The construction industry has been slow to accept technological advancements due to the highly complex nature of the work.

Most buildings are one-of-a-kind, so finding a cost-effective solution that is a good fit for many projects is challenging.

Luckily, some people want to improve the traditional way of doing things, and they are at the forefront of the technological revolution in construction.

If you’re one of them, this article is for you.

Read on to learn more about six types of construction technology to help take your construction business to the next level.

In this article...

Site Positioning Systems

A site positioning system measures the spatial position of an object using satellite imagery.

The construction technology provider SITECH explains the benefits of site positioning like this:

“Site positioning enables you to map out a location precisely and helps with staking, grade checking, progress measurement, and more. Using sophisticated systems such as portable GNSS receivers, high accuracy total stations, hand-held computers, and powerful software that you can access from your phone in the field or at the office, site positioning allows you to do all of the preliminary site analysis for a site without having to wait for surveyors.”

In short, site positioning uses global navigation satellite system (GNSS) technology to deliver exact measurements and help map a site.

A combination of software and hardware is used for this purpose, which means you control various positioning sensors (controllers and antennas) on a site via software on a tablet or mobile device.

Stakeout, survey measurement, and grading are just some of the things a site positioning system can help with, and it’s an invaluable tool for the site analysis and surveying stages.

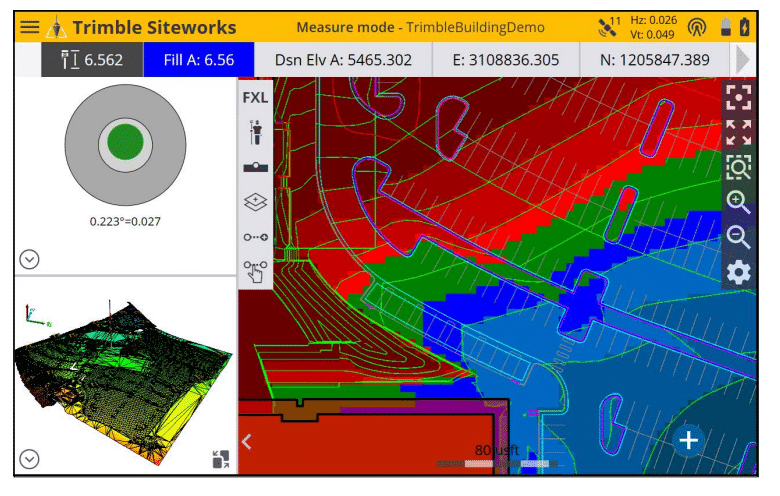

Below is an example of the Trimble Siteworks Positioning System at work.

The system can track activities across multiple sites and update information in real-time because controllers have a Wi-Fi connection.

The software also stores data to enable analysis and reporting, which makes a site positioning system an excellent comprehensive tool that helps all stakeholders make informed decisions about the site and the next steps in the project.

Even better, it saves money by removing the surveyor from the equation.

It makes the team more productive by granting everyone, from field managers and construction surveyors to machine operators, access to timely and accurate site information.

Construction Laser Scanners

3D scanners are a growing trend in construction and related industries, especially since the Covid-19 pandemic.

With laser scanning, instead of the traditional way of doing things with a tape measure, a laser beam is used to capture the actual site and measure all the dimensions, objects, and their spatial relationship to one another.

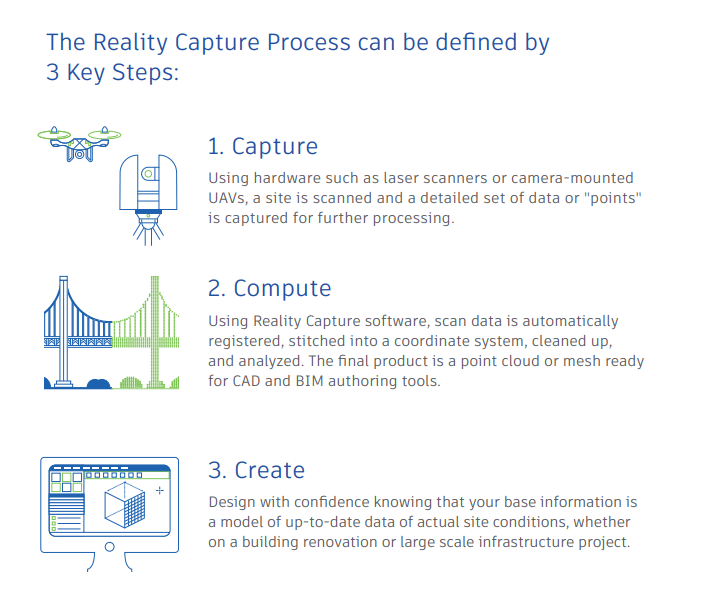

The scanning process is illustrated below.

It’s not hard to see the appeal—this technology is faster, more precise, and captures more details than a human ever could.

In fact, laser scanners are so popular that MarketandMarket anticipates that the 3D scanner market will reach USD 1.3 billion by 2026.

One of the reasons for the popularity of this technology is that it can reduce costs by 50%, compared to 2D scanning.

The savings mainly stem from not having to hire a costly survey specialist.

In addition, this high-precision technology yields impressively accurate results, which means fewer adjustments in later stages, and, therefore, fewer costs.

The San Antonio-based company ReckonPoint uses it for indoor mapping by sending a robot to take measures by doing laser scans.

The robot takes thousands of photos using the LIDAR technology (Light Detection and Ranging) and uploads them to the cloud, creating a 3D model known as a “point cloud,” a set of connected points in a 3D coordinate system.

According to ReckonPoint owner Gabe Ganza:

“Architects tell us that they have to go back 5 or 6 times to take more measurements. We don’t have to worry about going back a second time… all they have to do is go back to the point cloud and all the data is there.”

Furthermore, measurements using laser scanners take minutes instead of weeks, so in ReckonPoint’s experience, it’s 85% faster than the traditional way of measuring a site.

Augmented Reality

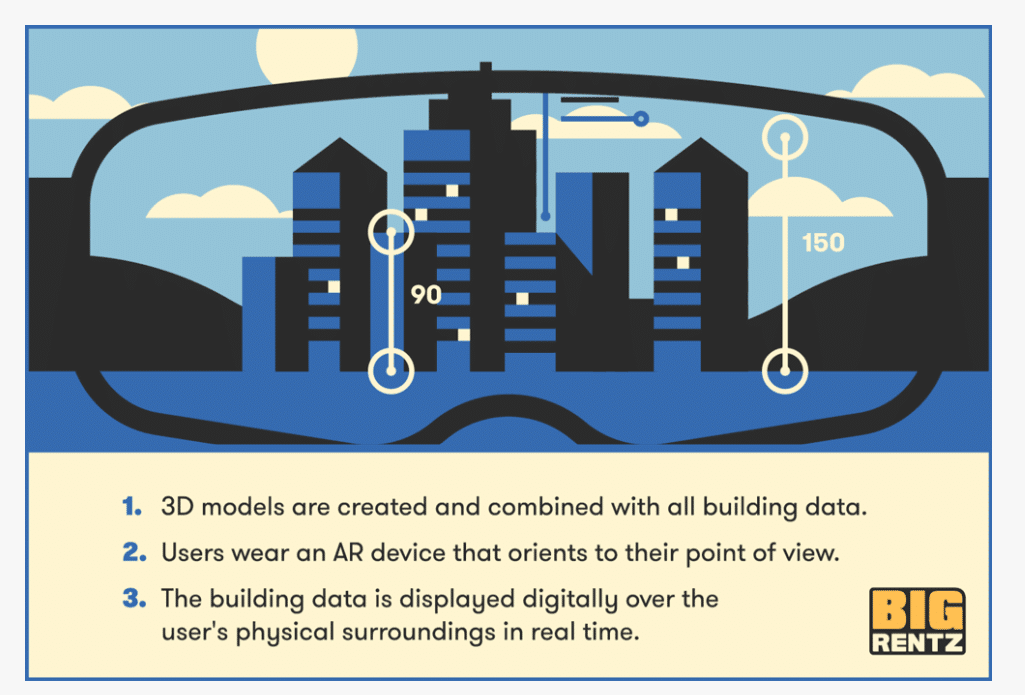

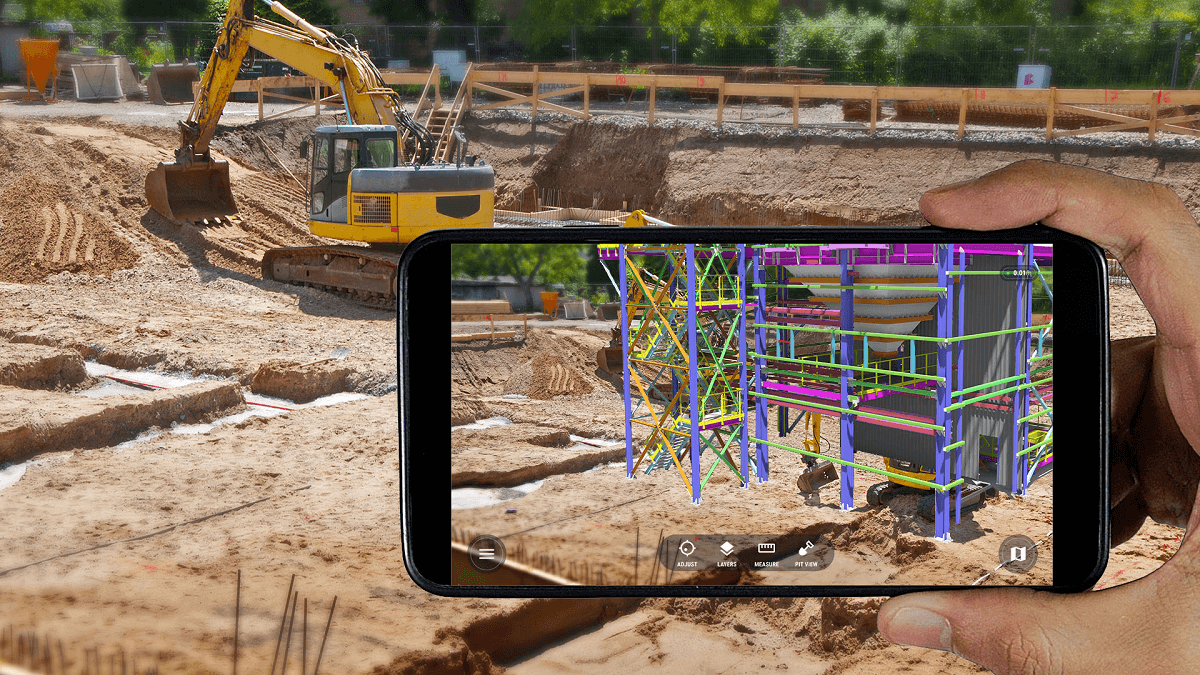

Another type of construction technology that has been gaining traction is augmented reality (AR).

In most basic terms, AR shows digital elements in the physical world to let users see what a concept would look like in real life.

For instance, when AR is used in the planning stage, it can show what a finished product will look like and allow you to visualize the building in relation to its surroundings.

Clients get a more accurate picture of the finished product, so adjustments can easily be made before the construction starts.

Below is Big Rentz’s illustration of how AR works in construction.

One major benefit of AR technology is that it can improve client relationships.

The fact that construction professionals can use AR to show clients the design in real life and experience what walking through a building will actually look like means that there will be fewer misunderstandings.

As everyone is on the same page throughout the process, changes can be made on time.

This means that construction is a seamless, continuous process without interruption and delays, leading to reduced costs, increased productivity, and, ultimately, a happier client.

AR technology also streamlines collaboration, which is particularly useful if project stakeholders are at different locations.

For instance, one person can be on-site wearing AR glasses, share the video with various stakeholders, and get input from, say, the client and the electricians and carpenters simultaneously.

Their feedback can then be used to make modifications as necessary. They can also quickly resolve any issues that arise at any point during the construction.

Small Construction Wearables

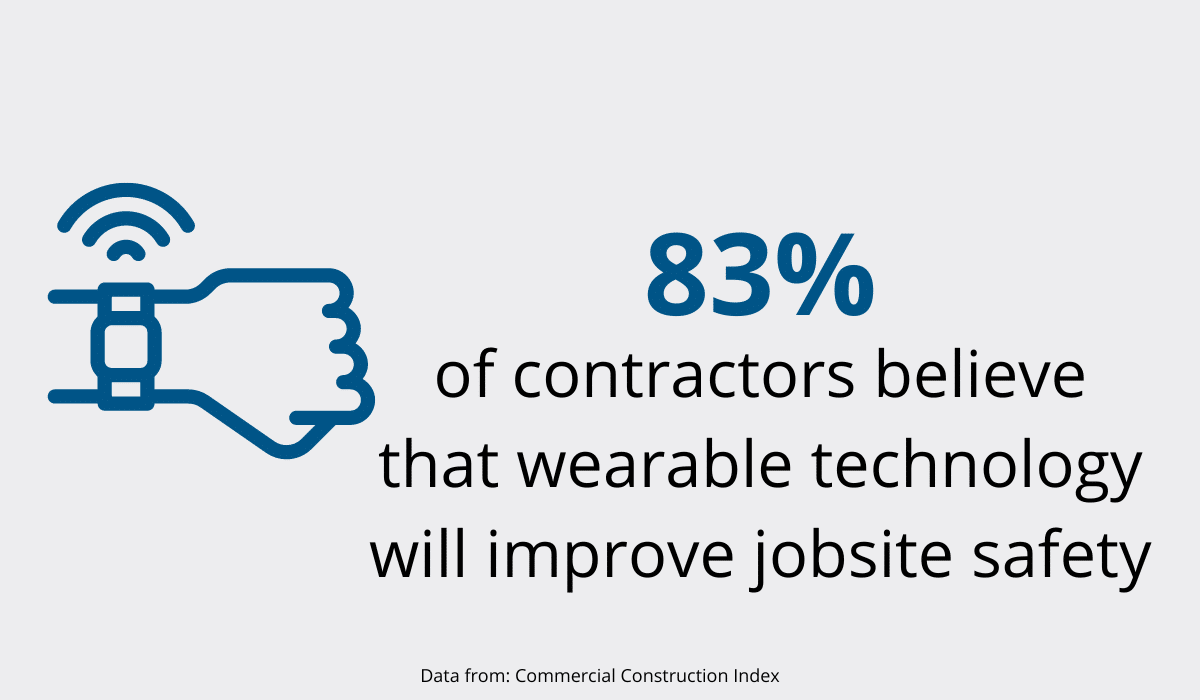

Small wearable technology can increase worker safety by registering potential hazards in their surroundings or notifying them of their exhaustion levels.

Construction workers have recognized this potential—the findings of the Commercial Construction Index indicate that an overwhelming majority of workers believe wearable technology will improve jobsite safety.

Let’s look at some examples of construction gadgets that can do this.

Smart Watches

Smart watches are the most commonly worn type of construction technology. They allow hands-free communication, which is essential for manual workers.

They can also monitor vital signs to help prevent exhaustion and immediately alert managers if an accident happens.

Receiving notifications instantly in case of an accident can minimize response time and help emergency services reach the worker quicker.

Smart Helmets

Smart helmets can do much more than protect workers from falling objects. For instance, SmartCap monitors the wearer’s vitals and signals when a worker needs to take a break.

As hard labor leads to fatigue, tired construction workers are prone to microsleep, which puts them at risk of serious injuries.

Smart helmets prevent this by monitoring brainwaves, helping workers stay focused, and keeping them out of harm’s way.

Smart Boots

Some smart boots are equipped with technology that can let you know if you’re trying to lift an object that’s too heavy, so they help prevent serious back injuries.

They also have location sensors and can notify workers when they spend too much time in unsafe areas or notify managers if accidents happen.

SolePower models can even be charged by walking and two hours of walking get you one hour of talk time on an iPhone.

Smart Glasses

We’ve mentioned that glasses can be used for AR in construction, but they can do much more.

Workers can access plans and blueprints recorded in the glasses app or use glasses to install behind-the-wall materials (e.g., plumbing).

Like other smart gadgets, they can also prevent accidents, for instance, by notifying workers when they get close to a leading edge.

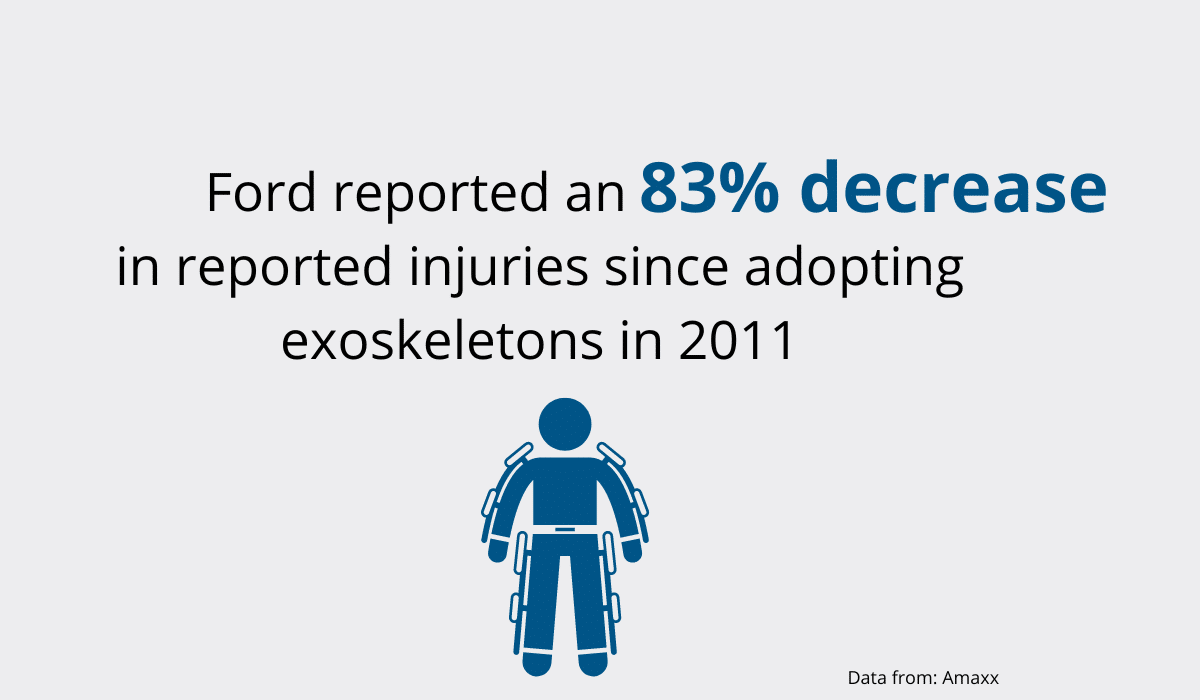

Exoskeletons

Even though you might think exoskeletons fall in the “science fiction” category, they are very much a reality in construction.

Exoskeletons are motorized wearable devices that reinforce workers’ strength or relieve pressure on a body part under a lot of strain.

They also make the wearer look like Iron Man—which is a bonus.

They can be mechanical, helping in weight distribution, or electrical, enhancing strength.

When Ford introduced exoskeletons in their factories, they saw an impressive 83-percent decrease in reported injuries.

There are different types of exoskeletons depending on the level of support they provide, so you can have full-body exoskeletons or exoskeletons for a specific body part.

The latter category includes support for:

- Crouching and standing

An example is the Chairless Chair which allows users to switch between different positions effortlessly and reduces strain on the back.

- Arm and shoulder

Ekso EVO helps reduce strain on shoulder and arm muscles when doing repetitive overhead movements.

- Back support

The SuitX BackX promises to ”reduce the strain on a wearer’s lower back by an average of 60% while stooping, lifting objects, bending or reaching”

One of the biggest benefits of exoskeletons is that the additional support they provide can help aging workers or workers with reduced mobility do their jobs.

This gives them more employment opportunities and a chance to stay in the workforce longer, while construction companies get to keep high-quality workers.

Exoskeletons also increase worker productivity. Workers don’t get exhausted, nor does their body endure as much stress, so there’s less fatigue, and workers can get more work done.

Data Collection Apps

It seems that there’s an app for everything, which is excellent for a data-rich industry such as construction.

Managers need to keep track of multiple sites and numerous pieces of equipment, so they need something to make their job easier and more manageable.

A tool-tracking app such as GoCodes Asset Tracking can come in handy in this regard.

The app allows you to track all your equipment as it scans QR codes on tools.

In addition to telling you where each tool is and who has it, it registers data on when a tool was checked in or out and when it was last serviced.

This helps managers manage their resources and plan finances better because they know when a tool will need to be replaced.

Furthermore, they know where each item is located, so there’s no risk of misplacing it.

Another thing managers can use is an app that captures their workers’ time data.

For instance, Spark developed an app that lets workers clock in and out on their phones.

These time entries were then synced with accounting to make payroll calculation seamless at the end of the month.

An app like this saves time a manager would typically spend on creating reports and analyses, as they can be made with a single click.

Last but not least, apps can help with safety, which is a significant issue in construction.

For instance, an app can be used by workers to watch training videos to increase safety awareness.

It’s practical, as separate training sessions don’t need to be organized, and there’s no limit on the number of attendees, allowing more employees to undergo training at once.

Managers can then check who watched the video to ensure safety compliance or even quiz workers to see how well they paid attention.

Conclusion

Construction professionals use more and more types of construction technology throughout projects.

Some types offer shortcuts to shorten lengthy processes or automate specific tasks in construction, while others allow managers and workers to get more accurate data and share it in real-time.

Things like exoskeletons and augmented reality, which used to be subjects of science fiction novels, are finding their way into construction and helping stakeholders do their jobs more efficiently and more quickly.

Thanks to them, construction is becoming a safer and more productive industry, one gadget at a time.