Key Takeaways:

- Strategically defined geofences ensure that the boundaries accurately represent the areas of interest, increasing the accuracy of geofence-triggered events and alerts.

- It is essential to train employees on how to interpret alerts and navigate the geofencing software in order to get the most out of it.

- Fleet managers should regularly monitor and analyze geofencing data. This will help them identify areas for improvement.

Fleet management of today is unthinkable without GPS technology and telematics, which pave the way for streamlined operations and greater efficiency.

A crucial part of all this is geofencing, which enables fleet managers to set up virtual perimeters around target areas.

But if geofencing is used poorly, it will not transform your business for the better.

You can have the best software, but you still need to learn how to properly use it and truly leverage its power.

Luckily for you, we’re here to help.

In this article, we’ll guide you through the best practices for using geofencing for your fleet management, so you too can reap the benefits of it.

In this article...

Set Clear Goals

Clarity is crucial when it comes to unlocking the true potential of tech solutions.

And geofencing is no different.

For starters, it is crucial to understand what kind of goals it can help you achieve.

It could be any of the following:

- Reducing operational costs

- Increasing worker safety

- Mitigating equipment theft

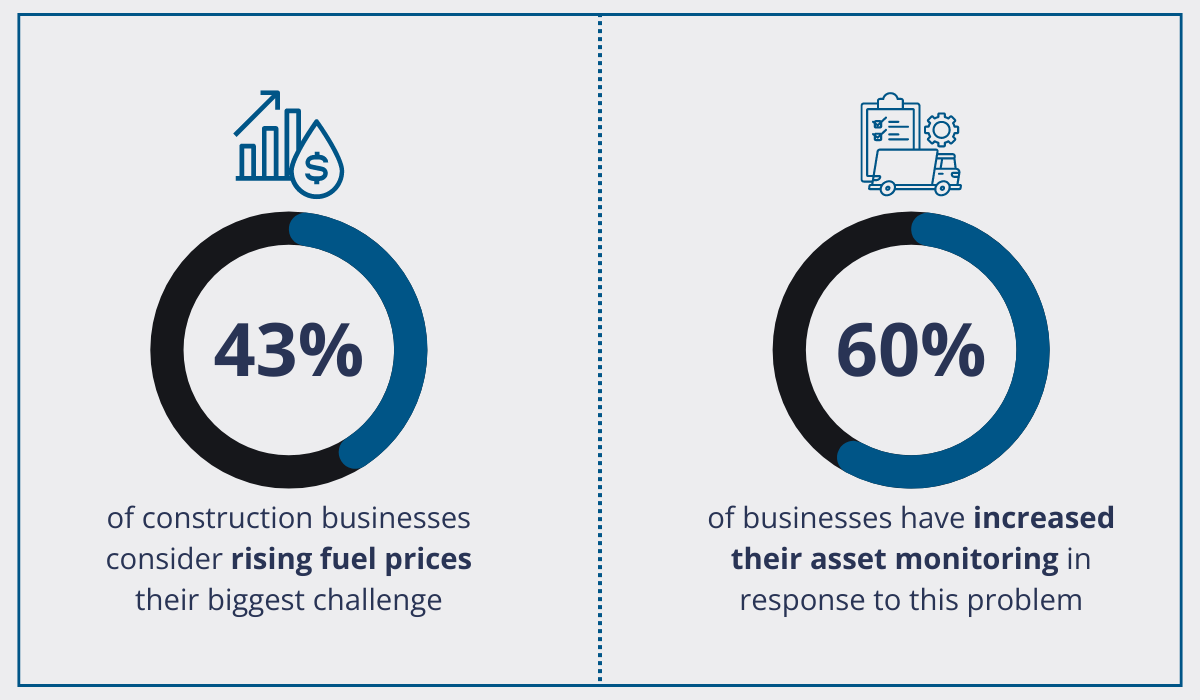

More and more companies are having trouble keeping up with increasing fuel prices and have started monitoring their assets to combat this.

This is where geofencing comes in handy.

By giving you a sense of what every asset is doing at any given moment, geofencing can help you identify and address the root causes, boosting productivity while also allowing you to cut back on costs.

Another scenario is where your construction site has several hazardous areas that you don’t want anyone stumbling upon.

In that case, geofencing technology can mean a difference between life and death.

As you can see, amazing tech advances create many opportunities for improvement.

The recent report by the Association of Equipment Manufacturers outlined several key areas where technology makes a considerable impact, whether it is productivity, safety, or sustainability.

With such potential for growth at hand, who wouldn’t rush to harness new technology?

But don’t be hasty.

Rushed implementation and lack of clearly defined goals usually lead straight to a gaping pitfall.

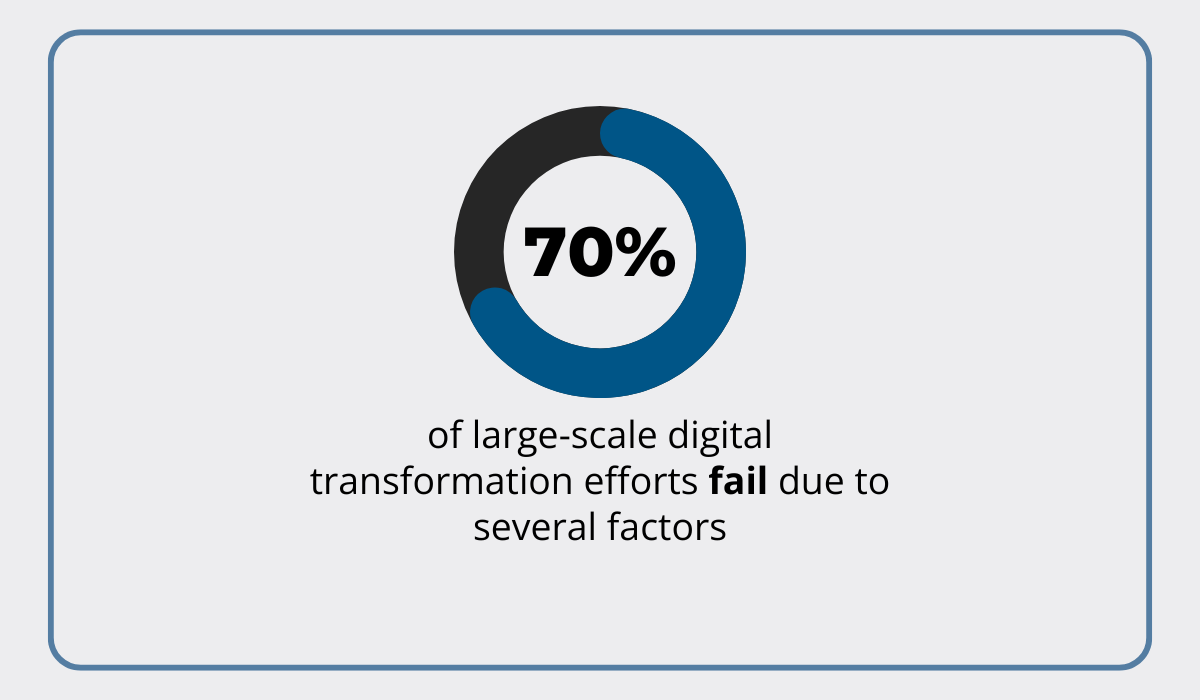

McKinsey’s research supports this notion, showing that a staggering 70% of digital transformations fail.

Delving deeper into the causes of these failed attempts reveals that companies frequently know they need change, but move in without fully defining their priorities and goals.

Many industry experts agree with that.

For example, Avi Shua, co-founder and chief innovation officer at Orca Security, urges clarity regarding goals, no matter if these relate to reducing costs or being more agile, concluding that

“Organizations need to understand what the key areas of focus are and what they are trying to achieve from the business point of view.”

So regardless of whether your focus is on productivity, safety, or combatting theft, the key is to have a clear vision of your priorities—only then can you proceed to use geofences to their maximum effect.

Strategically Define Geofenced Areas

Once you’ve identified your key aims, it’s time to go about setting your geofenced areas.

Keep in mind that clear, strategic geofence boundaries yield vital data.

On the other hand, a hastily defined perimeter puts you at risk of compiling false or irrelevant data. Moreover, you may lose precious time in re-organizing the entire framework.

Nevertheless, there are several critical areas that naturally benefit from the kind of monitoring that geofences offer, including:

- entry and exit points,

- fueling stations

- storage space for various equipment

One notable advantage of geofences when compared to their physical counterparts, is that while they are as robust as actual fences, they are much easier to set up.

Furthermore, they can be reviewed and updated with ease, in line with existing fleet management goals.

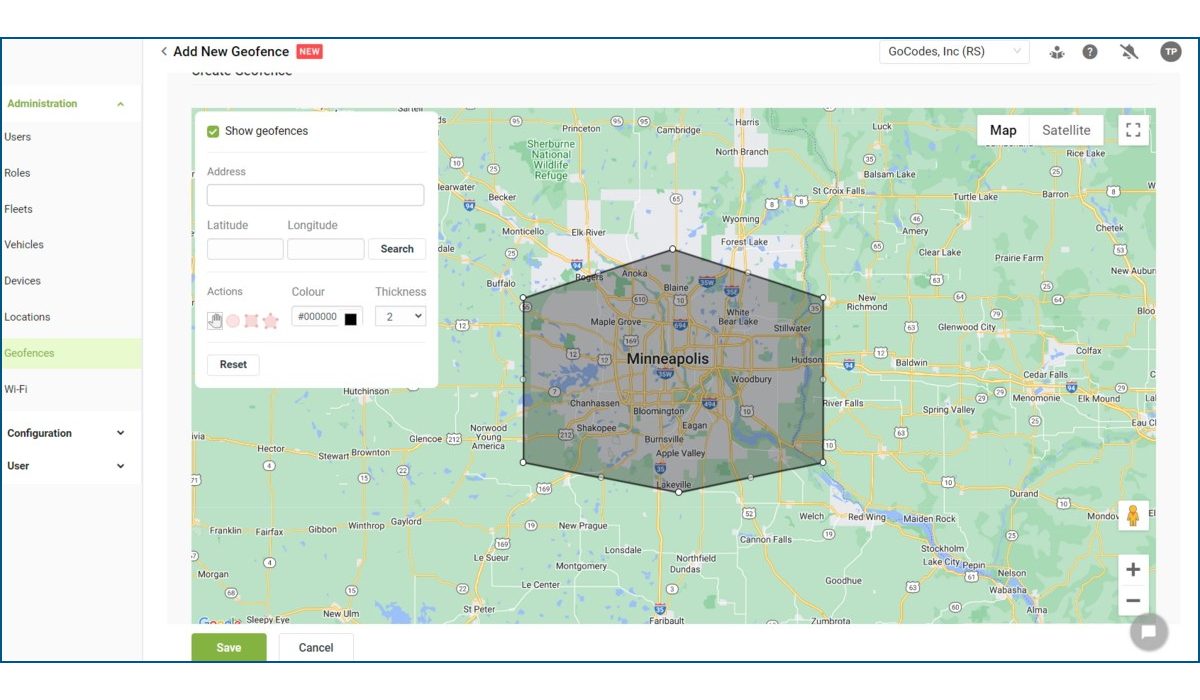

More advanced asset-tracking software like GoCodes comes with built-in geofencing, and the setup process itself is very straightforward.

Here’s what it looks like:

It’s worth pointing out that polygonal geofencing, as opposed to the traditional geofence radius, offers much greater flexibility and precision, particularly in regard to the collected data.

Trimble’s vice president of product vision and experience, Rishi Mehra, notes the limitations of older radius models:

“A simple radius covers the roads leading to a facility, but can’t differentiate whether a driver is in a yard or just approaching it. Precise geofences on entrances and exits provide more accurate real-life data.”

Lack of precision is particularly problematic if we take into account potential false alerts and their disruptive effect on ongoing processes and directly affected personnel.

Such disruptions would not only erode the workers’ trust in technology but also limit capacities to respond to actual cases of unauthorized use or major security breaches.

Geofences that are properly set up and perfectly aligned with the construction site’s layout, usually act as the biggest asset-savers and the best theft deterrent you could introduce.

Areas that hold the most expensive equipment and vehicles are frequently the first ones to be geofenced in, but ensuring maximum security requires you to leverage real-time alerts, which is our next best practice.

Set Up Real-Time Alerts

While geofencing is already a powerful ally in its own right, its full potential is unleashed only once you’ve successfully configured real-time alerts.

These alerts provide a window into the actual situation in the field, no matter where you are at the moment, shifting your attention to any and all lapses in compliance.

This is what makes them indispensable in numerous situations, from unfortunate delays and schedule deviations to full-blown crisis management.

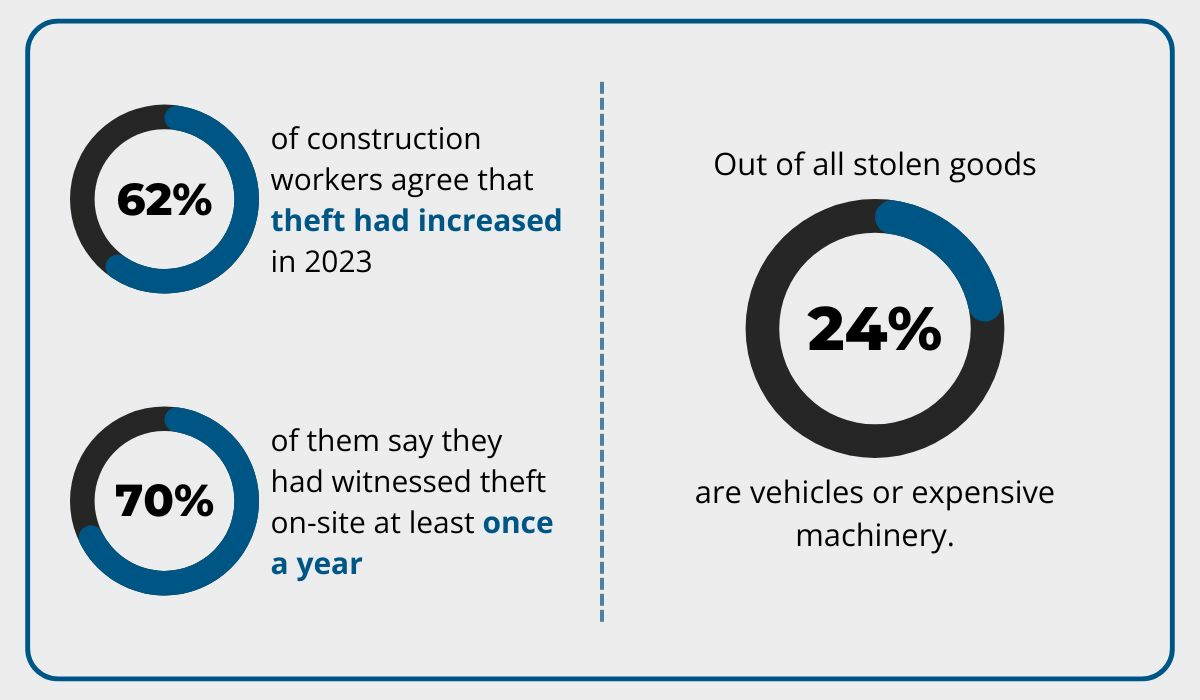

Given the marked increase in on-site thefts, real-time alerts really come in handy.

Bauwatch’s report outlines the widespread nature of thefts on construction sites in the UK and Europe, suggesting similar trends on a global level.

Particularly concerning is the extent of vehicle and machinery-related losses, which are costly in their own right, but also difficult to replace quickly, creating a negative ripple effect on the entire project.

Luckily, avoiding this is possible with some extra vigilance and clever software solutions such as geofencing.

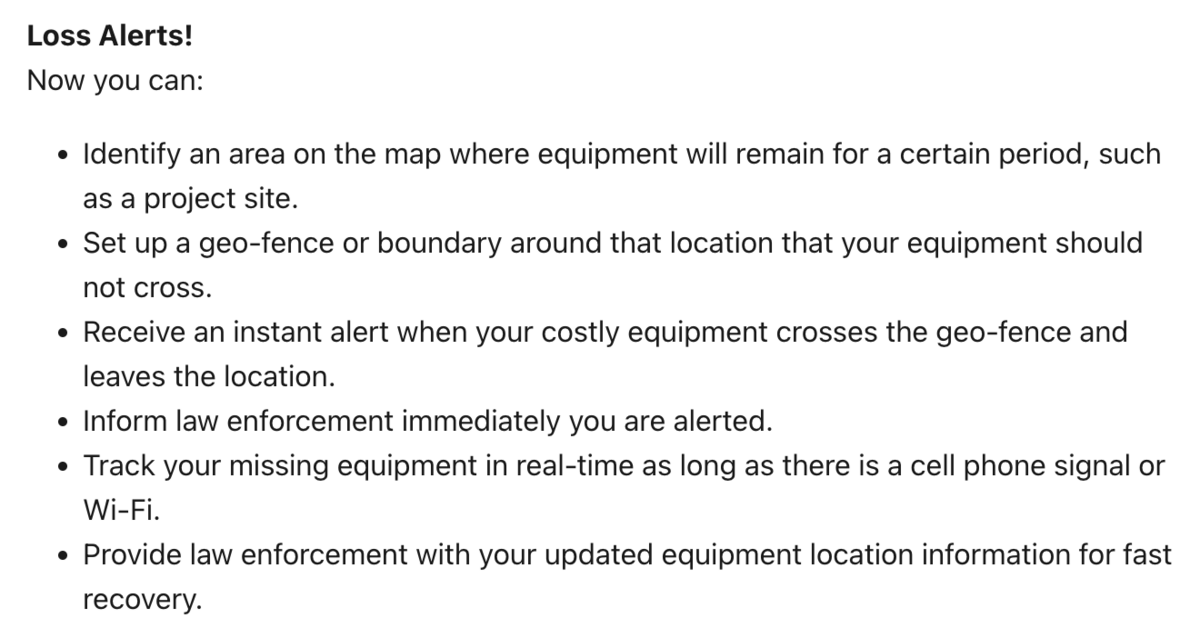

GoCodes “Loss Alert” feature allows you to instantly receive notification if any asset leaves its designated area, and to promptly inform law enforcement.

As long as there is a cell phone signal or Wi-Fi, it is possible to quickly exchange the missing assets’ latest location and aid in fast recovery.

Thanks to geofencing technology, cases of returned equipment are no longer few and far between.

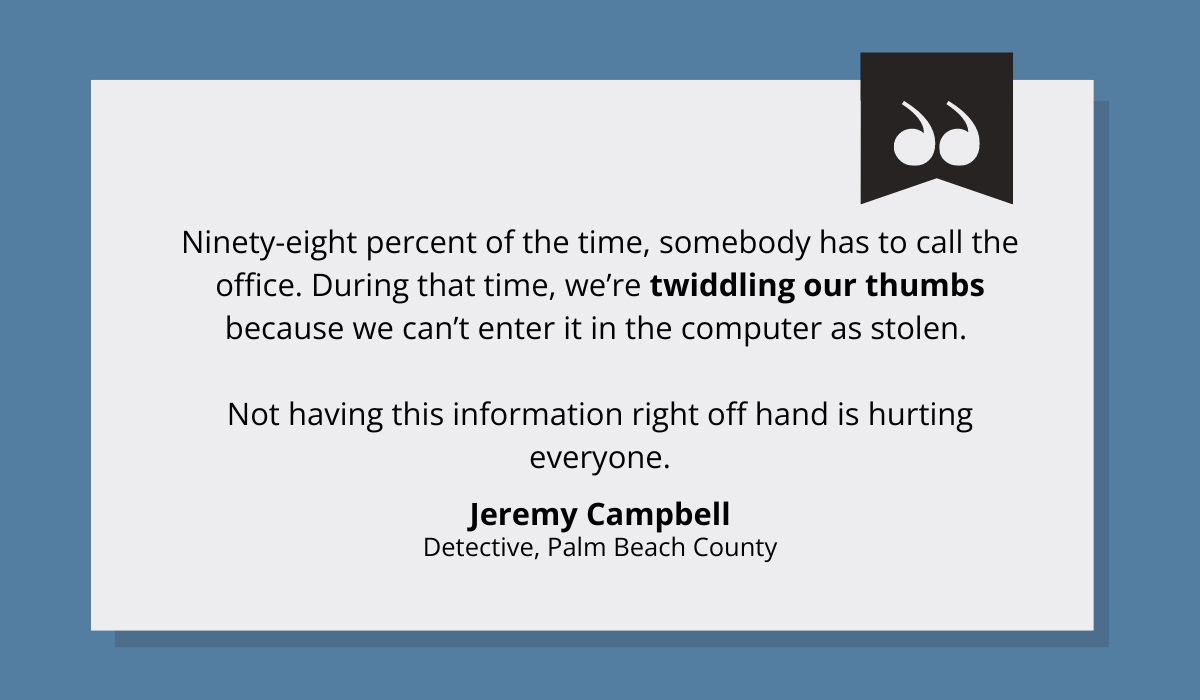

But, speed is still of the greatest essence, as pointed out by Jeremy Campbell, a detective from Palm Beach County.

Indeed, while digital boundaries significantly improve your chances of warding off thieves or retrieving stolen assets, they are not as efficient on their own.

Having all the crucial data in one place, and being able to pass it on to law enforcement is only possible by adopting fleet monitoring systems that incorporate a variety of identification labels and tracking devices, from QR code labels for easy mobile scanning to BLE beacons and real-time GPS trackers.

Still, no technology can work on its own nor can it be adopted overnight, which is why it is crucial to ensure your employees are in the know and properly trained.

Train Your Employees

One notable trait of successful construction companies is the readiness to turn things upside down and figure out how to do things differently for even better results.

In practice, this often means ushering in new and innovative technological solutions.

However, as mentioned earlier, digital transformations can be very tricky to pull off, particularly in construction, and one reason why is not having your employees on board and properly equipped to make the desired change a reality.

The reality is that the workers are not averse to learning or using new tech.

In fact, they expect to receive training to be able to do their jobs, and companies who neglect to provide this are facing losses.

Laurent Charpentier, the CEO of Yooz stressed the extent of the risks by referring to the company’s 2023 report, which tackled workplace technology in several sectors, including construction.

Taking the time to learn how to successfully leverage a tech solution is a wise strategic decision, which ensures that you will meet your goals while strengthening your overall company culture.

Begin by preparing a comprehensive starter pack and training plan that is in line with your needs and schedule.

When it comes to geofencing, start training your team by explaining the basic layout and the way of navigating through the software before moving on to core functionalities:

- setting up the geofences

- and configuring real-time alerts

You should spend some extra time explaining how to interpret the alerts, so as to avoid any confusion and minimize false alarms.

Finally, new software means updated procedures in cases of unauthorized access or suspected theft, so it is important to outline the course of action and explain how the system enables faster reaction time.

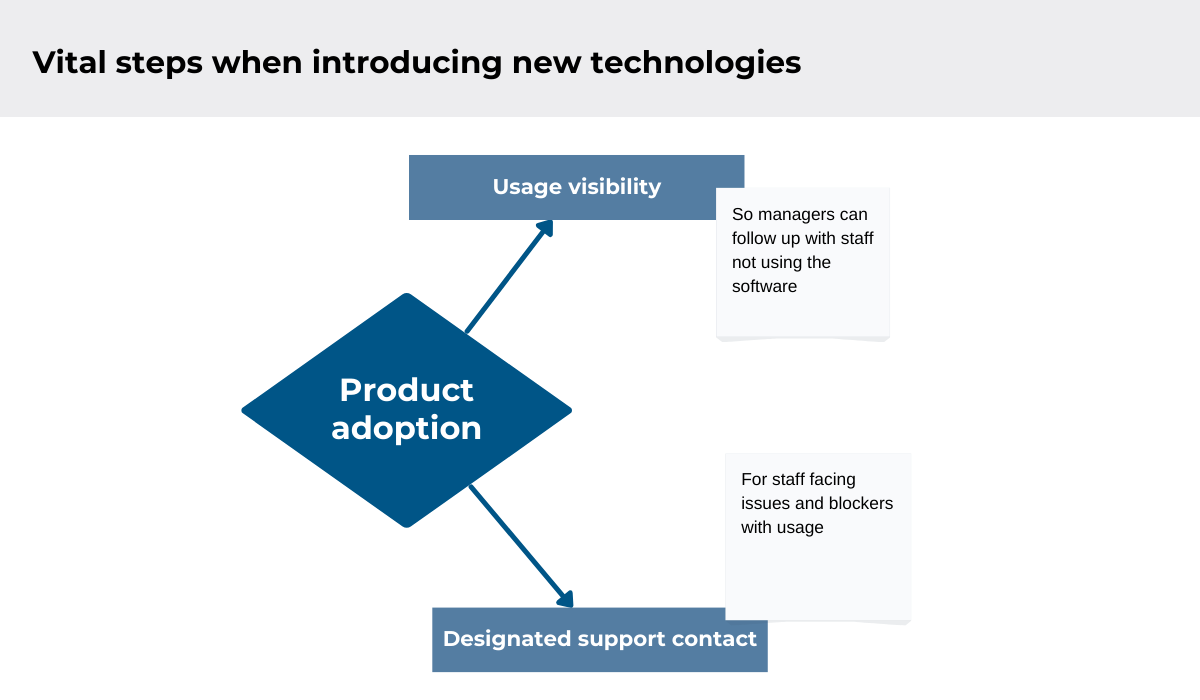

Even with the training over, don’t forget to do follow-up and provide ongoing support for workers, as advised by the StaySafe team:

Remember that practical training is also an extensive introduction to precisely those features that help workers in their day-to-day activities.

It is an excellent opportunity to highlight benefits and dispel any doubts or lingering fears.

Also, familiarity with different features raises awareness of how this technology helps workers, from geofencing safety alerts to preventive equipment maintenance.

Even besides real-time alerts, tracking brings in a bulk of data on drivers, enabling recognition of good practices and creating the basis to reward performance.

Ultimately, proper training and open communication pave the way for increased productivity and a healthy company culture, but the key that unlocks operational efficiency lies in data analysis.

Analyze the Geofencing Data

Relying on data enables you to identify trends and patterns, both positive and negative ones, and to tweak your operations accordingly.

Actionable data is precious, and it’s never been easier to collect and analyze.

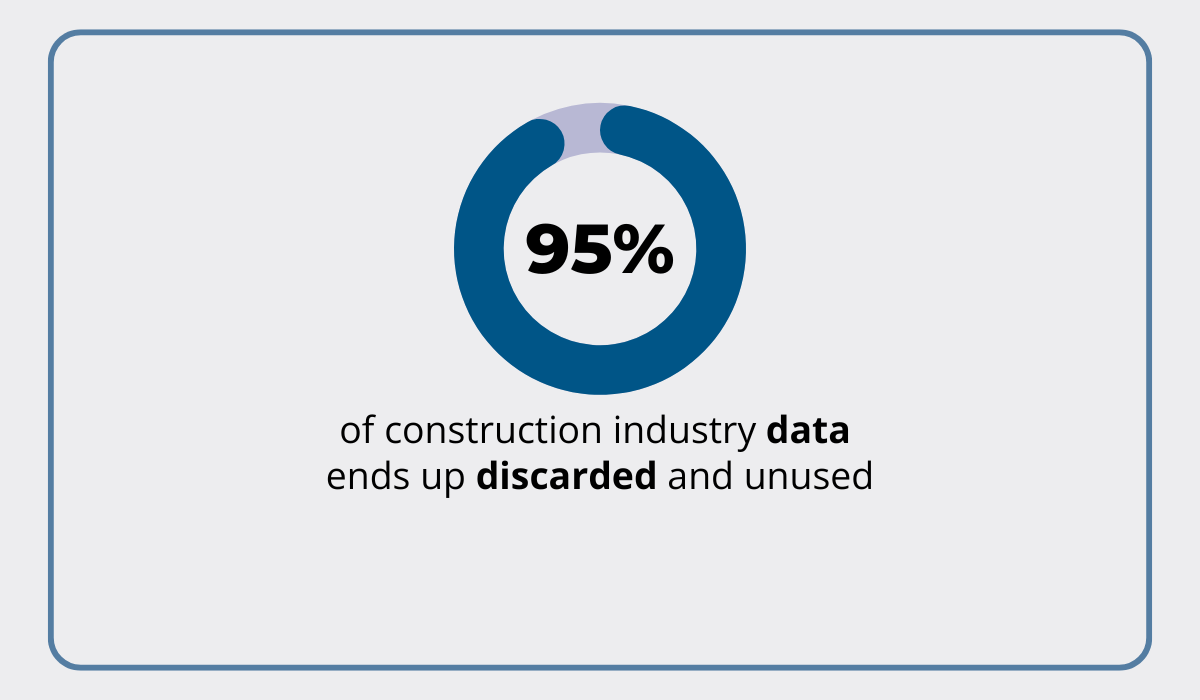

But contrary to it, findings by FMI Capital Advisors suggest a dire problem within the construction industry, one that relates to the astonishing loss of data.

This means that, in reality, key business decisions are made based on less than 5% of collected intel.

A part of it has to do with the industry’s complex, project-based nature, which slows down the adoption of technology and permits substantial reliance on Excel spreadsheets and traditional pen-and-paper documentation.

Software solutions are, nevertheless, creating an impact within the industry, with the immediacy of data and ease of access recognized as big perks.

The thing about data, however, is that an occasional glimpse of the metrics simply won’t do.

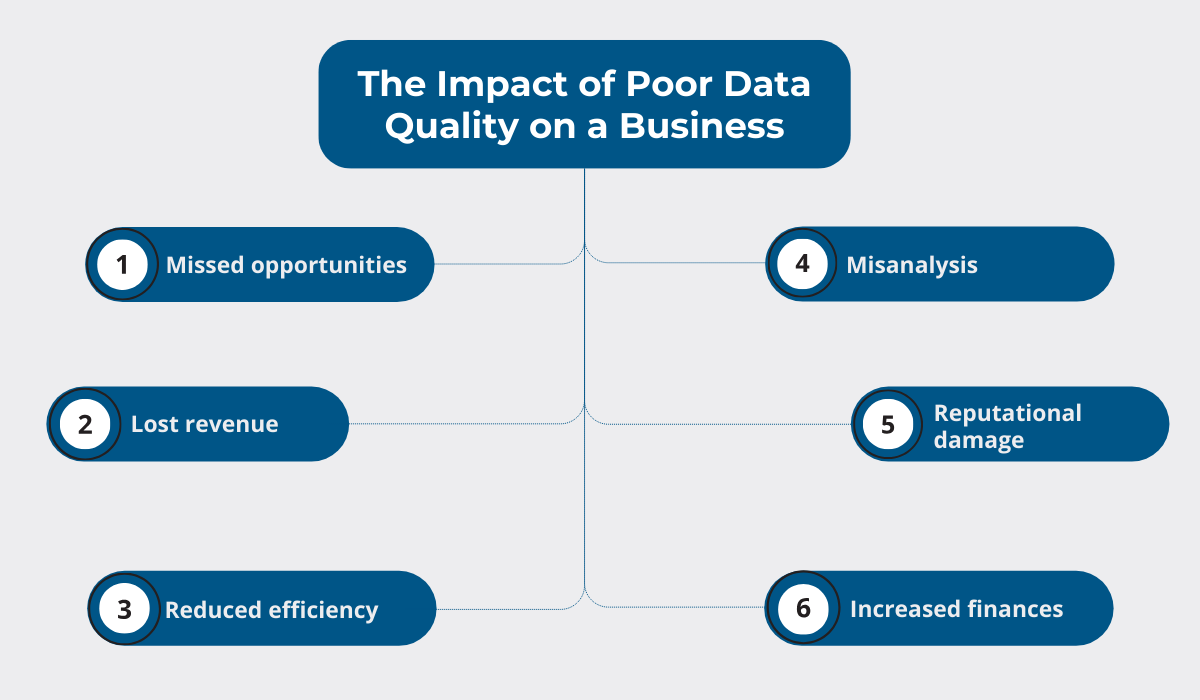

If you stop looking at the data as soon as you notice some slight improvements, you’ll be running your business based on poor data, bringing you back to square one and even risking revenue loss or reputational damage.

Think about it: the only way to keep a firm grasp on numerous processes happening at the construction site is by staying vigilant.

Through regular monitoring and analysis, fleet managers can ensure they’re acting based on fresh, relevant information that can successfully drive strategies that bring about leaps in productivity.

Word of caution though: having too much data can be just as dangerous as too little of it.

Having all that data at your disposal can make it harder to draw conclusions you can act on.

For this reason, it helps to go back to your main objectives and start from there.

Once you’ve determined how your geofencing data relates to different priority areas, move to interpret it bit by bit—the results will follow soon.

Conclusion

Fleet management is a complex endeavor, but it can be streamlined through technologies such as geofencing.

But like with any technology, it’s all about how you use it.

We hope these best practices have shown you how you will make the most of it, so it doesn’t end up being just another piece of technology that hasn’t moved the needle.