Construction is a dangerous line of work where employees are at risk daily.

These risks are further accentuated by certain mistakes companies make, like not providing personal protective equipment (PPE) or failing to train them to implement safe working practices.

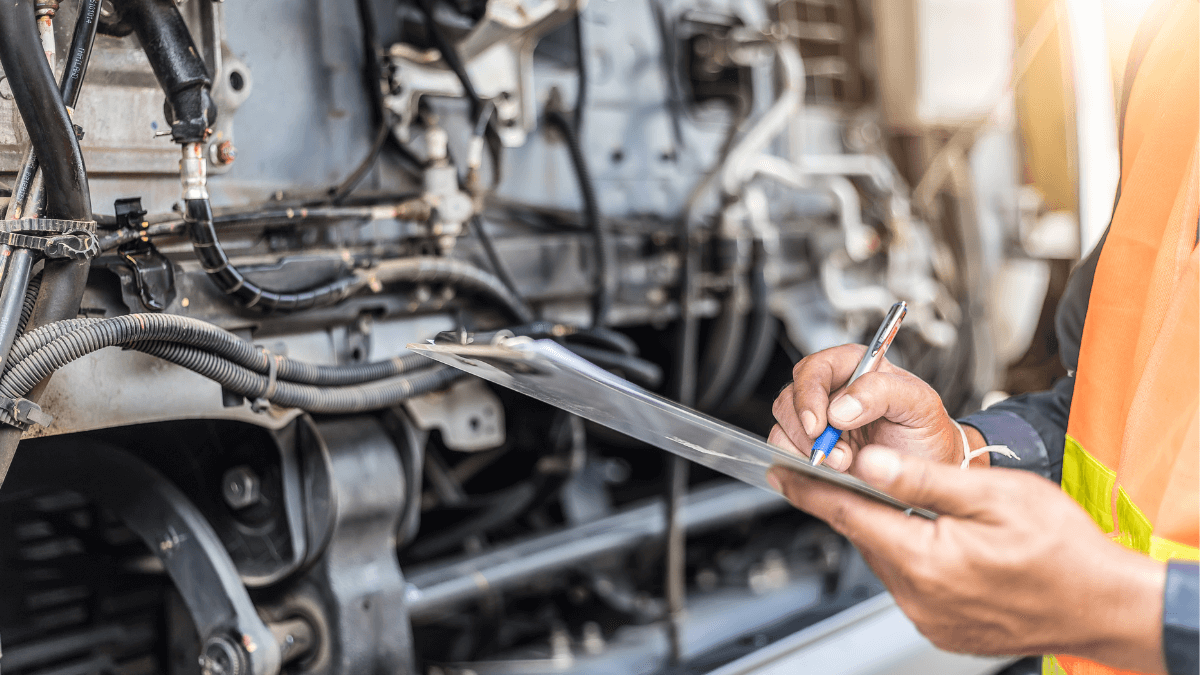

Other times, the employees put themselves at risk by ignoring the rules, which is why worksite inspections are necessary.

As a construction company, you should strive to eliminate as many worksite hazards as you can.

In this article, we’ll list the five of the most commonly cited Occupational Safety and Health Administration (OSHA) violations from 2021 and explain how you can minimize the number of such citations at your construction site.

In this article...

Revisit Your Fall Protection Practices

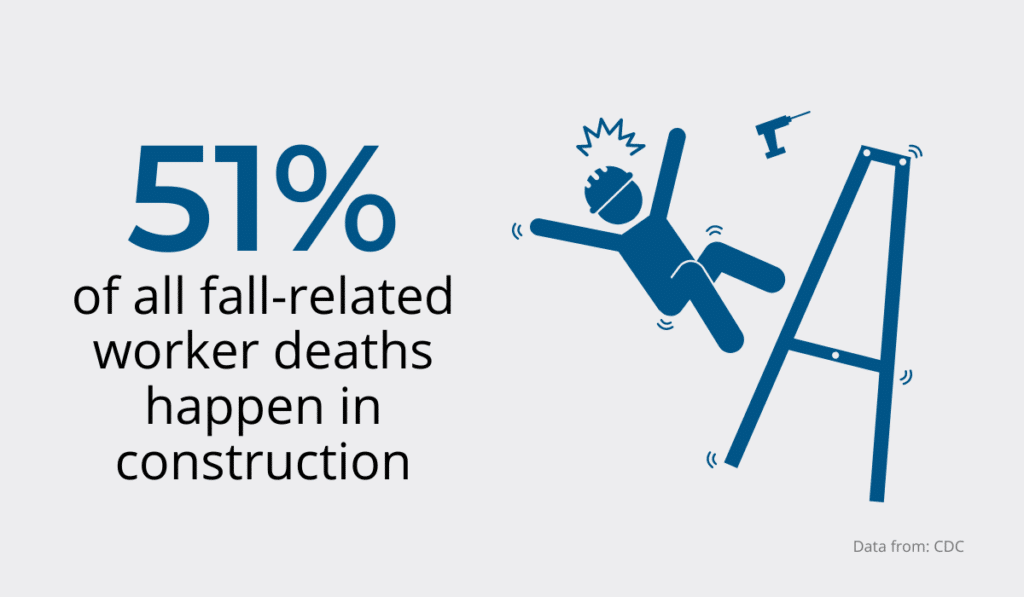

For years, falls have been the top cause of injuries and deaths on construction sites.

Moreover, failure to protect workers from falls has been one of the most common OSHA violations, which means that not enough is being done to prevent them.

No wonder the construction industry accounts for more than half of all fall-related worker deaths!

OSHA recently uncovered its list of top ten most-cited safety standards for 2021.

Not surprisingly, fall protection was at the top of the list again, with a whopping 5,295 citations.

In comparison, fall protection training came in seventh place with 1,666 citations. This means that employees lacked fall protection and training, which caused more accidents.

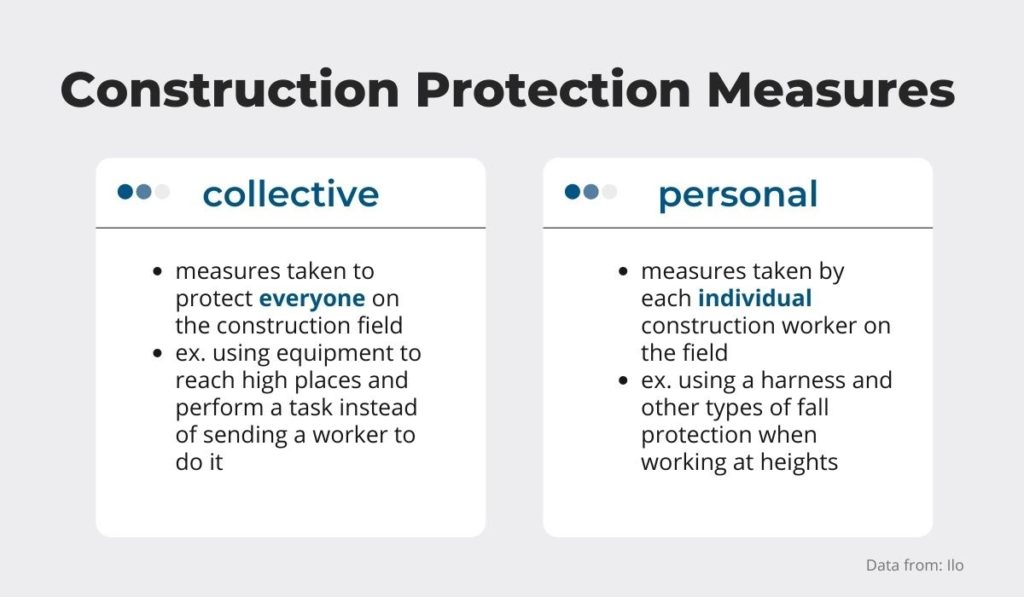

Because of this, you should invest in promoting worker safety culture more. Start by focusing on both types of construction site protection—collective and personal.

The collective measures are the ones you can take to protect everyone working on a particular task.

For example, if you’re trying to avoid having an employee work at heights, make sure to use equipment, e.g., cranes, to reach high places instead, thus eliminating the risk associated with this type of work.

Personal measures are the ones that each worker has to take when working around a specific hazard. For example, any employee working 6 feet above the ground must use harnesses and other protective measures.

Moreover, if there is anything dangerous they could fall into, the workers should use such protection even if they are not 6 feet above the ground.

This protection can be anything from guardrails and safety nets to personal fall arrest systems. As an employer, you must ensure that all these measures are in place.

Neglecting to use protective equipment or using faulty fall protection can result in death, which happened to an employee working on a telecommunications tower who slipped and fell.

OSHA found that the causes of the accident were lack of training, the fact that the safety device was faulty and tampered with, and the PPE in question wasn’t used properly.

Therefore, fall protection starts with good training and an understanding of collective and personal protective measures. The worker has to know how to use the equipment and recognize a defect. Otherwise, all your workers might be at risk.

Ensure Workers Use Respiratory Protection Properly

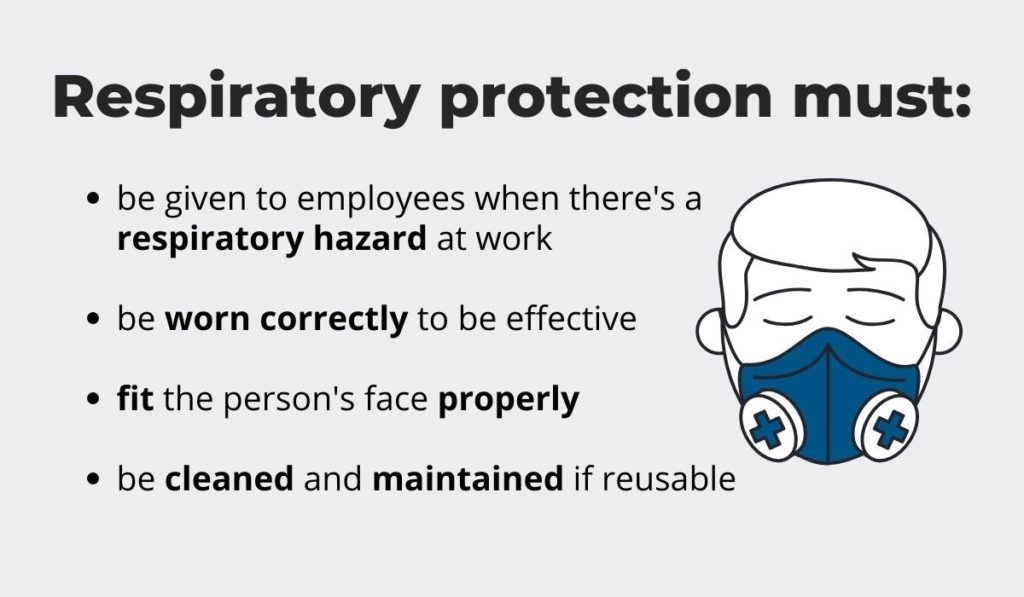

Respiratory protection violations consistently rank pretty high on OSHA’s citation lists, which doesn’t reflect well on employers as they have to provide this type of PPE.

Last year, OSHA issued 2,527 citations regarding this form of protection in the industry, meaning that employers still have many problems to address.

However, even when construction companies provide the necessary respiratory protection, there can be issues, like ill-fitting equipment or using the wrong type of material.

Once again, this is the employer’s responsibility, so you should know how well your team uses the provided PPE.

When providing such equipment for your workers, it’s also important to consider its size. Gear that doesn’t fit right won’t be able to protect your worker, so always offer more than one sizing option.

Protective equipment for the face should create a seal onto the skin to prevent fumes and particles from entering their respiratory system.

If the worker has a beard, for example, they should style the beard in a way that allows the seal to form. Otherwise, the facial cover will be useless.

Nevertheless, you can make certain exceptions if there is no risk to safety. For example, a worker complained to OSHA about having to wear an N95 respirator to stay safe from SARS-CoV-2 while having a beard for religious reasons.

Because of the beard, the respirator didn’t fit right. The worker wanted to know whether his employer was required to offer an alternative.

OSHA sided with the worker and agreed that a PAPR respirator could be a suitable replacement, since it is looser but still protects the worker from the virus.

On top of that, reusable respiratory protection needs to be adequately maintained since the employees will put it on again. This part of the routine needs to be an integral part of training for any process that involves reusable PPE like masks.

Without proper cleaning and care, respiratory protection cannot protect the person wearing it.

Promote Safe Use of Ladders

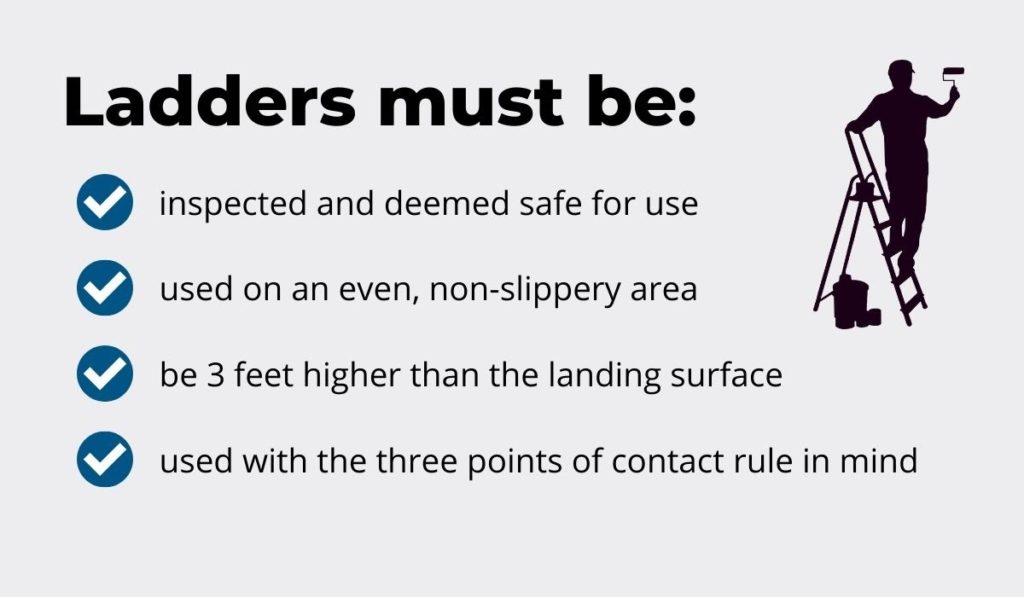

In 2020, ladder-related citations were the third most commonly-cited violation with 2,026 citations, accentuating the need for more training and safer use of this equipment.

The safe use of ladders starts with an inspection of the ones you own. If they are not in good shape or can’t support the weight of most of your employees, it’s time to replace them.

Do the same with single rail ladders due to how unsafe they are.

Throwing old ladders away might seem wasteful, but if you leave a ladder lying around the workplace, anyone could think it’s safe to use. So, you might be putting employees at risk by holding onto them.

When ladders are necessary at the job site, your construction workers should ensure that they are not placed on slippery or uneven surfaces.

It would be best if using them was a two-people job to decrease the possible risks.

Your workers should also know the weight limit of the ladders so as not to endanger themselves and others around them.

When they climb up, bringing too many tools with them could cause the ladders to break or tip over, resulting in injury.

Even if you teach your team all of this, the equipment you use can still get damaged due to impact or wear and tear, so it’s critical to carry out inspections at the worksite.

Before using ladders, someone should check if they are stable and if there are changes that might affect their balance.

One of the most important rules for the safe use of ladders is to maintain a three-point contact with the equipment at all times.

In other words, the person on the ladder should always have three limbs on it.

If they are unable to, there is something wrong with the set-up. Most likely, it’s the fact that the ladder is not at least three feet higher than the landing surface, as recommended by the industry.

Prevent Common Scaffolding Accidents

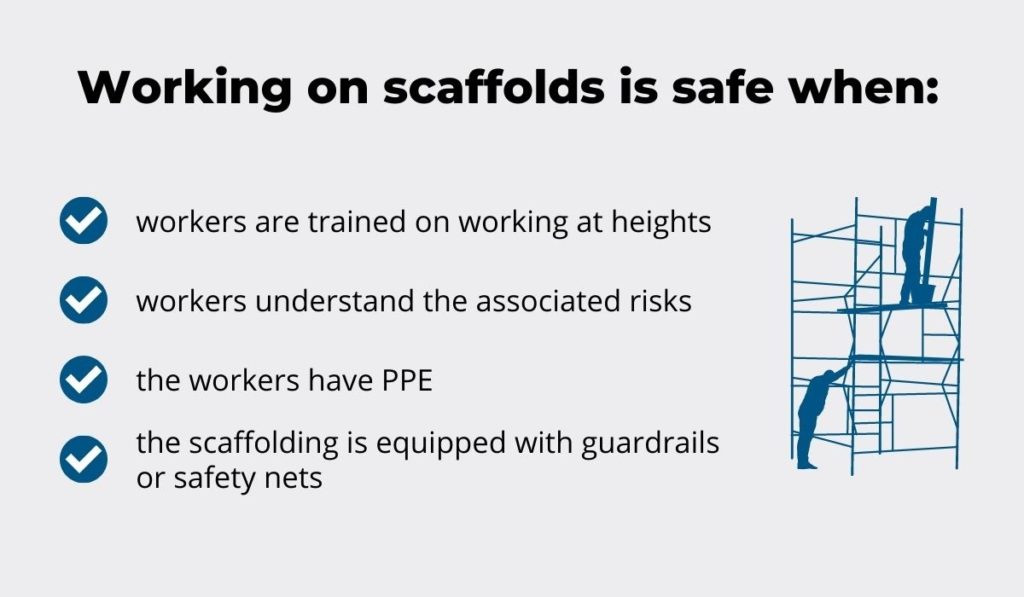

The right way to promote scaffolding safety is to train your employees to use that equipment well. Since there were 1,948 related citations in 2021, it’s clear that construction companies have to put more work into it.

Scaffolds are necessary whenever you work at heights that ladders can’t reach, and heights are always dangerous. Your workers have to receive training on using scaffolding and recognizing potential issues.

For example, construction workers should be familiar with the permitted weight for a specific scaffolding structure.

If they put extra weight on the surface in terms of materials and tools, they might be in danger.

When working on scaffolds, your employees should also be wearing hard hats.

No matter how quick or easy the task is, anyone who uses framing should be wearing PPE and fall protection.

It takes a moment for an accident to happen, which is why guardrails, netting, and personal fall arrest systems are crucial on the construction site.

In a quick video, OSHA explained just how dangerous scaffolds are and how quickly a fall can lead to death at the construction site.

The example they use is two workers using a ladder on a platform, which is in itself a significant OSHA violation as it’s a highly unsafe working environment.

One worker was on the ladder, installing vinyl siding on a two-story home, and the other was on the scaffolding, cutting siding. The worker on the ladder overreached and fell from a 20 feet height, resulting in his death.

The issue arose because of a lack of proper protection. The scaffold didn’t have a railing or any kind of safeguard, and the workers weren’t wearing any fall protection, either.

The ladder on the platform was also a big problem, as a higher scaffold with a railing would have prevented the accident.

Protecting workers from falls is mandatory when using scaffolds more than 10 feet above the ground.

Teach your team to recognize the dangers and make sure that the scaffolding and guardrails are secure. As OSHA puts it, fall protection could be the difference between life and death.

Make Hazard Communication a Habit

It is essential that employers warn their workers of potential chemical hazards in the workplace.

However, OSHA reported that hazard communication violations came in fifth place on their list of commonly cited hazards in 2021 with 1,947 citations, which means that many construction companies still haven’t perfected this.

So, what can you do to improve your communication?

Firstly, your workplace has to include warning signs for the potential threats. These signs have to be visible, so no employee can fail to notice them.

Place warning stickers and posters on the dangerous substances to ensure everybody understands what they are.

Then, your construction company has to have a plan and program for handling these chemicals and communicate them to team members.

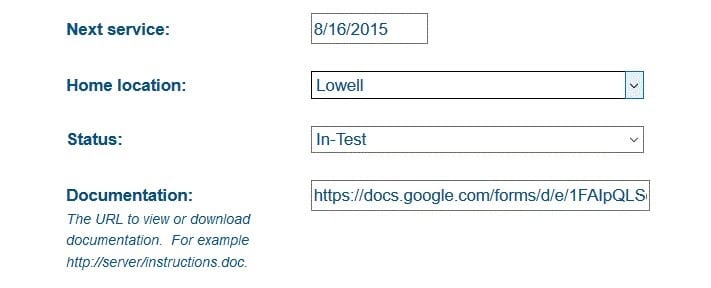

Moreover, you should keep documentation on worker safety training. You have to know who’s had training on which procedures and when at all times.

Only then can you confidently send construction workers in the field and know they will not be in danger.

Another big aspect of such communication is allowing your workers access to hazard information.

When your company introduces new equipment, methods, or safety procedures regarding such hazards, you have to effectively communicate it to the entire team.

On top of that, this information should stay readily available, as they are not likely to remember every single word from introductory training.

Besides, new questions arise when they get first-hand experience with the new assets or procedures.

A good way of having equipment-related information in the same place is using asset-tracking software that lets you link documents right on the equipment’s page.

For example, if a worker in the field has to move a barrel with warning signs on it, they can scan the QR code on it, and their phone will open this specific page in the app, listing all its details.

The worker will be able to read the instructions once again and see how they should move the barrel and what protection they should use when handling such materials. This type of data prevents incorrect handling and accidental damage.

If you pay attention to all three aspects of warning against hazards, you will decrease the risk of someone getting hurt while working at your construction site.

Conclusion

The most common OSHA citations involve hazard communication, respiratory protection, and heights, including fall protection and training, ladders, and scaffolding.

In other words, these are the things you should keep an eye out for at your workplace since these violations seem to be pretty standard in the construction industry.

However, these issues being prevalent doesn’t mean you can’t do anything to fix them. Quality training and both collective and personal protective measures will greatly improve the safety of your employees.

At the same time, these measures will decrease the risk of accidents and OSHA fines.