No matter how long a construction professional is in the business, it can seem overwhelming to take on a new task, especially if it’s a large and complex project.

Experienced project managers understand that the key to successful, on-time completion is careful planning. A major aspect of this is project scheduling.

With so many options to choose from when structuring a schedule, team leaders are wise to take the time to think about not only how the project will unfold, but which scheduling method to use.

Let’s explore 6 of them.

In this article...

Critical Path Method

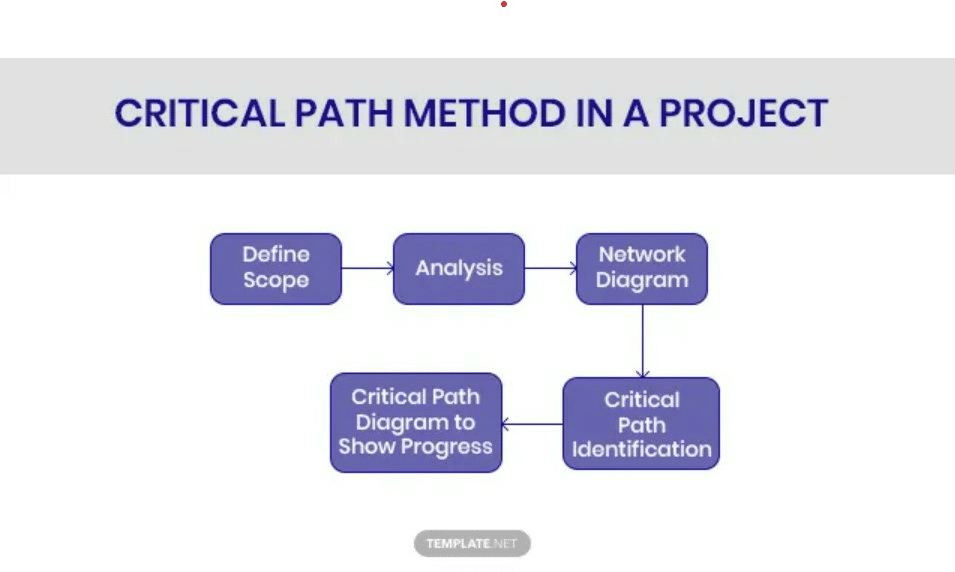

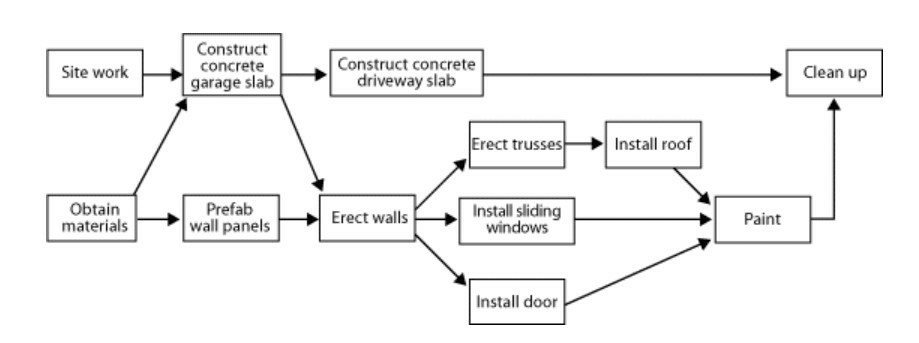

The critical path method (CPM) is sequence-based and relies on the use of a network diagram. As a result, it usually looks like this flow chart:

Project managers focus on the big-picture plan for the project, as well as the structure of the budget.

Studying these foundational aspects of the project gives the contractor an idea of what the restrictions on design and materials are and shape a further course of action.

First the project manager defines the scope of the project. This usually includes estimating the time frame, the size of the workforce, and reasonable weather expectations.

Data generated during this first phase is used in the second, which entails the analysis of the most efficient use of the resources.

This might call for a further breakdown of tasks identified in the first section.

Then, a network diagram—a visual aid to represent their plans to others—is built by using 3D modeling, blueprints, and slide decks.

If more than one contractor is involved, this is the stage at which they usually coordinate their plans.

Critical path identification can now begin.

This section identifies the sequence in which the work will take place; prioritizing is essential here to ensure a smooth flow of task completion.

A critical path diagram is used by all the different contractors to track progress and indicate development. Final deadlines and milestones are usually affixed here.

CPM is a popular form of planning because it is data-based and takes risk management into account.

It allows for cost cutting in the early stages of the project, and by working together, the different members of the team can make suggestions for one another.

However, the many details required in this method can quickly cause it to become unmanageable.

If the project is especially extensive, such as a hospital complex, so much up-front planning might prove especially difficult.

It also does not work for owners who want the flexibility of changing their minds.

Line of Balance Method

The line of balance (LOB) method is useful for projects that rely on repetitive actions, such as constructing homes in a housing project.

This method is good for project managers for whom on-time completion is a special priority.

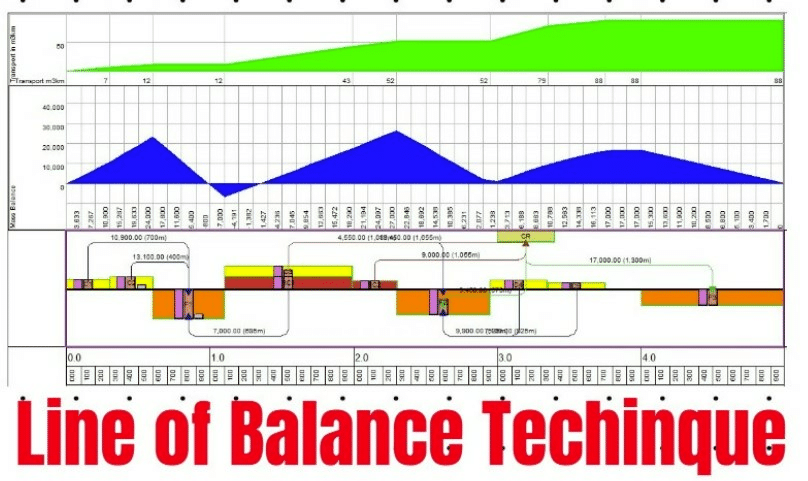

Graphs like this are used to plan LOB projects.

These numbers show the rate at which construction activity must take place in order to meet deadlines. When one part of the graph reflects a delay, the rest of the graph is also affected.

This form of planning is particularly useful if you want to help organize various work crews at multiple sites.

When a builder is in a time crunch, this type of visualization helps to show how adjustments can lessen the impact of a delay.

This method helps to efficiently use crews and materials that are interchangeable. Time and cost analysis is usually easier, since the entire project is visualized.

Modification is automatic with the right software, and project managers can make adjustments on the fly if they see that a schedule requires adjusting.

It is especially useful for projects for the minimization of waiting time between phases or sections.

Forecasting for good team efficiency and materials management is usually easier with LOB.

LOB is not as advantageous for projects that take place in a single phase, or for which each phase is materially different.

Sometimes, LOB depictions make it difficult to discern the big picture of the project.

Resource-Oriented Scheduling Method

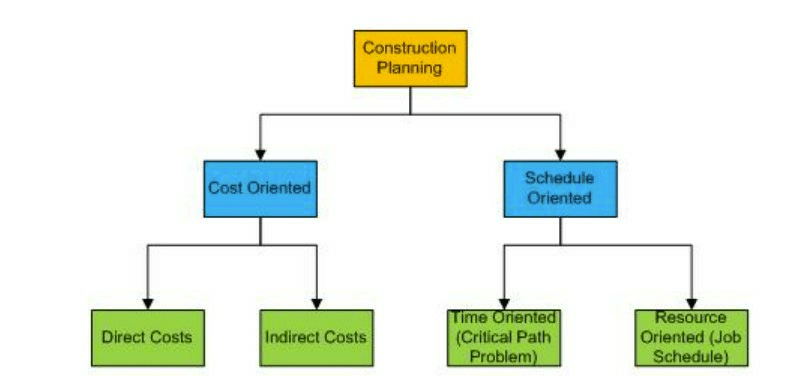

As the title suggests, the resource-oriented (ROS) method focuses on the resources that builders and contractors will use in the project.

This kind of scheduling is good for projects that might experience supply chain delays.

For those seeking an environment-first approach, this method is popular, because it starts with what is available for the project and then structures the rest of the build around that factor.

In other forms of scheduling, teams design the project, then find the resources and try to arrange for them to arrive in place at the proper time.

Here, you can see where ROS falls in contrast to other forms of construction scheduling.

Since it begins with available resources, it can be cost effective even though it’s not necessarily cost-oriented.

It can keep delays to a minimum and is good for teams seeking to improve productivity and milestone-meeting.

On the other hand, ROS is less effective for projects with an abundance of resources, or for more complex builds at which work must happen simultaneously.

ROS demands the careful distribution of equipment. This reduces waste and encourages repurposing, as well as efficient scheduling.

It takes into consideration functional materials, specialized labor, and seasonal material availability.

Knowing which materials will be where at certain times can assist the project manager with the efficient distribution of resources.

Quantitative Scheduling Method

This form of scheduling, also known simply as Q scheduling, is rapidly gaining popularity in the construction world. It uses advanced data analysis techniques.

Strong asset tracking and the ability to visualize the whole project at once are important parts of Q scheduling.

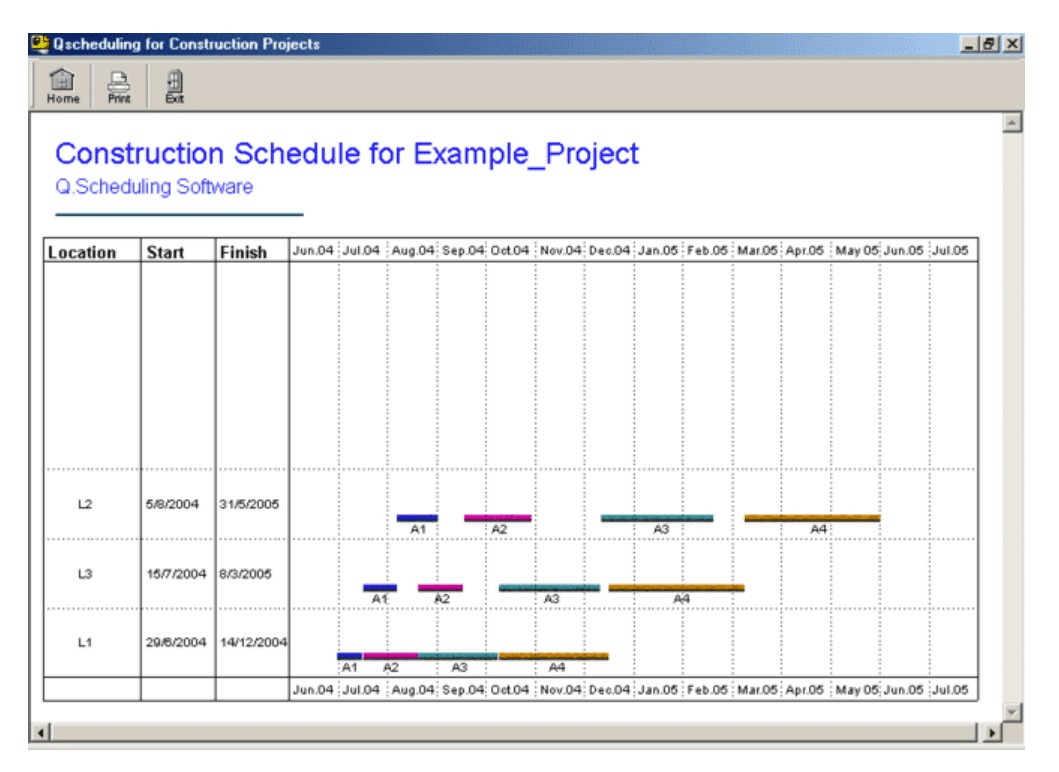

Q scheduling uses bar graphs to depict different aspects of the project. Not only does it schedule equipment distribution, but also material use and management.

In this example of Q scheduling, you can see that the bars are horizontally placed to represent different parts of the project, including locations, timelines, and possible overlaps:

Q scheduling is an offshoot of LOB. It uses more advanced analysis of repeated activities, however, and can tie together costs with scheduling. It is most useful for projects for which volume variation is a factor.

At the same time, Q scheduling, due to its complexity and advanced analytics, is not familiar to everyone in the industry.

In addition, loading data and effectively projecting resource availability can be difficult, so it might not be the best choice for projects in which the contractor is facing a great number of unknowns.

Program Evaluation and Review Technique

Also known as PERT, this is one of the most critical methods currently under use in the construction industry.

PERT focuses on the analysis of all the activities taking place in the project, then subjects them to analysis and evaluation.

This data is then studied to project the time duration for each milestone or activity.

PERT is a good choice for contractors eager to use visuals as a depiction of progress and planning.

The diagram not only shows the project’s order of operations, but also how many resources are to be used.

Some PERT diagrams also show how long these activities will take, or even several steps at once, as well as how to complete them simultaneously.

This example of a PERT diagram shows a plan to build a house. Note how the separate tasks are shown in groups or independent of one another:

In order to use PERT, the project manager must know the deadline for completion. Planning the project then flows backwards from there.

While it’s good for risk analysis, it is not the best choice for indecisive owners. This offers a good overview of the entire project and the various paths to reach the completed building.

However, PERT is not a very flexible form of planning. In case the order of tasks changes in any way, the entire chart requires reordering.

Therefore, PERT is usually best for companies with resources to expend on more elaborate up-front planning.

Gantt Chart Scheduling

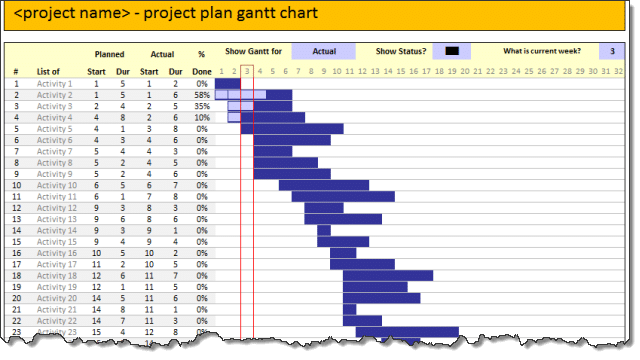

Like Q scheduling, Gantt charts use horizontal bar charts to depict how the project is progressing.

However, unlike Q scheduling, this method shows how one part of the project is dependent upon another.

It shows how each team member and subcontractor must work together in order to avoid disrupting the entire project.

Gantt charts are useful for projects with many moving parts and multiple detail layers. At the same time, Gantt charts do not focus on the materials the workforce requires.

This method also does not consider other resources such as equipment, specialized costs, or risk factors.

Thus, this form of scheduling is especially useful when the team has uncertainty as to which task must take precedence before another.

In the above example of a Gantt chart, you can see how various aspects of the project visually overlap. This is a good way for all team members to keep track of their responsibilities.

Scheduling with a Gantt chart is usually an accurate form of projection. It is typically easy to read and does not require deeply detailed data.

However, if a project involves many simultaneous activities, it can quickly become overloaded and difficult to discern individual parts.

It also forces different subcontractors and team members to agree on the hierarchy of tasks, and some might disagree.

Gantt charts must update constantly, but with advanced asset tracking, available with a solution like GoCodes Asset Tracking, these updates can take place automatically.

Conclusion

Studying the pros and cons of each scheduling method, along with the focus of the project, is essential when it comes to choosing an effective form of organization.

The critical path method uses a network diagram to indicate progress.

Line of balance is best for projects involving repetitive actions, while resource-oriented scheduling begins with the resources at hand for the build, then plans from there.

Q scheduling uses advanced analytics to visualize many aspects of the job at once, while the program evaluation and review technique is useful for depicting the flow of tasks in a job.

Finally, Gantt charts show how subcontractors and consultants can work together for on-time completion.