Key takeaways

- Design flaws, management missteps, and political interference made airport construction a notorious example of mismanaged projects.

- Projects like the Sydney Opera House and the Montreal Olympic Stadium went far over budget due to poor planning, complex design requirements, and external factors.

- Each case highlights how the intricate balance between architectural vision, public scrutiny, and efficient management is critical.

Cost overruns have a devastating effect on the whole course of the project budget, as well as your bottom line.

The worst part is that they’re bound to happen sooner or later.

But there’s good news: with experience, managing cost overruns and reducing construction risks becomes easier.

What’s more, many lessons can be drawn from the challenges faced by well-known construction projects.

Today, we’ll explore some of the most significant cost overruns in construction so you can learn from others’ mistakes.

Let’s start with the first cautionary tale.

In this article...

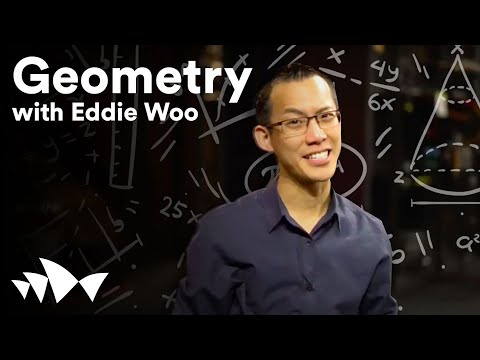

Berlin Brandenburg Airport

Initially envisioned as a project that would revitalize unified Germany after the war, the Berlin Brandenburg Airport (BER)’s conception to operation took 30 years and roughly 8 billion dollars.

The construction began in 2006, and the opening date was set for October 2011.

However, the airport became operational on October 31, 2020, and by then, the costs had ballooned significantly.

So, what happened during these 14 years?

For starters, it didn’t help that no general contractor was appointed initially, but the main causes of cost overruns included:

- Unrealistic design changes

- Poor spatial planning

- Faulty fire safety system

- General mismanagement

According to the project’s chief architect, Meinhard von Gerkan, political pressure overruled concerns about design flaws and the terminal’s capacity.

One of the project’s planning consultants, Dieter Faulenbach da Costa also highlighted the role of stakeholders.

After one of the project’s main contractors went under, the original opening in October 2011 was pushed back eight months.

But other problems kept piling up.

The airport lacked a fully automated fire protection system, and numerous issues with safety installations would continue to plague it well into 2017.

Due to the constantly changing scope, a massive number of defects, as well as a flurry of staff dismissals and corruption, the project would miss 7 deadlines in total.

After nearly a decade of delays, Berlin’s new airport eventually opened in 2020, even winning the 2023 Airport Innovation Award despite its rough first year.

Nevertheless, the Berlin Brandenburg Airport remains a symbol of mismanaged public projects and a cautionary construction tale.

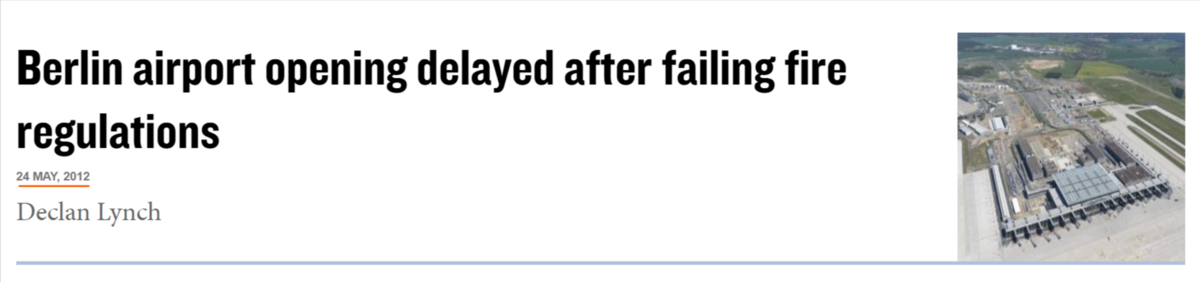

Montreal’s Olympic Stadium

Montreal’s Olympic Stadium is one of Canada’s architectural landmarks and the centerpiece of the larger Olympic complex.

It is also studied as an example of glaring cost overruns.

The entire budget for the 1976 Olympic Games was originally set to C$300 million, but it skyrocketed to $1.5 billion, with the main stadium accounting for most of the expenses.

What’s worse, the Olympic Stadium was not fully completed in 1976 and still requires significant funds for its overhaul and upkeep.

So, how did the costs explode in just 4 years?

An important external factor was the 1973 oil crisis, which caused a sharp increase in the cost of raw materials, but the main issues were project mismanagement, lack of cost control mechanisms, and corruption.

Hosting a prestigious event like the Olympics meant dealing with an extremely tight and fixed deadline.

The original project owner, the City of Montreal, found itself out of its depth and used any means to increase productivity, from double shifts and overtime to deploying extra machinery.

The implemented measures reflected the lack of expertise and delivered low ROI.

Poor project management and coordination between different parties resulted in the Province of Quebec stepping in, eventually inquiring into the underlying causes of huge budget overruns.

It turned out that the City of Montreal chose the French architect Roger Taillibert without competition to ensure the stadium had a striking design similar to his Parc des Princes.

The submitted bids were more realistic in many ways.

For instance, Taillibert insisted on working with concrete over steel—steel was the more affordable option that would have resulted in potential savings of C$100 million.

The irregularities of the bidding process and the role of Mayor Jean Drapeau were scrutinized further, showing that the contractors and suppliers also took full advantage of the situation.

Ultimately, the project was impacted by the politics and the prestige of hosting the Olympic Games, creating a lasting, but expensive legacy.

The Channel Tunnel

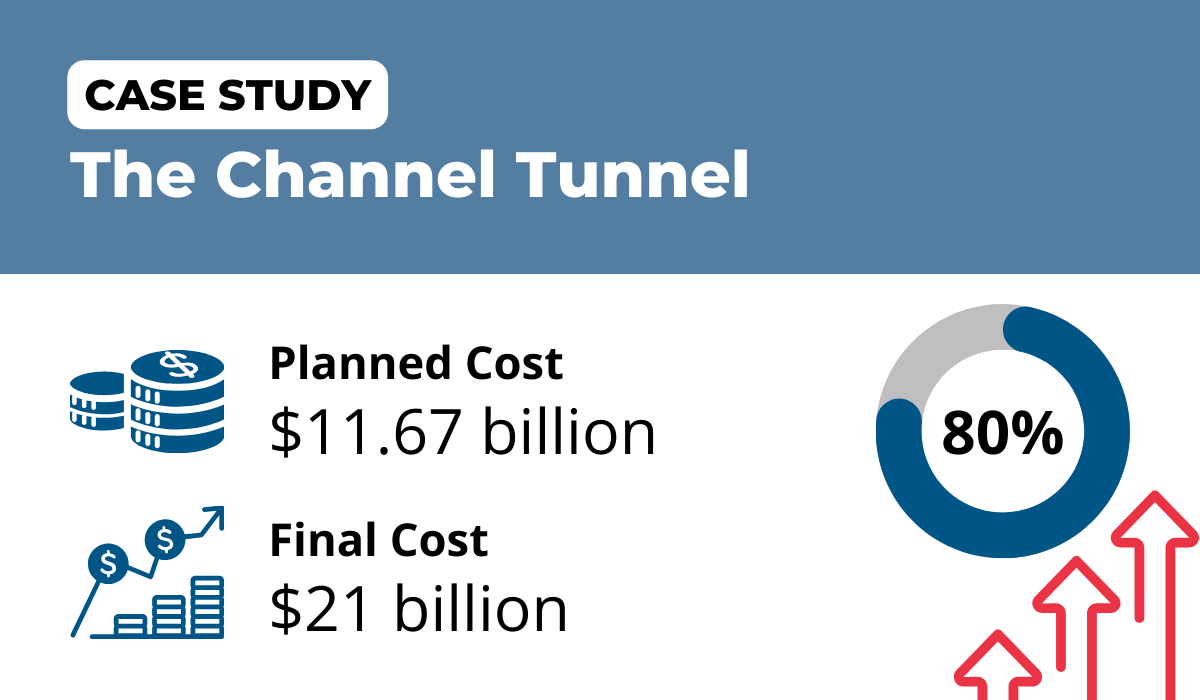

The Channel Tunnel (or the Chunnel) was a colossal 6-year-long project that resulted in a 31-mile-long tunnel structure connecting France and the UK.

It also went down in history as one of the most expensive construction projects, soaring past its initial budget.

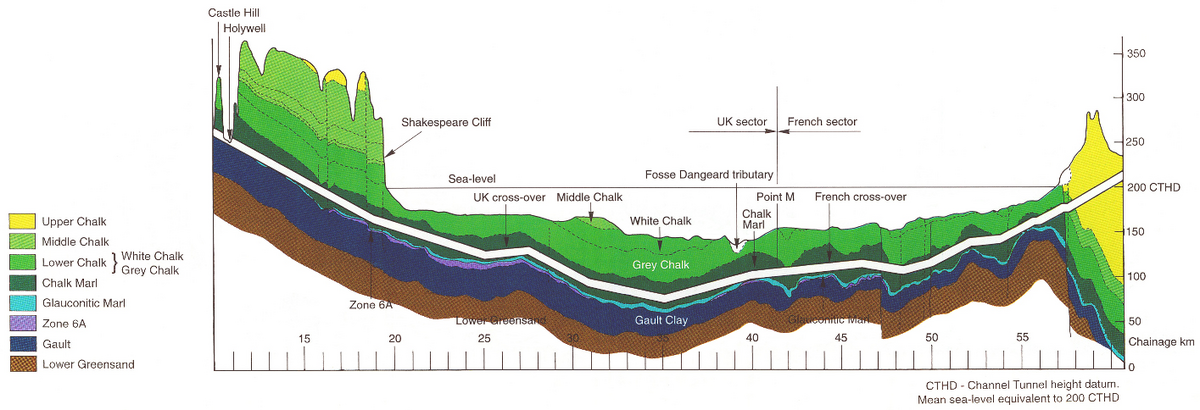

The project had to overcome numerous obstacles before seeing the light of day in 1994, and one of the biggest ones was the terrain.

Simply put, the geological formations were more complex than initially thought.

Staying in the right layer of the seabed at all times was challenging, and wet ground conditions, particularly on the French side, slowed down the progress considerably.

The danger of tunnel collapse and flooding meant constant monitoring of water levels, and the conditions led to safety incidents and loss of life.

The use of tunnel boring machines (TBMs) and top-notch equipment helped overcome engineering and safety challenges, but the question of making the project worthwhile in the face of rising costs remained.

The Treaty signed between Britain and France in 1986 specified that the project couldn’t receive state subsidies, which complicated funding and put additional pressure on the investors.

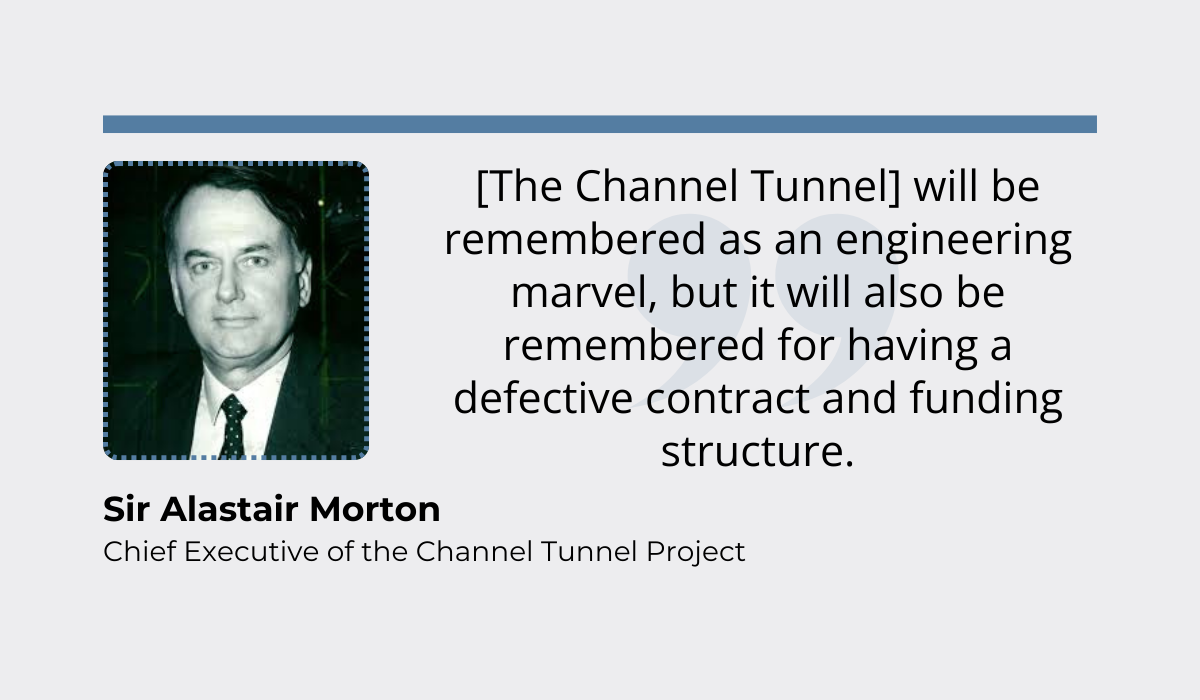

Alastair Morton, co-chairman of Eurotunnel, the project client, stated the following:

Neither Eurotunnel nor the contractor TML were entirely happy with how the other party handled the project and looked for ways to minimize their respective financial burdens, but eventually compromised.

Today, it remains a costly, but crucial transport link between the UK and France and a testament to engineering ingenuity.

New York MTA East Side Access

The Metropolitan Transportation Authority’s project laid out new underground infrastructure and a terminal on the East Side of Manhattan, aiming to accelerate commuting for 160,000 people.

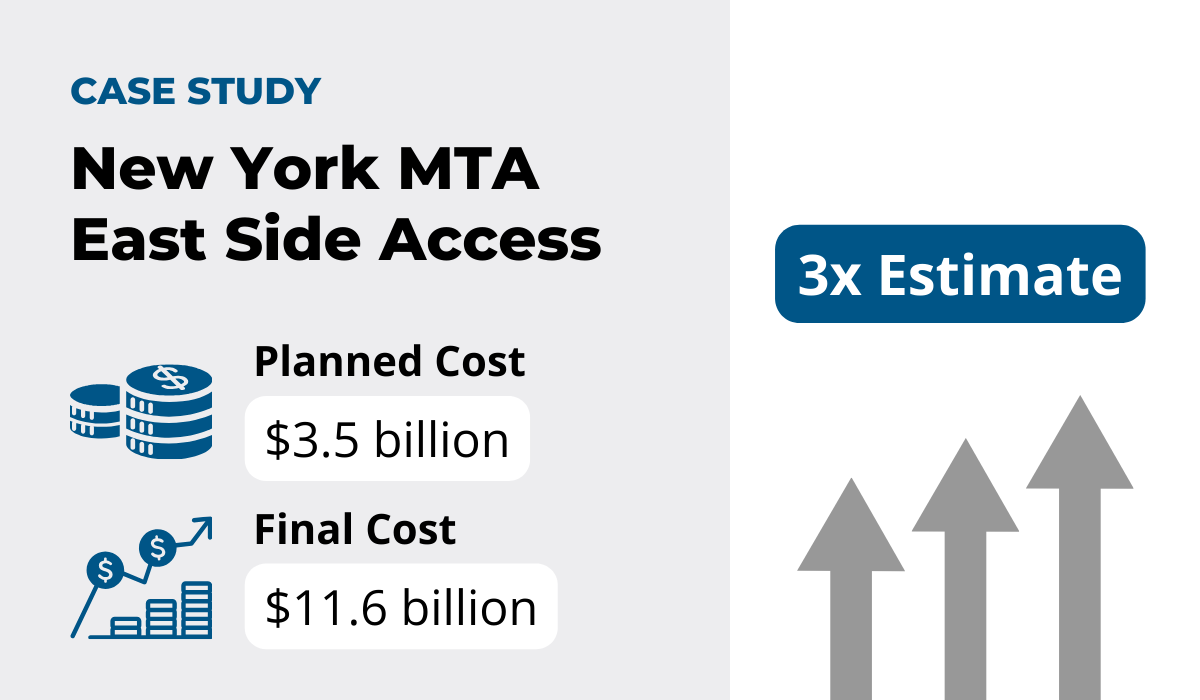

The earliest estimates soon jumped to $3.5 billion, and the costs continued to add up, reaching $11.6 billion in over a decade of delays.

Dubbed by the New York Times as “the most expensive mile of subway track on Earth,” the new tracks cost seven times the worldwide average.

But what contributed to the costs?

For starters, the project took part in a densely populated urban environment, deep underneath the already established transportation network.

Working beneath active traffic meant that engineers had to use coolant coils to freeze the soil for safe tunneling, which cost $1 million per foot.

Extensive tunneling and excavation ramped up the project’s complexity and costs, and working the busiest sections like the Harold interlocking railroad junction proved particularly costly.

On the other hand, managerial oversights and poor coordination impacted the project even more, pushing the opening date further and further.

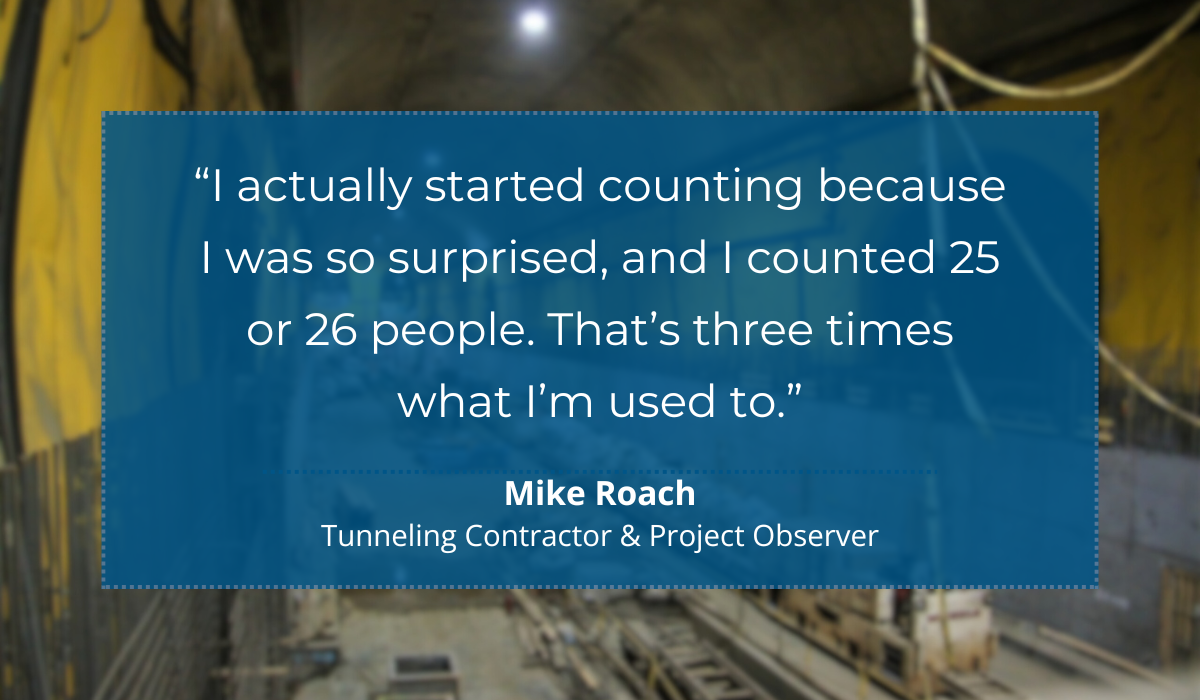

Investigations by the relevant bodies and journalists revealed how, at one point, 900 workers were employed for jobs that required 700 individuals.

For instance, working TBMs requires smaller crews, but based on one tunneling contractor’s experience, the on-site situation indicated blatant overstaffing and corruption.

Various circumstances led to the MTA hiring more workers, and these and similar situations inflated the costs further until the full service finally began in 2023.

One thing’s certain: only time will tell if a better connection and more efficient commute were worth the long wait and the extra costs.

Stuttgart 21 Project

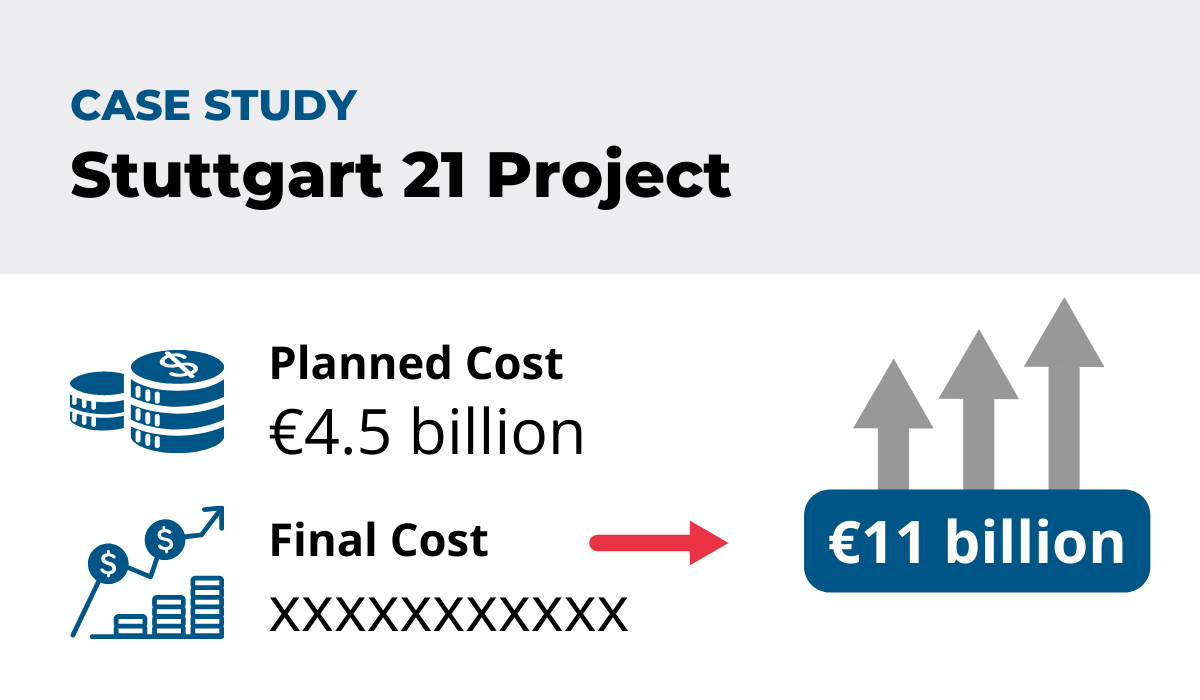

Stuttgart 21 is a major railway development in Germany and is the only project on our list that is yet to be completed and is still dealing with cost overruns.

Initially approved in 2011, the government-owned project aims to transform Stuttgart’s overground terminal into an underground hub, ensuring better connectivity and economic benefits.

However, since this project has been in the making for 27 years, it has eroded the notion of German efficiency much like Berlin’s new airport.

With the station’s opening delayed to 2026, the Stuttgart 21 project costs are expected to escalate to €11 billion (or 11.9 billion dollars), but let’s go back to the beginning for a moment.

The first reports of surging costs and potential delays go back to 2013.

However, the project has been criticized by the public since its announcement due to:

- hefty price tag,

- lack of transparency,

- environmental impact, and

- changes to the city’s visual identity.

The project sparked massive protests, bringing together people from all walks of life who weren’t convinced that the benefits justified the costs, the loss of biodiversity, and prolonged disruption.

While it could be argued that it was difficult to gauge the public’s reaction, the lack of planning and foresight was evident in the poor handling of specific situations.

In 2017, the project encountered delays and had to allocate an additional €15 million to safely move the endangered lizard species from the construction site.

According to activists like Johannes Enssle, the steep costs could have been avoided if the project leadership acted on the initial concerns raised in 2015.

At this point, it’s clear that no amount of public opposition or (un)expected situations will stop Stuttgart’s train station which is set to open in 2026.

Hopefully, the long-term benefits will end up outweighing the costs.

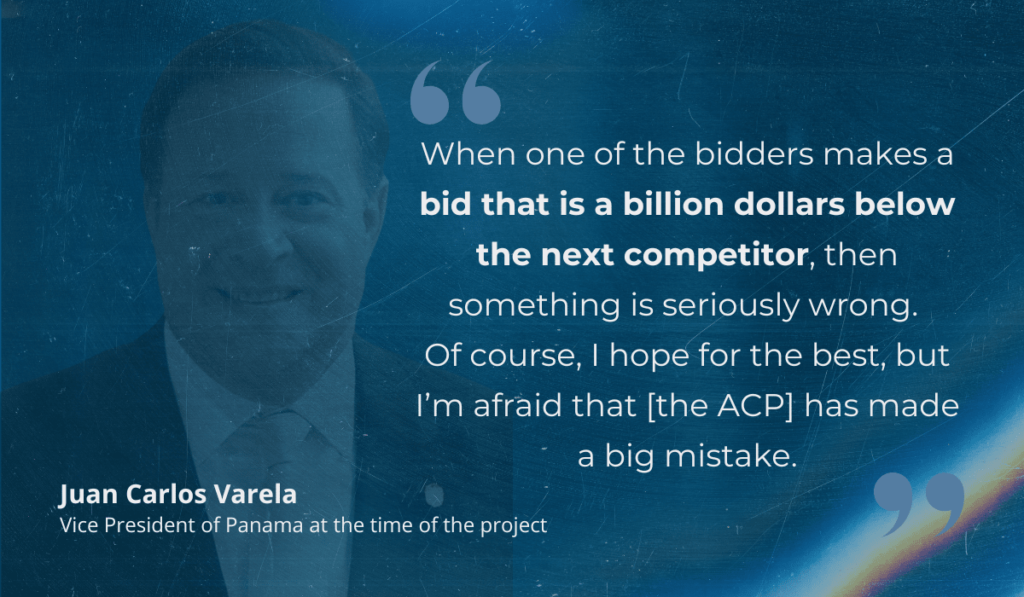

The Panama Canal Expansion

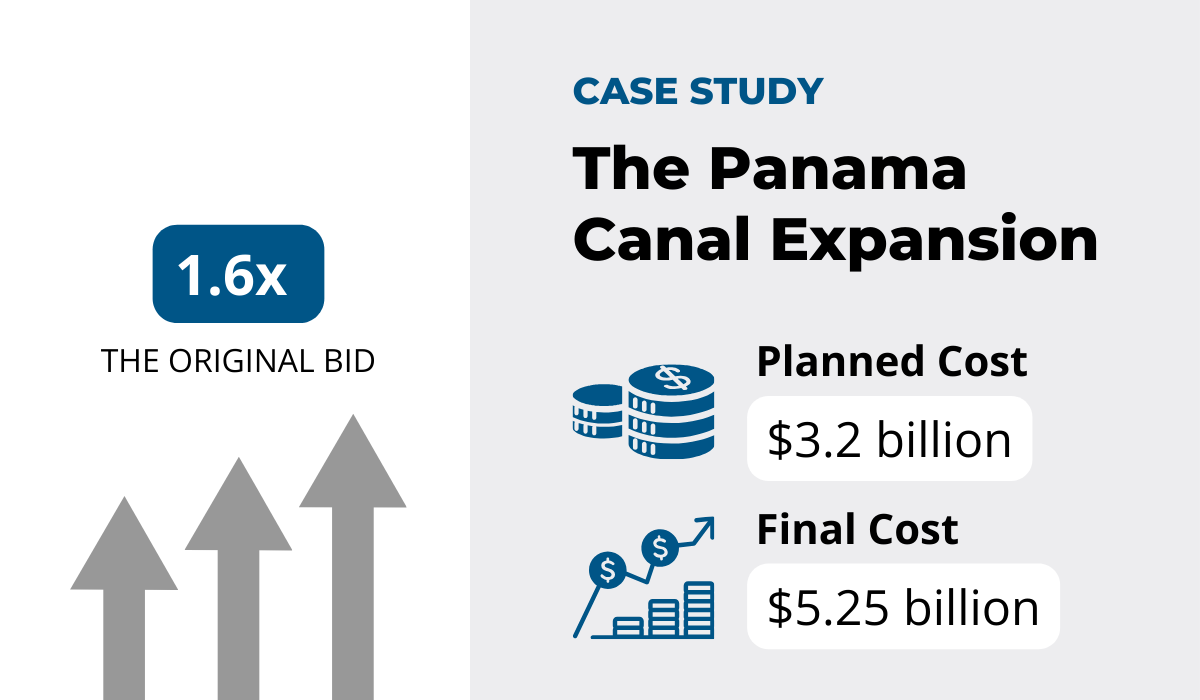

Another megaproject that broke the bank, the expansion of the Panama Canal was completed in June 2016 after six years, and an additional $2 billion.

The difficulty of procuring 100-year design life concrete, a lengthy union strike, and inclement weather created initial delays in 2012, helping drive up the costs.

However, much of the budget overrun occurred due to an ongoing dispute over who was responsible and liable for the mounting costs.

The installation of the third lock mechanism required familiarity with the terrain, and the consortium of contractors (GUPC) claimed that the operator’s flawed geological studies led to increased costs and delays.

The project operator ACP pushed back, setting out to investigate potential “defrauding of the nation’s resources.”

A major reason here was the GUPC’s original cost estimate, which was surprisingly low compared to other bidders.

With the next lowest bid coming in at $4.2 billion, some among Panama’s authorities at the time expressed doubts that landing the project came at the expense of its feasibility.

The GUPC was not awarded the full claim of $1.5 billion but partial compensation, with the legal proceedings stretching out well into 2023.

If we put aside the challenges that marked its 2016 expansion, the Panama Canal’s infrastructure remains a fully functional marvel, generating over $3 billion in annual revenues.

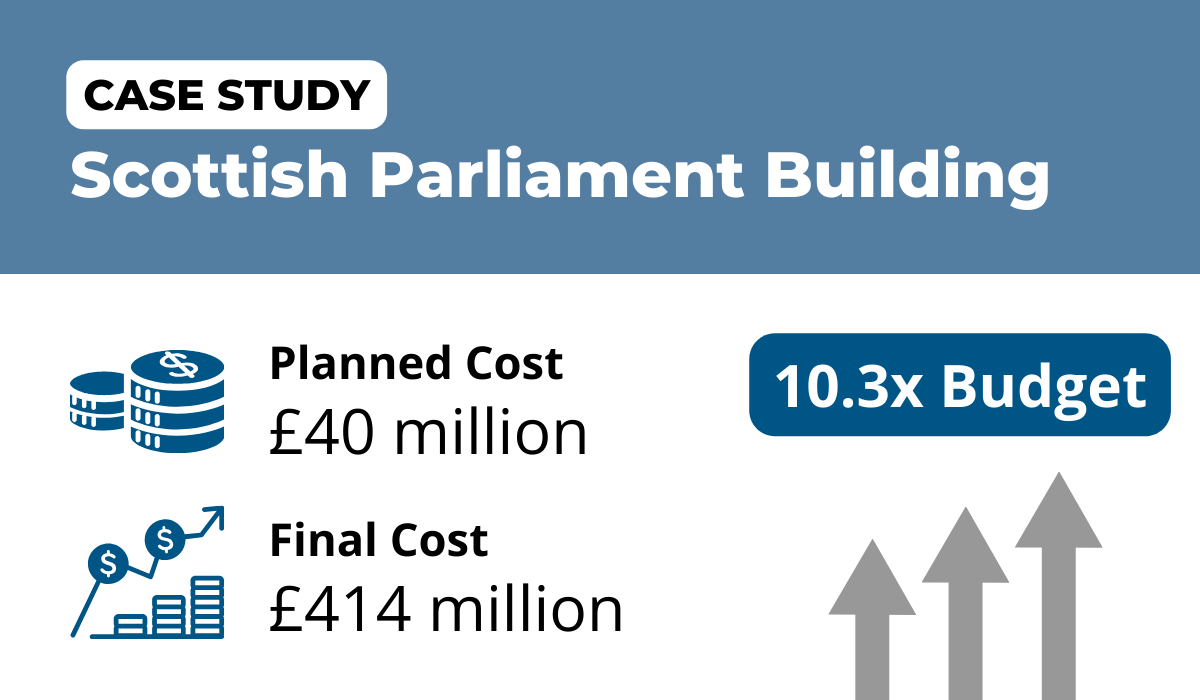

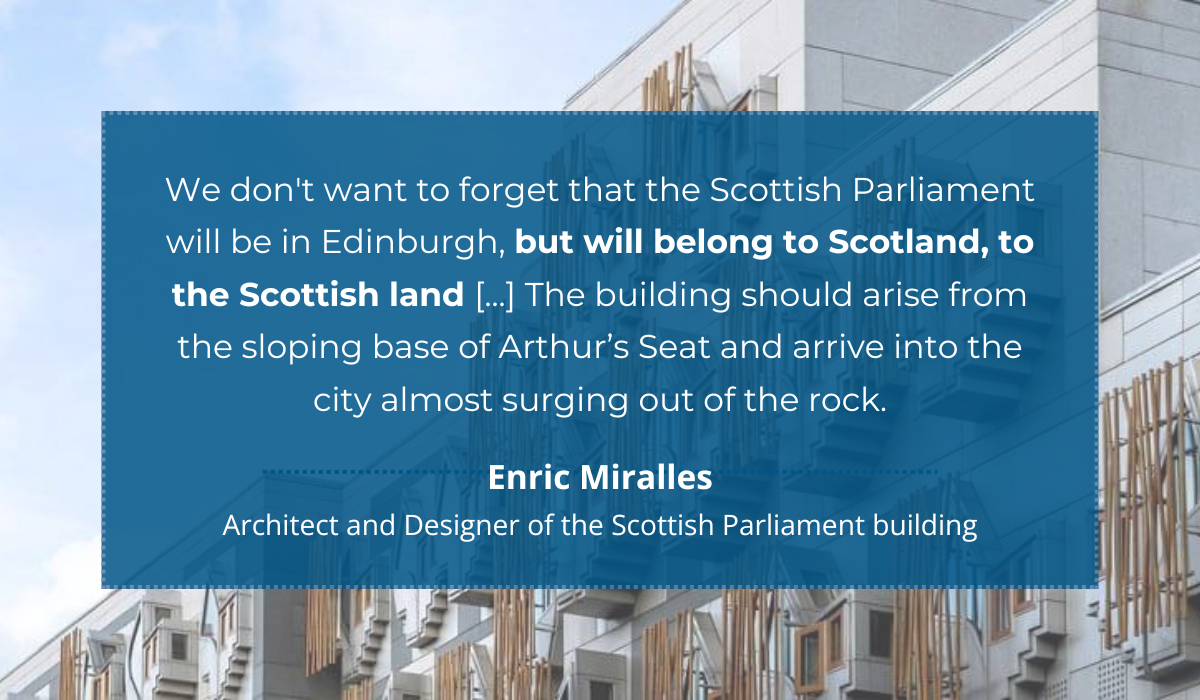

Scottish Parliament Building

The Holyrood Project resulted in the opening of the iconic Scottish Parliament building in Edinburgh in 2004.

It also became one of the UK’s most over-budget projects, with the costs spiraling to £414 million or roughly $745 million at the time.

The costs surged to £260 million in just two years due to common causes like labor shortages and bad weather, but also because of:

- poor project management,

- tensions between architects and contractors,

- increased emphasis on security following 9/11, and

- different design changes requested by Scottish MPs.

The building’s distinct asymmetrical design and features were already challenging to work with, but the sudden death of the chief architect, Enric Miralles, and the Parliament’s inherent symbolism complicated things further.

Prior to his death, Miralles explained that he drew inspiration for the project from Scotland’s national identity, which needed to shine through every facet of the building.

The symbolic significance was also the reason behind many requests for design changes, and even the requirement to use Scottish materials.

Inquiries into the astronomic cost overruns were launched, and at one point the project barely survived a close Parliament vote.

Despite its highly contentious history, the Scottish Parliament building exemplifies the risks and rewards of ambitious projects—in this case, winning 9 leading architectural awards and emerging as one of Scotland’s top attractions.

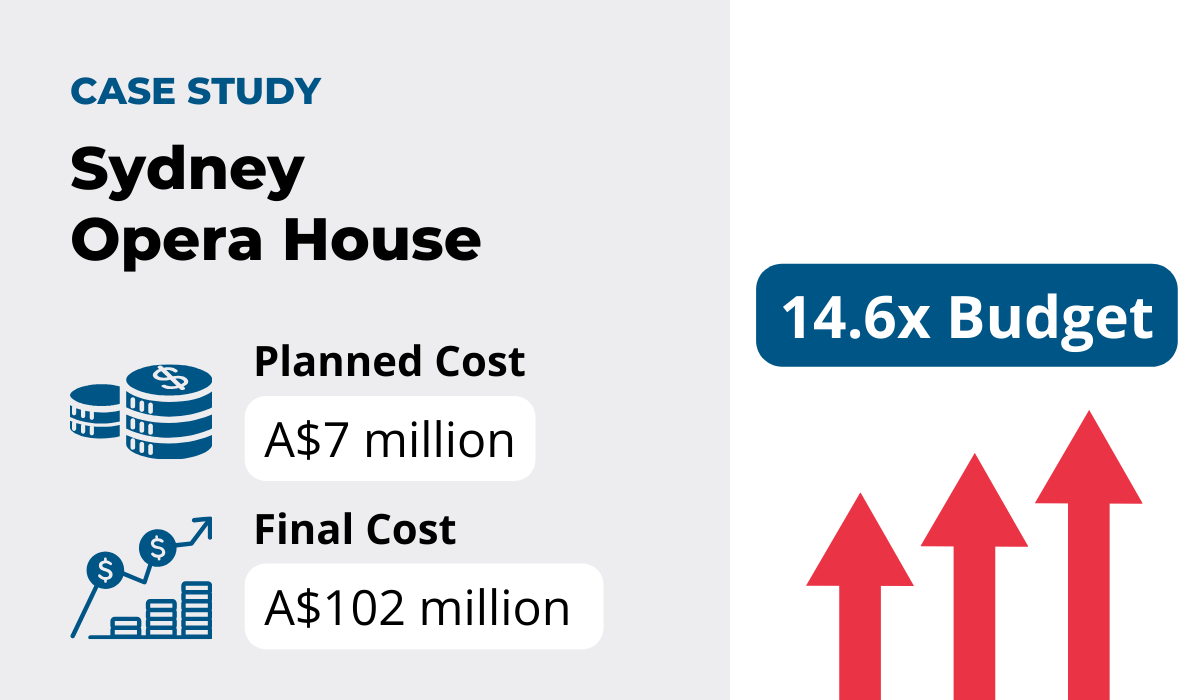

Sydney Opera House

Probably the most famous example on our list, the Sydney Opera House is a unique project whose 14-year-old construction history hides valuable lessons.

Namely, poor planning and design complexity increased the planned cost of 7 million Australian dollars by more than tenfold.

Construction started in 1959 and was supposed to last 4 years, but the project failed to prevent delays and cost overruns, resulting in an extra 10 years and A$95 million in costs.

One of the main reasons was the revolutionary, but complex design of the Danish architect Jørn Utzon.

Utzon would leave the project in 1966 due to frequent clashes with the overseeing government authorities, but not before he and his team derived the final form of the “roof shells” using spherical geometry.

Figuring out the math was one part of the equation, but the construction team also needed to employ then-innovative construction techniques, such as using precast concrete, to bring the vision to life.

However, the novelty of the approaches and reliance on ingenuity also meant the lack of clear, detailed plans and precise estimates in the project’s initial stages.

The departure from standard project management and accounting processes contributed to delays, but the final ingredient was the shifting political climate at the time.

The tendency toward cutting corners to wrap up the project quickly created the opposite effect.

Despite the countless obstacles and increasing costs, the Sydney Opera House was completed in 1973 and became a UNESCO World Heritage Site.

Even with a dismal financial track record, the project is widely considered a success, and another valuable source of lessons for construction professionals today.

Conclusion

Eye-opening, isn’t it?

Evolving project requirements, unforeseen conditions, and external pressures are a reality of all construction projects.

Many iconic construction projects were plagued by problems from start to finish and rose to overcome nearly impossible odds.

Despite the differences in key circumstances, project scope, or the number of stakeholders, analyzing megaprojects gives us a valuable road map for navigating cost overruns.

Now that you’re equipped with new knowledge, be sure to revise your practices and innovate where you see most fit.

You’ve got this!