Key Takeaways

- Underutilized equipment incurs maintenance and storage costs without bringing in revenue.

- Underutilized assets depreciate without contributing to revenue.

- The capital tied up in underutilized assets could be invested in newer technologies.

Every construction site has some tools or equipment that aren’t used to their full capacity.

While it might feel like there’s nothing wrong with a couple of gears sticking out of an otherwise well-oiled machine, the effect of it is inevitably felt over time.

The truth is, underutilized equipment slowly eats away at your company’s profits.

Understanding where the losses are coming from is the first step towards preventing them, which is exactly what we’re focusing on in this article.

Want to avoid wasting profits and opportunities? Join us for a deep dive into the true cost of underutilized equipment.

In this article...

Higher Operational Costs

Equipment that isn’t used as much as it could be can’t produce the output that your construction business requires.

Unfortunately, that’s only the tip of the iceberg.

What lurks underneath the surface are additional costs created by idle equipment, and these can pile up quite a bit.

But, let’s take a step back first.

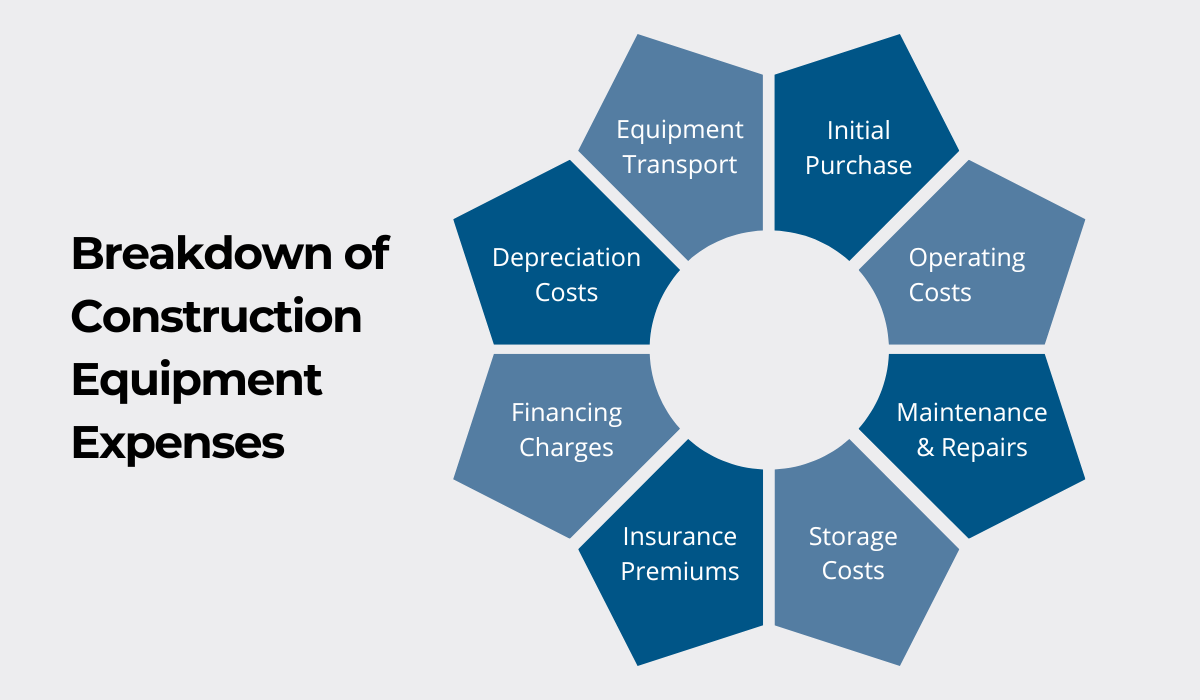

When we talk about equipment-related expenses, construction companies typically need to factor in a couple of different things for good budgeting.

For starters, there is the fact that the costs outside the initial purchase price are extensive no matter how productively you’re using your equipment.

You can see some of them in the image below.

Now think about equipment that remains idle: the costs simply add up!

From steep storage and insurance-related costs to various, often expensive, maintenance issues, underutilized equipment creates one problem after another.

For example, let’s say you’re renting a moderately-sized warehouse.

Indoor facilities are typically pricier than outdoor space due to better security and controllable conditions.

That is why you’d reserve this kind of space for some of your largest, most valuable assets.

But the four assets taking up considerable space are used moderately at best.

If we consider the recent findings of a major real estate player, Colliers, the unused space alone would end up costing your business a lot.

The 2023 increase is part of a larger trend that started during the COVID-19 pandemic.

Since there are few signs of slowing down, construction companies need to plan meticulously.

One possible strategy would be to use centralized storage, reducing the number of additional, smaller facilities.

However, this decision would still depend on other logistical challenges and overall efficiency, and wouldn’t solve the problem of idle equipment.

Maintenance-related costs are another important point to consider.

Deterioration happens even when equipment isn’t being used, meaning that companies facing this issue invest a substantial amount of money into equipment that doesn’t generate sufficient returns.

This is why many businesses rely on tracking equipment utilization and make a point to conduct preventive maintenance based on the gathered data.

Preventive maintenance is a cost-effective approach that reduces the chances of equipment and machinery failure. It also prolongs the asset life cycle.

Timely planning and scheduling bring multiple benefits to businesses, and the whole process is made easier with asset tracking software tools, such as our GoCodes Asset Tracking.

GoCodes Asset Tracking is a solution that increases the visibility of the entire inventory, helping you effectively track how your equipment is used, and manage the whole asset life cycle.

Workers can add notes on the equipment’s condition or immediately schedule maintenance, as well as access all utilization reports and historical data when needed.

Keeping an eye on your equipment utilization and getting the most out of it based on the insights from a solution like this is bound to help you minimize those operational costs that are avoidable.

Outside of tracking utilization, software solutions can also help you make better sense of your assets’ depreciation rates, which is another major cost factor for construction companies.

Equipment Depreciation

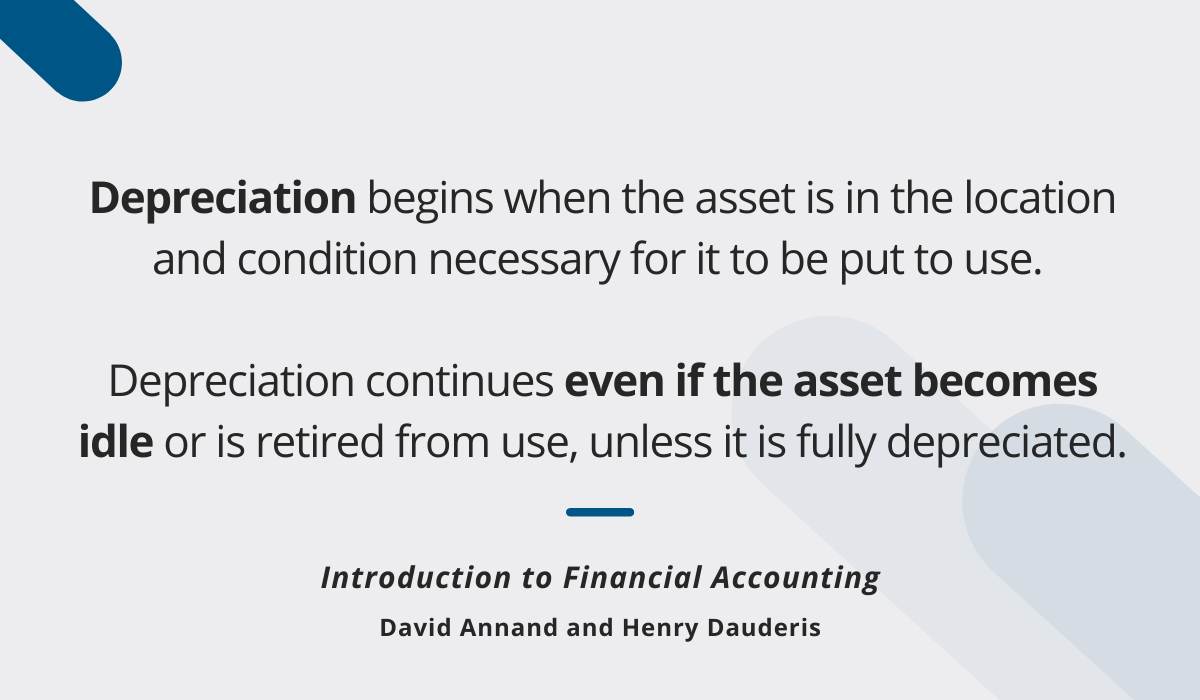

Regardless of how much or how little it’s used, equipment loses its value over time.

What makes underutilized assets problematic, though, is that they end up draining your budget without contributing to the revenue itself.

Construction businesses that are efficient at financial management remain mindful of the depreciation factor from the moment of purchase to the moment the asset is ready to be disposed of.

General depreciation rates for different types of equipment and tools can be found in different guides that provide a useful point of reference for companies looking to make the most of their assets.

Still, more precise calculations are crucial for filing financial statements and tax returns, but also maximizing your profits.

There are several factors that impact equipment depreciation, and that you should keep in mind, including:

- Usage Hours

- Equipment Brand

- Equipment Cost

- Estimated Useful Life

- Estimated Salvage Value

- Obsolescence

Usage hours are an important parameter to stay on top of.

Why?

Because heavy utilization means additional wear and tear, and consequently faster depreciation.

Conversely, underutilized equipment with fewer hours of use carries its depreciation burdens too, and the best course of action is to track and record them diligently.

So, what are you getting from all that tracking?

For starters, the data collected through regular monitoring allows you to stay as eagle-eyed about your asset utilization as possible.

This way, you’re in a better position to make the best possible decision on each asset’s future.

It typically means deciding between keeping, selling, or leasing the equipment, which impacts your finances tremendously.

Sandhills Global’s corporate sales executive, Russ Dolezal, illustrates how contractors achieve maximum profitability simply by knowing the right time to acquire or move an asset.

What makes these contractors successful is their understanding of the construction industry, but that’s not all.

Data-driven insights fuel savvy business decisions.

By tracking utilization and relying on data, you can capture the exact moment to find the break-even point, explains Matt Lang, an expert on commercial lending and financial analysis:

“Break-even is the time to get rid of an asset before you start paying maintenance/repair costs that exceed the value of the equipment itself.”

That way, you won’t have to worry about the depreciation of your underutilized equipment and the financial consequences that come with it.

Lost Revenue Opportunities

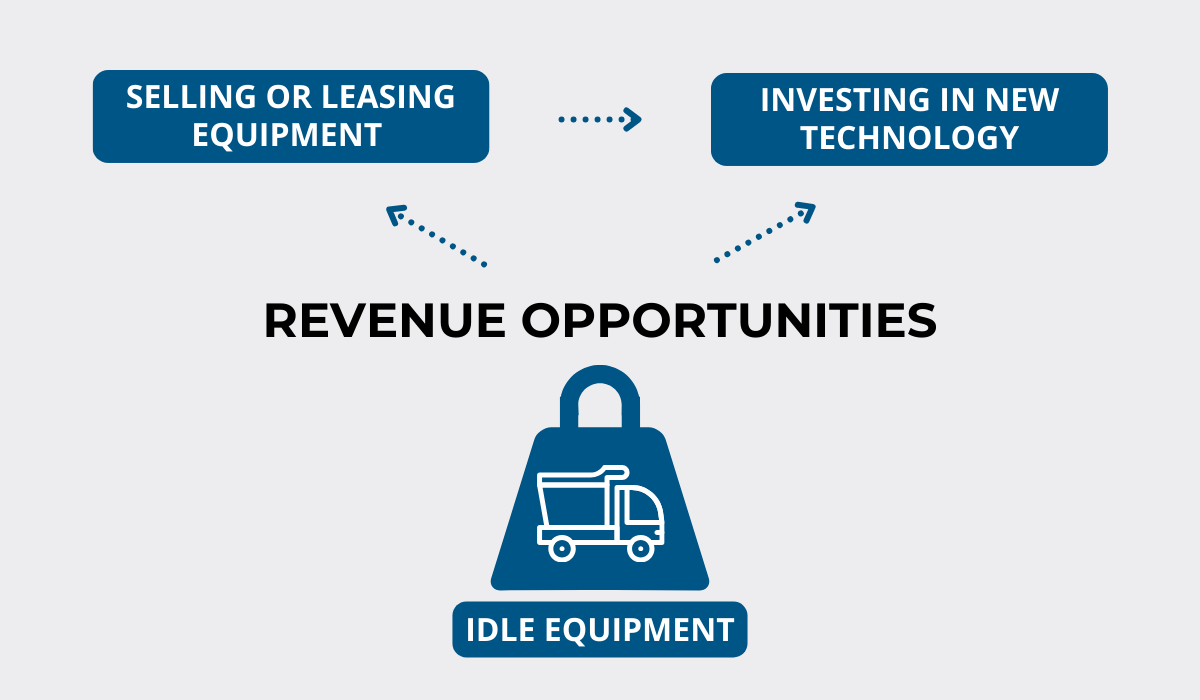

Equipment that’s insufficiently used fails to generate enough revenue on its own.

However, it also ties up the money that could be allocated elsewhere or invested more prudently in other business opportunities.

And if you’re wondering what sort of opportunities, just take a look at the Markets and Markets data on the projected value of the construction equipment market.

The research indicates that the market is ripe with technology-related potential, but also profits from equipment leasing.

Nevertheless, many companies are missing out on revenue opportunities.

One likely reason for this is the struggle to meet day-to-day goals and project deadlines due to operational inefficiency, which also links to underutilized equipment.

Another reason is that the idle equipment acts as a heavy anchor, binding the capital and limiting your ability to pursue additional revenue opportunities.

The bottom line is this: Companies that lack asset visibility and utilization data risk getting stuck with their idle equipment.

And to add insult to injury, their competitors are making money instead.

So the question is, what can you do to change this?

If we zoom in on the construction equipment rental market, currently worth USD 134.88 billion, it becomes clear that renting out your underutilized equipment is an option worth exploring.

There are numerous benefits to renting out construction equipment, from avoiding the heavy toll of depreciation to increased sustainability.

This means that your idle equipment could find a better use, generating more revenue in the process.

But where to start?

Well, after you’ve got a good grasp of what affects equipment resale value, it’s important to establish whether there is sufficient interest in your idle equipment.

Making a plan to position yourself and your underutilized equipment on the market means quicker revenue generation, which can then be invested based on your company’s needs.

It’s worth mentioning that many construction businesses think along the lines of investing in new technology, and turn to it as soon as the conditions are right.

The reason is simple.

The efficiency and versatility guaranteed by advanced solutions help construction businesses handle their ongoing projects with ease.

In turn, they’re in a better position to win new project bids, thereby building a competitive advantage and increasing their revenue substantially.

Obsolete technology, on the other hand, means an additional hurdle to overcome, and potential losses instead of profits.

Technological Obsolescence

Many construction companies aren’t keeping up with the technology available on the market, especially if the use of Excel spreadsheets for internal operations is anything to go by.

However, the situation is different when it comes to acquiring different machinery and equipment used on the job site.

Businesses are ready to invest in assets that bring greater efficiency to the construction site.

But here’s the tricky bit: what if they’re not used to their full potential?

With the rapid pace at which different construction machinery is evolving, older models are becoming outdated much more quickly than before.

And if you’re letting that equipment you’ve invested in sit idly in the warehouse, it can easily become obsolete before you’ve had the chance to experience any return on investment.

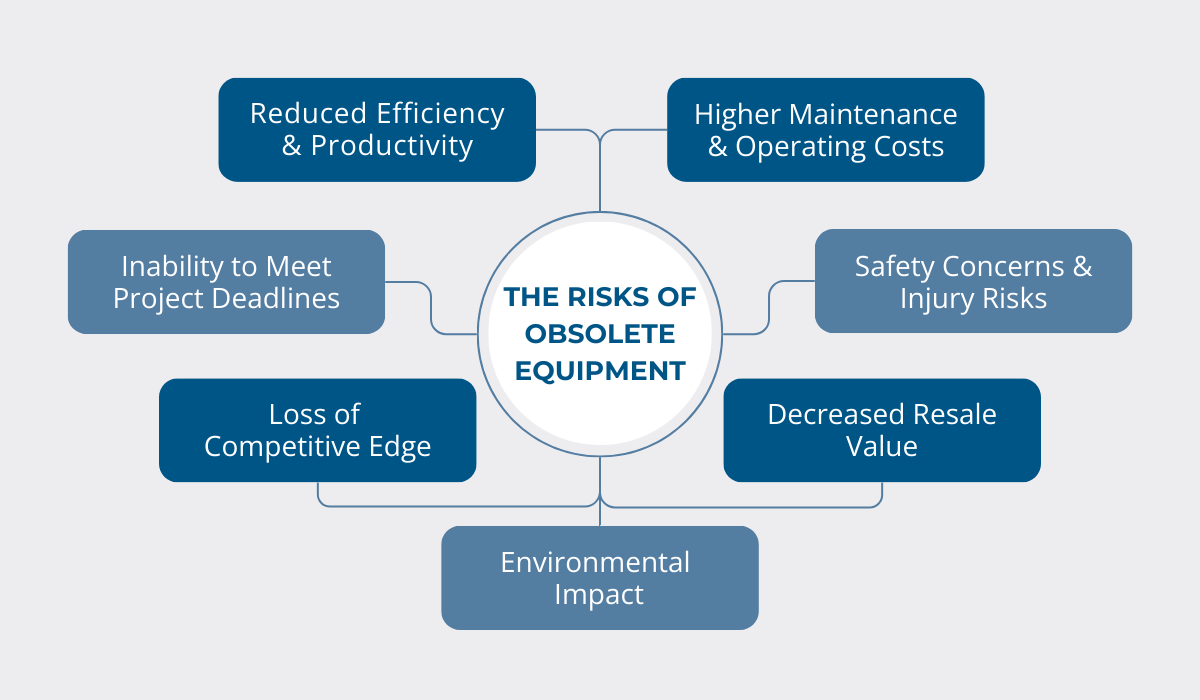

With that in mind, it’s no wonder that construction equipment obsolescence is a big topic, and it carries risks on many levels.

Obsolete equipment, among other things, incurs higher maintenance and operating costs.

And even when it’s kept in good condition, the odds are that its resale value would drop over time, making it difficult to break even, let alone generate profit.

The reduced value results in a financial impact that doesn’t seem too troubling at first, but it’s important to think about the long run, too.

So, what can you do about all this?

While you certainly can’t prevent the development of new construction equipment that might render your existing assets obsolete, there is something you can do:

You can make the most of it while it is still relevant in the market.

Whether you choose to rent it, sell it, or find a way to use it on your own construction site, the bottom line is:

Your currently underutilized equipment doesn’t have to incur additional costs if you make an effort not to let it.

Conclusion

With that, we wrap up the topic of the hidden and not-so-hidden costs of underutilized equipment.

The takeaway?

If you’re dealing with these financial impacts of your insufficiently utilized equipment, try to think along the lines of tracking and improving equipment utilization.

In doing so, you’re avoiding high operational costs and unnecessary maintenance, and putting yourself in a better position to make money by overcoming depreciation rates and technological obsolescence.

Even more importantly, construction companies that carefully manage their equipment’s utilization open new revenue opportunities, and position themselves above the competition.

Need any more reasons to start tracking your equipment utilization? We didn’t think so!