Key Takeaways:

- Real-time GPS trackers can pinpoint the location of moving assets within approximately 16 feet.

- GPS-enabled software supports geofencing, enabling both safety and security alerts.

- Over 50% of fleet managers reported a positive ROI from asset tracking within the first year of implementation.

From heavy machinery and vehicles to other critical equipment, construction companies manage valuable assets that move constantly.

Without GPS tracking, it’s easy to lose sight of them—literally.

That is where real time trackers come in, giving you instant visibility into where assets are and how they’re used.

In this guide, we’ll break down how these trackers work, how they’re used in construction, and why they’re worth your investment.

In this article...

How Do Real Time Trackers Work?

Real-time trackers rely on a combination of hardware and software to deliver live location data.

At the core is the Global Positioning System (GPS)—a constellation of satellites orbiting Earth and continuously transmitting signals to receivers on the ground.

As shown in the image below, when a GPS tracker receives signals from at least three satellites (plus a fourth for calibration), it can triangulate its exact position anywhere on the planet.

Source: Hyperphysics

But that position data alone isn’t useful unless it can be shared.

That’s where data transmission comes in.

Most real-time GPS trackers send location data over cellular networks, with some models also using Wi-Fi for added accuracy or as a backup.

In remote areas without cellular coverage, like oceans, deserts, or wilderness, satellite communication may be used instead, though at a higher cost.

Once transmitted, the data is sent to a cloud server, where it’s stored, processed, and made available to users.

Typically, this is done through a tracking app accessible on their devices.

Source: GoCodes Asset Tracking

So, how precise are these tracking systems, and how often is their location recorded?

Most GPS trackers provide location accuracy within about 16 feet (5 meters), depending on satellite visibility and environmental conditions.

Update intervals vary widely based on the device, use case, user preferences, and power settings.

For instance, high-value or high-risk assets might be tracked every 10 seconds, while moving vehicles update every 30 to 60 seconds.

Meanwhile, stationary assets in low-power mode may ping only every 10 to 60 minutes.

This brings us to how real-time trackers are powered.

They generally fall into two categories:

- Battery-powered standalone trackers – easy to install, highly portable

- OBD-connected trackers – plug-and-play with vehicle power, medium portability

Source: GoCodes Asset Tracking

There’s also a third category: hard-wired trackers, which are fixed in place and require professional installation.

Some GPS trackers include built-in sensors (e.g., speed, engine hours, harsh braking), while others connect to your asset’s internal systems or externally installed sensors.

These telematics features can provide additional asset data—such as engine diagnostics, temperature, and pressure—but GPS-based location tracking remains the core function.

Now that we’ve covered what real-time trackers are, how they work, and what types are available, let’s explore how they’re used in the construction industry.

What Are Real Time Trackers Used For in Construction?

Thanks to their multifunctionality, real-time GPS trackers serve a wide range of construction-specific purposes.

From route navigation and maintenance planning to safety and security, we’ve grouped their most common uses into three core categories.

Asset Management

GPS trackers enable real-time tracking of physical assets—equipment, vehicles, tools, and materials.

But attaching GPS devices to every single asset would be costly and, for smaller items, impractical due to the size and power needs of the trackers.

That’s why GPS is typically reserved for high-value, mobile assets like heavy machinery and vehicles.

Smaller tools and materials are often tracked using lower-cost methods such as QR code labels, RFID tags, or Bluetooth Low Energy (BLE) beacons.

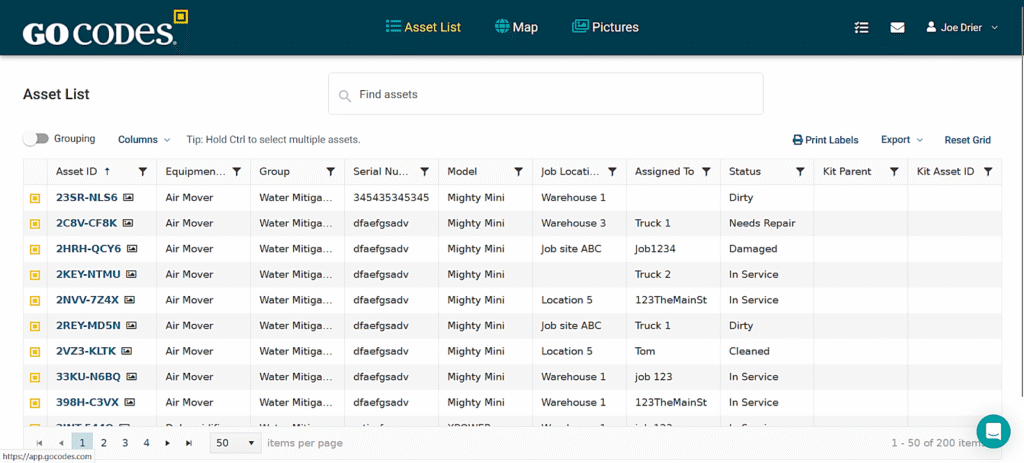

Source: GoCodes Asset Tracking

These asset tracking technologies can be effectively combined with GPS trackers and asset management software to monitor and manage everything from bulldozers to screwdrivers.

Together, these components form a complete asset management system that enables:

- Visibility: Know where your assets are at all times, whether they’re on-site, off-site, or in transit

- Utilization tracking: Understand how often equipment is used, when it sits idle, and how it’s deployed across projects

- Maintenance management: Schedule preventive maintenance, log service history, and receive real-time updates from sensor-enabled machines

Ideally, all these functions are housed in a single software system, i.e., a mobile app like our GoCodes Asset Tracking.

Source: GoCodes Asset Tracking

In practice, real-time GPS trackers help contractors instantly locate valuable equipment, monitor usage, and streamline planning.

They make it easy to spot idle or underused machines, detect when assets leave a site unexpectedly, or schedule service based on usage hours.

GPS also supports route navigation, helping drivers reach job sites more quickly and safely.

Alongside these asset management capabilities, real-time trackers also enable a range of site-specific applications.

Site Management

Efficient site management in construction hinges on visibility and coordination—knowing where your assets are, where they need to be, and when they’re expected.

Real-time trackers help contractors oversee multiple job sites, monitor daily activity, and manage complex logistics.

Whether it’s dispatching equipment from storage to a project site or coordinating deliveries between several locations, GPS provides a live view that improves responsiveness and saves time.

Source: GoCodes Asset Tracking

With accurate location data, managers can track how long equipment or vehicles spend on-site, monitor arrivals and departures, and verify that deliveries happen on time.

This level of insight supports better scheduling and helps avoid unnecessary downtime.

When managing multiple sites or moving assets between storage and job locations, GPS tracking also improves dispatching and route planning.

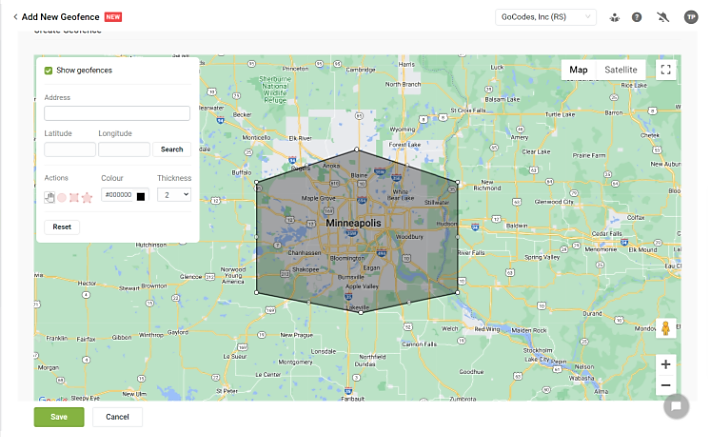

To streamline site operations even further, most tracking systems include geofencing: a GPS-based feature that lets you draw virtual boundaries on a map around job sites, storage yards, or restricted areas.

Source: GoCodes Asset Tracking

Depending on the settings, geofences can trigger real-time alerts when vehicles or equipment arrive at or leave designated zones, or if they exit unexpectedly.

This helps automate recordkeeping, reduce manual check-ins, and enhance control over high-traffic areas.

In addition to tracking assets, on-site workers can also be monitored—with their consent—using GPS-enabled ID cards, smart safety vests, hard hats, or other wearables.

This kind of employee tracking can provide valuable insights for improving workflow efficiency, crew allocation, and on-site coordination.

Beyond streamlining operations, these same GPS tools also play a major role in protecting workers and preventing equipment theft.

Safety & Security

Safety in construction goes beyond physical hazards.

It also includes how equipment and vehicles are operated.

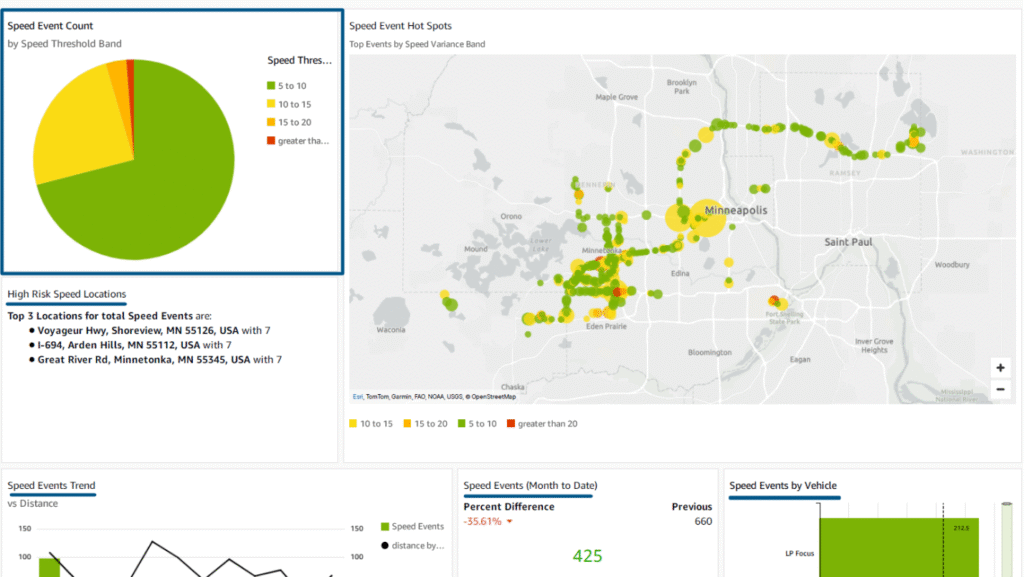

Real-time GPS trackers can monitor driver behavior and flag unsafe practices like speeding, harsh braking, and rapid acceleration.

These insights help fleet managers spot recurring issues and take corrective action early, thus preventing accidents, reducing equipment wear, and promoting safer driving habits.

For instance, GPS systems record vehicle speed and generate reports that show where most speeding events happen and which drivers are involved.

Source: GoCodes Asset Tracking

Such centralized monitoring ultimately helps improve the safety of both drivers and equipment operators.

On-site, GPS-enabled geofences and wearables further support worker safety.

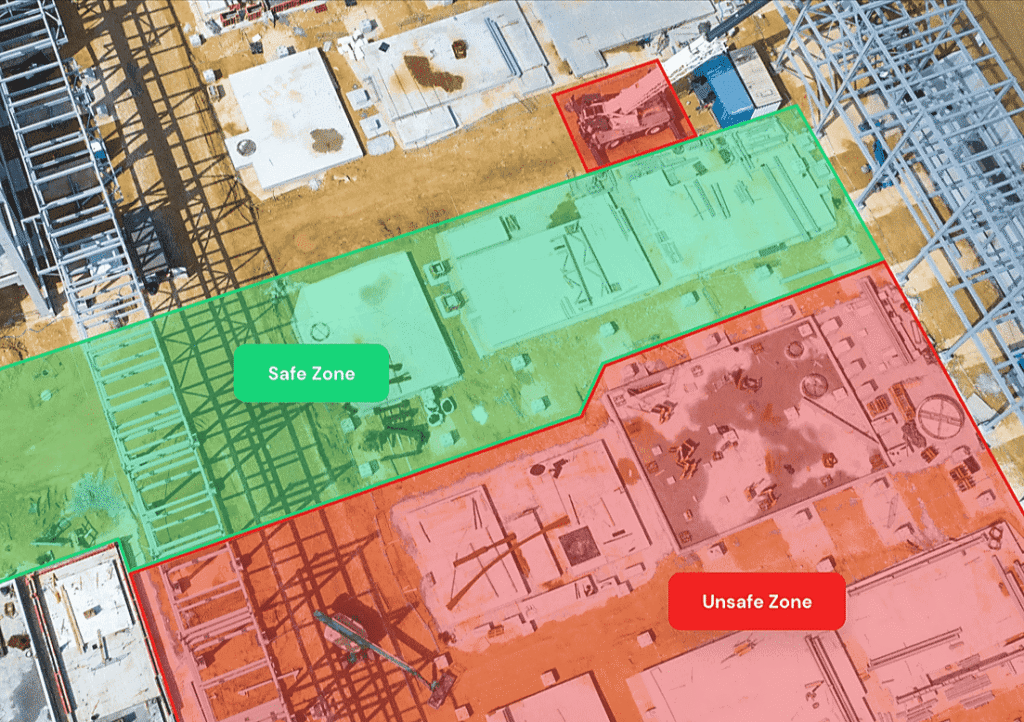

Geofences can mark hazardous or restricted zones, triggering alerts when workers or equipment approach them.

Similarly, smart hard hats and other GPS-enabled gear allow supervisors to track worker locations in real time, supporting lone worker monitoring and enabling rapid emergency response.

Source: Struble Design

GPS tracking also plays a vital role in improving security.

Real-time geofence alerts notify you when high-value equipment moves outside designated zones, helping detect theft or unauthorized use.

And if theft does occur, GPS provides precise location information to assist law enforcement with recovery.

With both safety and security enhanced, we’ve now covered the core ways real-time GPS tracking is used in construction.

Next, let’s explore the key benefits contractors gain by putting these capabilities into action.

What Are the Benefits of Real Time Trackers?

As we’ve seen, real-time trackers don’t just keep tabs on asset locations.

They provide data that supports smarter operational and financial decisions.

Paired with asset tracking software, these insights translate into measurable improvements across key areas of construction operations.

Let’s take a closer look at what those are.

Greater Asset Control

Knowing the location of critical construction equipment at all times eliminates guesswork and improves day-to-day coordination.

And real-time trackers typically provide this for high-value, critical equipment and vehicles.

They’re usually coupled with scan- or proximity-based tracking methods for other tools and equipment and integrated into a central software dashboard.

This setup gives you a single, up-to-date overview of all assets across job sites and storage locations.

Source: GoCodes Asset Tracking

This kind of centralized, real-time view allows managers to quickly check equipment availability, confirm asset status, and allocate resources without delays or confusion.

It also supports better project planning and scheduling, enabling informed decisions based on actual usage patterns and asset activity.

This level of asset control goes beyond just knowing locations: it includes access to other key data categories, as illustrated below.

Source: GoCodes Asset Tracking

Together, these data points help reduce the risk of misplacement and breakdowns, support proactive maintenance planning, and minimize equipment-related delays.

Ultimately, combining GPS with other tracking methods and centralized software gives you full control over asset location, usage, and upkeep, extending equipment lifespan and driving efficiency.

Improved Operational Efficiency

Just like with asset visibility, GPS combined with software and other methods unlocks powerful ways to improve efficiency across your construction operations.

For starters, managers can track where each asset is, how it’s being used, and when it’s sitting idle—all in real time.

This enables:

- Optimized equipment allocation

- Reduced idle time and fuel costs

- Streamlined logistics

- Faster issue resolution

Regular location updates also cut down the time spent searching for assets.

That can lead to major efficiency gains, as Nokia’s Tom Richter points out:

Illustration: GoCodes Asset Tracking / Quote: Manufacturing Digital

He adds that, with asset tracking in place, lost time can be redirected toward productive work, accelerating task completion and reducing project delays.

These efficiency gains help explain why most companies using asset tracking report a quick, measurable return on investment.

In fact, 55% of fleet managers surveyed by Geotab cited a positive ROI in less than a year—proof that operational improvements quickly lead to cost savings.

Ultimately, streamlined asset management powered by real-time tracking and supporting technologies boosts efficiency on multiple fronts, including job site risk management.

Enhanced Jobsite Risk Management

By now, it’s clear that real-time trackers are essential for improving jobsite safety and security.

Let’s take a look at some practical examples.

To begin with, trackers collect crucial data, and software automates alerts to help contractors detect and prevent unsafe behaviors before they escalate into bigger issues.

For instance, GPS-based fleet management software can send live alerts when speeding, harsh braking, or sharp cornering is detected, allowing for immediate intervention.

Source: Radius Telematics

Even if alerts aren’t immediately sent to drivers, GPS-enabled monitoring allows for targeted safety coaching and swift responses to incidents.

Next are geofences, which have both safety and security applications.

For instance, you can set up geofences around restricted or hazardous areas and receive immediate alerts if equipment, vehicles, or on-site employees (if tracked) enter these zones.

Source: Tended

Similarly, geofences can be set around job sites or storage areas to trigger movement alerts outside of working hours, helping detect potential theft or misuse.

Moreover, in the event of theft, real-time location data can aid law enforcement, as demonstrated in numerous news reports.

Source: Fox 11

Additionally, asset tracking software stores critical data on usage and maintenance, making it easier to comply with regulatory and safety standards, as well as warranty conditions.

Overall, precise location tracking, geofences, and alerts—powered by real-time trackers and software—help significantly reduce both safety and security risks across your operations.

Conclusion

It’s clear that real-time trackers and centralized software give construction teams full visibility and control over their equipment.

The result?

Greater efficiency, fewer delays, improved safety, and stronger regulatory compliance.

With smarter asset use enabled by tracking, you can streamline operations, reduce costs, and keep projects on time and budget.