Heavy equipment refers to sturdy machines and vehicles designed to handle demanding construction tasks. They’re used every day to power the construction industry and finish construction projects on time and within budget.

Whatever you need, you’ll probably find a suitable machine for the job. But there are six common types of heavy equipment that you’ll see on every construction site. Let’s look at what they are and how you can use them.

In this article...

Excavators

Excavators are among the most commonly used types of heavy equipment. As their name suggests, they are primarily used for excavation, but they’re also highly versatile and suitable for many different construction jobs.

What allows them this versatility?

First, they come in various sizes, enabling extra maneuverability, load capacity, and power. For example, if you have small-scale projects with tight areas, you can find a great mini excavator that will easily navigate through small spaces.

Actually, there’s a mini-excavator from Komatsu, with a 661 lbs operating weight and 2.1-gallon bucket capacity! Check it out in action.

Though at first glance it looks more like a toy than a serious construction machine, according to the manufacturer, it’s suitable for home improvement projects, urban projects, gardening, and pipe-laying.

On the other hand, large-scale projects can significantly benefit from excavators with a longer reach, larger load capacity, and more engine power. So, dragline excavators and hydraulic excavators are familiar sights on these construction sites.

When you also pair excavators with the right attachment, which can include a bucket, grappler, trencher, hammer, or ripper, you can repurpose them for construction jobs such as:

- Demolition

- Dredging

- Mining

- Cutting

- Drilling

- Lifting

Still, even though heavy equipment is widely used in the construction industry, operators frequently make mistakes that lead to injuries or equipment failure. One of them is operating too fast and abusing the bucket load capacity.

Sometimes, when operators are in a hurry, they will make quick starts and stops, or turn too quickly, which will cause the material to fall out of the bucket. Not only will this create additional work in terms of cleanup, but it’s also a major safety concern.

Related to this problem is frequent overloading of the bucket with the construction material.

While filling the bucket beyond its recommended capacity may look more efficient because operators will need to make fewer trips to move the materials, in the long run, it may break the bucket and cause irreparable damage to the excavator.

This could result in expensive repairs or even replacement purchases.

All in all, when you operate your excavators properly, you’ll be able to reap great benefits from this highly versatile, robust, and adaptable heavy equipment.

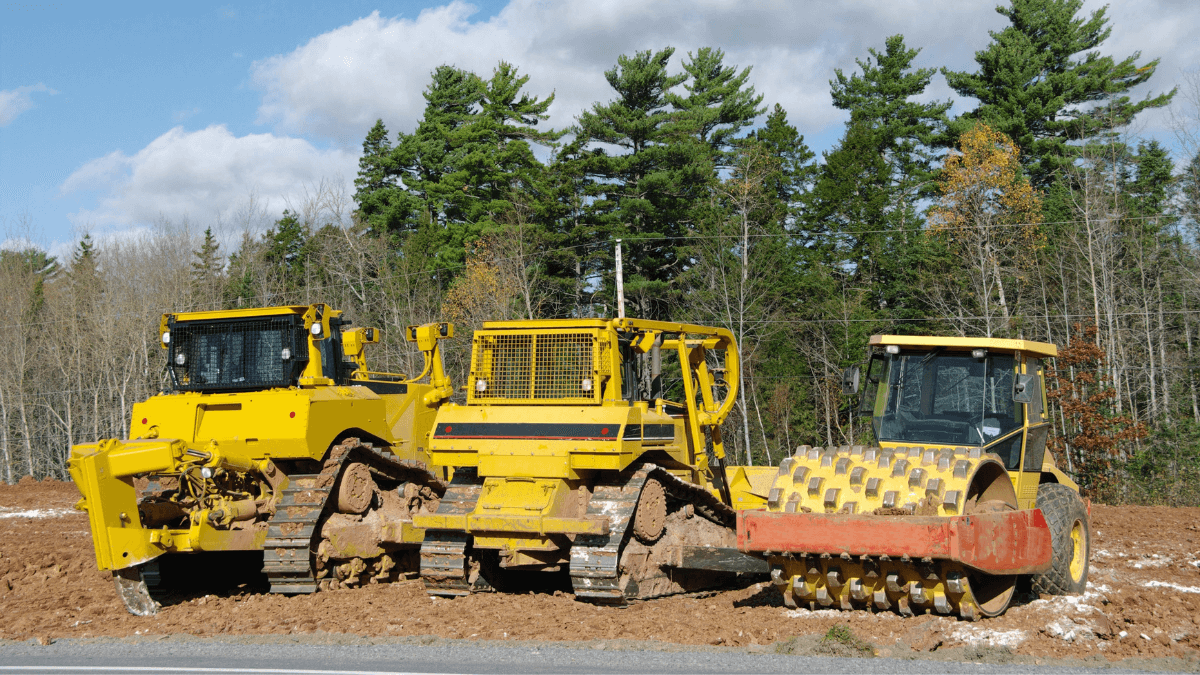

Bulldozers

Like every other piece of heavy equipment, bulldozers are designed to make construction easier and more manageable. That is why you can see them used for various purposes, from demolition and mining to road building and earthmoving.

Basically, any area of construction that involves the moving or modification of large quantities of materials will need a bulldozer. But which one to choose?

A typical bulldozer comes with a large metal blade (also called a plate) on the front, a ripper on the back, and tracks. Their most recognizable part is the large metal plate used for material removal and can be lowered or raised using hydraulic pistons.

They come in three different types:

S blade |

|

U blade |

|

S-U blade |

|

Now, even though bulldozers are extremely efficient when it comes to pushing massive amounts of soil, they come with specific maintenance problems.

For instance, issues with tracks are common. Keep in mind that bulldozers rely on the force of their tracking system to work. Tracks are the reason why bulldozers can move on rough terrain and transport heavy loads at the same time.

Since bulldozers are used for construction tasks that result in significant soil and debris accumulation, important machinery parts can get clogged.

With that in mind, it’s no wonder that track problems are frequently diagnosed during maintenance.

Similarly, if your bulldozer doesn’t move backward or forward, the problem might be in the hydraulic filter. If there’s some debris lodged in, you’ll probably need to service your hydrostatic drive pump.

In short, like all heavy equipment, bulldozers are susceptible to certain maintenance problems. Nevertheless, their reputation as one of the most powerful and reliable pieces of construction machinery is well deserved.

Telehandlers

Have you heard of telescopic handlers, teleporters, or boom lifts? They’re all various names for the same type of lifting equipment, also known as telehandlers.

Those are some of the most vital pieces of equipment for construction projects that require lifting and handling materials at heights.

They might resemble forklifts at first glance, but the main difference is that telehandlers have different attachments, and they can also reach much higher places, as well as carry heavier loads.

Typically, they can carry between 2.5 and 45 tons, with booms reaching heights from 19 to 100 feet. Moreover, with the advancement of technology, some manufacturers like Magni can create machines that can reach 150 feet and lift 13,200 lbs!

To get the most out of telehandlers, you have to find the machine with the right size and arm length. Here, it is important to keep in mind that bigger is not always better, and sometimes a smaller machine with a shorter boom might be more efficient for your specific needs.

Yet, the best part of working with a telehandler (no matter the size) is that you’ll have a combined functionality of a crane, forklift, and a work platform. If you use the right attachment, of course.

But, what are the main uses for telehandlers?

Unlike the forklift (a piece of equipment they’re often compared to), telehandlers are mainly used for outdoor working environments.

Their specific uses will depend on the attachments on the boom, but in general, they’re great for moving, lifting, and placing materials. In some cases, they can be a more cost-effective solution to cranes.

Furthermore, attaching a work platform on a telehandler will allow workers to access tall buildings or statues for maintenance and repairs.

Basically, one telehandler can manage two to three different construction tasks on the same job site. This makes them some of the most important pieces of equipment for any construction site, so always make sure you have one in your fleet.

Dump Trucks

Dump trucks have a single task on construction sites, but it’s an important one—to transport construction and demolition materials on the road or the job site.

Yet, don’t be fooled by the simplicity of their primary function. These vehicles are some of the strongest machines in the field, powered by robust engines to carry vast quantities of materials on any type of terrain.

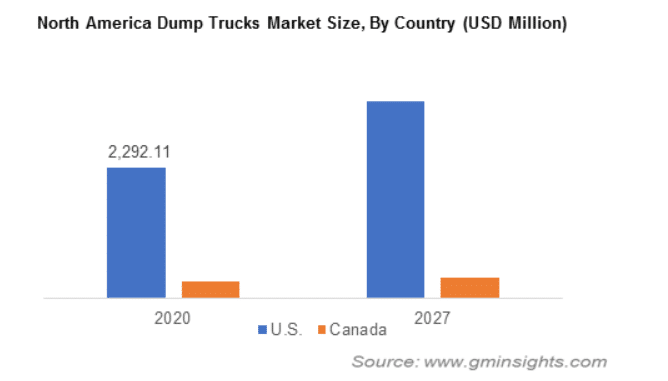

Additionally, the dump truck market is growing annually, with some experts estimating that it will reach $20 billion by 2027. Investments into dump trucks amounted to $2.2 billion in 2020 in the US alone.

The main reasons for the high demand for dump trucks include increased mining activity, particularly in the search for valuable minerals, as well as fleet replacement. Moreover, they are indispensable for an efficient and productive construction site.

So, how do you choose the right dump truck?

There are several things to keep in mind when getting a dump truck that will serve your needs. First, look into body styles. There are three main ones available: rectangle, half-round, and semi-elliptical.

- The traditional rectangle shape can give you more room and a lower center of gravity, which means more strength when carrying heavy loads.

- The half-round shape offers greater payload capacity, and the material doesn’t stick to the floor. Finally, the semi-elliptical shape is a hybrid between the former two.

Second, the metal used on the body plays a significant role in the type of material you’ll be transporting. Your main options are steel and aluminum.

If you’re working with gravel and concrete, stick to steel because it offers more protection, while aluminum is more suitable for non-abrasive materials.

Third, find a dump truck with the right engine power. A powerful dump truck like Belaz 75710 with a 2300 kW engine looks impressive, but unless you’re in the mining industry and need a huge payload capacity, you’ll be better off with something less robust.

Finally, look into gross vehicle weight rating (GVWR), which will determine the maximum limits you can legally transport on highways and roads to comply with federal laws.

To sum up, dump trucks are an essential part of any construction project, but the good news is that there are plenty of choices to find what you need.

Compactors

Whenever construction companies need to flatten the ground, they use a compactor. But the type they’ll choose mainly depends on the type of soil they’re compacting.

There are two types: light soil and hard soil.

For light soil, you’ll usually need compactors that can be used in confined spaces. Ideal solutions for this are vibrating plate compactors and rammers (also called jumping jacks).

Vibrating plate compactors use a downward force, and the vibration moves soil particles closer together.

A jumping jack, on the other hand, creates a series of blows into the surface—similar to a jackhammer, but the machine has a flat surface instead of a pointed end.

Now, you’ll have more options when it comes to hard soil. These compactors have more maneuverability and are typically used in open areas. Here are some of them:

Smooth Roller (Static) |

|

Smooth Roller (Vibrating) |

|

Sheepsfoot Roller |

|

Pneumatic Rollers |

|

Each type of compactor has different uses, but their primary purpose is to create a stable and strong foundation for construction projects.

Yet, it’s not uncommon that operators make two big mistakes: over-compacting or under-compacting.

You’d think that the more compact the soil is, it will become stronger, but that’s not true. Over-compaction can actually cause breakdowns in the soil mix, resulting in more weaknesses.

On the other hand, under-compaction can happen due to several factors.

First, you might not have the right compactor for the job at hand, and second, it could be that the operator didn’t pass the area enough times.

Under-compaction is a serious problem since it can create uneven terrain that can lead to structural issues.

You’d usually have a dedicated expert for large projects that will determine the soil type and the appropriate compaction, but even small projects can implement these key tips.

Hence, ensure you have the right equipment and understand the soil type you’re working in.

Compactors might be simple machines, but they create the foundation for every construction project, so choose the right one for your fleet.

Motor Graders

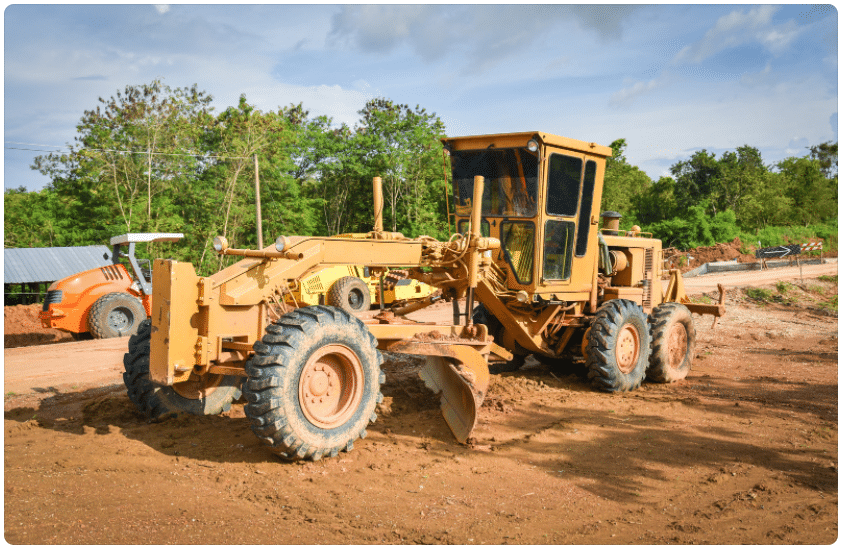

Graders or motor graders are a type of heavy equipment typically used to construct roads.

They have a cabin on the rear and a horizontal blade (also called a moldboard) between the front and rear wheels. They use this blade to level the terrain they’re working in.

But many construction experts see operators make unnecessary mistakes and don’t maximize the potential of motor graders.

According to Scott Mennenga, a motor grader instructor in Illinois, grader operators often work without enough angle on the blade.

They need to roll the material across the blade from its toe to the heel, but they push the material like a dozer instead, which doesn’t produce the best results.

Mennenga’s advice is to put the blade on the ground during the first passes to get everything perfectly flat. This might require making several passes before you can make finer adjustments.

But that’s not all you can do with a motor grader. You can also attach different parts to the machine’s rear end like rippers, blades, or compactors.

In addition, you can also change the main moldboard, which allows you to work on different tasks.

Apart from grading, you can also use your motor grader for:

- Snow removal

- Roadway maintenance

- Material spreading

- Creating inclines

- Earthmoving

- Trenching and ditching

Now, the essential part of a motor grader is the blade. The machine’s proper functioning depends on the condition and positioning of the blade, so you have to take extra care of it. Worn-out blades will cause the machine to use more power and increase fuel costs.

Therefore, keep the motor grader blade sharp. Regular professional maintenance should be enough, but you can replace it if it gets worn out.

It all comes down to utilizing reliable and productive machines, so regular maintenance and operator training should ensure that you get the most out of your motor graders.

Conclusion

We’ve described some of the essential pieces of heavy equipment to create a fleet that will serve your every need for any construction project. Each of them is highly versatile and efficient in completing different tasks.

While you may need other machines in addition to those we’ve talked about, this short list provides a healthy mix for maximum cost-effectiveness and productivity for any construction company.

Investing in any of these machines will be a good choice to help your company finish construction projects successfully.