Key Takeaways:

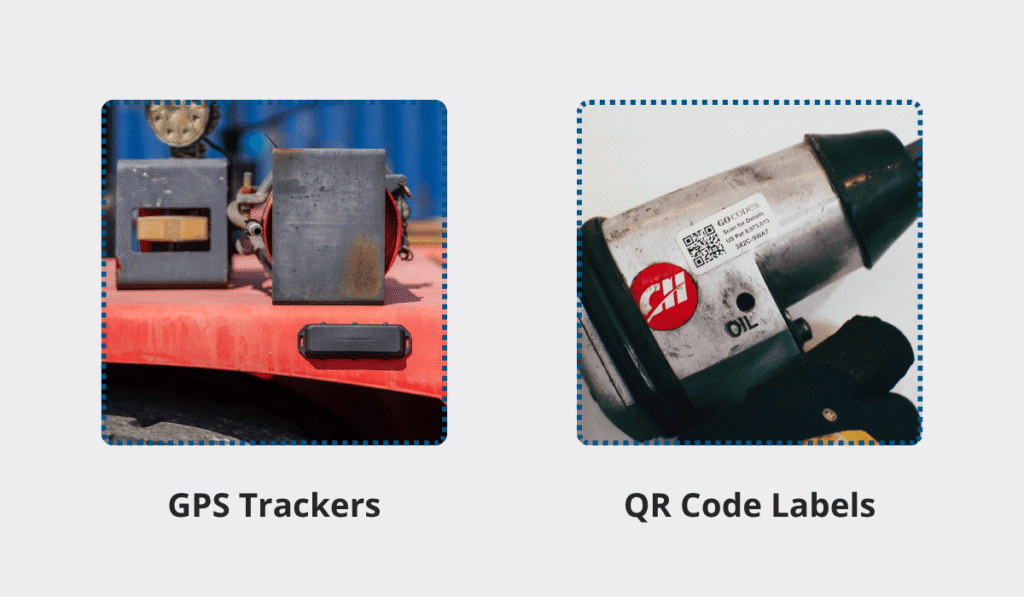

- GPS delivers continuous updates ideal for site monitoring and safeguarding equipment.

- Dynamic QR code tracking is a low-cost, plug-and-play solution.

- By combining both systems, companies cover all asset types and workflows.

Effective asset tracking isn’t just about preventing on-site losses. It also drives efficiency, improves safety, and protects your bottom line.

Between real-time GPS systems and cost-friendly QR code labels, construction managers need a clear understanding of the strengths and limitations each option brings to construction equipment tracking.

In this guide, you’ll discover how both technologies work, where they excel, and how they stack up in terms of cost, reliability, and overall business value.

Let’s get started.

In this article...

GPS Tracking Overview

When it comes to monitoring construction equipment, GPS tracking is one of the most effective technologies for real-time location management.

At its simplest, it starts with the tracker itself: a rugged device installed on heavy equipment to transmit location data via satellite.

Source: GoCodes Asset Tracking

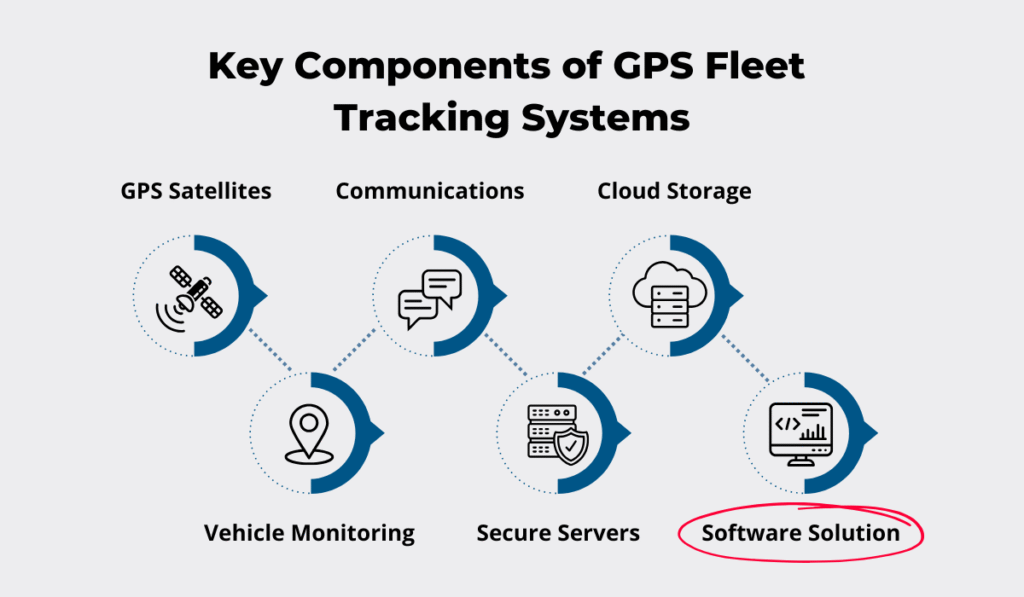

However, GPS tracking is more than just hardware.

It’s a combination of physical devices and software systems that work together to deliver up-to-date location, movement, and status information to project managers and fleet supervisors.

Installed on vehicles and machinery, GPS trackers use satellite signals to calculate precise asset locations and relay that data through a communication network to a secure cloud-based platform.

From there, it’s processed and displayed through software dashboards accessible via desktop or mobile apps.

Source: GoCodes Asset Tracking

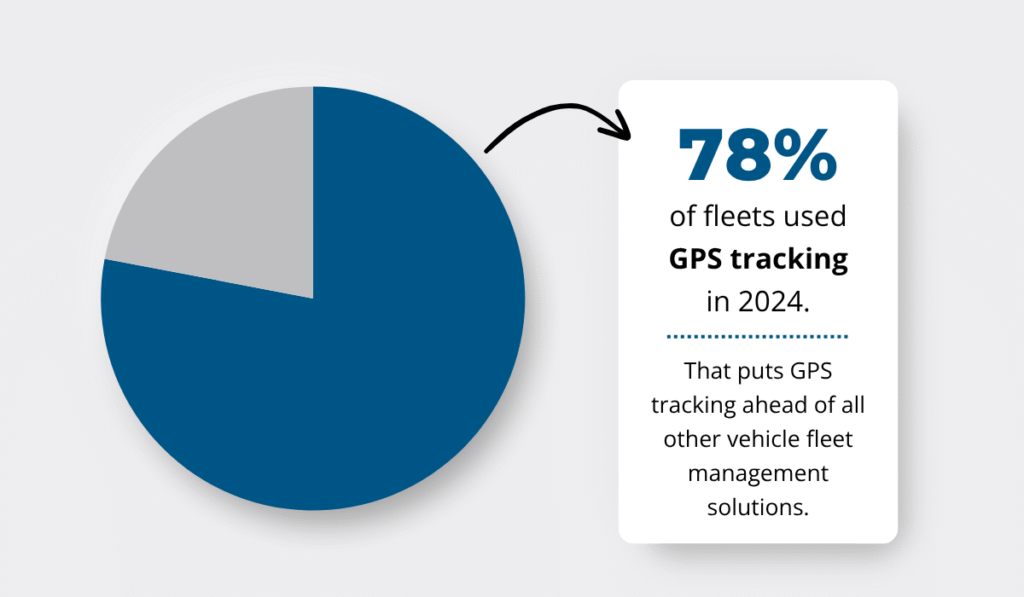

The adoption of GPS technology across the construction sector has grown rapidly.

According to Verizon Connect’s 2024 survey, 78% of fleets now use GPS tracking.

Illustration: GoCodes Asset Tracking / Data: Verizon Connect

So, where does this popularity come from?

One of the biggest advantages of GPS tracking is its ability to improve visibility over equipment across large, busy, or multi-site projects.

Imagine a large jobsite with dozens of subcontractors sharing machines, or high-value equipment moving between distant locations.

In these contexts, live location updates and geofencing alerts are essential for both security and efficiency.

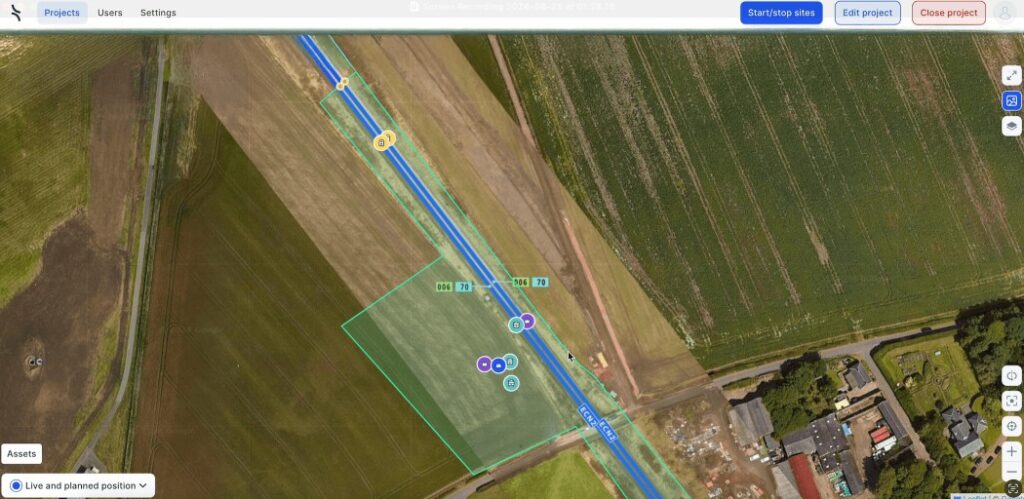

One example is Tended’s geofencing technology, used by SPL Powerlines on Scottish rail projects to help managers monitor trackside equipment and optimize distribution while enhancing worker safety.

Source: Tended

The SPL Powerlines’ Regional Director, Lee Pounder, explains that this technology helped enhance site visibility and improve decision-making across teams through key insights in real-time.

Illustration: GoCodes Asset Tracking / Quote: Tended

In practice, this means better site control, reduced safety risks, and fewer costly delays.

While geofencing has multiple use cases in construction, it’s commonly used to safeguard mobile, high-value assets like bulldozers, excavators, and trucks, especially in the face of climbing theft rates.

After all, without live tracking, stolen machinery is often unrecoverable.

One older but telling case involves a Saudi contractor recovering stolen backhoe loaders over 900km away.

Source: Construction Week

Omer wasn’t alerted to the machinery’s movement because the telematics system on one of the assets was inactive.

As such, recovery only became possible once the local JCB dealer reactivated the said system. It’s not difficult to imagine what would have happened without it.

When paired with fuel monitoring sensors, GPS tracking also contributes to operational savings.

Namely, suspicious fuel drops or inefficient driving habits trigger immediate alerts, helping curb costs.

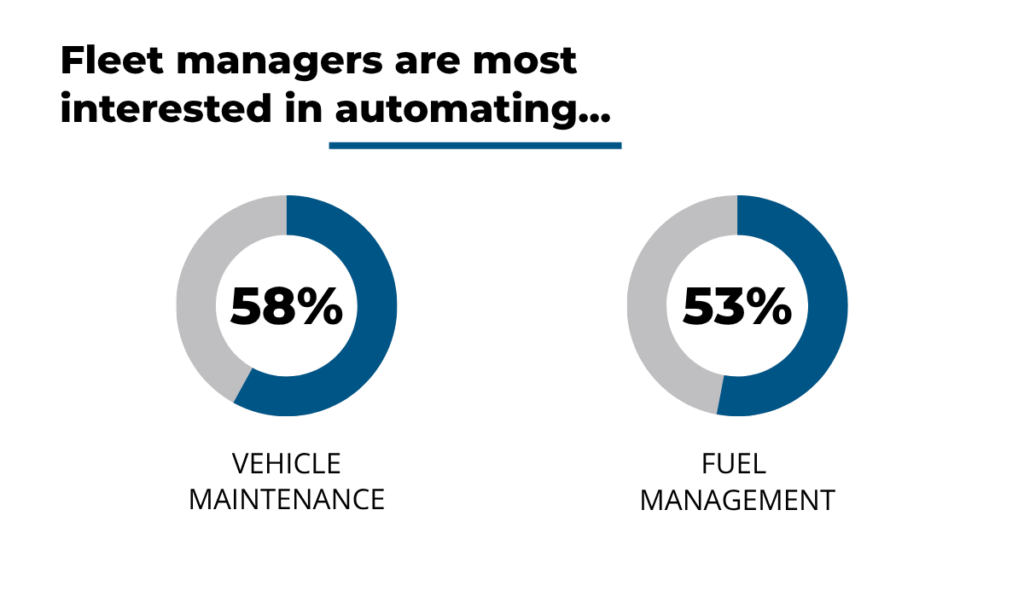

According to Teletrac Navman, 47% of fleet managers cited fuel costs as their top business challenge.

It’s no surprise, then, that Motive’s data shows fuel management as one of the most automated fleet processes, second only to vehicle maintenance.

Illustration: GoCodes Asset Tracking / Data: Motive

Beyond fuel tracking and theft prevention, another strength of GPS systems lies in how seamlessly they integrate with broader construction management platforms.

These integrations extend the value of GPS data beyond simple location monitoring, helping teams manage jobsite activity, workforce hours, and equipment deployment in one place.

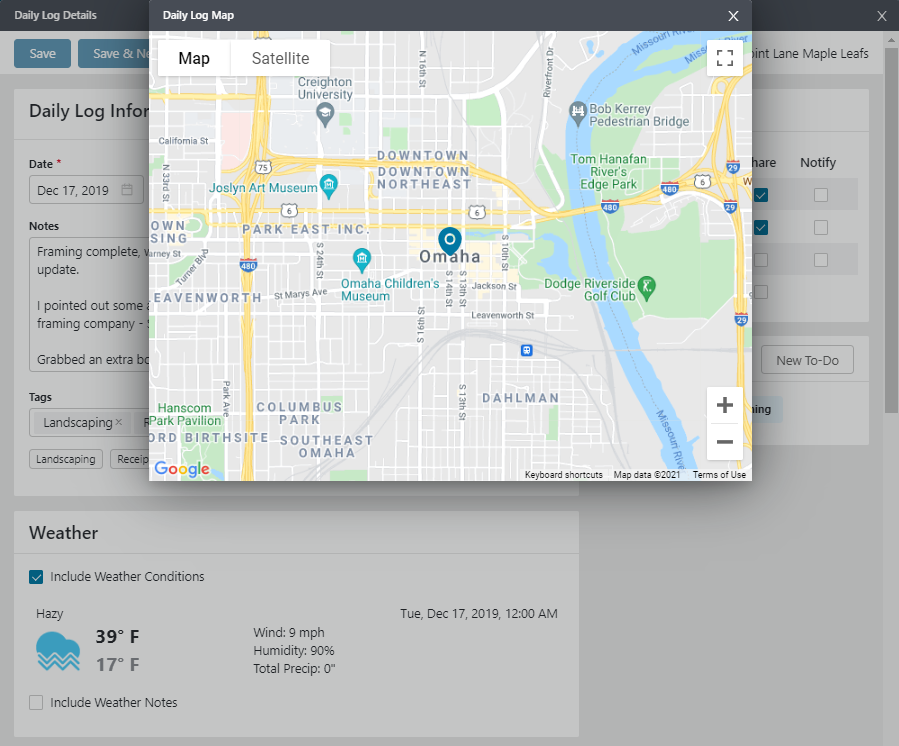

Buildertrend’s project management platform is a good example.

Their GPS-enabled daily logs enable managers to confirm the exact location of specific equipment whenever appropriate tags are added.

Source: Buildertrend

That is pretty nifty when you need to boost jobsite accountability, reduce reporting errors, and keep key subcontractors and teams aligned.

In short, GPS tracking isn’t just about knowing where your assets are—it’s about improving safety, reducing costs, and running more accountable, efficient projects.

QR Code Tracking Overview

While GPS trackers handle continuous, automatic location monitoring, QR code tracking systems offer a simpler, more budget-friendly way to manage construction equipment and tools.

The process starts with attaching a durable label bearing a QR code to each asset.

Source: GoCodes Asset Tracking

Unlike GPS, QR code tracking is a passive, manual system.

It relies on workers scanning labels with a smartphone, tablet, or handheld scanner.

In construction, QR codes are typically used as part of check-in/check-out systems.

Each scan logs when and where a tool or asset was used, by whom, and what its current status is.

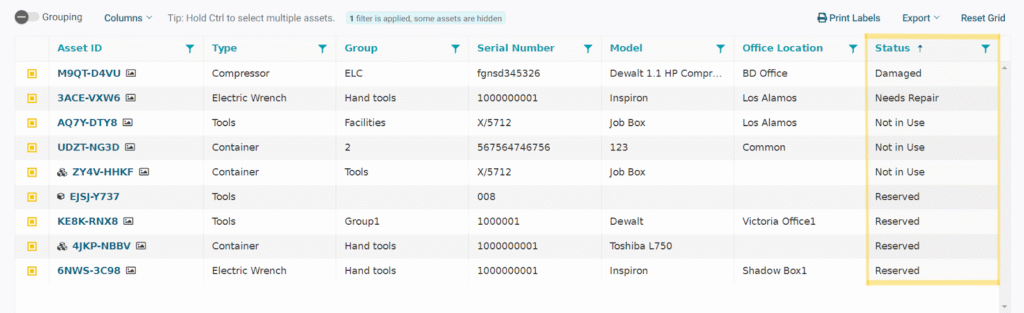

Source: GoCodes Asset Tracking

In other words, you’re keeping asset information current without requiring sophisticated telematics.

This technology is ideal for smaller, mobile, or consumable items that don’t justify the cost of a GPS tracker, such as:

- Power tools

- Ladders

- PPE

- Inventory stock (e.g., extension cords, fasteners, pipe fittings)

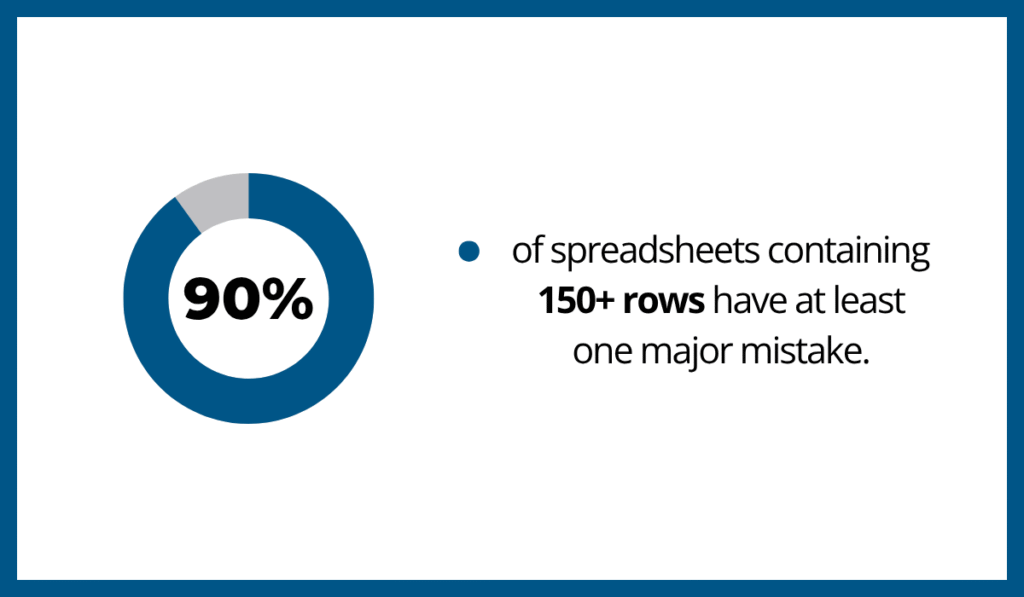

“But what if I’m already tracking all this through Excel?” you may ask.

Although many construction firms still track assets and more using spreadsheets, research suggests that this is incredibly risky.

Namely, 90% of spreadsheets with over 150 rows contain at least one major error.

Illustration: GoCodes Asset Tracking / Data: IGI

Spreadsheets are slow, error-prone, and lack real-time data validation, increasing the chances of assets being lost, misplaced, or unaccounted for.

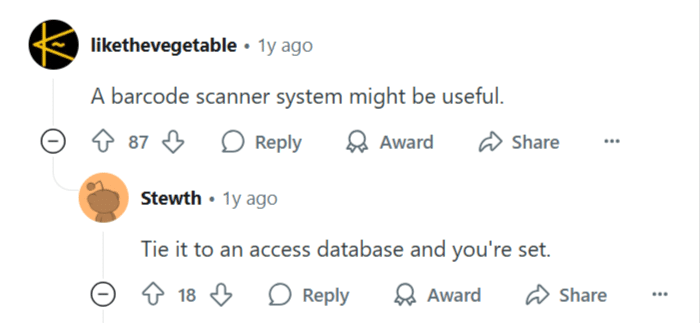

That’s why, when a Reddit user posted about his new company struggling to track 100 items in Excel, the community members recommended switching to a scanner-based tracking system.

Source: Reddit

For small to midsize companies managing inventory manually, or those seeking a plug-and-play tracking solution on a budget, QR code systems offer the perfect starting point.

They’re especially effective in contexts where the priority is accountability, rather than GPS-level location tracking.

Tying asset check-ins and check-outs to a live database helps ensure instant updates and builds a transparent, searchable history for every tool—something spreadsheets can’t reliably deliver.

It also addresses a major cause of losses: employee theft.

As Lee Schwartz, principal of a management consulting firm, Schwartz Profitability Group, notes:

Illustration: GoCodes Asset Tracking / Quote: Assembly Magazine

With a cloud-based audit trail in place, every tool movement leaves a record.

If an item goes missing, the system can identify who was the last to scan it and where, thus deterring theft and improving recovery chances at the same time.

One limitation of QR code systems is that updates depend on manual scans.

In other words, if a worker forgets to scan or if a label is damaged, data accuracy suffers.

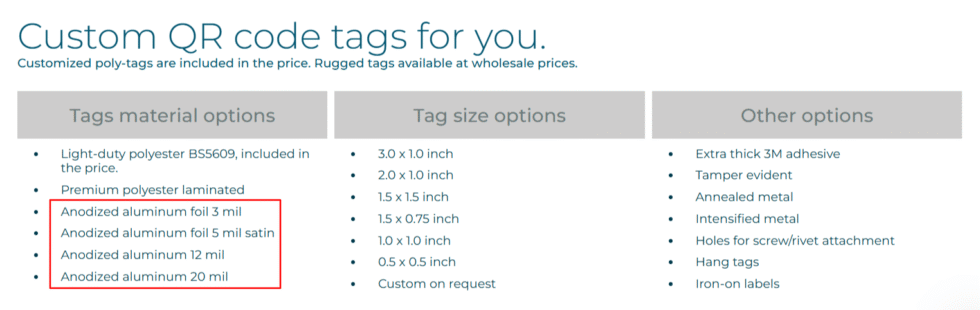

QR codes also need to remain visible and readable, meaning labels exposed to rough environments must be durable.

The difference between labels for indoor and outdoor applications is explained by experts from Camcode:

Source: Camcode Bar Code Products on YouTube

As industry experts advise, using metal or industrial-grade plastic labels for outdoor tools extends label lifespan and prevents readability issues from dirt, fading, or abrasion.

Although this is about barcodes, the same thing applies to QR code tracking.

You can prolong the QR code lifecycle as much as possible by choosing rugged materials like metal for the outdoors.

Source: GoCodes Asset Tracking

In short, QR code tracking is an affordable, scalable, and easy-to-implement tool accountability system.

This makes it perfect for firms ready to leave spreadsheets behind without committing to higher GPS tracking costs.

GPS vs QR Codes: Main Differences

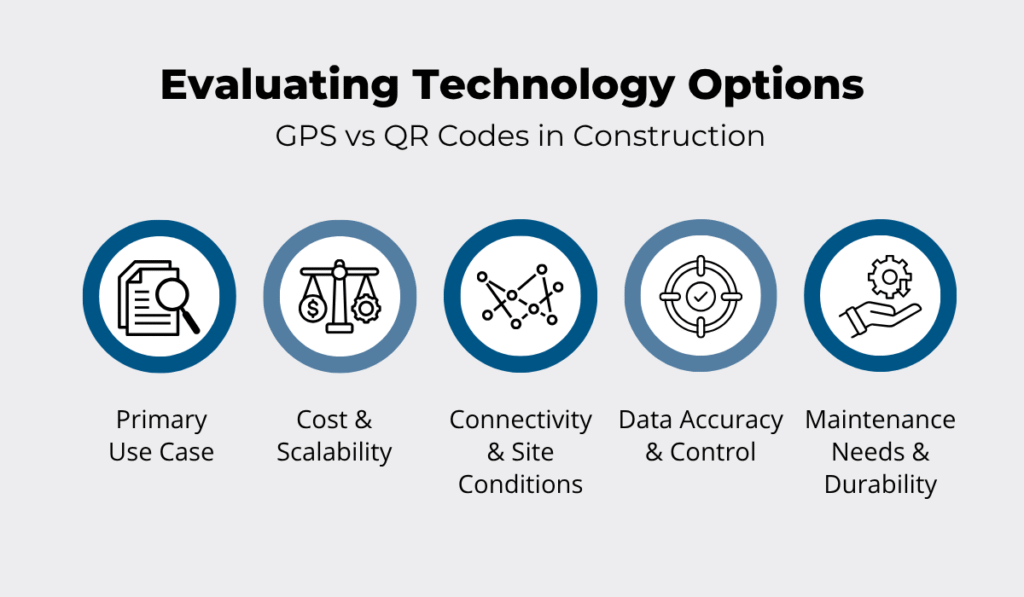

When it comes to construction equipment tracking, both GPS and QR code systems offer clear strengths and drawbacks.

The right choice depends on your asset types, operational needs, and budget.

So, let’s compare them across the key factors that influence the choice of technology, as well as the tracking performance on a jobsite.

Source: GoCodes Asset Tracking

The primary difference lies in how these systems capture and deliver asset location data, which then impacts the use case.

As we’ve established previously, GPS trackers automatically transmit real-time location information via satellite networks, minimizing human input and error thanks to built-in alerts and geofencing features.

Meanwhile, QR code labels require manual scans using a smartphone or tablet to log an asset’s location or status, which leaves room for missed updates if labels wear out, go unnoticed, or if users forget to scan them.

Cost-related differences are another important point.

Namely, GPS tracking requires dedicated hardware, data plans, and ongoing platform subscriptions. This automatically means a higher upfront and long-term investment.

In contrast, QR code systems require only low-cost labels, free or inexpensive mobile apps, and occasional tag replacements.

When it comes to general connectivity, GPS offers high location accuracy globally and the fastest update speeds.

However, in remote or dead-zone areas, updates may pause until coverage resumes.

On the other hand, QR code systems work well offline.

While data accuracy depends on the last recorded scan, scans can usually be stored on the device and synced to the cloud as soon as the connection has been restored.

To recap the key differences, here’s a clear, at-a-glance summary table:

| Factor | GPS Tracking | QR Code Tracking |

|---|---|---|

| Cost (Initial + Maintenance) | High (hardware, subscription, general upkeep) | Low (labels, mobile app, eventual tag replacements) |

| Dependence on Direct Input | Low, location updates are automatic and continuous | High, requires manual scans to log or update the location |

| Accuracy | High, real-time location data | Moderate, data can be outdated between scans |

| Offline Accessibility | Limited, live tracking requires network coverage | High, scans can be stored offline and synced later |

| Data Update Speed | Instant, continuous data feed | Manual, updated only when scanned |

Oded Ran, CEO of Clue Insights Inc., notes that tracking apps typically provide key asset information through GPS or QR codes.

Illustration: GoCodes Asset Tracking / Quote: Clue

But it doesn’t have to be an either-or decision.

While your construction firm might lean toward one system, the most effective asset management strategies often combine both technologies.

Knowing this, providers like GoCodes Asset Tracking offer both options within a single, cloud-based platform.

This gives managers flexibility to track everything from excavators to small tools within one system.

Source: GoCodes Asset Tracking

Ultimately, whether you need continuous tracking or simple status logging, matching the right tool to the right job is what keeps your assets accounted for and in peak condition.

This, in turn, means projects follow budgets and timelines, giving you an edge over your competitors.

Conclusion

So, should you opt for GPS or QR codes? The truth is, there’s no one-size-fits-all answer.

Both GPS tracking and QR codes offer reliable ways to manage construction equipment, but their true value depends on the specific demands of your projects.

GPS systems excel at tracking high-value, mobile assets and providing remote oversight, while QR codes deliver a cost-effective, easy-to-deploy solution for on-site inventory and maintenance logging.

The smartest move?

Assess your fleet’s mobility patterns, theft risk, and operational priorities. Then, look for a solution that can cover your core hardware and software needs.

That way, you’ll ensure each asset is tracked with the technology that will ensure maximum protection and utilization.