Even though the construction industry is predicted to grow by 15.6% in 2021 alone, it is one of the two least digitized industries, which sets it back.

As the worth of a market increases, so do its needs. The construction sector cannot afford to keep lagging.

If you haven’t already turned to technology to digitize and automate at least some of your workload, this article will encourage you to do it.

We will explain which benefits you can reap by using GPS to track your heavy machinery. It’s a big step towards using technology to your advantage and adapting to the market changes.

Let’s get to work!

In this article...

Equipment Theft Prevention

One of the most valuable advantages of using GPS for equipment tracking is the decrease in theft.

After all, if someone sees that you’ve invested in equipment tracking, they are less likely to steal from you, knowing that the chances of you locating your machinery are high.

Since theft is quite prevalent in the construction industry, this added layer of security should be incentive enough for you to invest in tracking solutions.

However, if you want further proof, we’ll take a closer look at the latest National Equipment Registry’s (NER) Annual Theft Report, which explains that only 21% of stolen machinery is ever retrieved.

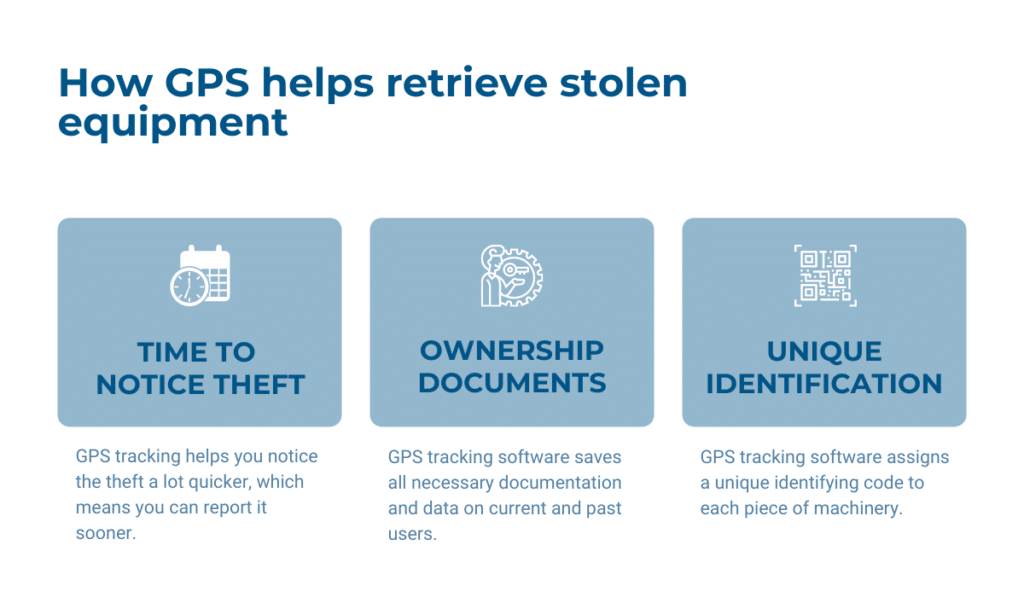

Thieves tend to remain uncaught because of the following set of circumstances:

- It takes a long time for the construction company to notice and report the crime.

- The company doesn’t have all the necessary documents, which makes it harder to establish ownership.

- The equipment’s identification isn’t unique, thus additionally hindering efforts to prove that the piece of machinery belongs to the company.

- Limited law enforcement resources slow down the investigations.

The good news is that GPS tracking can help you deter thieves and retrieve your machinery if someone steals it. Using software that allows you to locate your equipment eliminates at least three of the issues mentioned above.

First, when you use software to track your equipment, you know exactly who is using it and when you are getting it back.

A solution like GoCodes Asset Tracking emails you when someone exceeds the agreed-upon return date. After checking in with the current user, you can determine where the equipment is. If it’s lost, your team can report the theft to the authorities immediately.

The software makes it easier to save all the necessary documentation to the cloud and attach it to the page dedicated to that specific piece of machinery. That way, whenever you scan the durable QR code on the item, you will access its designated page and have access to records that prove your ownership.

Furthermore, GPS tracking software can assign each piece of machinery a unique ID.

Most software providers offer cross-company unique identification, meaning that two pieces of equipment you own can’t have the same ID.

GoCodes Asset Tracking, however, provides a globally unique identifier for your equipment. Even if other companies use the same software, your codes won’t be the same as theirs, which will help you prove that the equipment is yours.

Moreover, our labels are rugged, which means they are made to withstand even the harshest conditions, ensuring that they won’t get ruined at the worksite.

Additionally, if you’re worried about your ID tags getting removed intentionally, you can choose to weld them to your machinery.

That way, potential thieves will have a harder time getting them off the equipment, and as a result, the item will be easier to locate afterward.

If preventing theft is a priority for you, invest in equipment tracking to not only deter potential thieves but also increase the chances of retrieving your stolen property.

Streamlined Site Management

GPS tracking helps you manage your worksite seamlessly, so here’s how to make the most of it.

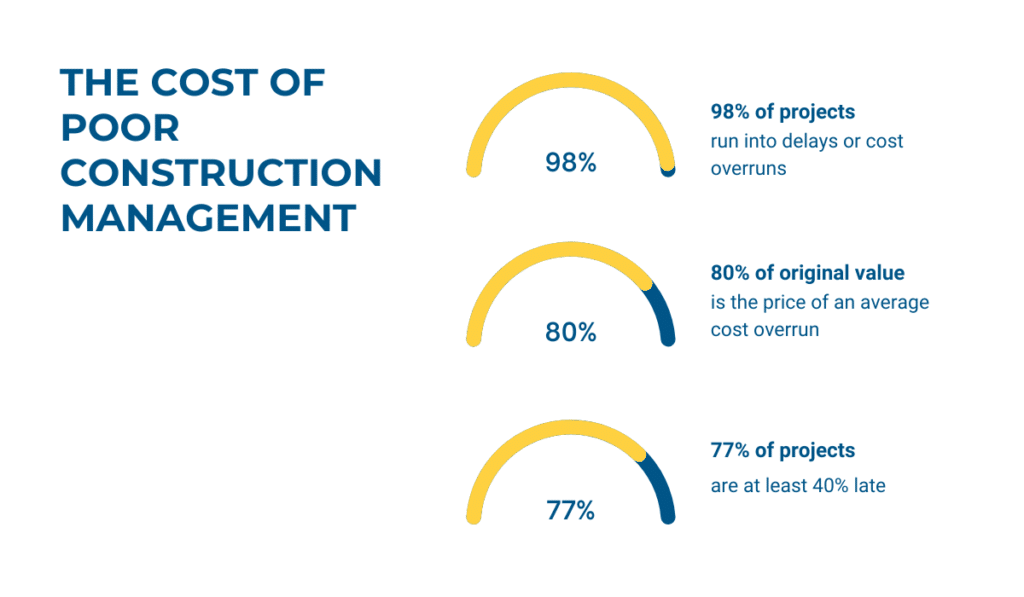

Good site control is critical for construction project success. Otherwise, you’re facing some pretty serious risks. McKinsey’s construction industry research has uncovered some staggering facts about poor site management and the dangers associated with it.

Firstly, almost all (98%) major construction projects run into delays or cost overruns, which results in additional expenses for the company.

On average, the overruns amount to 80% of the project’s original value, making them an extremely costly problem.

When you consider that 77% of these projects are at least 40% late, it’s clear to see that any setback can mean a significant drain on a company’s resources.

So, if you can use GPS tracking to help you manage your worksites better, why not? Better management leads to faster project completion.

Software that allows GPS tracking can help increase efficiency by:

- Creating detailed equipment reports

- Lowering your downtime

- Promoting communication between teams

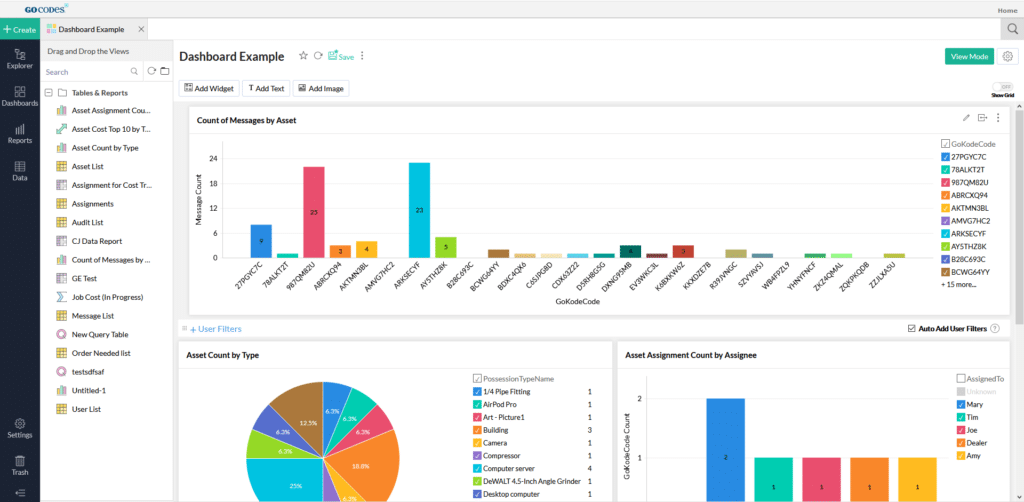

If you opt for a tracking tool that allows you to create and download equipment reports, you can save yourself hours of valuable time.

Nowadays, such software offers the option of creating and downloading usage and maintenance reports at the very least.

You can also create customized reports, with the data you’ve selected yourself according to the company’s needs. The best part, though, is that you can generate detailed reports in a matter of seconds, making you time-efficient.

Moreover, GPS equipment tracking helps you eliminate downtime. Extensive projects are often delayed because there isn’t enough equipment, or the machinery is not at the site on time, and there is no coordination between teams.

Tracking your equipment makes you aware of its last known GPS location and user at all times. The software will show you when the equipment will be available and when it’s reserved, allowing you to plan around it.

This option helps you avoid double-booking since employees will see when a piece of equipment is needed at the worksite and when they need to return it.

Of course, the opposite is also true: if you need to use specific machinery, a quick database search will help you check its status and, if possible, assign it to yourself.

Finally, systems that allow you to check equipment in and out usually enable users to leave messages on the machinery’s page. For instance, if a worker in the field notices a strange sound while using an excavator, they can scan the tractor’s QR code and make a note regarding its condition.

After getting the notification, your admins will be able to organize a quick check or even send a replacement while the tractor gets a detailed inspection from the service crew.

Therefore, GPS helps your team in the field communicate with the administrators and the maintenance team in a couple of clicks without leaving the worksite.

When you track your equipment, you help your team stay on top of the project and eliminate downtime and delays. If you finish your project on time, you’ll be more efficient than 98% of your competition!

Improving Accountability for Rented Equipment

If you are renting your heavy equipment to others, you want your renters to handle it with care.

It’s no secret that people tend to be less careful when using something that isn’t theirs, especially if it belongs to a company. That’s why your goal should always be to find a way to promote accountability among your renters.

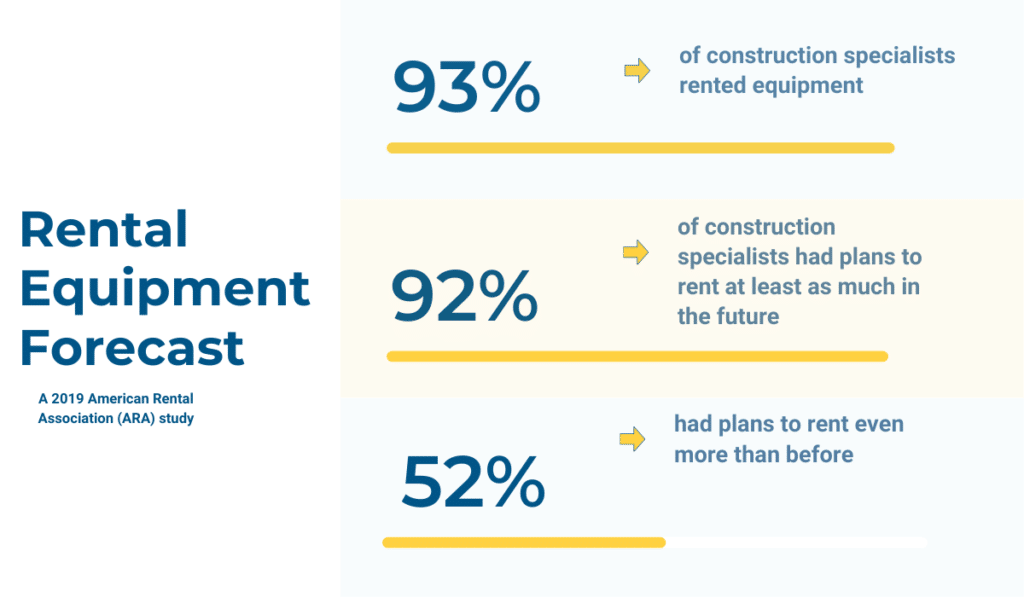

An American Rental Association (ARA) study found that 93% of construction industry specialists rented equipment in 2019. Out of the 93%, almost all of them said they planned to continue to rent just as much in the future, while half of them plan to rent even more.

Therefore, it is likely that, in your time renting equipment, you have already witnessed the lack of responsibility for machinery among your renters. Some clients don’t honor the contract they’ve signed, while others even go so far as to steal the equipment they’ve borrowed.

GPS equipment tracking can help you put an end to this, though.

When you rent your machinery to a client, you have no way of determining whether they are abiding by your agreement or not. All you can do is sign the contract and hope for the best.

However, if you invest in software that allows you to track your machinery, you’ll always know where it is.

GPS tracking helps you determine where your users last scanned an asset, which pinpoints its exact location at the time of the scan.

That way, you can check whether the equipment is being used in the area determined in the rental agreement.

This point is essential for both the renter and the rentee. If there is a dispute between you and the people you rented to, the data collected by an equipment GPS tracking system can save everyone involved a lot of trouble.

Using the information stored in the software, the owner can prove if the client left the agreed perimeter and fine them for it. Of course, the client can also ask the owner to check the scanned GPS locations in case they didn’t leave the perimeter and want to use the data as proof.

On top of that, this practical option can help you locate your stolen rental equipment. As already explained, you can easily track your machinery using GPS. If you have to prove ownership after finding your stolen property, you can do that by scanning the QR code you’ve placed on the equipment.

Information on Timely and Proper Equipment Maintenance

Equipment servicing is one of the pillars of construction, as no project can be completed with faulty machinery. Therefore, the fact that GPS tracking helps you manage it becomes a benefit you can’t turn down.

Without proper maintenance, your equipment won’t be reliable. You also won’t be able to tell how long the machinery will last and when you can expect it to become useless. Your projects will end up getting delayed, with the expenses piling up.

However, you probably already have a maintenance plan in place if you’re serious about your business. If not, you should create a servicing plan as soon as possible, or you’ll run out of money soon enough.

But, even if you have a great maintenance plan, it’s sometimes difficult to keep up with all the information surrounding it. This is where GPS tracking can be helpful.

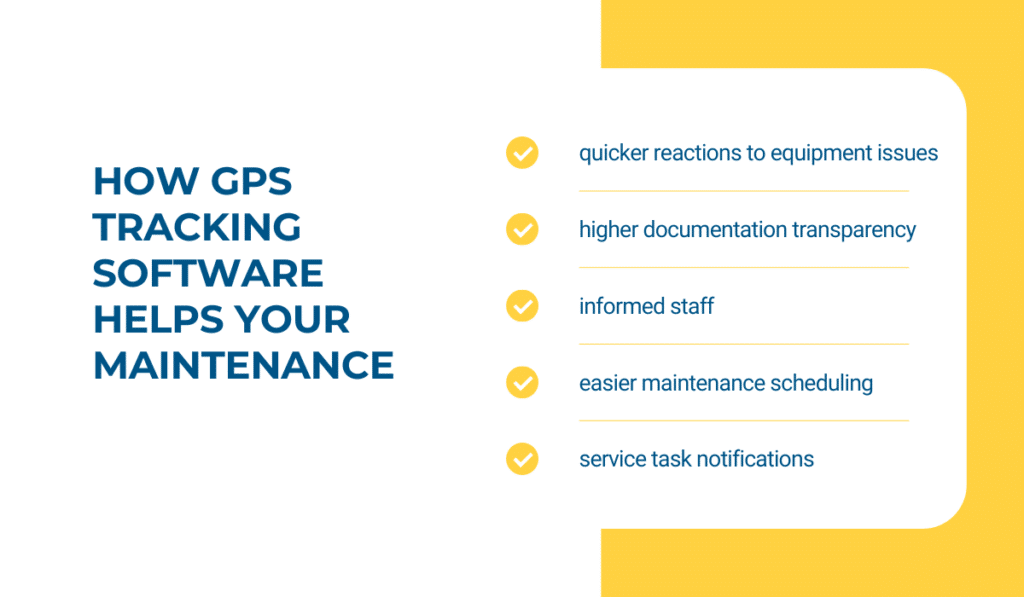

If you opt for GPS-enabled software for tracking your heavy equipment, you empower your team to report the issue quickly.

When the team in the field spots a problem, they scan the label on the machine and leave a comment detailing the issue. The maintenance team can then work to solve the problem as quickly as possible. By doing this, your team will bring downtime to a minimum.

As explained before, equipment tracking tools allow you to access the machinery database through a quick tag scan. What that database will contain is entirely up to you.

If your goal is to track your maintenance as well, then you can instruct your team to:

- add servicing logs after each session

- document the machinery’s condition before and after every use

- leave a message on the equipment’s page whenever there is an issue or a change

This way, your equipment’s status will be transparent and easily accessible to the members of your team. Your maintenance staff will have records on previous services in a click or two, allowing them to prepare for the next session.

The team in the field will be able to check these records if they need more information on the current state of the equipment. On top of that, the field employees will have access to the machinery’s manuals and instructions on proper use.

An additional benefit of equipment management and tracking software like GoCodes Asset Tracking is that it allows you to schedule future maintenance sessions in advance. So, after your service team updates a report on a maintenance task, they can plan the next one right away by simply selecting the date.

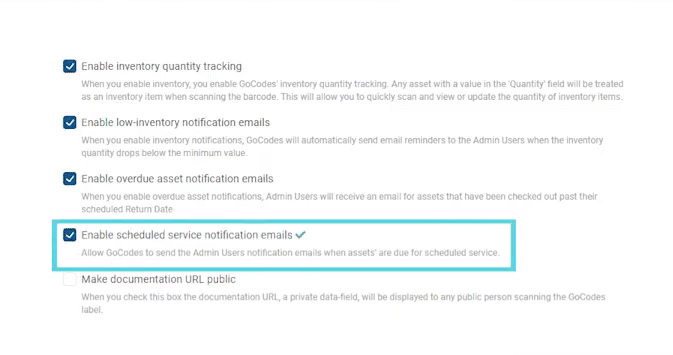

However, if you want to ensure that you never miss a maintenance date, turn on the notifications!

If you enable the option to receive emails for scheduled maintenance, the software will send you an email to remind you that a piece of machinery is due for servicing, ensuring that you never skip the activity.

Overall, GPS tracking software gives you a clear overview of your scheduled maintenance tasks and past service records, which is highly beneficial if you have more equipment than you can count.

Conclusion

GPS tracking is one of the most accessible technological solutions for locating equipment.

All you have to do is get the software that supports satellite-based radio navigation, understand how it functions, and train the team on using it. After correct implementation, the software does half the work for you!

Yes, it might take time for your workers to adapt to the new way of doing things, but once they do, you’ll see numerous benefits, such as time-saving, information transparency, more efficient maintenance, and consequently decreased downtime.

Overall, GPS tracking can help you stay on top of your equipment and achieve better results.

Why not use it?

GoCodes Asset Tracking Can Help

We use QR code tags with a unique visual code that you can scan with your smartphone. When scanned, GoCodes Asset Tracking tags provide GPS information about equipment location, making heavy equipment tracking easy. Sign up for a free trial here.