Creating a successful construction inventory management process is the key to efficiency and control in a world in which the global supply chain is still reeling from the COVID-19 pandemic.

While it’s important to maintain a reasonable amount of control over the management process, it’s just as vital to leave room for flexibility and fast pivoting. This article covers how to do this— and more.

Read on for more information about building a network of reliable suppliers, checking received deliveries as soon as possible, scheduling regular inventory audits, deciding who is responsible for managing inventory, re-evaluating and improving inventory protocol, and purchasing high-quality management software such as GoCodes Asset Tracking.

In this article...

Build a Network of Reliable Suppliers

Building a network of reliable suppliers is the first step in creating a successful construction inventory management process.

Even with thorough planning, construction companies can still experience unexpected inventory shortages.

For this reason, construction companies should maintain a list of dependable suppliers, along with their delivery centers and contact information.

It is imperative to keep in mind that if your company is experiencing a shortage, there’s a good chance that others are also scrambling to find necessary items.

That’s when having a network of suppliers pays off.

Taking the time to build personal connections and relationships with suppliers can sometimes reward you and your company handsomely should your main supplier need to make decisions about where to sell precious materials.

If you have proven yourself a valuable and trustworthy partner who meets invoices quickly and maintains loyalty, your relationship with a supplier could be the deciding factor that ensures you get what you need before your competition.

Good relationships facilitate the exchange of ideas and information, as well as money.

That’s why it’s never a good idea to end business relationships on unfriendly terms, be it through violating contracts or losing your temper.

It generates negative impressions which are often then passed on to others, and a moment of anger expressed several years prior could backfire badly when items are needed from a supplier with whom you’ve been feuding.

In short, cultivate your relationships with your suppliers and you’ll reap multiple benefits.

Check Received Deliveries Right Away

Checking received deliveries for problems is fundamental for preventing issues down the line.

For example, the wrong materials might have shown up, or the right materials could have appeared in the wrong quantities or at the incorrect address.

Ensuring that the right materials were delivered in the right quantities can help prevent inventory shortages caused by incorrect deliveries.

If your own company is involved in redistributing materials, it’s likely easier to use your own fleet and driving force. If these drivers and cargo shift teams are trained to inspect and verify materials, they have a much better chance of delivering quality goods to clients and subcontractors.

In the event that deliveries are accepted at a central hub, it’s even more vital to ensure that what was ordered has arrived undamaged and in usable condition.

This way, the items can undergo transport to the building site without the potential nightmare of opening incorrect or unusable materials just when they are needed most.

Depending upon supplies that are not, in fact, the correct ones, but not discovering this until a crucial moment in a project timeline, is a problem no one wants to face.

In addition, some suppliers might enforce policies stating that once an item is signed for, it is non-returnable and non-refundable.

Taking just a few minutes to check, test, and count a supply delivery could save significant amounts of money, time, and resources.

Schedule Regular Inventory Audits

Inventory audits should take place at regularly scheduled intervals in every construction company.

Construction inventory audits can help provide new avenues for procedural or accounting improvement.

They confirm inventory numbers and can help familiarize staff members with the location of items and give them a better understanding of how the company categorizes them.

An inventory audit, especially one conducted just before beginning to use an asset tracking system, can help to provide an accurate count of project-specific items and establish a baseline for setting re-ordering limits.

An inventory audit can also help confirm what is shown in company records, as well as provide an opportunity to eliminate ghost assets.

A ghost asset is an item that appears in a company’s system, but it is actually missing or unusable.

Ghost assets can incorrectly account for 12 to 25% of a company’s inventory.

If inventory is received and delivered in narrow time margins, that incorrect information could quickly cause a major mishap on any number of jobs.

Having an incorrect idea of how much inventory is actually usable invites a surprise shortage in the event of a snarled supply chain or missed delivery.

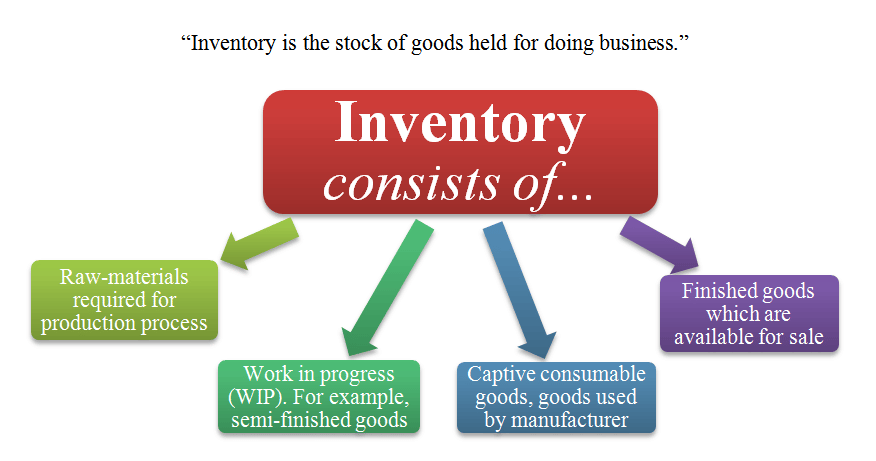

Before you schedule and begin your audit, it is worth the time and effort to first establish what your company considers inventory.

Is it just raw material, or does the term encompass pieces that are partially assembled in-house? What kinds of materials?

This chart can help you with sorting inventory items:

Leaving inventory audits to “when I feel like it” or “when it seems like something is wrong” is almost as detrimental as not conducting audits at all.

Irregular, sporadic audits cannot provide a reliable baseline or reveal inconsistencies that could flag a problem in the company’s supply flow or finances.

What is more, they open the door to inventory mismanagement, fraud, theft, and lack of knowledge about potential material shortages.

Therefore, it’s a good idea to establish an inventory audit schedule and stick to it.

Decide Who Is Responsible for Managing Inventory

Designating inventory management is another integral step in creating a basis for proper inventory management.

A trusted and experienced employee can take on these duties, but it’s good leadership practice to remember to lessen their workload elsewhere or provide additional compensation to reimburse them for the additional inventory-related tasks.

It’s also possible to establish an entirely new position of inventory manager.

Your inventory manager should take charge of at least some of these duties:

- Organizing storage

- Tracking assets

- Distributing items across various sites

- Maintaining good relationships with suppliers and clients

- Communicating with worksite foremen and project managers about current needs

If your company has never paid much attention to inventory management before, it is key to introduce this person’s new role to other employees and establish them as the primary point of contact for inventory-related concerns.

A productive inventory manager is aware of supply chain flows and shifting market needs beyond their own company:

Creating or shifting this role might seem like a significant investment, but the return on investment (ROI) is likely also significant.

Putting a single person in charge of inventory can help prevent the diffusion of responsibility, in which everybody thinks inventory management is someone else’s job. It also saves you from leaving your company’s warehouse in a constant state of confusion because no one is sure who has done what.

Your new inventory manager can focus solely on asset organization and optimization, and that means they can quickly spot abnormalities, devote time to finding advantageous pricing, or attend to delivery problems without leaving the rest of the workforce short.

Purchase Inventory Management Software

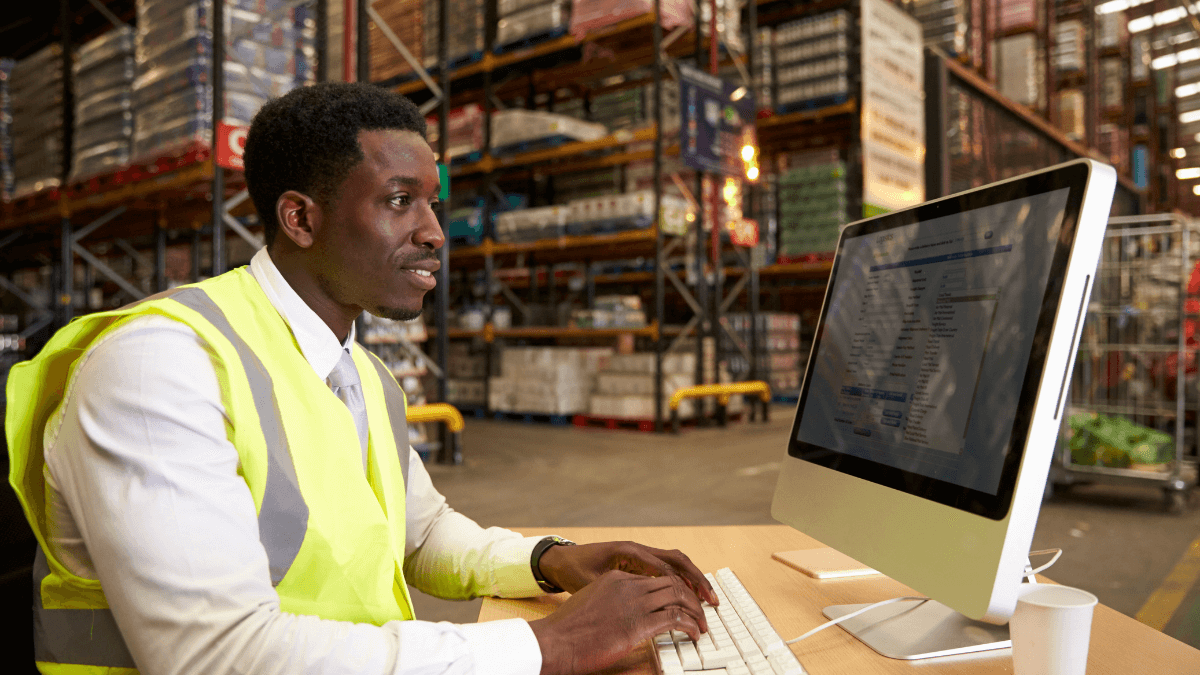

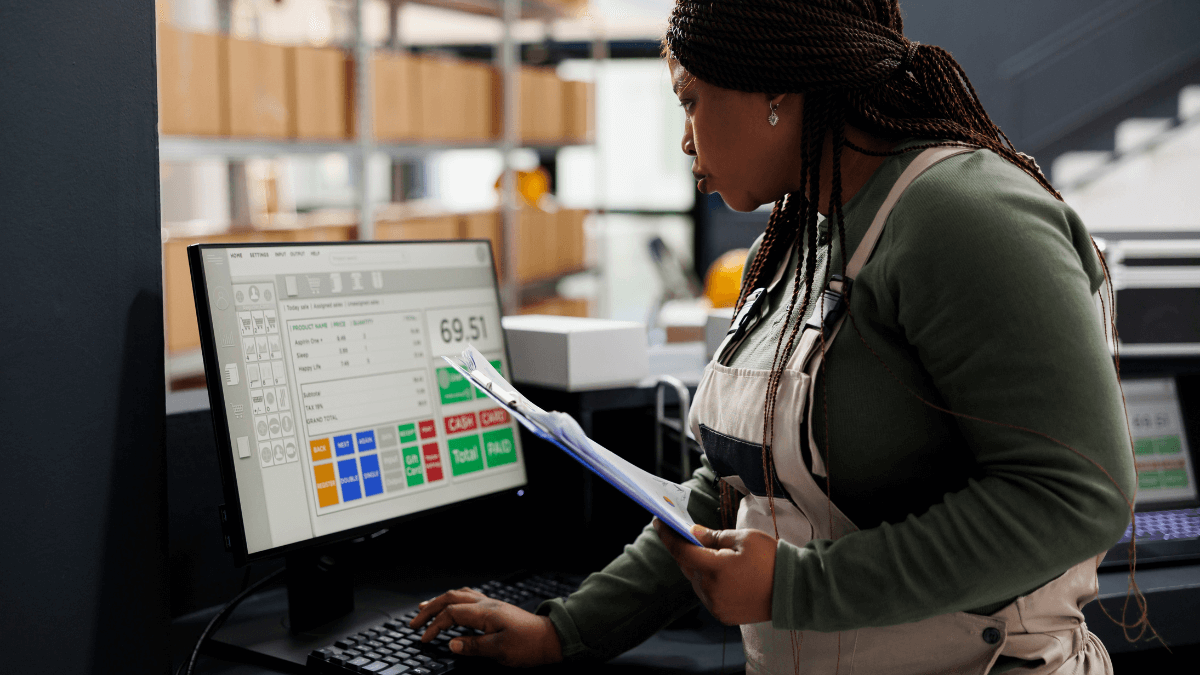

Even the best inventory manager needs a well-integrated system to help manage each asset.

Such software is a must to allow each employee to access and update information to keep inventory data current.

Some construction companies often manage several construction sites at a time, which involves keeping track of a large amount of construction inventory.

Therefore, an investment in an inventory management solution is necessary to optimize the cost and function of each item.

The right inventory management software should allow construction companies to effectively manage all their inventory across several construction projects—even ones that have not yet broken ground.

GoCodes Asset Tracking provides an ideal solution for inventory management and asset control, and it’s available on just about any mobile device.

That means GoCodes Asset Tracking is ideal for quick and accurate audits. Here’s a sample of what a GoCodes Asset Tracking screen can look like with a single scan:

Notice how much information is packed into this easy-to-digest display. In addition to the basic function of keeping track of what is present in a certain location, GoCodes Asset Tracking can also store and present the following information:

- Where an item is located in a large warehouse

- How many specimens of that item are present, as well as which are reserved by someone

- Which assets are in the field, and where

- Provision of GPS location on item’s last scan

- Maintenance information

- Warranty terms

- Employee check-in/check-out

- Contact information for the asset’s supplier

- Item serial number, photo, model number, VIN, etc.

- Warnings at predetermined low inventory levels

This last item is perhaps most important for the construction industry, especially when its entire supply chain is in upheaval.

Early warnings that the supplies of a must-have item are low can provide plenty of time to source replacements.

This can prevent submitting to expensive markups by having the time to buy in bulk.

In addition, it helps avoid paying extra fees for rush delivery, or, worst of all, falling behind on a job because the right kind of concrete hasn’t arrived at the site yet.

Keep Improving Your Inventory Management Process

If you have followed these suggestions, once it’s established and integrated within your company, your inventory management process should hum along nicely.

However, it’s a mistake to think that even well-flowing inventory management processes couldn’t benefit from scrutiny and refinement.

By continuously monitoring their inventory management process, construction companies will inevitably discover areas that could be improved in order to make the system more efficient.

The employee who takes charge of your inventory management process should remain educated on effective leadership skills, continuously maintaining attention to detail and learning new strategies for navigating an always-fluctuating supply chain.

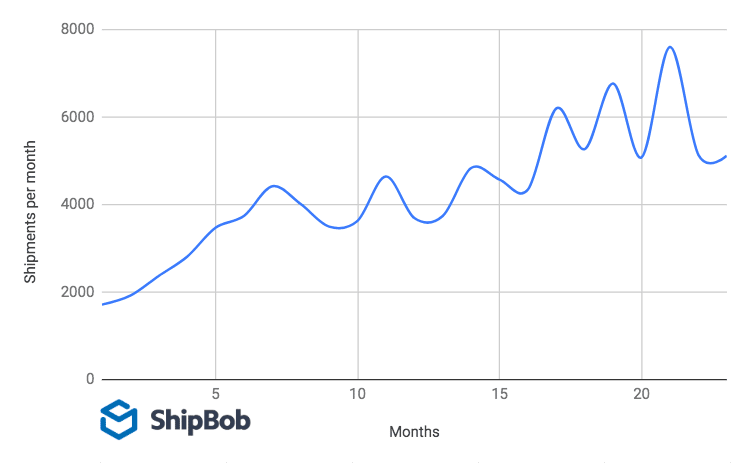

Sometimes the improvements you should make are suggested by the data your asset tracking system collects.

For example, the chart below shows that project and consumer need for a certain type of inventory fluctuates at various points throughout the year. It is useful in predicting which items are needed and when.

Revisiting the process your company uses to keep track of inventory shifts can help you to better meet evolving needs, market conditions, or company growth.

For example, if your company buys an additional warehouse ten miles away from the current one, a change in inventory flow and distribution is necessary.

Conclusion

Creating a successful construction inventory system can result in a calmer, more productive workplace that is more apt to meet project milestones.

It involves building a network of reliable suppliers, checking and verifying deliveries immediately, undertaking inventory audits on a schedule, assigning an employee to manage inventory, using a robust inventory management software system, and continually seeking ways to improve the process you have implemented.