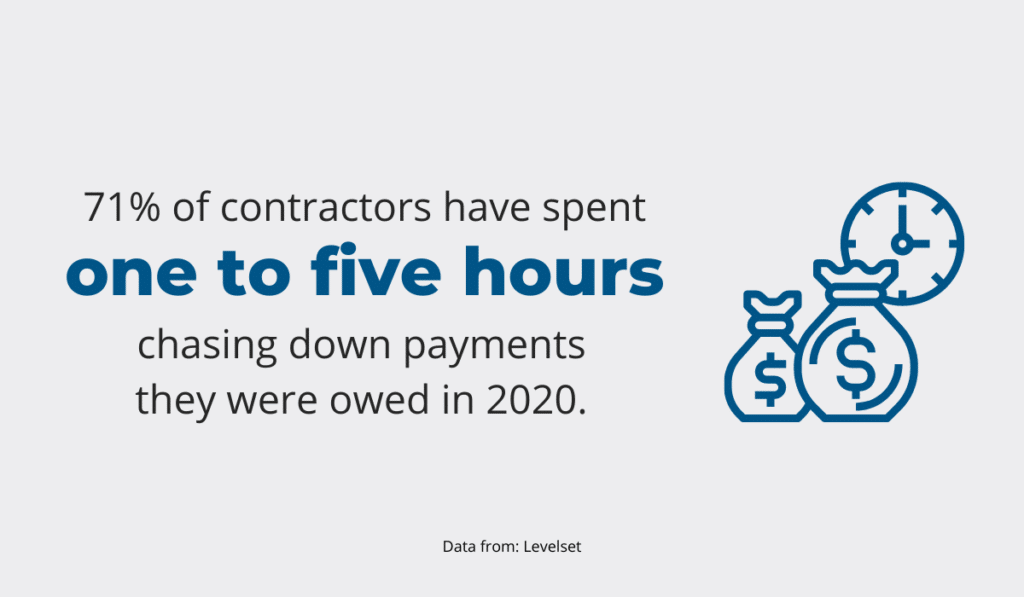

In 2020, construction contractors reported getting paid late more often than not, and the majority have spent anywhere from one to five hours chasing down payments for their work.

Your chances of landing a skilled professional will increase if you’re a prompt payer.

If you want the subcontractor to be present at all project-related meetings, mention that in the contract. Otherwise, you can’t expect them to come simply as a sign of goodwill.

Think of including additional requirements in the contract, such as:

- The subcontractor has to keep the workplace clean and tidy

- The subcontractor has to respect safety standards and procedures

- The subcontractor should report any possible workplace hazard

- The subcontractor should notify the company of possible delay causes such as the need for rework and shortage of materials or people

- The subcontractor should submit a breakdown of the tasks listing their price, including all the materials, time, and manual work

Consult your legal team and HR when drafting the contract to ensure maximum protection for your company while guaranteeing the work is done on time and professionally.

Establish Good Management Practices

Your relationship with the subcontractors doesn’t stop once they’ve signed the contract. Quite the opposite, that’s when the real work starts.

When working on the project, your subcontractor needs to feel like a part of the team and have the same options as the rest of your team members.

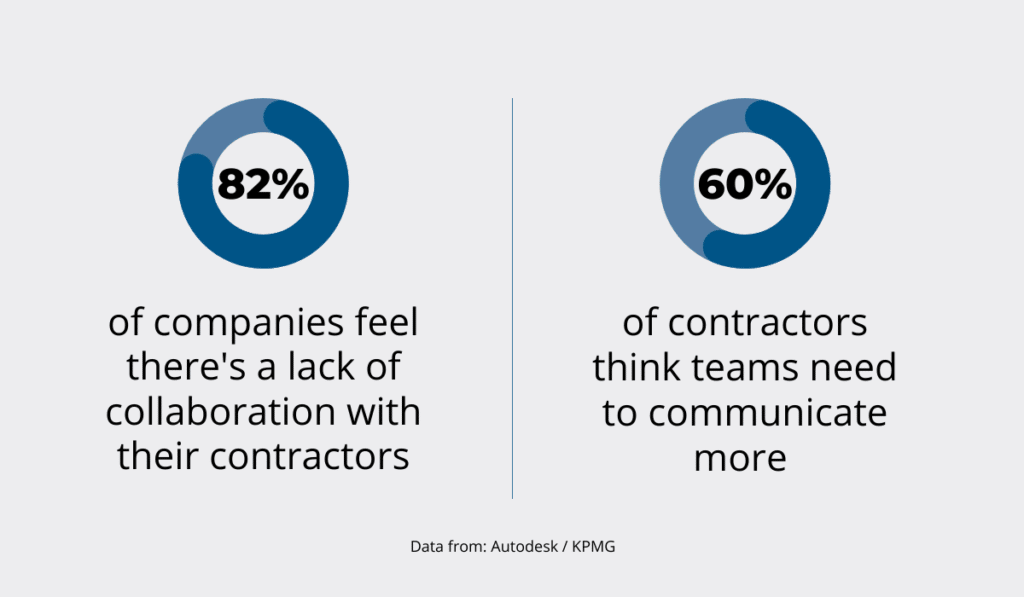

This requirement sounds relatively simple, but studies show it poses a significant challenge to construction companies.

Communication is a big problem for the majority (60%) of contractors out there, who report that the failure to convey expectations and the situation in the field in a timely manner obviously slows down the project.

On top of that, another 82% of companies feel like they need to improve the way they collaborate with contractors.

To prevent this problem at your construction site, include your subcontractors in all official communication and give them an easy way to contact your team.

If you’re providing the equipment, you must find a quick and easy way for all your workers to report a problem with the equipment or access its instructions.

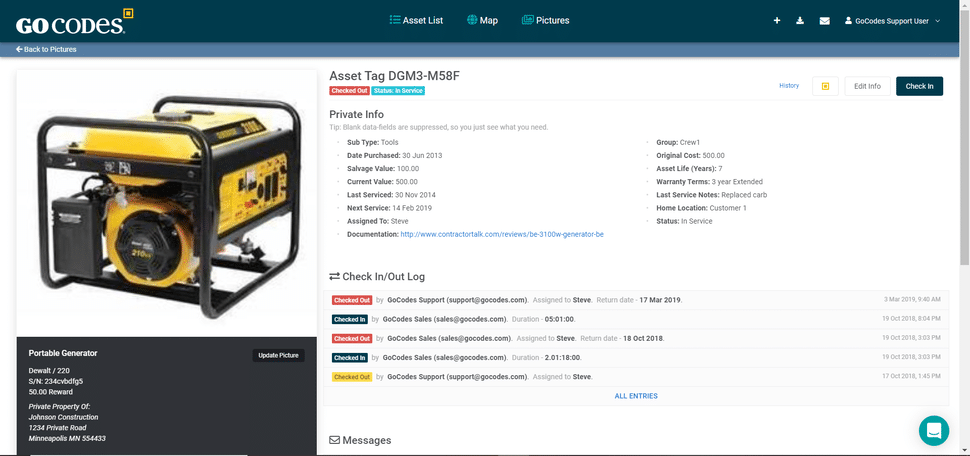

A great way of doing that is to use QR codes for tracking your machinery.

Whenever the team needs more information, they can scan the machine or tool’s QR code and land on its page in the cloud, with all the relevant information available in a click or two.

This data includes the manufacturer’s manuals and the option to leave comments regarding the equipment’s condition.

Tracking software lets your team communicate more effectively and manage the equipment better, which is a crucial part of every construction project.

Having an overview of who is using which machine and when it’s available for others to use will help your subcontractors stay on track with the project, as well.

Besides working on communication and collaboration to help manage the entire field force, you should enforce quality control. Doing so only after the job is already done is setting yourself up for failure.

Instead, agree on having project meetings throughout, where you and the subcontractors can update each other on everyone’s progress and eventual setbacks.

If improved results are not incentive enough, maybe savings will be.

McKinsey states that a European contractor reduced their project costs by an astonishing 25% after implementing detailed quality control.

The company wanted to make sure that they were getting the work they paid for, and the action itself paid off since they saved a quarter of the project expenses.

Conclusion

Finding and hiring subcontractors doesn’t have to be as challenging if you do it right.

The most crucial trait you need from a subcontractor is reliability. You want someone who will deliver quality work under the agreed-upon terms and conditions.

A written contract is a must if you want to be taken seriously by not just your competition but potential employees and employers.

Finally, the fundamental requirement for success in any construction project is good management. When working with subcontractors, that includes monitoring how the equipment is used and communicating with the team, whether field or maintenance.