Owning your construction equipment is no longer a must.

More and more construction companies rent equipment because it’s the more cost-effective solution, especially for short-term or specialized needs.

Chances are, you’ve rented construction equipment before. But how well do you know the full range of equipment available for rent?

Today, we’ll explore eight unlikely rental options to help you close projects on time and within budget.

If you want to enhance your decision-making and consider every alternative, this article is for you!

In this article...

Skid Steer Loaders

Skid steer loaders are versatile champions of construction equipment.

These machines can help you complete core earthmoving tasks like digging, trenching, and excavating while fitting in tight spaces.

One of the biggest benefits of renting a skid steer loader is the flexibility it offers.

You can easily adapt the machine to different tasks by using various attachments, making it a budget-friendly choice for projects with diverse needs.

However, to make the smartest decision, you need to be aware of the different skid steer loader types available on the market.

For example, there are wheeled and tracked skid steers, each suitable for different types of surfaces and terrains.

Plus, there are two distinct lifting mechanisms to choose from: vertical lift and radial lift. Your choice here will impact the efficiency of:

- loading

- site development

- material handling

- digging and backfilling

For a more detailed breakdown of the differences between vertical and radial lift, check out the video below:

You’ll also want to look at the skid steer loader’s frame size.

The classification is based on the machine’s Rated Operating Capacity (ROC) and horsepower (HP), and generally goes as follows:

| Small Frame | ROC between 1,500 and 1,750 pounds, with up to 50 HP |

| Medium Frame | ROC between 1,750 and 2,200 pounds, with 50 to 70 HP |

| Large Frame | ROC of at least 2,200 pounds, with over 70 HP |

Frame size affects not only rental costs but also the compatibility of attachments, which can either be rented along with the skid steer or separately.

Keep in mind, however, that skid steers’ small size and versatility make them a frequent target of equipment theft, so be sure to keep a close eye on your machine.

Scissor Lifts

Scissor lifts offer construction businesses much-needed flexibility, providing vertical access for both indoor operations and outdoor heavy-duty work.

Renting these compact aerial work platforms is a smart choice because they can replace bulky scaffolding or ladders, making overhead work much more efficient.

Today’s scissor lifts come in various models and sizes, including:

- rough terrain scissor lifts

- hydraulic scissor lifts

- electric scissor lifts

- diesel scissor lifts

As always, the key is to pick the model that fits your project needs and unique circumstances.

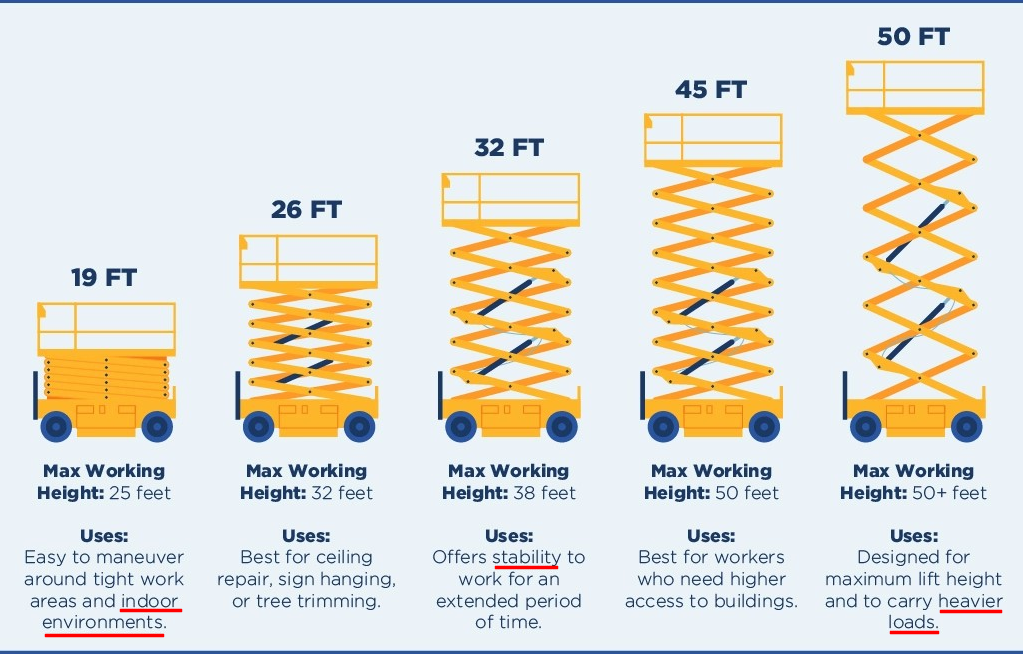

You need to consider a couple of features, but let’s start with the most obvious one: scissor lift size.

Here’s an overview of different working heights and their use cases:

For example, you likely won’t need maximum lift height if you’re going to be using the mobile platform for indoor construction or maintenance tasks.

But, when working outdoors, with a heavy load, it might be ideal.

Of course, pinpointing the right vertical range is only a part of the equation.

You also need to factor in load capacity.

In other words, your platform must safely support the necessary number of workers and materials to prevent accidents or equipment failures.

Finally, your working environment dictates the most appropriate type of scissor lift based on its drive system, power source, and overall maneuverability.

Once you have all the insights, you’ll be ready to move in the right direction with your rental, maximizing efficiency while ensuring safety.

Road Graders

Road or motor graders are needed for a wide variety of construction, roadworks, and mining tasks, from spreading and fine grading to site clearing and even snow removal.

That said, their primary function is surface leveling and creating the ideal grade for future roads.

One reason why companies love renting this machine is that it helps them avoid huge upfront investments, which can be crippling for anyone, especially smaller businesses.

In fact, motor graders are some of the largest and most expensive types of construction equipment, with even used graders averaging close to $150,000 apiece.

Renting is a more affordable solution, making it easier to access these vital machines.

Plus, newer graders are equipped with telematics and technology that enables precise grading and leveling, as demonstrated in this video:

Renting, in this case, allows you to take advantage of the newest technology, without breaking the bank.

So, what kind of road grader should you choose?

The two main types of graders are classified based on their frame type:

- rigid frame road graders

- articulated frame road graders

Your initial choice here depends on the kind of grader precision and maneuverability you need on the job.

As the name implies, the rigid frame type is more standard and offers less precision while the articulated frame motor grader can work effectively even in tight spaces.

Beyond frame type, graders also come in different size categories to suit specific jobs:

| Small (80-150 HP) | For small construction jobs and landscaping projects |

| Medium (150-300 HP) | For larger jobs on highways, roads, and construction sites |

| Large (above 300 HP) | For residential, commercial, and other heavy-duty operations |

Once you’ve identified the right size category, it’s also worth considering some other factors, like:

- blade size

- tire type

- whether the terrain demands a 4-wheel drive system

These can help you narrow down your choice even further.

The bottom line is this: graders are crucial for a range of construction projects.

Therefore, choosing the right rental option is sure to boost your productivity without the risk of overspending.

Trenchers

Trenchers are another type of earthmoving equipment, widely used for installing irrigation systems, utility lines, or drainage solutions.

Before you start with any trench digging, however, you need to consider a couple of things, including:

- project size and scope

- trench depth and width

- soil type and conditions

These parameters will help you decide between walk-behind/manual trenchers or ride-on trenchers.

Manual trenchers are perfect for laying phone lines, making landscaping modifications, or other light-duty tasks that require only shallow cuts.

On the other hand, ride-on trenchers are more powerful, helping you prep difficult terrain and dig deeper trenches.

Both types can be outfitted with either a toothed metal wheel or chain/belt with digging teeth, as shown in the image below.

The toothed wheel attachment enables you to cut narrow trenches, but if you need longer and deeper grooves, chain trenchers are the way to go.

Additionally, you can use micro trenchers, which are ideal for specialized fiber-optic installations, and enable businesses to cut extremely narrow trenches in urban environments.

All in all, even if you already own a trencher, renting additional or specialized equipment can provide the flexibility and scalability you need, without committing to a long-term investment.

Concrete Pumps

Concrete pumps are crucial construction tools that help quickly transfer freshly mixed concrete to the worksite as needed.

The video below outlines different pump types, along with their applications.

Essentially, making the optimal choice starts with assessing your project needs, including the volume of concrete required, the distance to be covered, and the type of mix being used.

For instance, construction businesses that need to reach high-rise structures or difficult-to-access areas should opt for powerful boom pumps.

In contrast, line pumps work great for projects that require more maneuverability and flexibility.

However, zooming in on key specifications such as pump capacity and reach is essential to avoid any rental mistakes and ensure you’re getting exactly what you need for your project.

Here are some factors to consider:

| Pump Capacity | Determines pumping efficiency, typically ranging from 15 to 200 cubic meters of concrete per hour. |

| Max Horizontal Reach | Signals the pump’s maximum reach across the job site which falls between 50 and 1,000 feet. |

| Max Vertical Reach | Determines the pump’s maximum reach on higher levels which falls between 30 and 300 feet. |

| Power Source | Affects how mobile and suitable the pump is for different job sites. Can be electric or diesel-powered. |

| Boom Size | Impacts flexibility and maneuverability around on-site obstacles. |

Overall, concrete pumps are a great way to save labor and time, especially for large-scale pours.

Renting allows you to adjust to different project sizes without committing to a purchase, ensuring you have the right tools for the job.

Construction Rollers

Road rollers are a type of compaction equipment designed to compress and smooth surfaces, ensuring the necessary structural integrity, stability, and overall longevity.

Unlike versatile skid steers, construction rollers are highly specialized, fitting specific compaction needs.

Since one type of roller can’t handle multiple compacting-related tasks, renting emerges as a practical solution to address different project needs.

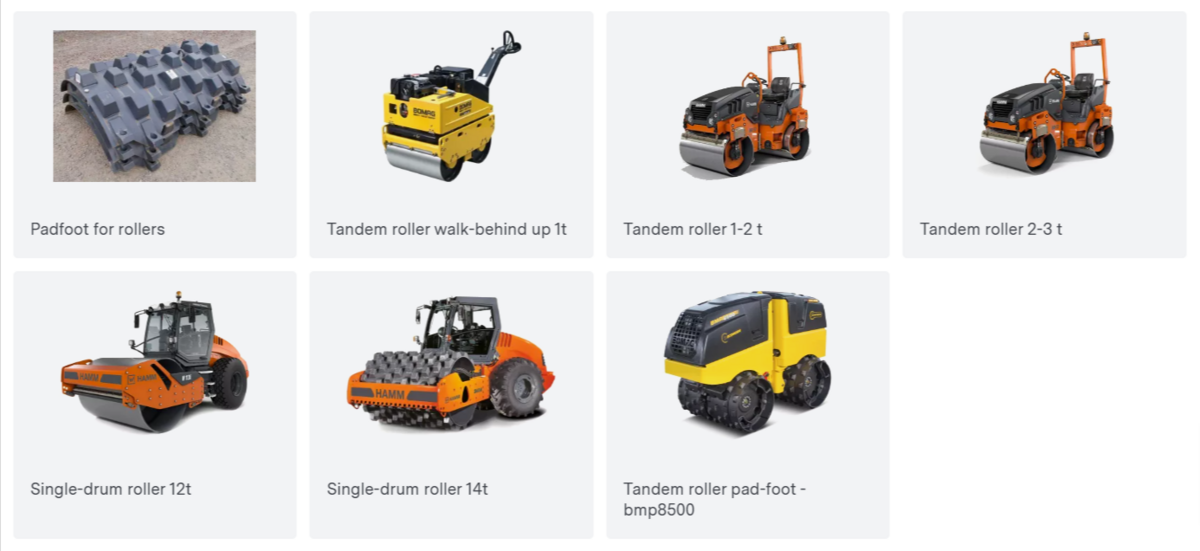

So, what are your options when choosing a road roller?

Here’s a quick breakdown of different alternatives:

Much like trenchers, rollers can be divided into walk-behind and ride-on models, but the categorization depends primarily on their compacting mechanisms and capabilities.

Broadly, we can define 6 distinct types:

- smooth wheel or static rollers

- pneumatic rollers

- cylindrical rollers

- vibratory rollers

- sheepsfoot

- grid rollers

Each of these has its own advantages and disadvantages, as well as specific use cases.

For instance, cylindrical rollers are very lightweight and drawn by hand, which is why they have few uses outside of small and private projects.

Smooth wheel rollers, available in single-drum or double-drum variations, are ideal for flat terrain but can also be equipped with studs to boost efficiency on more difficult soils like clay.

Vibratory rollers appear nearly identical to the previous group but include a specialized vibrating component that enhances structural integrity and is well-suited for crushed rock or gravel.

Essentially, terrain conditions and project duration are the biggest factors impacting your choice of roller.

Therefore, as long as you keep them in mind there’s no chance you’ll be making wrong choices.

Asphalt Milling Machines

By removing the top-most, damaged layers of asphalt, the asphalt milling machines help resolve issues related to aging asphalt, from emerging cracks and uneven surfaces to bleeding.

These machines are essential for restoring the texture and integrity of asphalt surfaces, but only if you choose the right type of milling machine.

Once again, project requirements play a major role in the decision-making process, particularly when it comes to choosing the size class of the machine.

Kyle Hammon, who worked as Roadtec Inc.’s product manager for mills for six years before his promotion, elaborates.

Although Hammon’s advice was geared toward equipment owners, understanding the job requirements will ensure you’re matching the machine with the work needed when renting too.

For example, while a compact machine might suffice for smaller patching jobs, full asphalt replacement calls for a larger, more powerful machine.

Here are a couple of figures to guide you:

| Key Dimensions | Smaller Jobs | Larger Jobs |

|---|---|---|

| Horsepower | 100-200 HP | 500-800 HP |

| Machine weight & dimensions | 350mm-1200mm (width) / 110mm-300mm (depth) | 2000mm-2200mm (width) /330mm-350mm (depth) |

| Milling drum | 27–35 inches | 48–72 inches |

Another important consideration is the traction system that guarantees you’ll maintain stability and maneuverability during all operations.

For instance, machinery with advanced traction systems, like those equipped with rubber track pads, boost performance on challenging terrain and reduce damage to the surrounding pavement.

Only by accounting for all these key elements can you ensure you’re making the best possible renting decision.

Conclusion

Renting the right equipment at the right time can be a game-changer.

It goes beyond accessing overlooked types of machinery—it’s about empowering your business to tackle all challenges as efficiently and cost-effectively as possible.

Having the full picture of all your rental options ensures you can adapt to unique project demands while building foundations for long-term growth.

So, embrace these possibilities and see how quickly your next project benefits from smarter equipment rental choices!