If you’re a construction company owner or manager who is considering using barcodes to track your assets, like tools and equipment, you’ve come to the right place.

Barcode tracking offers a simple, cost-effective solution for streamlining asset management processes and minimizing asset theft and loss.

In this comprehensive guide, we’ll explain the ins and outs of barcode-based tracking of construction assets and provide tips to help you make the best decisions for your business.

In this article...

What Is Barcode Asset Tracking

As the name suggests, barcode asset tracking refers to generating and affixing barcodes to your company’s assets (physical objects, fixed or movable), which can then be scanned with a barcode reader, and data processed and presented by asset-tracking software.

Therefore, a barcode-based asset-tracking system has three main components:

- barcode labels or tags

- a barcode scanner or scanner app

- asset tracking software

This system can be used to track and manage durable construction assets like heavy machinery, equipment, tools, and an array of other items used in everyday operations.

Likewise, the same system can track and manage consumable inventory (materials, supplies, spare parts, etc.), thus acting as an inventory management system.

However, we will focus on how construction companies utilize barcodes to monitor the location, status, and usage of more durable construction assets we mentioned.

In such cases, asset tracking software can also be used to streamline asset maintenance operations and lifecycle management.

Not that the basics are covered, let’s see why barcodes are so widely used for tracking construction assets.

Why Are Barcodes Used for Tracking Construction Assets

The short answer to this question would be: maximum benefits at minimum cost.

When the benefits of barcode asset tracking are concerned, they range from minimized manual data entry and reduced errors to improved overall asset management.

Likewise, barcodes are low-cost, while the barcode tracking system is easy to set up, simple to use, and requires almost no employee training.

This affordability and simplicity are what sets barcode tracking apart from other asset-tracking methods (Bluetooth, RFID, GPS) in terms of running costs and ease of deployment and use.

In fact, most—if not all—asset tracking systems will use barcodes at least as an additional way to retrieve asset information quickly and easily by scanning the barcode.

For example, this Bluetooth beacon (used for real-time asset tracking within a limited area like a warehouse or construction site) also has one of the barcode types—QR code—we’ll discuss below.

In this case, although the beacon will enable mobile or stationary Bluetooth receivers to automatically detect the asset within their range, the barcode is still used as additional means of identification and a convenient way to access asset data.

The point is that barcodes are so cost-effective and easy to use that they’re typically used as the primary asset-tracking system, which is then enhanced with other tracking technologies we’ve mentioned.

Types of Barcodes Used for Asset Tracking

When deploying a barcode-based tracking system, you’ll basically be choosing between two types of barcodes: classic, one-dimensional linear barcodes and more advanced, two-dimensional barcodes known as quick response (QR) codes.

One-Dimensional (1D) Barcodes

These well-known barcodes consist of parallel vertical lines and spaces representing numbers and letters.

Although convenient and widely used for different purposes, 1D barcodes have some downsides.

More specifically, these classic barcodes can store less data, the scanner must be aligned with the barcode, and any small damage will render the barcode unreadable.

Two-Dimensional (2D) Barcodes

As said, 2D barcodes (QR codes) are enhanced versions of traditional 1D barcodes.

Because they show the data in a square-shaped matrix, they can store much more information than their predecessors.

Moreover, QR codes can be scanned at any angle (time-savings plus convenience) and, maybe most importantly, can be read even when significantly damaged.

Since there is no price difference between 1D and 2D barcodes, all this makes QR codes a more suitable option for tracking assets in typical construction environments.

How Does Barcode Asset Tracking Work

As mentioned earlier, a barcode-based asset-tracking system has only three components: barcodes attached to assets, barcode readers, and asset-tracking software that ties everything together.

When the system is up and running, users can scan an asset with a barcode using a dedicated scanner or a mobile device (smartphone, tablet).

The scanning device will read the barcode, and the tracking software will process the data, record it, and enable users to access the individual asset’s info page and the software’s central database.

This is the core function of a barcode asset-tracking system, as it allows workers and managers to view, update, and track different asset data in real time.

Ultimately, this enables construction companies to actively track their assets’ condition, location, and usage and reap benefits like reduced asset theft and loss, improved maintenance, enhanced worker accountability, and increased productivity.

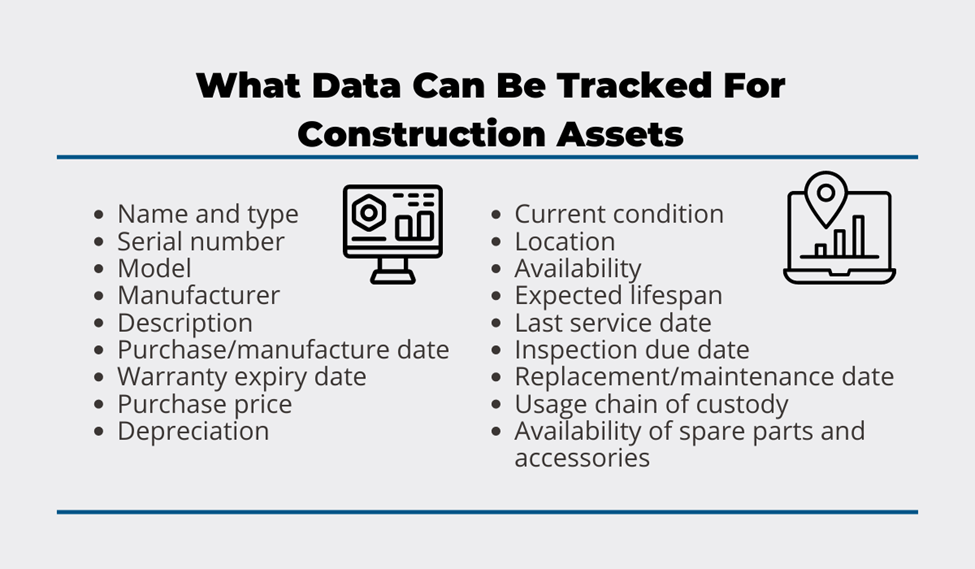

To illustrate, here is a list of potential asset data that can be tracked, some of which are fixed (e.g., serial number, purchase date, and price), and some can be regularly updated (e.g., current user and location, availability, last service date).

Of course, to enable workers and managers to simply scan the barcode (or log into the tracking app) to access all this wealth of information and functionalities, you’ll first need to establish a barcode asset tracking system.

The three steps described below follow the sequence when a company builds its own barcode system by sourcing the components from multiple vendors.

However, if a company opted for an all-in-one barcode asset-tracking solution, the order of these steps would be reversed and start with selecting asset-tracking software.

Generate Barcodes and Attach Them to Assets

When barcodes are concerned, you can order them from any vendor or print them yourself.

However, in the case of barcode labels/tags for construction assets, the most convenient and cost-effective option is to get them—and other tracking system components—from one provider.

This ensures seamless integration and compatibility between all system elements, simplifies the setup process, and allows for selecting label or tag material, type, and attachment method appropriate for construction assets.

Once barcodes are generated and attached to assets, it’s time to consider what they will be scanned with.

Get a Barcode Scanner or Scanner App

Barcodes can be read by special barcode scanners or by smartphones and tablets with a scanner app installed, or both.

In other words, some tracking solution providers offer dedicated mobile barcode scanners that communicate with the central software system, thus enabling the barcode tracking system to work.

Other providers rely on a more cost-effective method that involves purchasing much less new hardware, namely providing cloud-based tracking software with an in-app barcode scanner that is installed on mobile devices your company or your workers already own.

Compared to other potential barcode systems involving special scanners and/or on-premises software, this tracking system setup is the simplest and most affordable method to track the location and usage of various construction assets.

Of course, the entire system is run by asset-tracking software, which first needs to be installed and deployed.

Choose and Install an Asset Tracking Software

Assuming you already chose the software solution that fits your company’s tracking needs, it should be installed on all devices to be used for scanning barcodes and/or accessing the tracking software.

After that, you will need to populate the software’s central database with relevant data about each barcode-tagged asset, which can—depending on the number of assets to be tracked—be a time-consuming task.

When doing so, it’s recommended to, for starters, enter only unchangeable asset data we mentioned, such as the name and type, manufacturer, serial number, purchase date, etc., and fill the database with other data over time.

Once the database is populated with initial asset data and the system is deployed, the tracking software will automatically record specific data, such as the identity of the user who scanned it and the date and time of scanning.

As for the asset’s location, when a barcode is scanned, the tracking software will either automatically record the asset’s location using the scanning device’s GPS function (when scanned with a smartphone or tablet) or prompt the user to manually enter the location.

In either case, the barcode asset tracking system enables construction companies to track the location, usage, and condition of their assets, thus streamlining asset management and improving operational efficiency.

Signs You Should Consider Barcode Asset Tracking

This is fairly simple.

If you’re still relying on manual, time-consuming pen-and-paper or spreadsheet-based methods for tracking your assets, which are notoriously susceptible to errors, you should consider barcode asset tracking.

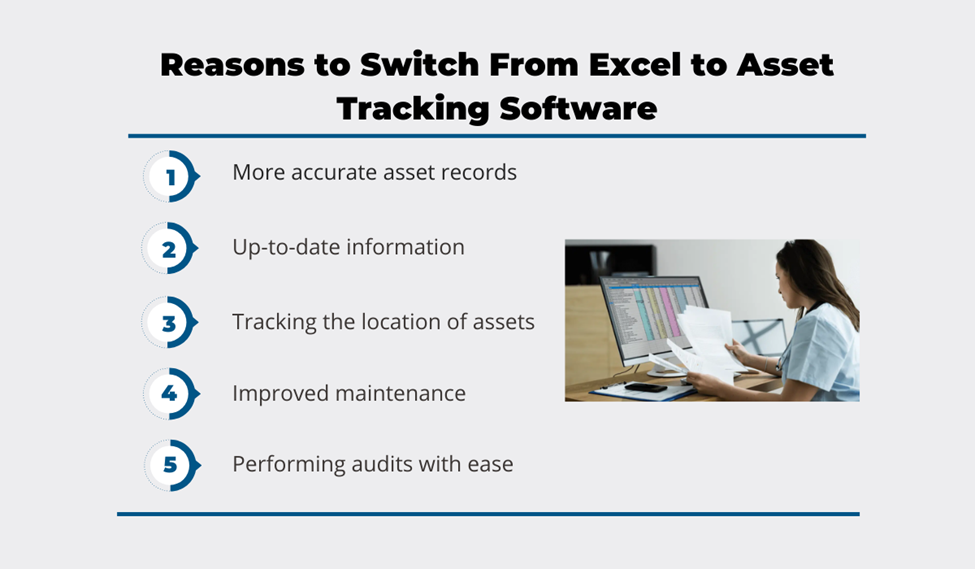

For example, even though that’s not its primary purpose, many construction businesses still use Excel to keep track of their assets.

However, that system is outdated and lacks the fundamental features offered by a barcode-based asset-tracking system.

In other words, switching from Excel to barcode asset-tracking software will provide the following benefits:

Moreover, asset labels/tags and asset-tracking software will directly address the issue of stolen, misplaced, or poorly handled/maintained tools and equipment in a way no Excel spreadsheet can.

Therefore, if you’re frustrated with how much time your employees spend on looking for tools and equipment they need and how much money your company spends on replacing lost/stolen/broken down assets, it’s time to consider barcode asset tracking.

Features to Look For in Barcode-Based Tracking Software

So, what features should your barcode-based tracking software have?

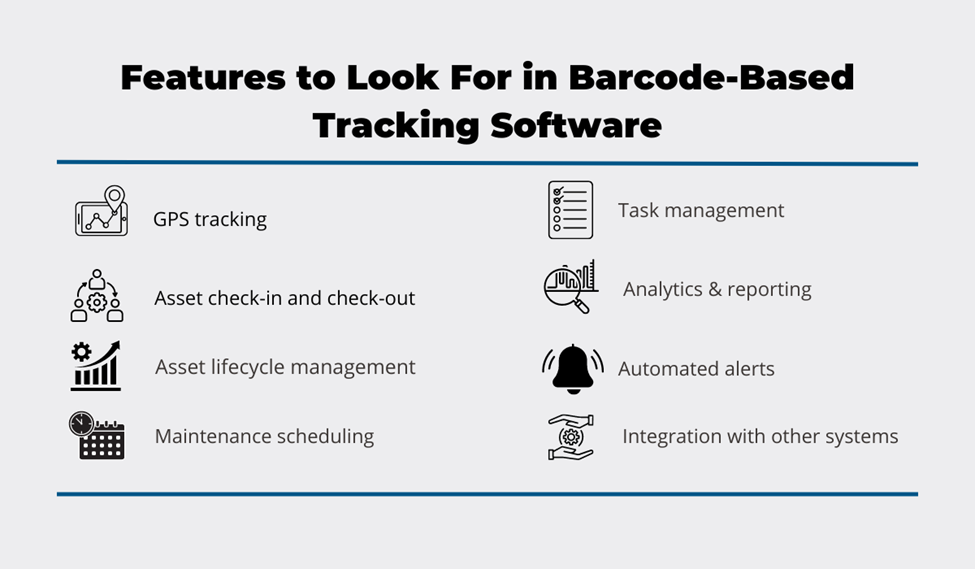

We already established that such software should ensure barcode generation and scanning, as well as be cloud-based, to provide full mobility, instant accessibility, and convenient user experience.

These two key features aside, here are eight other ones that construction companies typically need to efficiently track and manage their assets.

For instance, GPS tracking refers to the tracking software automatically recording the asset’s GPS location when its barcode label/tag is scanned and showing it on a map.

This feature gives you the last location where the asset was scanned while keeping an accurate record of the asset’s previous locations.

Coupled with an automated check-in/check-out feature (the software recording who is taking and returning tracked tools and equipment), this ensures that, in the case of asset theft or loss, both the last location and the responsible user are known.

Needless to say, the asset check-out feature alone has a profound effect on worker accountability, minimizing instances of negligent handling, improper operation, and internal theft of construction tools and equipment.

At the same time, the GPS tracking feature—and durable asset labels/tags—can help recover assets stolen by outsiders.

Furthermore, features like maintenance scheduling, task management, and automated alerts allow companies to plan, monitor and manage the entire asset lifecycle, ensuring that assets are well-maintained and optimally used.

Naturally, comprehensive asset lifecycle management also includes analyzing the data collected by your tracking software, generating customized reports, and integrating the software with other systems to streamline operations.

Finally, the right barcode tracking software will take into account that an internet connection is not always available, allowing users to work while offline.

One software that is tailor-made for the construction industry and has all the above features (and more) is our asset-tracking solution, GoCodes Asset Tracking.

Naturally, there are other more or less specialized barcode tracking solutions that will claim their solutions provide the same functionalities, and we invite you to research and evaluate their offer and prices.

As for GoCodes Asset Tracking, other publications and reviewers often praise it for its simplicity, affordability, and ease-of-use, and cite it as best for construction companies.

Conclusion

Having covered what barcode tracking for construction assets is and how it works, let’s just repeat that barcode tracking is so widely used because the system is easy to implement and use and costs less than other asset-tracking technologies.

At the same time, implementing a barcode-based asset tracking system can generate significant benefits for construction companies (e.g., reduced theft and loss, improved maintenance and lifecycle management, increased productivity, lower costs, and higher profits).

When we put these facts together, it’s clear that barcode asset tracking is a smart choice.