Any business that uses equipment invests in its maintenance to ensure the assets can be used safely and fulfill their purpose.

However, at a certain point, you need to understand how efficient your service processes and your team are, and what you can do to improve, which is why upkeep metrics are crucial.

The article will explain what these metrics are and how they can be beneficial to your company. It will also list six of the most critical metrics and offer insight into efficient tracking metrics.

If you want to upgrade your servicing and get the most out of your equipment, keep reading!

In this article...

What Are Equipment Maintenance Metrics?

Metrics are measurements that you can use to understand how efficient or productive your assets, employees, or processes are.

Businesses use them to determine where they’re doing well and identify where there’s room for improvement.

In upkeep, metrics measure the success of servicing and equipment, how long it takes to fix a malfunction, or how much time passes between breakdowns.

Metrics express the productivity of an asset, process, employee, or team numerically, thus allowing you to understand which part of the process is not doing as well as it should.

Since your tools, production, and business often depend on assets, servicing plays a key role.

It’s essential to have productive servicing, use the proper maintenance method, and allocate your resources wisely to ensure you fix the issues promptly while eliminating downtime but protecting the workers’ health and safety.

When you have the numbers to explain how well your team or processes function, you can compare that with the set standards to get to your goal.

Once you establish that baseline, you can often measure some metrics to understand how well your team is developing over time.

Therefore, you can get to the cause of a problem and fix it to improve its metrics and overall performance.

Leading vs. Lagging Metrics

A standard metrics division is the one between leading and lagging metrics.

The former metrics relate to future goals and standards and indicate what to fix to achieve them, while the latter report the results that are already achieved and take some time to measure.

To be more precise, leading metrics refer to something that will affect future performance, and lagging metrics report on past performance.

An example of a leading metric would be the relationship between estimated versus actual performance, which tells you what you can expect of the item, employee, or process in the future.

Downtime is an example of a lagging metric as it measures the hours of downtime for a particular asset or set of assets.

Why Are Maintenance Metrics Beneficial?

Once you introduce maintenance metrics to your business, you will reap many benefits.

For starters, you and your team will understand how each employee’s actions affect the bigger picture, boosting efficiency.

This knowledge helps engage the employees more, making them more productive and less likely to leave the company, which is your goal.

An employee might not understand how their work directly impacts a company’s goal.

Still, once you put some metrics in place, you can easily explain how, for example, the great work the team member has done on preventive upkeep positively affects a project, production, and the company in general.

Maintenance metrics can also help you reduce downtime and improve health and safety.

They let you understand how much downtime you have and what causes it, allowing you to develop an improvement strategy.

Some preventive service metrics help you determine how efficient you are at preventing damage or breakdowns which can affect your workers’ health.

On top of that, such metrics can help you figure out if you’re spending more money or time than necessary on certain parts of the process.

You will receive figures that will show how much you’re spending on processes, allowing you to compare them with numbers that a new solution or a method would bring.

What’s the Difference Between Maintenance Metrics and Maintenance KPIs?

Maintenance KPIs measure performance and give you information on how effectively you are achieving the desired results and goals.

Each KPI should directly tie to your plan, as you can then easily keep track of what KPIs you need to excel at to reach your goals.

The numbers help you understand how quickly you are moving towards the objective—if you are moving at all.

Such indicators usually revolve around decreasing downtime and costs and improving overall service efficiency.

On the other hand, maintenance metrics help you understand how effective your performance is—whether it’s team or employee performance or the process itself.

The main goal of such metrics is to provide you data that lets you stay on track with a strategy and explain how well it is performing.

When selecting upkeep metrics, think of those related to your company and ensure that each metric ties to a specific key performance indicator (KPI).

KPIs relate to your goal directly, while metrics are the numbers indicating the small steps you’re taking to achieve the KPI.

Keep in mind that more than one metric can affect a KPI.

To give an example, let’s say that your company’s goal is to increase income.

A KPI you would take into account is asset performance as it relates directly to productivity.

However, metrics that you would use for this KPI are asset uptime and overall equipment effectiveness, which let you understand how efficient your equipment is and how much you get out of it.

6 Important Equipment Maintenance Metrics to Track

When your company heavily relies on equipment and focuses on servicing, you should choose maintenance metrics that will help you track your progress.

You can consider many upkeep metrics, but these are some of the most important ones to help you achieve your KPIs and get closer to realizing company goals.

Planned Maintenance Percentage (PMP)

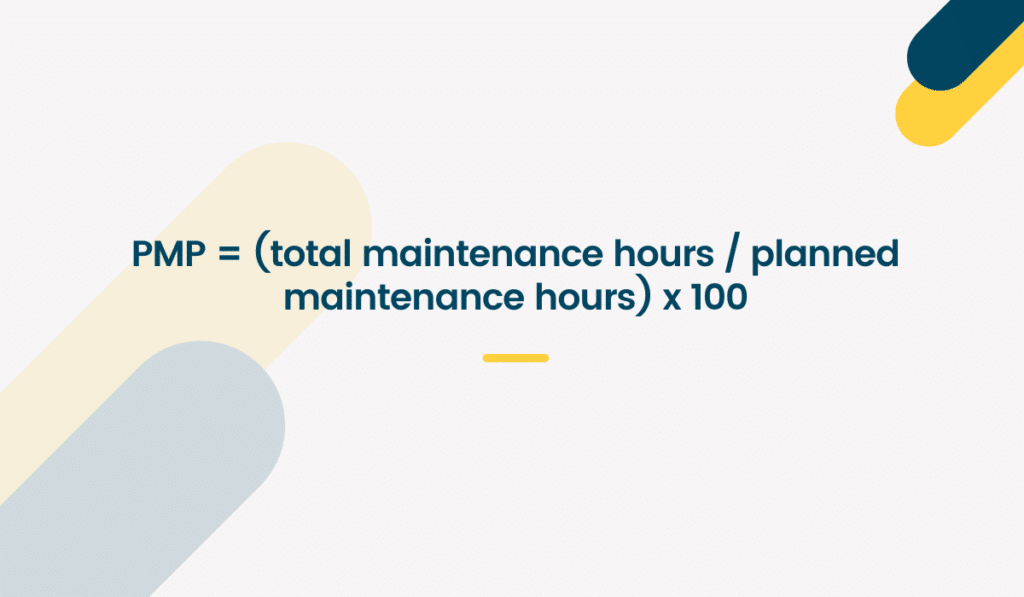

This metric gives you a percentage of hours spent on planned upkeep compared to the total upkeep hours.

Therefore, it points to the effectiveness of your servicing. The lower the PMP, the more unplanned servicing you have, which means that your equipment breaks down unexpectedly.

A formula you can use to calculate PMP is:

A low number could point to lower equipment quality, a need for asset replacement, or ineffective upkeep or practices that let the problematic asset slip through the cracks and go unnoticed until it encounters a failure.

A company should strive to avoid reactive servicing and perform preventive maintenance.

This means that you should invest in planned service of all assets instead of using them until they break down.

Waiting for the malfunction costs you more money than you’d spend on regular servicing. It also causes downtime and poses a risk to health and safety.

PMP helps you understand how successful your current planned maintenance plan is and points to different causes of the issue.

Once you get to the root cause of a low PMP, you can fix it and increase the number of planned servicing.

Overall Equipment Effectiveness (OEE)

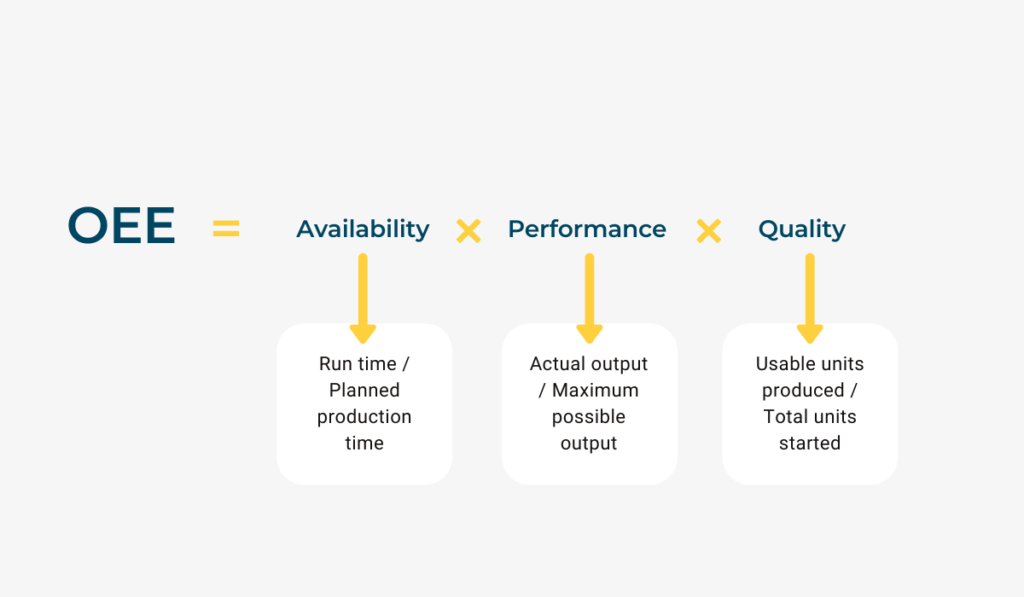

You can use the OEE metric to measure the productivity of your equipment using three factors: equipment availability, performance, and production quality.

Availability measures how much of the time the asset is available when you need it.

Performance measures the speed and amount of produced goods, units, or services, while the quality factor measures the quality of the final product.

You can calculate OEE the following way:

You have to calculate each factor to use them to calculate OEE.

When it comes to availability, you divide the total number of hours the equipment runs with the planned production time.

If you were supposed to use an asset for eight hours but only used it for seven due to a malfunction, its availability is 0.875 or 87.5%. The ideal rate is 90%

Divide the actual equipment production with the maximum possible production to understand the asset performance.

If an asset can produce 250 units, but in reality, it produces 225, the performance rate is 0.9 or 90%, 5% below the ideal rate.

You can determine the quality by dividing the number of produced units you can use with the number of products that the asset has started to make.

Suppose an asset started 500 products, but 75 of them had a defect or are unusable. The equipment’s quality rate would be 0.85 or 85%, while the ideal is 99.9%.

The OEE for this asset would be a little under 67%—far from the benchmark of 85%.

Mean Time to Repair (MTTR)

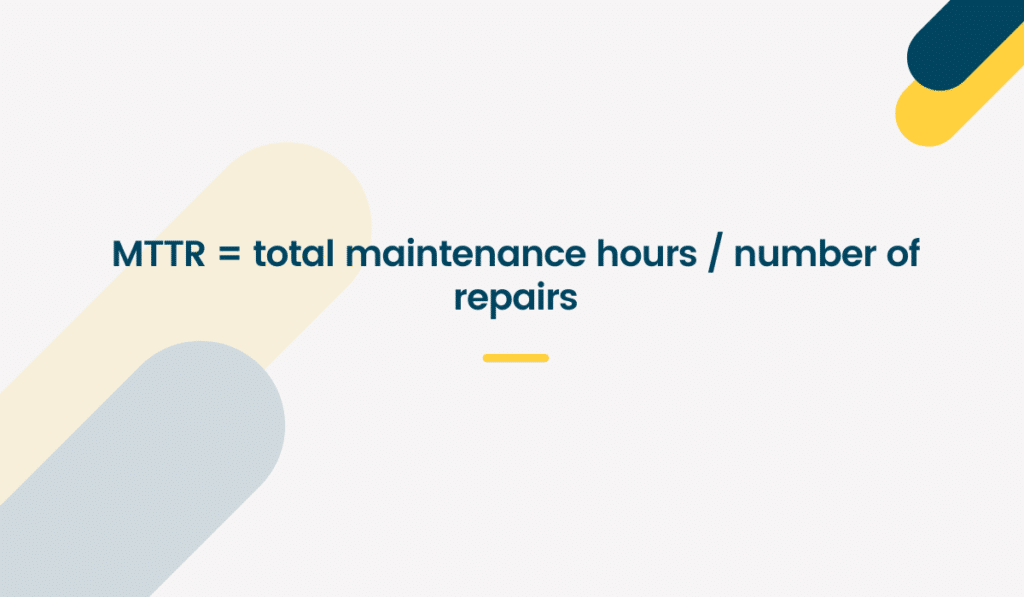

The MTTR metric concerns the time it takes for your service team to find the issue and solve it, and it helps you understand how successful you are at handling unexpected breakdowns.

MTTR considers the time that passes between the moment that the problem occurs and the time when you can use the asset again.

You can calculate MTTR by dividing total hours spent on one asset’s upkeep by the number of its completed repairs:

If one of your assets has spent 70 hours on 12 repairs in one year in maintenance, the mean time would be 5.83 hours.

Many factors affect the mean time, including age, the type of asset, life cycle stage, and risk potential.

However, the desired repair time is under five hours.

Higher numbers can point to either inefficient service or unreliable equipment that you need to replace.

This metric can point to the need to replace an item instead of wasting many hours on repairs, thus saving you money.

It can also be helpful to understand whether some equipment has gone through scheduled upkeep before breaking down, as this is a clear sign that your servicing process is flawed.

The point of scheduled maintenance is to fix any minor problems and avoid breakdowns and downtime. If you have unexpected issues despite regular servicing, you should find the cause of the problems.

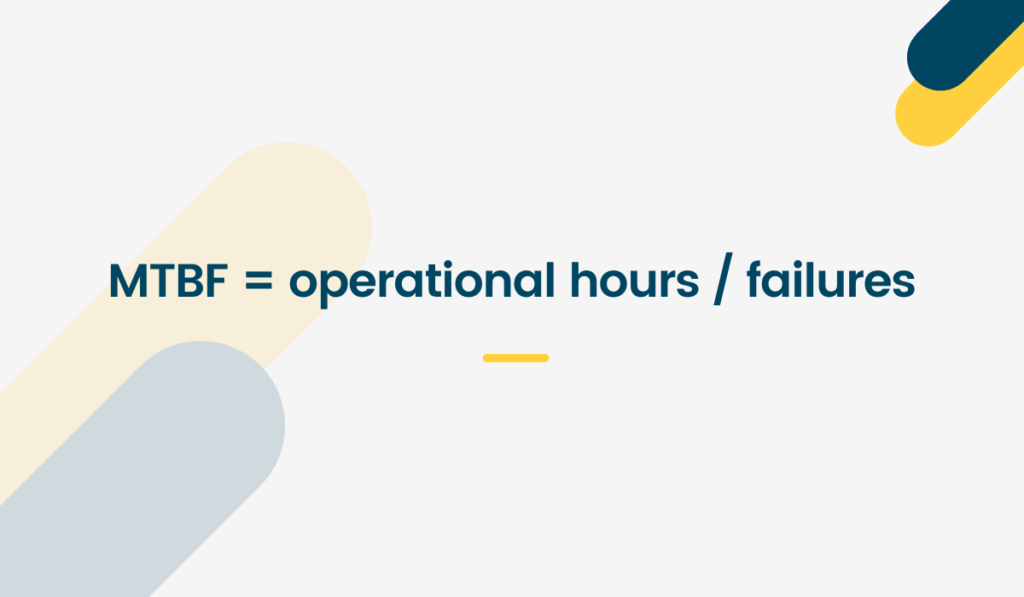

Mean Time Between Failure (MTBF)

The MTBF metric helps you measure the time an asset spends working between two unexpected upkeeps.

In other words, it determines how long you can use an asset before it breaks down again.

It doesn’t include planned servicing as this is not a failure but a scheduled activity to prevent asset concerns.

This metric helps you understand how fruitful your servicing process is by pointing out how much time passes between two failures and how reliable the asset is.

If an asset frequently breaks down, you won’t be able to use it often, and its availability rate will be low.

MTBF can also serve as a pointer to faulty equipment or assets you should replace when its value is below standard.

To determine the average, don’t rely solely on the manufacturer’s manuals.

Instead, consider the industry standards, the equipment condition, and maintenance history, which can help you determine the MTBF values acceptable for your assets.

Determine the hours of MTBF by dividing the total number of hours the asset spent working by the number of failures it experienced:

The higher the MTBF is, the longer you can expect your system to run without failures.

If the number is deficient, you need to find the cause of the issue, whether in equipment or the upkeep process.

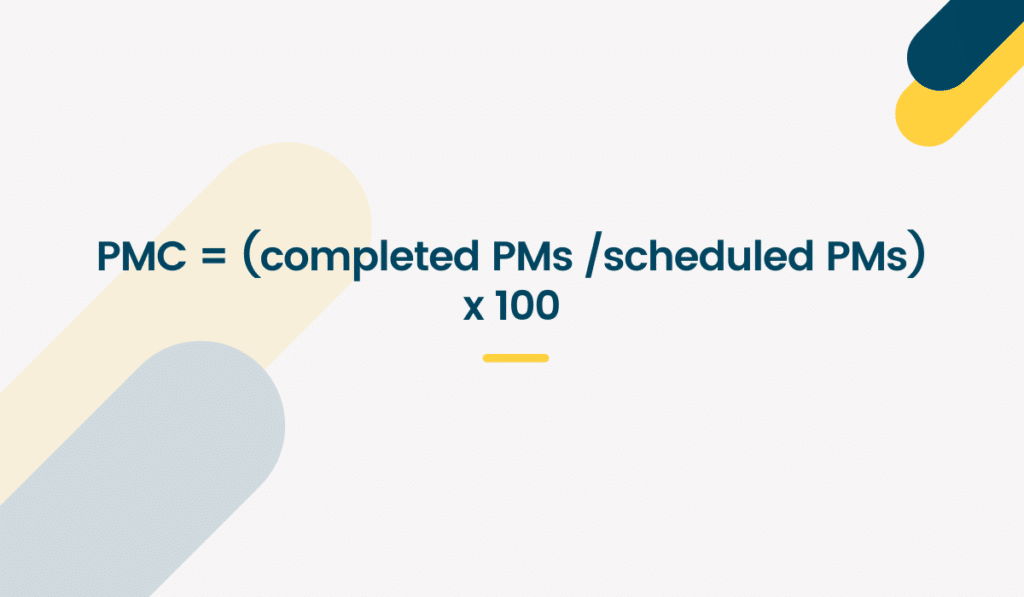

Preventive Maintenance Compliance (PMC)

If you want to know how many preventive maintenance (PM) tasks your upkeep team has completed on time, the PMC metric will assist you.

It shows the number in percentages, revealing your team’s effectiveness and the overall quality and productivity of the current processes.

The metric can ensure that you use your resources wisely and get the best out of your team and equipment.

If the number is low, it might be time to investigate why the team cannot handle many PM tasks.

The formula you can use to get the PMC number is:

If your team had 10 PMs planned but only managed to complete 8, their rate is 80%. The ideal percentage is 90%, so you should increase anything below that number.

Figure out why the team cannot perform all scheduled tasks.

Are they planning more than they can handle?

Maybe the issue lies in the number of assignments versus the number of employees who can complete the tasks, or it’s equipment-related.

A significant disadvantage of this metric is that it doesn’t consider whether the tasks were completed late or not.

To figure out if your team is behind on assignments, look into their work orders and check if they respected the deadlines.

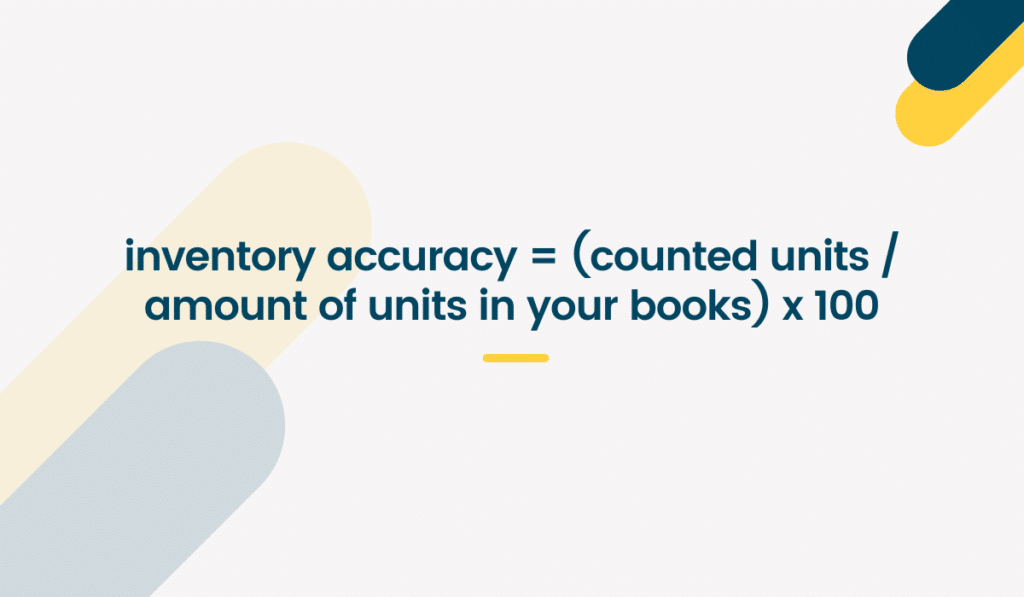

Inventory Accuracy

The inventory accuracy metric calculates the difference between your actual inventory and the inventory you have in your books in percentages.

It’s an essential metric since assets are the key to any business that relies on equipment to make a profit or create products.

If you want to keep track of your items and invest in their maintenance, you need to have a definitive inventory list.

Based on this list, you can plan preventive servicing and know whether you can rely on these assets to fulfill their purpose.

The formula you can use is:

Suppose you counted 230 items, but your books show you should have 250.

Your inventory accuracy would be 92%, which still means you have fewer items than you thought, and that you need to write them off as ghost assets.

Most businesses used to rely on pen and paper or spreadsheets to write down their assets, so there were discrepancies between the real-time data and written records.

If you switch to software that can serve as a centralized asset database, you will improve your efficiency.

You will also be able to track changes better, ensuring that you are always close to 100% when it comes to inventory accuracy.

How to Monitor These Metrics?

You can’t use metrics without having a system that gives them context or provides the data needed to calculate a metric.

This is where software comes in handy.

Each of the formulas above mentions specific numbers you need to get from your system.

Otherwise, you will be basing your calculations on guesses, meaning they probably won’t be correct, and you, therefore, won’t be able to rely on the data as it might be inaccurate.

To prevent that, you should switch to software or apps that can help you get some of this data and access more documentation instead of using pen and paper and spreadsheets, which might not be available to all team members.

Your best option is to use computerized maintenance management systems (CMMS).

Such a system will allow you to successfully manage your upkeep and stay on track of all changes.

If you’re still using a pen and paper, only certain people can update information and numbers, slowing operations down significantly, especially when it comes to inventory tracking and servicing.

Different apps and software let you have a database of information to update the asset’s state and maintenance dates.

You can even upload images of the assets, assuring that everyone is up to date on details regarding your equipment.

Conclusion

Maintenance metrics help you understand how productive your equipment or team is and how efficient your servicing process is.

When you regularly perform such checks, you can easily notice the progress or setbacks in certain areas.

Using specific metrics like MTTR, MTBF, OEE, or PMC helps you determine where precisely the problems arise, allowing you to focus on that point and fix it.

Software that allows you to keep track of the factors needed to calculate upkeep metrics is a far better solution than pen and paper.

It lets the entire team have access and get insight into processes, assets, and servicing, which helps everyone be more productive and informed.

GoCodes Asset Tracking Can Help

We use QR code tags with a unique visual code that you can scan with your smartphone. When scanned, GoCodes Asset Tracking tags provide GPS information about equipment location, making tracking its use easy. Sign up for a free trial here.