Spreadsheets have been around for many years, so it’s no wonder that, by sheer virtue of familiarity, many of those in managerial positions are comfortable using them to track their company’s assets.

However, automatic asset tracking is a vastly more optimized and money-saving way to track your company’s tools and inventory.

Spreadsheets are not only inefficient, they are inaccurate. Moreover, since they lack trackability, they make it impossible to locate assets.

When using spreadsheets, maintenance is difficult to follow, and audits present a major headache.

Finally, spreadsheets are difficult to use on a mobile device, which is already a stumbling block on the way to achieving full efficiency, and will become increasingly so as time goes on.

In this article, we’ll go over those and other reasons why you should abandon spreadsheets in favor of more efficient asset tracking solutions.

Let’s begin.

In this article...

Using Spreadsheets Is Inefficient

Using spreadsheets for asset tracking takes a long time and a great deal of effort for employees who need to manually enter asset data into a spreadsheet.

You may be thinking how that sounds like no more a minor annoyance, but consider this statistic from Perillon:

As you can see, with so much time wasted, even small errors can cost a construction company a great deal.

Sending managers or other team members chasing after missing assets or attempting to reconcile differing tallies means that they aren’t performing other duties or concentrating on what they do particularly well in your organization.

When a construction company insists upon manual inventory because it seems safe and requires simply running in place, decision makers are missing the larger picture.

Automatic asset tracking, by contrast, is much more efficient.

Inventories are completed with the tap of a screen and are always up-to-the-minute, not to mention far more accurate.

Slow inventory processing can quickly lead to frustrated customers, wasting money on unnecessary purchases, and paying premium prices for items that are badly needed but not on hand.

Inaccuracies Can Be Expected

Because they require asset data to be entered manually, spreadsheets are more susceptible to human error than automated solutions.

Effective tracking software solves many inventory-related problems, and can generate positive results in nearly every other part of a construction business.

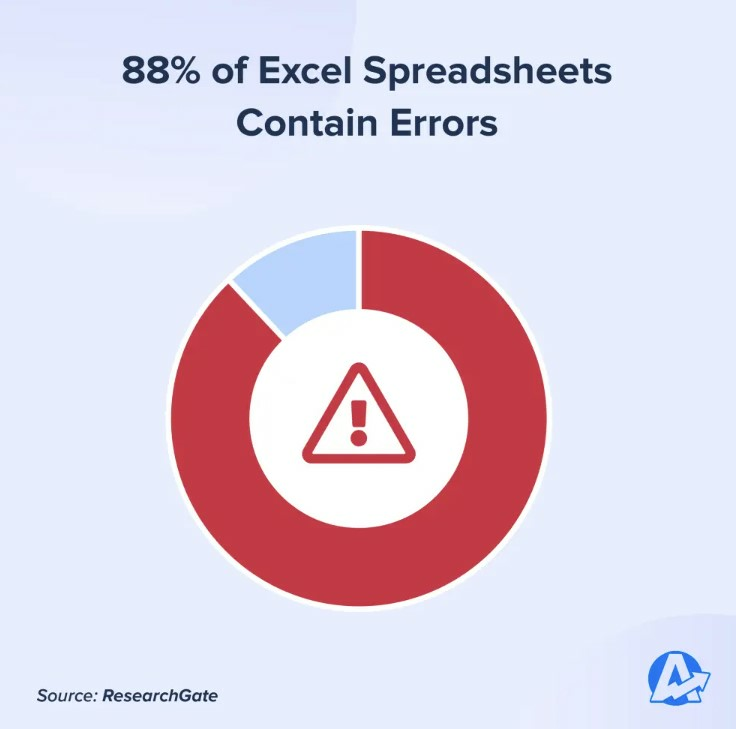

Spreadsheets that are manually populated and updated are ripe for compounding errors. For example, do you know how many Excel spreadsheets contain errors?

This statistic is shockingly high, and can, of course, lead to compounding errors over time. Some studies place this number even higher, to almost 90%.

The outdated and closely clustered design of spreadsheets means that they are difficult to fill and maintain accurately, even with the help of automatic calculation.

To sum up, spreadsheets are remnants of an era in which all bookkeeping was performed by hand.

However, the complexity of modern data, as well as the expectations from clients for real-time answers and immediate fixes, require a more sophisticated solution.

Asset Data Is Difficult to Update

Due to the high inaccuracies of spreadsheets, relying upon them to make major business decisions, tend to customer information, protect sensitive company information, or produce data projections is not wise.

Because manually updating spreadsheets requires a long time and a huge amount of effort, employees are less likely to do so diligently.

This is a disheartening job that can involve long hours of trying to find the root of inaccuracies that might stretch back several years.

As a result, spreadsheet asset data is more likely to stay outdated, unlike automatically tracked assets, which are updated in real time.

The difficulty in updating asset data doesn’t end with erroneous spreadsheets. Sometimes, dangers lurk that construction company decision makers might not have considered.

Here’s one such issue, highlighted by Investopedia:

Off-balance sheet items, described above, can quickly lead to an accounting disaster.

Left unchecked, they can even lead to construction companies finding themselves out of compliance because they are relying on data that is outdated or otherwise misrepresents the situation in the company, such as debt or assets the company no longer owns.

Spreadsheets Lack Traceability

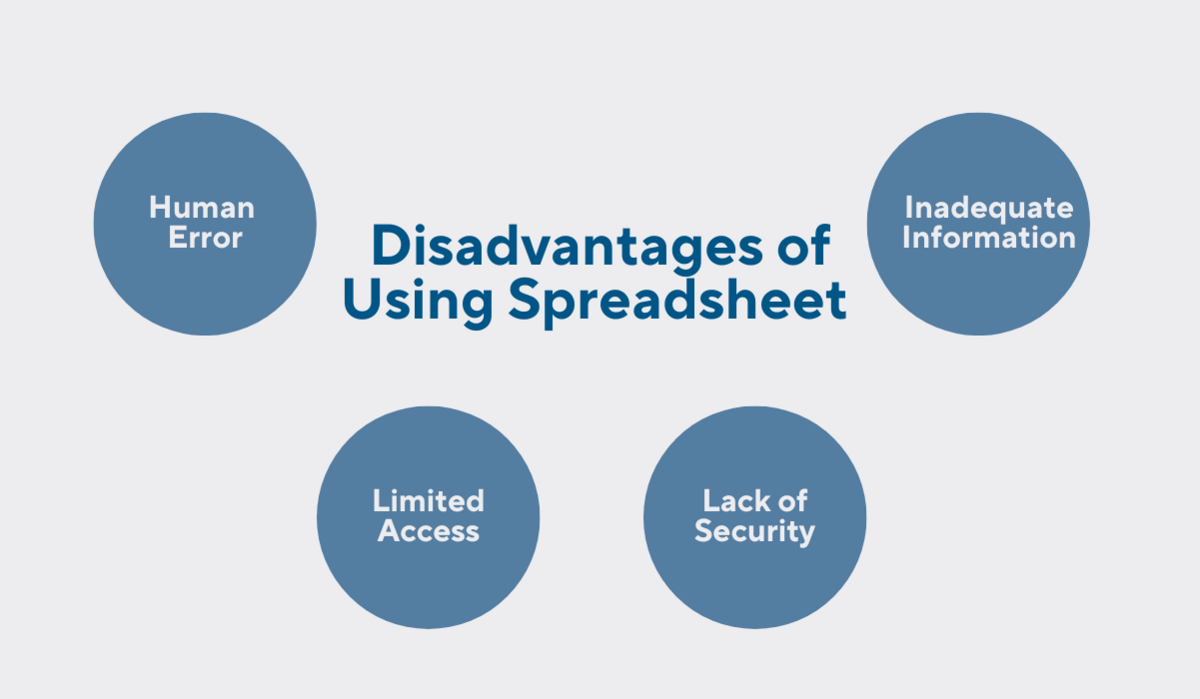

Another problem with spreadsheets is that they cannot track who edited the spreadsheet, what data was added or changed, or when it was last updated.

Nevertheless, in an era in which data is especially vulnerable and 30,000 websites are hacked every day, it is especially important to know who is accessing confidential company information, and when.

Asset management relies upon not only historically accurate numbers, but also the assumption that the numbers the company is using have not been corrupted, either accidentally or on purpose.

This is only possible with ironclad traceability.

Limited access is also a problem, not only for employees seeking the information they need, but also for authorized employees who are scattered across many construction sites.

And there are other drawbacks, highlighted in the illustration below:

In all, it is extremely difficult to maintain the security of a traditional spreadsheet program, not least because employees accessing the program must frequently log in and out, and spreadsheets tend to share the same password throughout a system, which leaves them extremely vulnerable to hackers and other bad actors.

It Is Impossible to Locate Assets

Since spreadsheets were not designed specifically for hand-calculated bookkeeping and not asset tracking, they are not good tools for finding assets when they are misplaced, lost, stolen, or no longer part of the company.

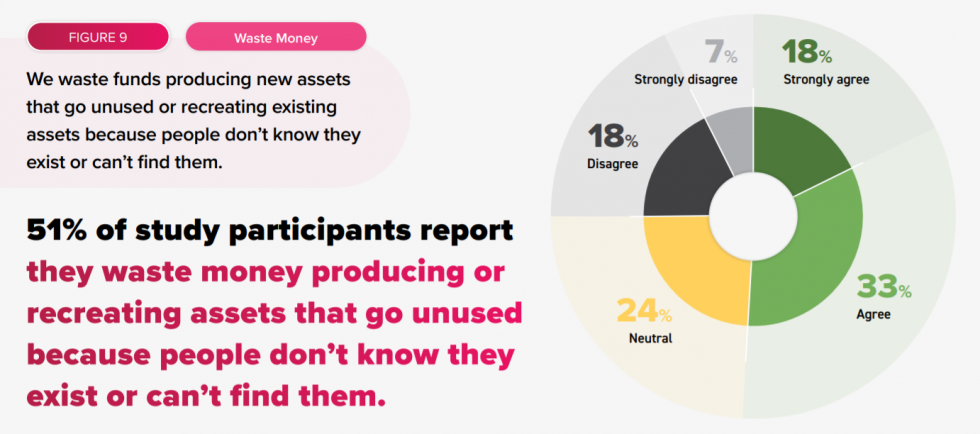

Sometimes this leads to buying unnecessary doubles, or “swiping” tools or assets from other company departments when previously assigned items go missing.

In fact, just over half of companies waste funds producing new assets, looking for them, or simply buying unnecessary replacements:

One answer to this is a robust asset tracking system like GoCodes Asset Tracking.

Construction companies can attach GoCodes Asset Tracking’ QR code asset tags to their assets, then scan them with GoCodes Asset Tracking’ specially designed mobile app to update asset locations.

This way, if an asset is misplaced, lost, or stolen, the item’s last known location is recorded, along with information about which employee had control of the asset.

Construction companies can also attach GoCodes Asset Tracking’ Bluetooth beacons to their assets, and GPS fencing is also a possibility.

Because of GoCodes Asset Tracking’ Guardian feature, construction companies will be notified if an asset leaves the predefined range.

This allows security personnel or law enforcement a chance to evaluate why the asset has exited the perimeter, as well as when and with whom, and take the steps needed to retrieve it, if necessary.

Maintenance Is Difficult to Track

Even in the best of circumstances, maintenance is challenging to stay on top of, and asset maintenance is especially difficult to track with spreadsheets.

That’s because spreadsheets might not have complete maintenance records for all assets.

Maintenance tracking requires a vast quantity of information.

For instance, to track mechanized tools, it’s best to not only include an item’s asset number and location, but also its warranty information, manufacturers’ recommendations and operator’s manual, and its record of maintenance.

This should include past and upcoming periods of scheduled downtime and inspections, all of which are essential for keeping assets in good working order as long as possible.

For assets with irregular preventive maintenance schedules, using asset tracking software with maintenance notifications will ensure that the item remains in compliance, up to code, and ready to work.

While preventive maintenance is key to prolonging an asset’s life cycle, there are other types of maintenance that are also important.

All of these types are much easier to handle with automated asset tracking.

Even when an item has met all of its preventive maintenance goals, it’s still possible, though less likely, that it may suffer a breakdown.

When this happens, a good asset tracking software suite makes it possible to quickly react and redirect items to cover the gap. None of this is possible with spreadsheets.

Audits Are Difficult to Perform

Audits are necessary to prove regulatory compliance, meet corporate goals, and ensure that inventory records match what is on hand.

Audits also provide an opportunity to clear out and correct off-balance items or new acquisitions.

Inventory audits might require expensive temporary workers to complete; in addition, these audits tangle up regular office tasks and can slow down the usual workflows within the company.

Also, as this quote points out, audits are best performed as an ongoing production:

Waiting too long to perform an audit to “do it all at once” can result in frustration and further inaccuracy.

By working with automatic asset tracking, these painful intervals are a project of the past.

Instead, you and your team perform tiny pieces of an audit each day, one scan at a time. This manner of validating data is far more efficient and forward-thinking.

Hard to Use on Mobile Devices

Finally, using spreadsheets on mobile devices is possible, but difficult. After all, spreadsheets were initially electronic versions of wide, old-fashioned ledger books.

They were then retrofitted for use on large desktop screens.

Trying to shrink this data grid down to the size of a phone or even a tablet is an easy route to confusion and error.

In addition, imagine trying to conduct a live audit while dragging a desktop computer through the narrow aisles of a warehouse.

In light of all this, Switching from Excel to asset tracking software is a smart choice if only for how much more usable tracking is on a mobile device.

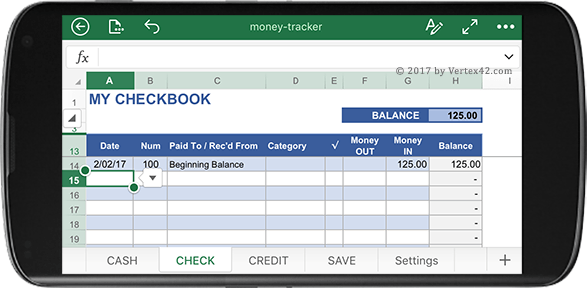

Below is a screengrab of how a popular spreadsheet program looks on a modern smartphone:

This text is small, there is little room to see several sections at once for comparison, and one wrong finger swipe can disrupt the data.

The sample shown here is just a simple checking account, so imagine how cluttered, cramped, and aggravating it could be to try to track a company’s assets in this way.

Good asset tracking offers much more information than in a checking account, and a well-designed program is intuitive, clean, and a help rather than a hindrance.

Conclusion

While spreadsheets might seem like a comfortable and low-cost option for tracking assets, in the end, they cost construction companies an inordinate amount of money and time.

Updating asset data on spreadsheets is difficult, and spreadsheets also lack traceability.

Besides, it is impossible to locate assets on a traditional spreadsheet, and maintenance is difficult to track in this fashion.

Finally, not only do they make audits difficult to perform, spreadsheets are difficult to use on mobile devices.

Because of all this, using asset tracking software instead avoids the inaccuracies and inefficiencies of spreadsheets.