Perhaps you’ve noticed that QR codes have become ubiquitous. They’re surfacing on everything from product packaging and restaurant menus to bills and invoices.

So, it’s no surprise that you can use them to transform your construction site management, too.

Inside those seemingly simple, monochrome, pixelated squares lies the potential to revolutionize the way you manage your construction projects.

In this article, we’re going to show you how, when done right, QR codes can significantly improve your on-site operational efficiency.

Our goal isn’t just to give you a theoretical insight into this technology, but to walk you through practical steps you can start applying in your everyday operations.

In this article...

Share Standard Operating Procedures

One of the common problems anyone in the construction industry can attest to is handling standard operating procedures.

These procedures are a set of step-by-step instructions for routinely conducted operations.

Who does what? When and where is it done? How critical or challenging is it? What can happen if it’s done incorrectly?

These are the questions that the standard operating procedures answer precisely.

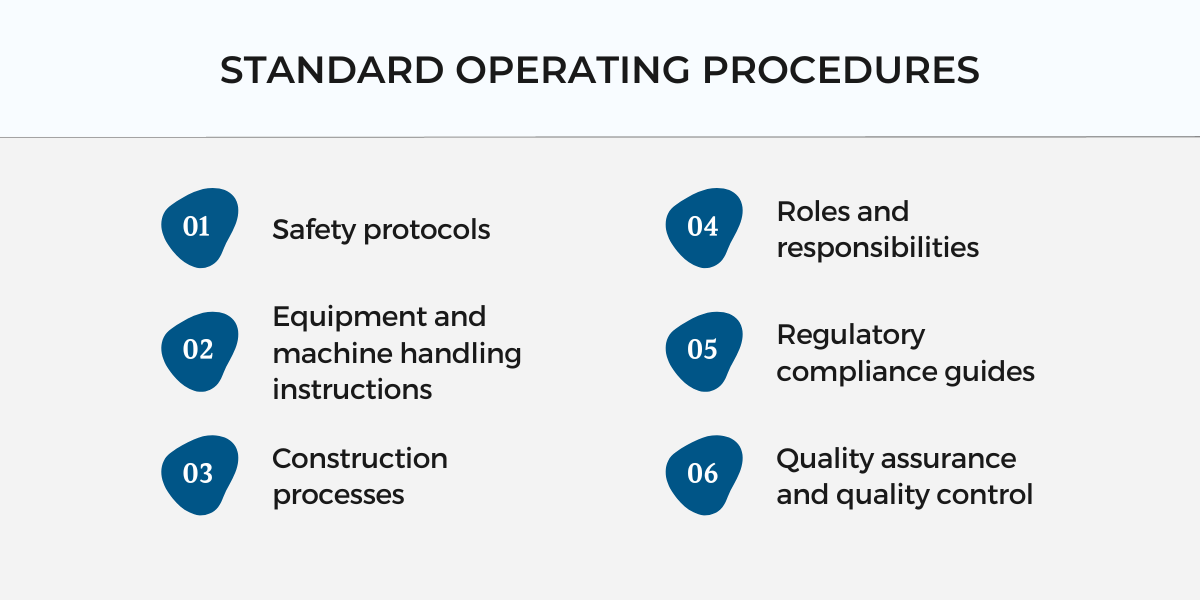

For instance, machine handling instructions, safety protocols, construction processes, and regulatory compliance guides, to name just a few, fall under the category of standard operating procedures.

They are important because by following the exact same procedures every time, companies can maintain consistency and uphold industry standards and regulations.

The challenge?

They’re traditionally hefty documents, difficult to lug around, and impractical in printed format on a busy construction site filled with dust, dirt, and heavy machinery.

Here, QR codes can be of great help because they make these documents more accessible.

You can, for example, seamlessly integrate a QR code across various touchpoints at your construction sites, from the main entrance to specific locations.

Team members just have to hold up their smartphone, scan the QR code, and they’ll instantly be redirected to a page containing a PDF outlining the work procedures.

The process is easy and straightforward, and there’s no concern about misplacing a multi-page document while working.

Doesn’t it all sound more efficient and less of a barrier already?

Make Instruction Manuals Available

On a construction site, there’s a range of diverse tasks to accomplish, and a whole array of equipment to tackle those jobs.

As you know well, each piece of equipment comes with a specific instruction manual, detailing the proper installation and operation steps for its safe and efficient use.

However, being able to locate and access these manuals when you need them can sometimes be a bit of a hurdle.

Here, QR codes can also serve as a means of sharing information quickly and conveniently.

By placing a QR code directly on each piece of equipment, you’re providing easy and immediate access to the page where your team can find usage instructions.

Workers no longer have to flip through pages of a physical manual or dig through a database to find what they need.

They can use their smartphones or tablets, scan the QR code, and instantly access detailed instructions.

Now, let’s bring this to life with an example. Consider a situation where you have excavator operators about to operate a newer model of excavator for the first time.

Say, one equipped with 360° safety cameras or enhanced with 3D grade control, but they’re not familiar with it. In the traditional scenario, this could lead to trial and error or unnecessary safety risks.

But with a QR code on the equipment, they can scan the code and get detailed instructions, catered to their location and job.

This ensures proper usage and accident prevention, which, as a result, translates to a safer worksite and higher efficiency for construction projects.

Provide Access to Updated Blueprints

It’s hard to imagine a construction project without various types of blueprints.

Blueprints, also known as technical drawings or plan sets, are detailed representations of building designs that guide construction teams throughout the process of building structures.

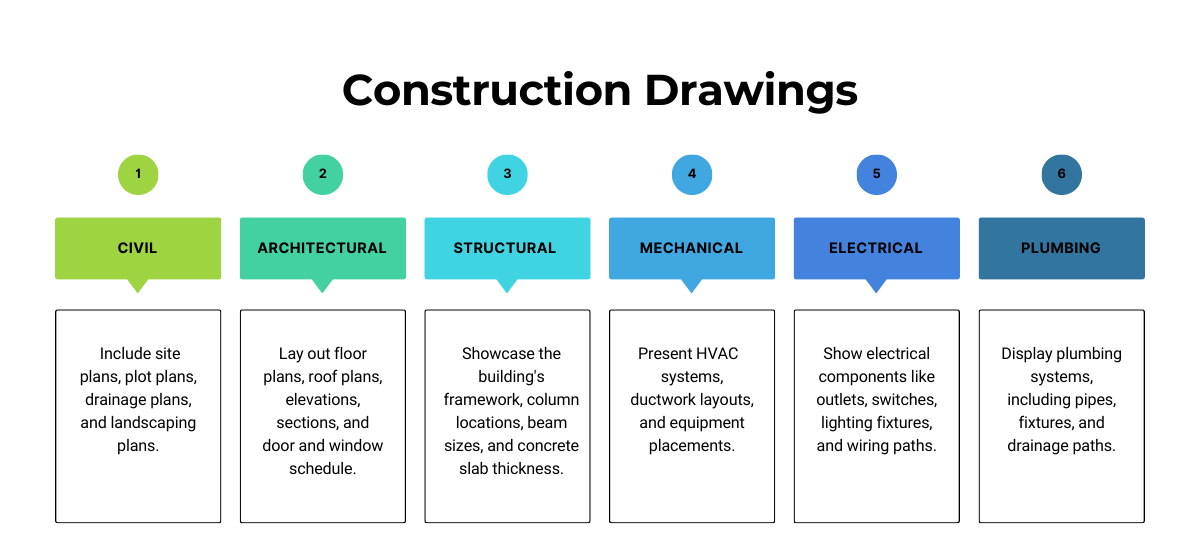

Among the many types of construction drawings, some of the most common ones include civil, architectural, structural, mechanical, electrical, and plumbing plans.

But as vital as these blueprints are, they aren’t set in stone. With changing project needs, updates are common and necessary.

However, every time those blueprints change, everyone on the team needs to be updated.

Sharing updated blueprints traditionally involves sending large files via email or printing them and distributing them to everyone on staff.

Sounds exhausting? It is. Not just for the person distributing the files, but also for those on the receiving end.

Time and efficiency are crucial in the construction industry, and sadly, this process can eat away at both.

This is a situation where dynamic QR codes can be more than helpful.

A dynamic QR code is a flexible, adaptable QR code that can be updated anytime, anywhere.

This means that instead of designing a new QR code for each blueprint change, you can modify the content of a dynamic QR code, and it retains the same appearance.

After that, everything is pretty straightforward.

When you place dynamic QR codes on your construction drawings, construction site, or on-site offices, your staff just needs to scan the code to access the latest blueprint.

No need for wasteful printing or the confusing hand distribution of updated plans–one scan, and they’re viewing the latest update.

Imagine the ease it brings to your construction process: less confusion, fewer errors, and easier updates.

Monitor On-Site Employee Activity

At first glance, it might not seem like a small square of black and white pixels could help you with on-site activity management.

Yet, QR codes have proven their worth as a convenient way to indirectly monitor employees.

They’re usually accompanied by a check-in and check-out system, which is akin to a library, where you can borrow a book but need to return it for others to use.

Every tool or piece of equipment you possess on-site can be assigned its own unique QR code–just like books in a library.

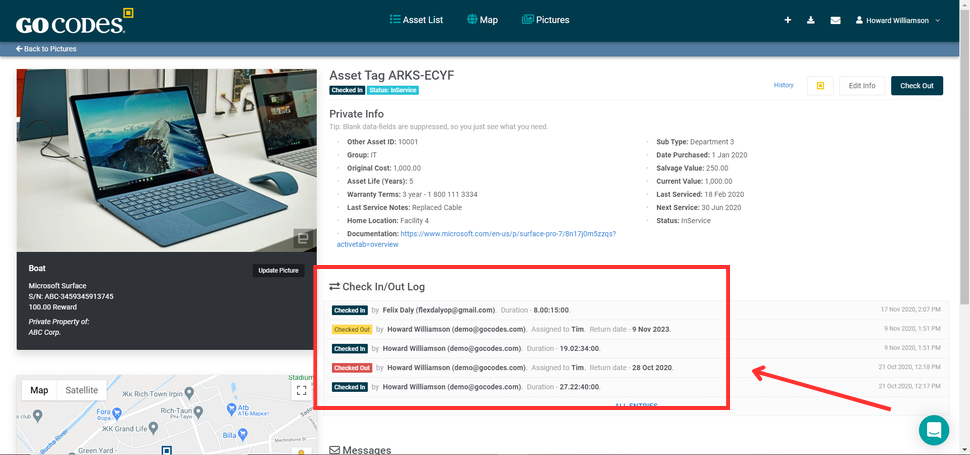

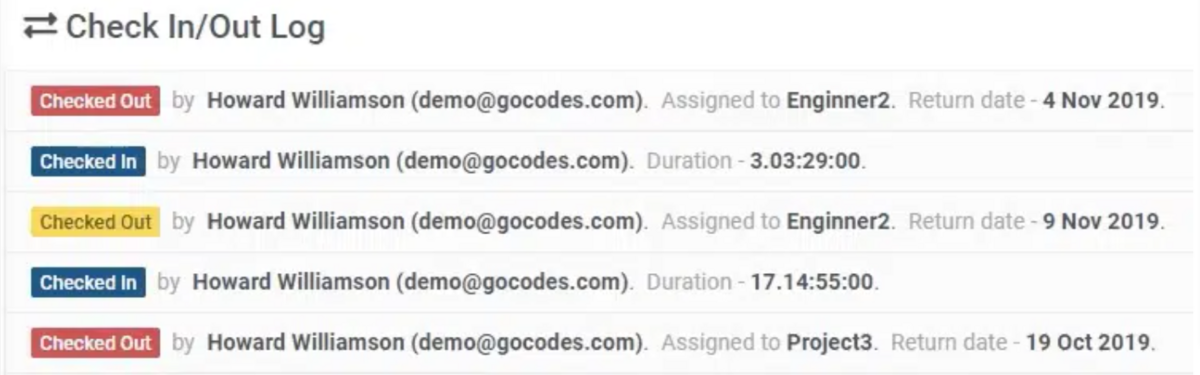

When workers need a tool, asset managers can simply scan the QR code to lend them the tool.

The system registers the check-out, logging important data like who took the equipment, and when they took it, as you can see below.

After the job is completed, the return is just as easy. Another quick scan, and the tool is checked back into its virtual inventory.

But, you may ask, what about employee attendance?

While it’s a valid point that QR codes don’t provide a way to track employee attendance and clock their hours and breaks, they do record the interaction between workers and resources.

What you’ll have on your hands is a detailed log of who used what tool, how often, and for how long.

Over time, this can give a valuable account of your employees’ on-site activity.

Track the Locations of Assets and Materials

Tracking the constant movement and location of tools, machinery, and materials within the bustling environment of a construction site can often present a logistical challenge.

However, this task can be simplified with QR codes in combination with advanced asset management software.

Let’s use our own software, GoCodes Asset Tracking, to demonstrate this concept.

GoCodes Asset Tracking enables you to assign every asset on the construction site a distinctive QR code label. You can think of it as an individual ID for every asset.

GoCodes Asset Tracking is designed to generate these codes, making the process straightforward for you and your team.

As workers move tools and equipment across the site or even between multiple sites, all they need to do is scan the QR code using a smartphone or tablet and the integrated scanner in the GoCodes Asset Tracking app.

This one action is sufficient to update the asset’s new location within the system, making it visible to all authorized users.

Are you wondering where a specific tool is or do you need to fetch details about a piece of machinery? Once more, all it takes is a simple scan of the QR code.

This action leads you right to the individual asset’s information page, which gives you all the essential details you need: actual location, current availability, maintenance status, and even past usage.

All this real-time information is stored in a cloud-based database, which means you can access any required data, from any location, at any time of your convenience.

QR code labels have another crucial role: establishing clear ownership of your assets.

If any ownership disputes arise, the QR code label on your asset or material acts as a clear sign that it belongs to your company.

Another notable feature of these QR code labels is their built-in GPS tracking capabilities.

As a label is scanned, the software logs the smartphone’s location automatically, thereby significantly reducing instances of loss and theft, while fostering a healthy sense of responsibility within the team.

Conclusively, QR codes and sophisticated asset management software such as GoCodes Asset Tracking can enable you to transform the often complex logistics of a construction site, making them far more streamlined and user-friendly.

Conclusion

It’s clear that employing QR codes isn’t just a passing trend, but a shift toward improved efficiency on the construction site.

QR codes can make sharing standard operating procedures simpler.

It can ensure instruction manuals are readily available on the go, provide immediate access to the latest blueprint updates, record on-site employee activity, and keep tabs on asset locations.

But remember, reading about it is just the first step. The true impact comes when you successfully apply this technology to your construction site management.