If you want to carry out a construction project on time and within budget, you must be prepared.

One crucial aspect of this preparation is planning all your construction costs.

However, construction cost planning can be quite challenging, likely leaving you with a myriad of questions.

What to include in the cost plans? Are we talking about cost estimations or actual budgets? What type of costs are there to plan? Do I have to track all cost deviations manually?

And many more.

Truth be told, it’s a lot to take in. But we’ve got you covered.

Today, we will answer all these questions and prepare you to plan your construction costs wisely.

Without further ado, let’s start.

In this article...

What is a Construction Cost Plan?

A construction cost plan systematically breaks down all project costs, encompassing materials, equipment, labor, and indirect expenses.

Unlike cost estimates—which are based on limited data in the initial project planning stages and offer rough predictions—cost plans, typically prepared by a consultant, provide evolving and more precise estimates as project details emerge.

So, the cost plan is, in fact, a dynamic document that changes as the project progresses.

This Reddit user explains the difference between the two very vividly:

Cost estimations are like watching a coastline from space, while cost plans take into account all the details when zooming in on the project.

But keep in mind that both are necessary for better financial management of your projects!

At this point, we also have to note the role of a budget.

In essence, a budget is a predetermined amount set by the client for a specific project period, acting as a limit for expenditure.

This budget should be established early, grounded in evidence, and realistic to avoid later complications.

Typically, the process starts with the cost plan being developed by a consultant, providing evolving estimates of likely actual costs.

Based on this information, the client then sets the budget, outlining the available funds for the project.

Why Do Construction Professionals Need It?

The answer to this question is quite straightforward.

Construction professionals need cost plans because they are the financial backbone of a project.

They prevent money headaches by providing a clear path for allocating the right amount of resources to materials, labor, equipment, and other essential aspects during the lifespan of a construction project.

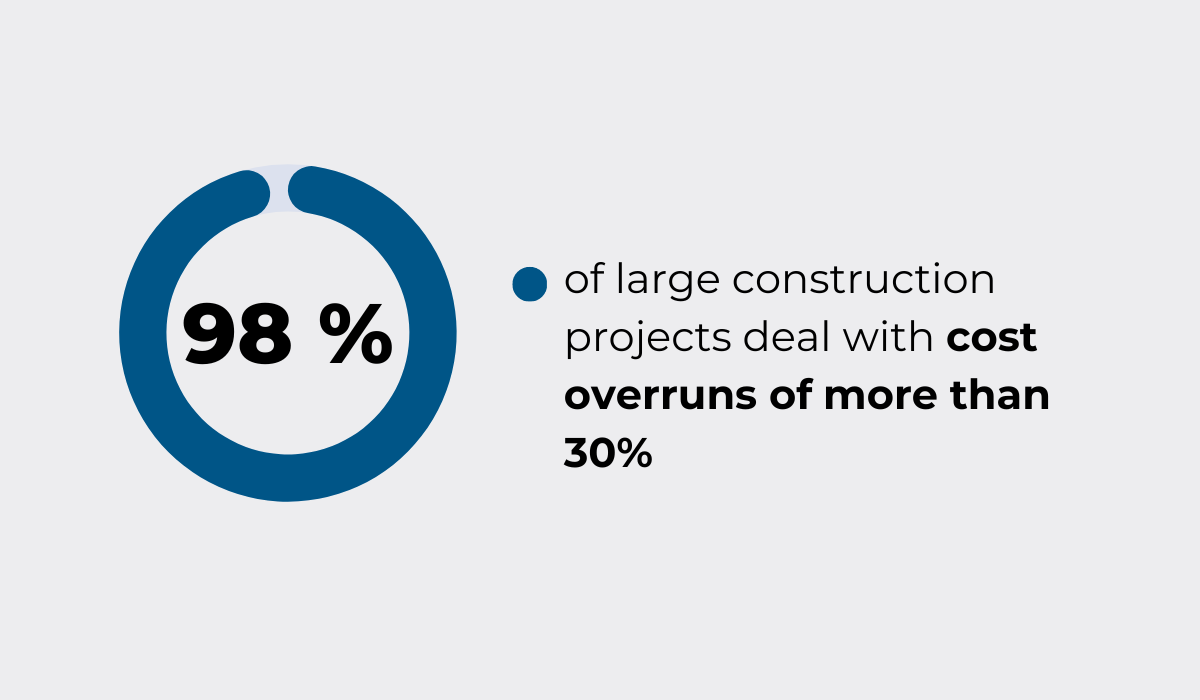

According to McKinsey, 98% of big construction projects suffer cost overruns.

This alarming statistic should already indicate that better cost planning is needed in the construction industry.

And in fact, meticulous cost planning is the way to avoid such significant cost overruns.

When carefully breaking down all expenses during all project stages, you can set more realistic budgets and financial limits to prevent these potential cost overruns.

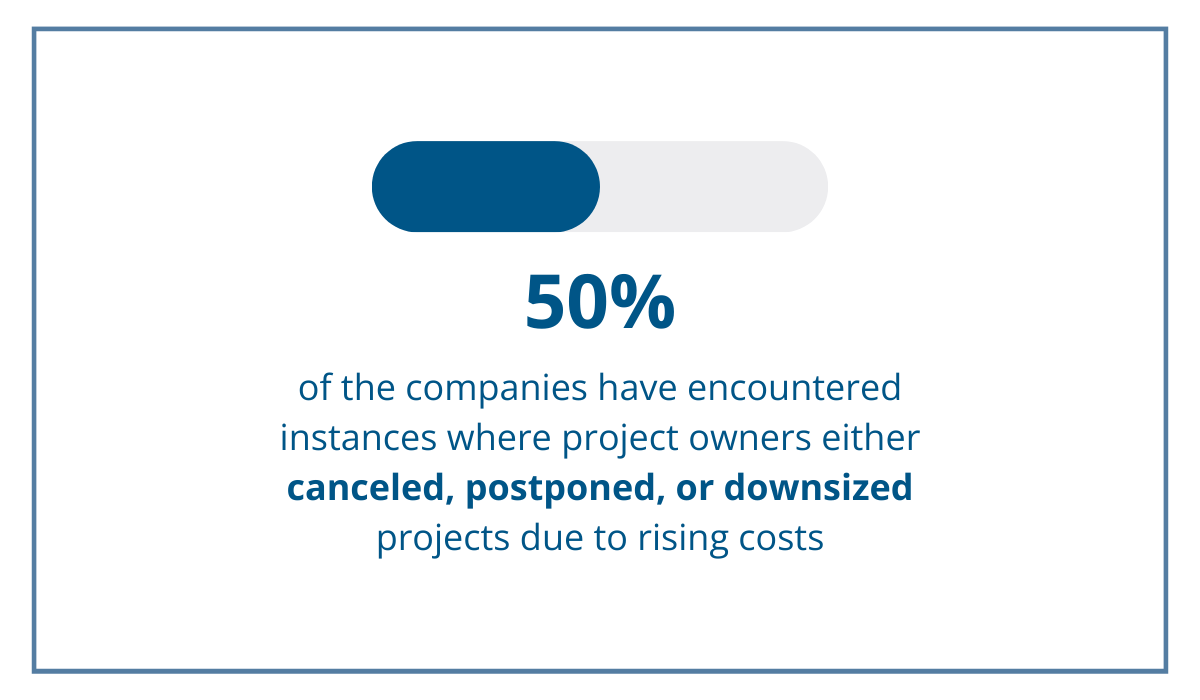

What’s equally concerning is the fact that 50% of firms have experienced owners canceling, postponing, or scaling back projects due to increasing costs, according to the Associated General Contractors (AGC) report.

When cost plans are done in-depth and adjusted as the project progresses, you can make more informed decisions and avoid this from happening.

Andrew Kleimola, director of estimating at Ansver Advisory, points out the importance of risk management within cost planning.

Cost plans involve a detailed breakdown of anticipated expenses at each project stage, allowing you to identify and understand potential financial risks spanning from supply chain disruptions, labor shortages, unexpected regulatory changes, and fluctuations in material costs.

Anticipating these unforeseen expenses also enables the inclusion of contingency amounts in the budget.

By having these funds available, you can manage and mitigate unforeseen issues without disrupting the overall budget and maintain financial stability and project progress.

All in all, from project managers fine-tuning details to architects planning designs within budget constraints, the construction cost plan is an indispensable tool that keeps everyone on the same financial page.

Are There Different Types of Cost Plans?

Yes—there are several different types of cost plans that serve different purposes and are also developed during different stages of a construction project.

Today, we will explain the three types of cost plans that every construction project should make, no matter the size and scope, as these plans will help you clearly define the budget and stay within it.

Preliminary Cost Plan

This plan is developed in the early stages of a project when detailed information is limited.

It provides a rough estimate to help stakeholders understand the potential financial scope and decide on the feasibility and viability of the project in the first place.

Also, regulatory authorities commonly ask for this plan to evaluate the project’s financial feasibility and stability and issue approvals.

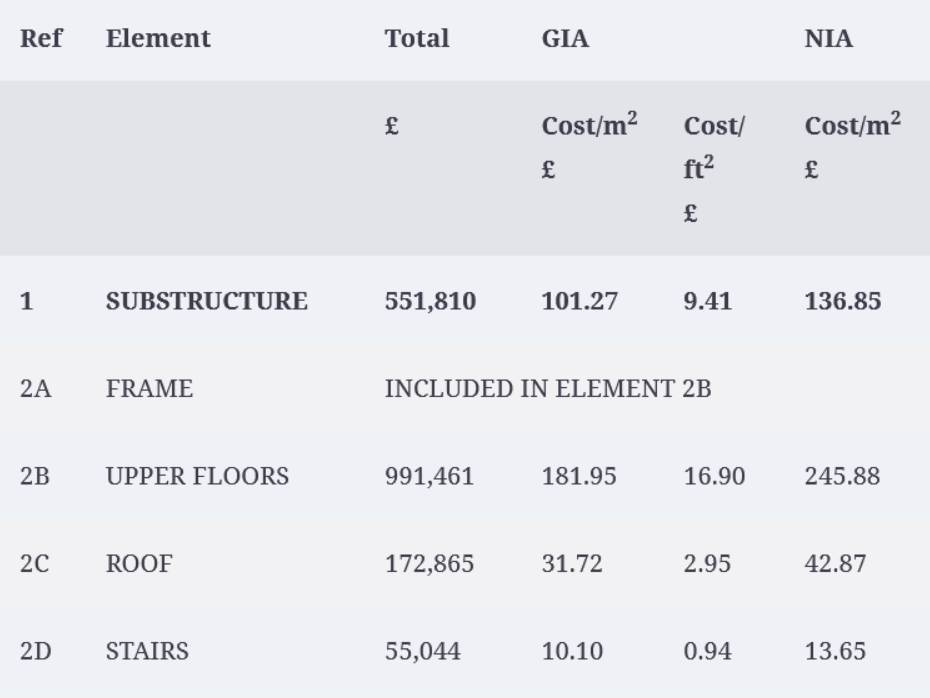

Elemental Cost Plan

As the project progresses, an elemental cost plan breaks down costs into distinct elements, like foundation, structures, interior finishes, etc., giving a more detailed estimate for each component.

It allows for a more granular understanding of where the money will be allocated.

Such cost plans are essential for easy tracking of expenditures throughout the project life cycle, identifying areas for potential overruns, and using cost control measures.

Detailed Cost Plan

Developed as the project becomes more defined, a detailed cost plan involves a precise breakdown of costs for materials, labor, equipment, and other components.

Based on this information, you can procure materials and services and manage contracts per the budget.

In essence, a detailed cost plan is used for precise budgeting and financial management.

As you can see, each type of cost plan serves a specific purpose in the project lifecycle, adapting to the level of detail and information available at different stages.

The transition from a preliminary to a detailed cost plan reflects the evolving understanding of the project’s requirements and allows for more accurate financial planning.

What is Included in Cost Plans?

Cost plans should factor in many elements, from the cost of construction materials and labor needed to complete the project to the administrative costs and contingency funds.

These costs can be put into a few categories, so let’s go through each.

Direct Costs

Direct costs are what their name suggests: expenses directly associated with the project’s execution.

These costs encompass material costs, such as concrete, steel, and wood, the wages and salaries of the labor force involved in the construction, alongside the expenses related to equipment and machinery.

These costs are also the most substantial project costs.

For example, renting an excavator can cost up to $3,500 per day, and what about all the other tools and materials?

To learn how to reduce your direct costs by reducing equipment costs, you can explore our article 5 Ways to Reduce Equipment Costs.

Indirect Costs

Indirect costs are indispensable for the overall success of a construction project, covering essential expenses that may not be directly linked to a specific construction task.

Overhead costs, including utilities, office space, and administrative staff salaries, are part of these indirect expenses.

Administrative costs related to project management, necessary permits, and insurance expenses also fall under this category.

To gather this data, you should review your historical financial records, lease agreements, and administrative staff payroll details to estimate such costs.

Profit Margin

The profit margin is essential for financial sustainability and represents the desired return on investment for the project.

This margin supports a construction company’s operations and growth.

You can derive data on profit margins from financial projections, industry benchmarks, and considering the company’s financial goals.

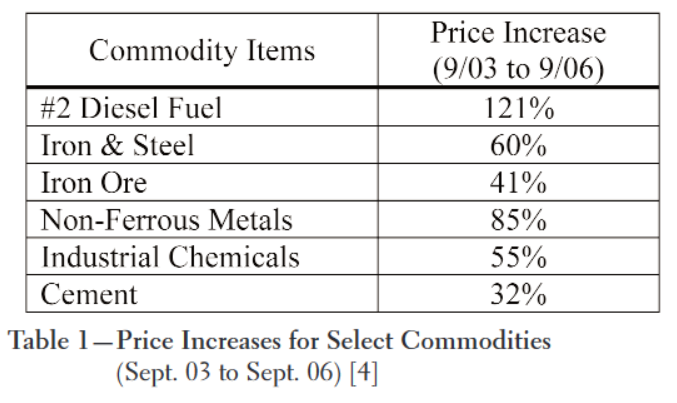

Escalation

The Association for the Advancement of Cost Engineering (AACE) defines escalation as changes in price levels driven by underlying economic conditions.

As construction costs are influenced by factors like high demand, labor shortages, profit margins, and inflation, understanding and monitoring escalation is crucial for accurate cost planning.

Data for escalation can be gathered through economic forecasts, industry reports, and a careful examination of historical trends in price drivers.

Contingency

And last but equally important are contingency funds.

Contingency is a safety net set aside to address unforeseen events or changes in project scope, providing a proactive approach to risk management.

Included as a percentage allowance in early-stage cost plans, they are determined based on intuition, past experience, and historical data.

Gathering historical data on similar projects and consulting with experienced estimators can aid in determining appropriate contingency percentages.

To sum up, a comprehensive cost plan, factoring in direct and indirect costs, profit margins, escalation, and contingency funds, will help you prepare for project execution and completion within budget.

Which Technology Helps With Construction Cost Planning

By now, you can see that cost planning is quite challenging.

From collecting all the data on direct and indirect costs, going through historical data and comparing benchmarks to developing different cost plans, you probably wonder—do I have to do all this on my own?

Luckily, the answer is no.

There are several tools that will help you with construction cost planning.

Let’s explore the options.

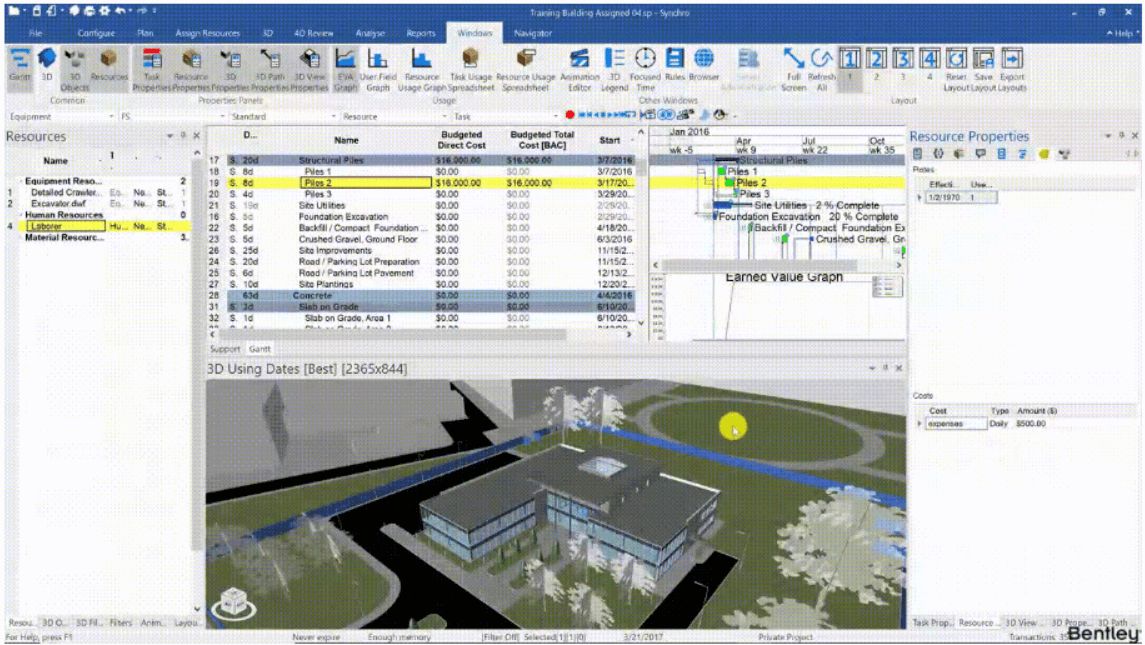

Building Information Modeling (BIM)

Building Information Modeling (BIM) transforms traditional building design from 2D drawings to an extensive 3D model, considering time as the fourth dimension and cost as the fifth.

In terms of cost planning, BIM directly extracts detailed quantity information from the digital model.

In other words, this tool precisely determines the amount of material you need for a construction project by examining the digital model of the building.

This minimizes errors in manual calculations of required materials, allowing for more precise budgeting.

Overall, integrating BIM brings about a more streamlined and efficient approach to cost planning.

Construction Cost Estimating Software

Construction cost estimating software streamlines cost estimation for construction projects by automating calculations and providing access to current material and labor costs.

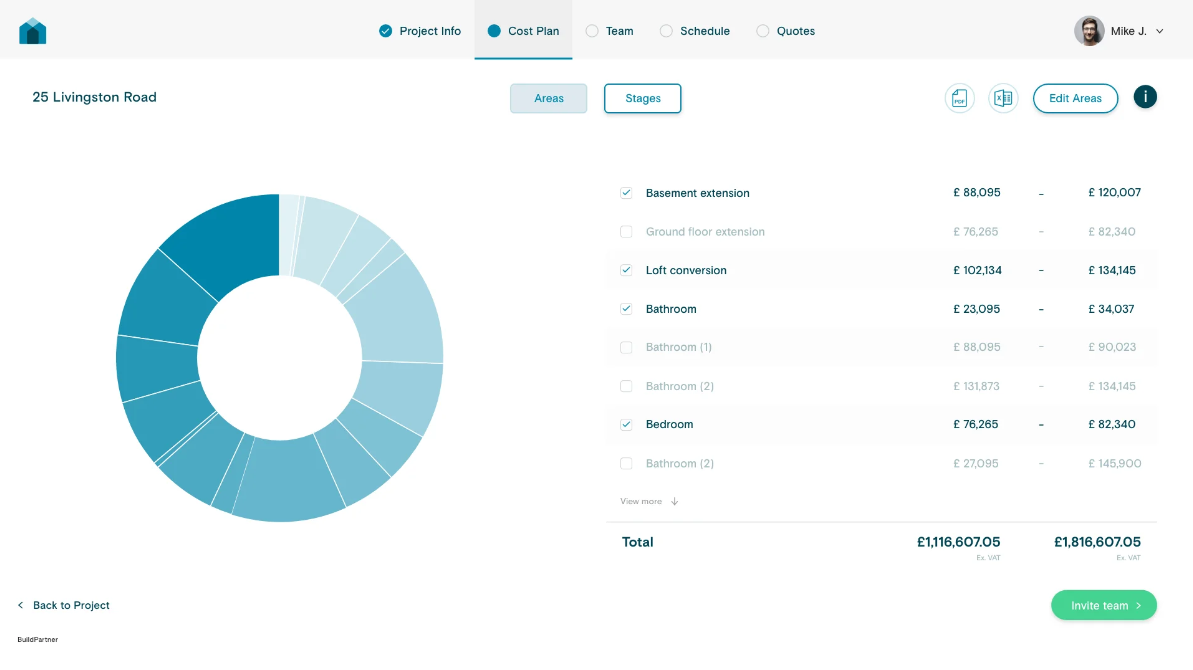

BuildPartner’s software, for instance, automatically generates precise cost plans based on the latest UK material costs, benefiting architects and builders by saving time and effort while ensuring an accurate and up-to-date cost plan.

Usually, construction cost estimating software also facilitates quantity takeoff, manages bids, tracks costs in real-time, and offers integration with BIM—all these support optimized cost planning.

Real-time Project Cost Tracking Tools

While the first two solutions can already help you in the initial planning phase, cost-tracking tools will come in handy later during project execution.

With such tools, you can track your project costs in real time, which means you can detect cost variations between planned and actual costs on time.

As a result, you can take corrective actions, which is crucial for staying within budget and ensuring the overall financial health of the project.

All in all, utilizing real-time project cost tracking tools provides transparency and helps make informed decisions to promptly address cost-related issues.

Conclusion

Developing detailed construction cost plans is crucial for adequate project preparation, even though it may seem time-consuming and challenging.

However, with the right tools and a comprehensive understanding of the various costs to consider, cost planning can become much more manageable and streamlined.

Remember—a detailed cost plan enables accurate resource allocation, prevents potential overruns, and ensures the overall health of the project’s budget.

So, make it a priority in your construction company!