With almost 70% of construction executives making decisions with outdated, incomplete, or inaccurate data, it’s clear that data collection practices could do with some polishing. This is especially true when it comes to keeping track of fixed assets.

Fixed assets include property, buildings, vehicles, and equipment you use to produce goods or services.

Since they depreciate over time, it’s essential to record all changes and impairments—a challenge many construction companies struggle with and end up with incomplete records as a result.

So, are you ready to leave unreliable spreadsheet data in the past?

This article will guide you through four common challenges of tracking fixed assets and tell you how to manage your assets efficiently.

In this article...

Maintaining Accurate Asset Records

If you want to be on top of your fixed assets at all times, you should work on diligently maintaining fixed asset records. You can achieve that by entering all changes on time and rectifying inaccuracies as they occur.

Workers in construction know all too well how easy it is to lose count of supplies or expendable materials.

You’d think keeping records on fixed assets would be more manageable, but poor asset tracking practices leave a lot of room for error here as well.

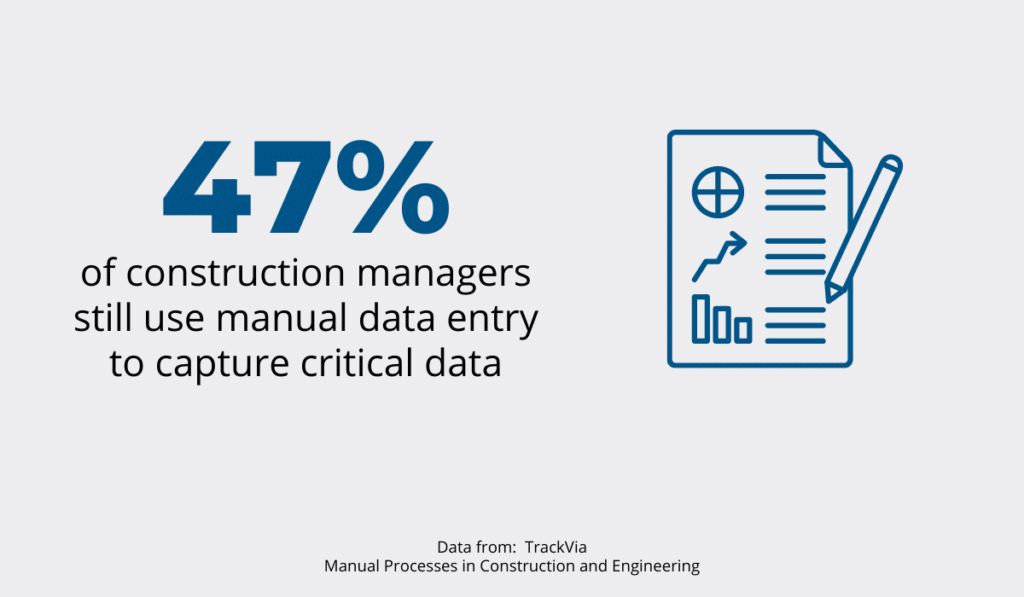

For instance, almost half of construction managers still rely on manual data entry.

In October 2020, a human error in data entry caused 16,000 Covid-19 cases to go unreported.

Public Health England was responsible for collating the test results from public and private labs, and their employees failed to notice the row limit in Excel, which led to this disastrous health hazard.

Construction and engineering aren’t immune, either.

A French train operator ordered almost 2,000 state-of-the-art trains. The trains were built, looking and functioning perfectly. Do you know what the problem was?

The trains were wider than the stations and couldn’t be used. That was a $68,4 million mistake.

The source of the problem was in the inaccurate records of the company’s fixed assets, i.e., railroads and train platforms.

The company sent the contractor measurements for the platforms built in the last 30 years. They failed to update the documents with the dimensions for platforms built before that, leaving the contractor with incomplete, inaccurate data.

You can take this incident as a cautionary tale.

Don’t underestimate the importance of keeping accurate records of your fixed assets, even if you’ve had them for a long time.

If you’ve joined an already ongoing project, it’s a good idea to check if there are any existing inaccuracies in the fixed asset records.

When it comes to newly acquired fixed assets, or those that have undergone changes, try to record any changes or updates as soon as they occur.

You can make the process more precise by bypassing manual data entry and opting for automated record keeping.

Managing Vast Amounts of Data

Compiling data on fixed assets can be a challenging task because there are many areas to cover. It gets even more complicated when you involve different departments of your company.

To overcome this problem, focus on organizing the data and unifying it.

Tracking fixed assets helps you estimate the worth of your company, plan for maintenance, and meet regulatory or compliance requirements. Notice how each of these activities is the responsibility of a different department.

Therefore, merely tasking a worker with compiling an Excel spreadsheet with your fixed assets is a short-sighted approach. The data that makes sense to your maintenance team may not mean much to your finance department and vice versa.

To illustrate the importance of keeping your data organized, let’s go through a list of all parties that could use the information about your fixed assets.

Construction companies usually consist of:

- Project management

- Materials purchasing

- Human resources

- Finance

- Marketing

- Business development

- Sales

- Logistics and operations

- Risk management and insurance

Specialized companies can have even more departments. In other words, you have to ensure that the data on fixed assets is understandable and available to people across all departments, not just to the person that compiled it.

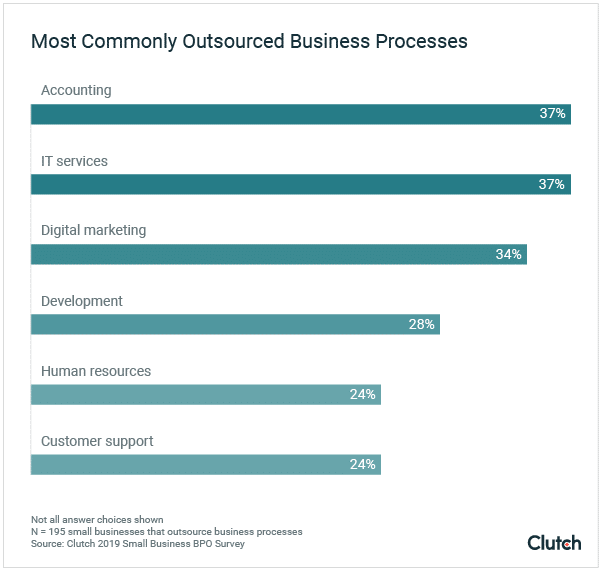

Data transparency is also crucial if you outsource some processes to other companies, as many businesses do—especially for accounting and IT services.

So, if your business often works with other companies, you may want to review your data management practices.

Otherwise, unorganized data and poor data exchange across departments can cost you a lot of money, as one British construction company learned the hard way.

Mouchel Infrastructure Services had to write down profits by £4.3 million due to an error in an accounting document. The error didn’t come from the Mouchel team, but from an outside actuarial firm.

Nevertheless, the Mouchel team failed to review the data and, consequently, the company suffered losses.

To prevent such mistakes, you should allow easy access to all data across different teams. A great way to do so is by using cloud computing.

Remember, your data managing solution is only as good as the data you put in, so make sure to always enter accurate, updated information.

Ensuring Asset Visibility

Lack of asset visibility is a common challenge in tracking fixed assets. Not labeled or improperly labeled assets are often unaccounted for, leaving your reports incomplete. To prevent that, you should make every item visible with a unique ID tag.

Before we get into ways to ensure asset visibility, let’s first see what the practice can bring to your company.

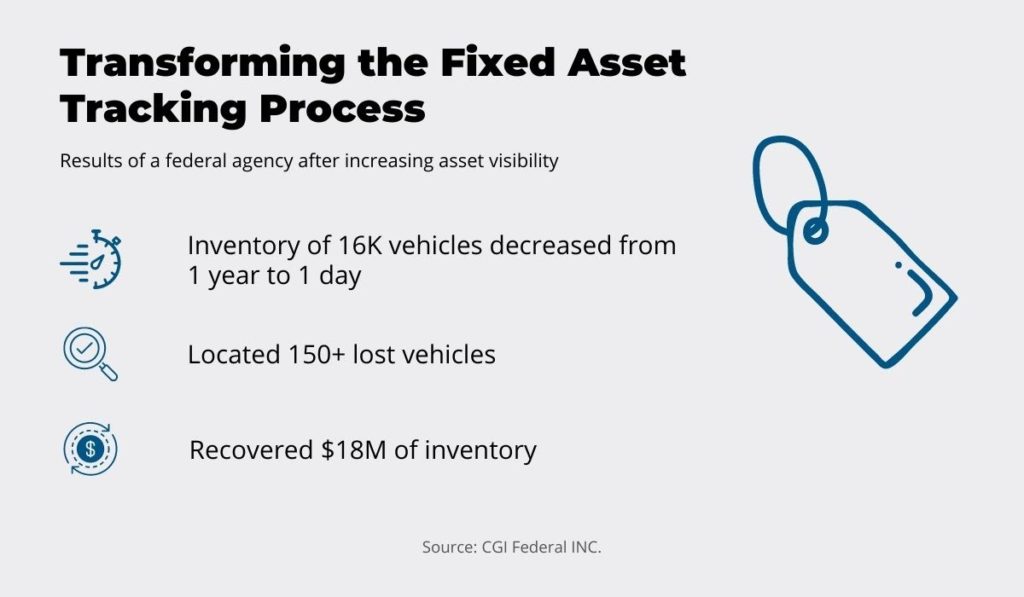

The US Department of Defense is the prime example of an organization that combined asset tags and the Internet of Things to assist in asset tracking.

The DOD was facing numerous challenges tracking their assets, with potentially deadly consequences, such as vehicles being mistakenly taken on mission or exercise.

Difficulties keeping track of warranty and maintenance records were an additional issue.

When they implemented sensor-scannable tags and connected them to an online database, they were able to cut down the work that used to take over 125 people to complete down to something manageable by just one person.

The inventory process that used to take a year was reduced to only one to two days.

That’s not all. They even managed to recover $18M+ of inventory by locating 150 lost vehicles.

Luckily, you don’t have to have the resources of a government institution to upgrade your asset tracking practices.

GoCodes, our tracking solution, helps construction companies manage their fixed assets. Your phone and our patented QR code tags are the only equipment you need to get the most accurate representation of your inventory.

If you’ve ever done an inventory count, you’ve probably come across the problem of vague entry descriptions, such as “computer” or “forklift”. Improper categorization is another common issue.

You can combat those issues by assigning each item a unique ID.

Our solution generates a QR code for each of your items, so when you scan the code with your phone, you get an overview of all product details, such as serial number or last service notes.

Durable labels allow you to identify even those fixed assets kept in harsh conditions.

Ensuring asset visibility also minimizes the risk of duplication, yet another common inventory count problem.

Keep in mind that tracking all your fixed assets is only a part of the job. A significant portion of the work involves managing the data you’ve collected.

A unified database provides you with an overview of your assets and their usability status. With so much to handle, construction managers can sometimes forget to keep track of assets that are not directly visible, such as equipment in offsite storage.

Luckily, a good tracking solution gives you an insight into your inventory regardless of location.

Tracking the Fixed Asset’s Life Cycle

To get even more out of your newly compiled fixed asset list, you should supplement it with the latest information on each of your asset’s life cycles.

A common challenge in tracking fixed assets is getting a list devoid of actionable notes on the condition of the equipment or tools.

The fact that there are ten forklifts in your inventory doesn’t mean a lot unless you know when they were purchased, how much they were used, or if they require servicing. This is why you have to keep track of the asset life cycle.

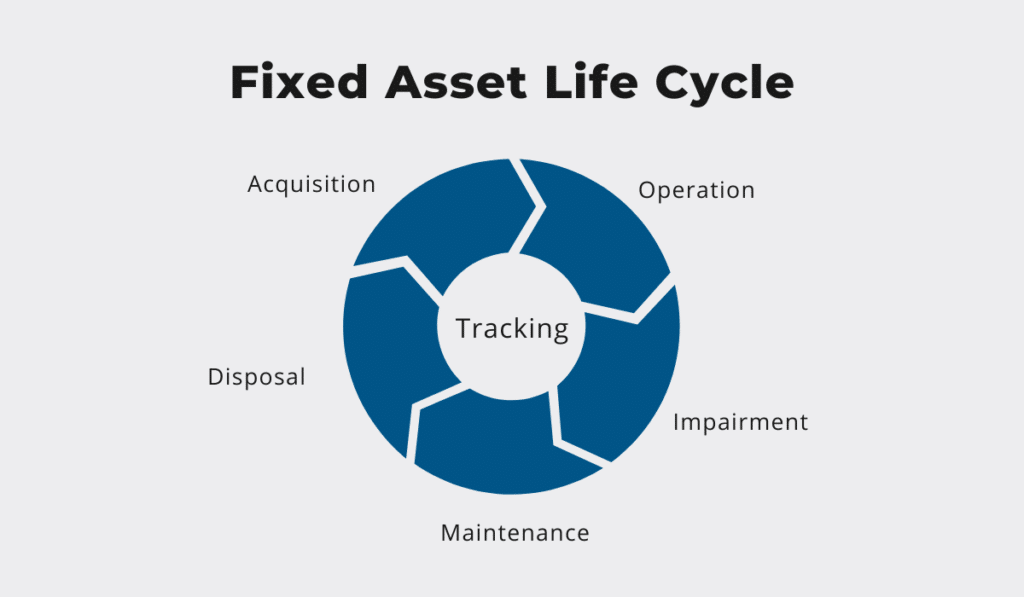

The asset life cycle includes every action you take from the moment you realize you need a new piece of equipment, to the moment you dispose of it.

But, how do you decide if you should invest in repairing a malfunctioning machine or try to replace it?

The answer is in tracking.

For example, each time you replace a machine part, you should note the repair cost and the downtime the servicing caused.

When you have an overview of these bits of information in the same place you store the information about warranties or previous repairs, you’ll be able to calculate the worth of your fixed asset precisely.

Matt Lang, assistant vice president at The Bancorp Bank, advises construction workers to use the equipment’s life cycle data for better decision-making.

“Break-even is the time to get rid of an asset before you start paying maintenance or repair costs that exceed the value of the equipment itself.”

Finding the break-even point is difficult without knowing the true extent of the costs related to the maintenance of your assets. You can overcome that challenge by examining the data from your tracking solution.

This practice helped Bunzl North America, a distribution company, to assess when to service, replace or reassign equipment and evaluate maintenance trends.

The process began with Bunzl drivers tracking the use of forklifts and trucks. The corporate personnel accessed truck maintenance data through the internet and analyzed it.

They were then able to maximize truck productivity and manage equipment costs.

If you aim to get a realistic estimate of the state of your assets, labeling and counting the equipment is just the starting point.

The insights you get can be significantly more realistic if you include warranties and maintenance history information into your calculations.

Conclusion

Fixed asset tracking helps you keep your valuable assets organized. However, approaching the task without preparation won’t get you satisfactory results.

The tracking process should include verifying that all data you have entered is accurate and up to date.

It’s a good practice to enable remote access to the data. When you authorize more people to access the data, you increase the chances of spotting and rectifying any inaccuracies.

Asset management isn’t complete without the records on the life cycle of your equipment, so remember to include all information on maintenance and warranties.

Don’t forget that you can track fixed assets more efficiently with the help of technology.