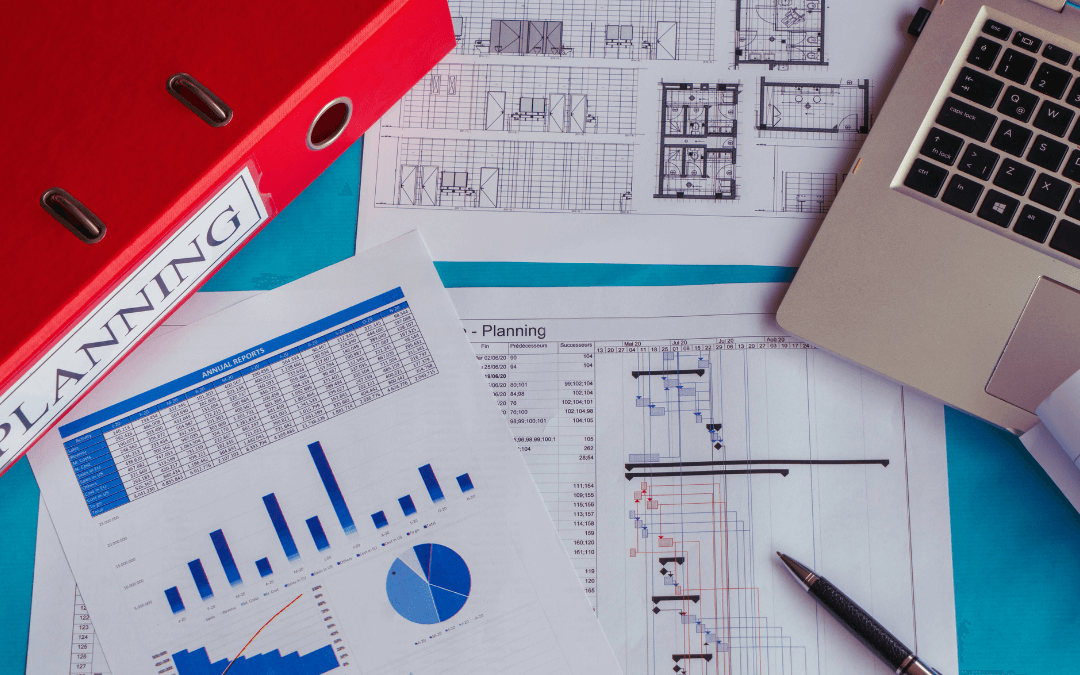

What is Construction Scheduling

This article will explain what a construction schedule is and how it can be used to improve the management of construction projects.

What is Construction Scheduling

This article will explain what a construction schedule is and how it can be used to improve the management of construction projects.

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

More from the blog

Tool Tracking System: Everything You Need to Know

Tools are among the most easily lost and misplaced assets in public and private organizations. Maintaining real-time information about their location is invaluable. Tool tracking is an important function for construction companies, retail outlets, nonprofit...

A Guide to Preventive Maintenance Checklist

When specialized technicians need to work on your equipment, a preventive maintenance checklist presents standardized information for all the assets in your company. Preventative maintenance checklists also provide an identical basis of information for employees, management, and outside contractors.

Comparing Milwaukee Tick with QR Codes trackers

Introduction Milwaukee Tick Tracker What’s the number one headache shared by tool and trade companies everywhere? Yes, how to keep track of that expensive equipment which can move from site to site and person to person sometimes on a daily basis. If tracking is not...

Heavy Equipment Maintenance: All You Need to Know

Heavy equipment maintenance and repair is a must to keep your business moving. We are sharing tips on avoiding costly repairs, and best maintenance practices.

Asset Tagging: 5 Best Practices You Should Follow

Asset tagging best practices include knowing what to tag, what information to include in labels, and which labels to use.

Construction Site Theft Prevention: 10 Ways To Do It

There is no single measure that will help protect your site from theft. You need to look at this as a holistic approach. We’ve put together a list of actionable steps that you can implement.

A Guide to Small Business Asset Tracking

Small businesses need to track their assets too, but they face different challenges than big corporations. This guide answers all questions.

Equipment Maintenance Best Practices

Whether you’re in construction or manufacturing, the health of your equipment is the lifeblood of your business. Equipment downtime can lead to massive time waste and affects your bottom line. That’s why keeping the equipment in good working condition should be a priority.

We explain the four types of equipment maintenance and their best practices.

8 Causes Of Heavy Equipment Failure (And How To Prevent It)

Heavy equipment failures happen when you least expect them, and cause downtime, stress, and cost you money. This unplanned downtime can cost project managers around 400 to 800 non-productive hours per year, per machine. To put a prevention plan in place, you first need to understand what the primary causes of these failures are.

School Asset and Inventory Tracking

Exclusively for schools! GoCodes School Inventory & Asset Management—Education Edition. Sign up for a free trial today to see why over 50% of schools who try GoCodes chose us for their school! School inventory tracking has traditionally been a massive...