Using a tool tracking system in construction helps companies save money, work more efficiently, and prove compliance with local, as well as national regulations.

With a robust tool tracking system, project leaders and decision makers can maintain an overview of these company assets across multiple locations.

Moreover, tool tracking makes business scaling easier and improves client communication. It also allows access to tool information and reduces administrative costs.

Last but not least, tool tracking minimizes unnecessary tool time.

Read on for more information about the many benefits of investing in a tool tracking system for your corner of the construction industry.

In this article...

Enables Multi-Location Overview

What’s better than tracking assets and tools on one site? One thing: tracking assets and tools on multiple construction sites simultaneously.

With multi-location overview, it is not necessary to go from site to site in order to figure out where the tools are, how they are used, and what condition they are in.

The ability to understand what is happening on multiple sites at once saves gas and time, and can assist with proving regulatory compliance.

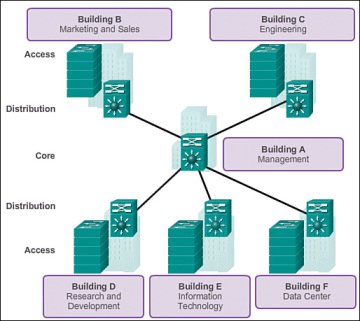

As the above graphic indicates, the ability to communicate between multiple buildings is an advantage.

Imagine how much more helpful it is to see and speak to employees on remote sites, even far from company headquarters.

Before the advent of digital information and advanced asset tracking, construction companies were forced to work from one database in a single location, which was not only limiting, but posed a security risk.

Asset tracking enables informed multiple-party communication.

Field technicians, third-party contractors, and decision makers can all look at and discuss the same data at the same time.

That means real-time information about maintenance, work progress, and tool condition.

Multi-location overview can also help with employee safety, as it allows a fresh perspective from someone who might recognize a danger that those on site cannot.

Allows Access to Tool Information

A tool tracking system makes it possible for construction teams to access information regarding tools in real time.

From initial purchase costs, to the last maintenance date and last fixes, as well as the location and user of the tool, all the data on a tool is gathered in a single centralized place.

Not only that, this information is readily available for analysis against other items and trends across time, jobs, employees, and seasons.

While it’s common to track heavy equipment, it’s important to remember that even small items, such as office supplies and tiny bolts, are appropriate for tracking.

Best of all, authorized employees are able to access the data and images they need on just about any device.

As long as credentials are verified and access to cloud storage and updating is available, your team can find out what it needs from anywhere in the world.

It’s even possible to allow limited and temporary access to designated parts of the system, which is particularly useful when working with temporary employees or third-party contractors.

This feature also allows examination from union or government officials to verify code compliance.

Reduces Administrative Costs

Reduced administrative costs means a higher profit margin and opportunity to scale up your business.

When a company invests in a tool tracking system, the burden of processing information from the field is largely lifted from administrative staff.

Field members are freed from checking for information at a single physical location, and staff members are no longer required to pause tasks in order to provide information that is now available in real time at the employee’s location.

Tool tracking also allows for third-party contractors such as architects and masonry specialists to access data they might otherwise request from a central office.

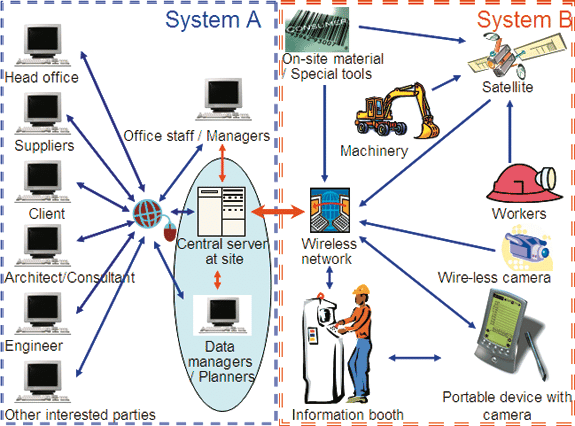

Depending on how your company is structured and the needs of your projects, you can set up your tool tracking system in a way that works for you. Here are two examples:

Tool tracking also increases accuracy both in the field and office. Handwritten lists and keyboard-entry data sheets are notoriously error-prone.

Even worse, they are expensive to store, they lack security, and it’s easy for these records to go missing.

When construction companies use asset tracking, the possibility for error is much reduced, and employees will know where tools and equipment are.

This feature is especially useful on sprawling construction sites, when many acres might separate employees from one another.

Improves Regulatory Compliance

See the graphic below for just a few of the details and points of concern with regulatory compliance:

Most construction projects involve community standards, national compliance requirements, company policies, and much more.

Meeting regulatory compliance becomes even more of a struggle if a project straddles multiple worksites in different townships or counties.

In addition, union requirements can be onerous, leaving little room for error.

Not only do construction companies face a number of code expectations, each agency might ask for compliance proof in a different way.

Both internal company and external government expectations are much easier to meet with a tool tracking system.

This is especially useful in the construction industry, in which hazardous materials or high-risk machinery are often in use.

A tool tracking system stores real time information in the cloud, which means it’s accessible from any location. In addition, companies seeking ways to improve regulatory compliance have a wealth of data to analyze asset tracking.

Decision makers can configure the system to record time of use, maintenance updates, shutdown hours during extreme weather, and more.

It’s also possible to know which employee has had access to control of each piece of equipment.

Should regulatory questions arise, it is only the work of a moment to summon exactly where, when, and with whom an incident took place.

Of course, such information is invaluable when it comes to employee training and safety reminders as well.

The GoCodes app helps to track operational information about tools, assets, and employee actions. The system even helps to generate compliance reports tailored to your needs.

Makes Business Scaling Easier

The first step of scaling is to form a complete picture of a company’s assets as they currently stand.

Rushing to scale up or scale down without this information could greatly hinder the operation, making for great expenses or delays.

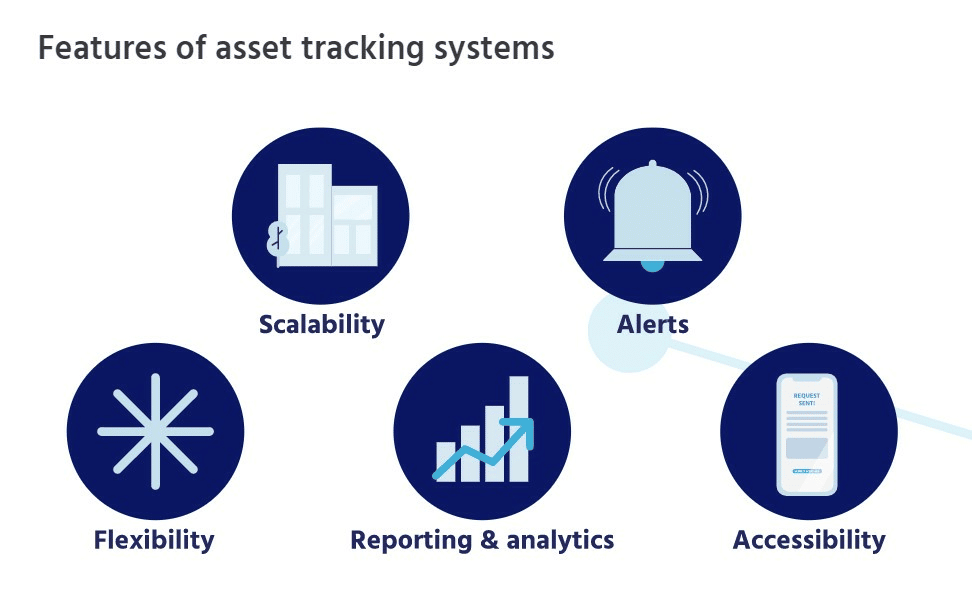

One of the best aspects of implementing a tool tracking system is that many benefits arise from its introduction. Operational speed can improve, as well as flexibility.

Both of these are vital when a company is seeking to scale its operations or cope with ceasing operations on certain projects.

See the graphic below for the features of tool tracking systems that can accompany assistance with scaling:

In the event of a sale or merger, a tool tracking system can validate assets and provide useful information about where each major item is in its life cycle.

Such data is immeasurably helpful for accountants, lawyers, and brokers.

This information can also help to prove company diligence in tracking down lost or stolen tools and proof of keeping items in good working condition as much as possible.

Improves Client Communication

A client lavished with personalized attention is seldom an unhappy one.

It is also important to demonstrate that your company is taking steps to provide the client with an experience that exceeds expectations.

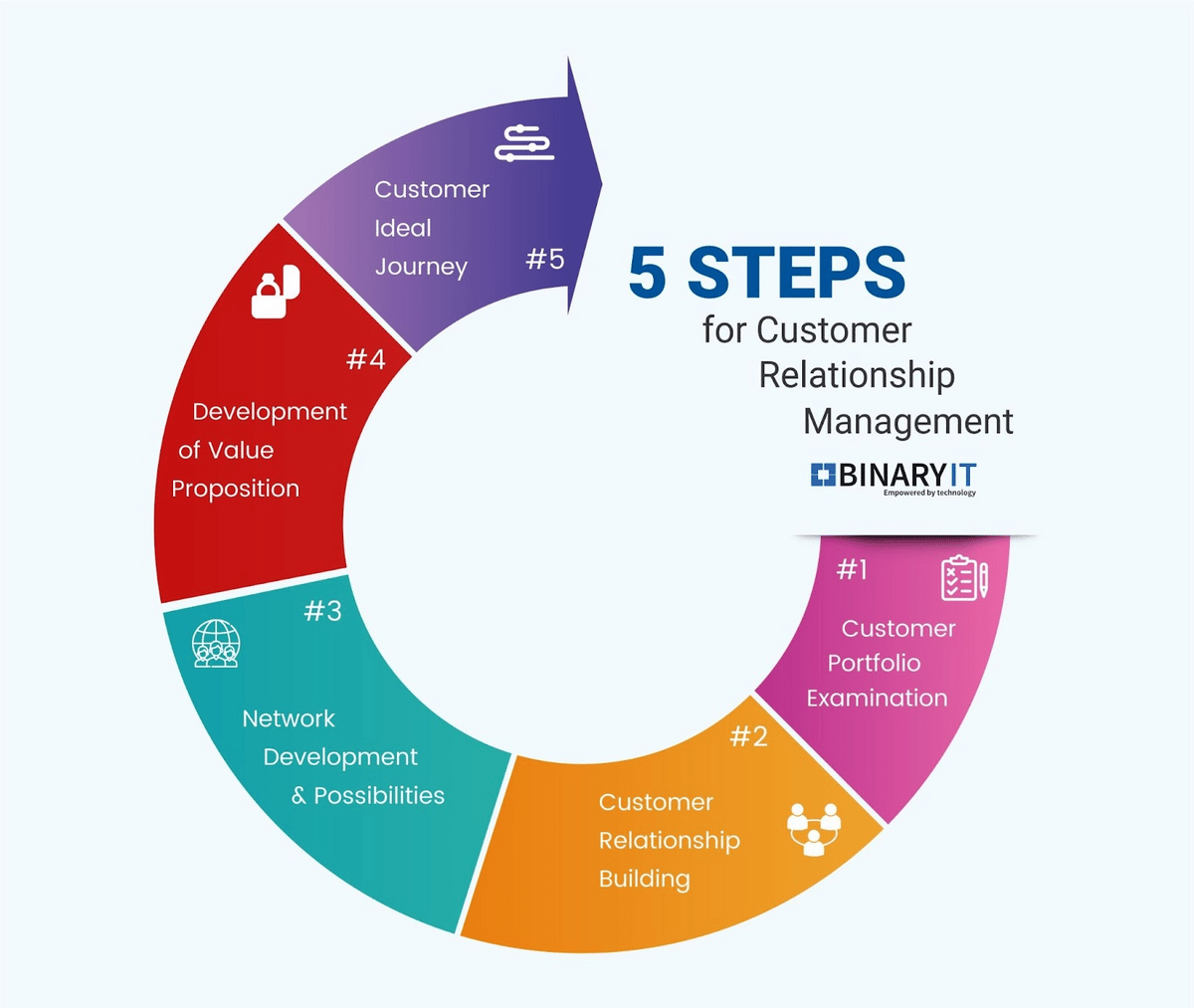

For example, some customers might approach a construction company about a project that could require teaming or the use of specialists.

When this is the case, project managers must manage expectations and establish relationships with not only the client, but those who the client’s project needs.

This graphic discusses the many aspects of client communication. It is a multi-step process, and never a finished job, as sometimes clients might serve as references.

How can tool tracking help with this multifaceted reality of the construction industry?

First, since asset tracking can quickly result in wider inventory, easy data analysis, and better utilization of tools, project managers are thus left with more time to develop and maintain personal relationships with multiple clients.

And, since tool tracking is a path to faster delivery, instant communication, and the ability to answer client questions quickly, IT plays a role in helping the client feel listened to and respected.

Construction tool tracking also allows companies to provide more accurate start times, milestone placement, and completion dates.

The abundance of precise data that asset tracking provides allows for these on-the-mark projections, and they also assist in explaining to clients about supply chain snags, weather delays, and labor shortages.

When clients can see data and pertinent information about their project, they tend to be more understanding when dates slip, inventory is unavailable, or equipment is damaged by natural forces.

Real-time GPS updates are also extremely useful in letting clients know an estimated arrival time of a crew member, piece of material, or fleet item.

All of this helps to cement a healthy relationship, one based on trust and honesty.

Minimizes Unnecessary Downtime

Downtime is a nightmare for construction companies for a number of reasons. It causes timeline slippage and threatens to disappoint clients.

Downtime is costly, too, because project managers must often scramble to rent replacement equipment, pay for employee overtime, and undertake repairs.

However, construction tool tracking can play a role in minimizing downtime as much as possible.

Sometimes downtime is a result of misplaced or stolen assets.

Since systems like GoCodes offer GPS tracking, this danger is often eliminated altogether, as it’s possible to see where an item is or was last used. This helps to avoid costly downtime:

The ability to monitor equipment is also helpful in the quest to minimize downtime. Tool tracking supports the ability to check on maintenance needs.

It allows for easy updates on preventive maintenance, and the data trail tracking leaves provides useful information for in-house techs or third-party repair teams.

When tools are kept in good operating condition and maintained as the manufacturer intended, it’s much easier to avoid catastrophic breakdowns.

Conclusion

Using a tool tracking system in construction offers many benefits. It can enable multi-location overview and ease access to important tool information.

In many ways, asset tracking reduces overhead and administrative costs while improving employee communication.

It also helps to ensure regulatory compliance and aids in business scaling.

Construction tool tracking also minimizes unnecessary downtime and is a vital part of providing clients with an ideal customer journey.