Assets and inventory seem like interchangeable terms, but these are two distinct terms for what a company or organization owns.

Understanding and leveraging the difference between asset and inventory is important to achieving an efficient, forward-looking employee team and management structure.

Both asset management and inventory management require a structured, tailored approach for effective implementation.

Companies working with a great deal of physical assets or inventory (or both) will benefit from the strategies discussed here.

COOs, decision makers, stakeholders, those involved with significant amounts of fieldwork, and financial officers can profit a great deal from perceiving and working with the differences between assets and inventory.

In this article...

What Is an Asset?

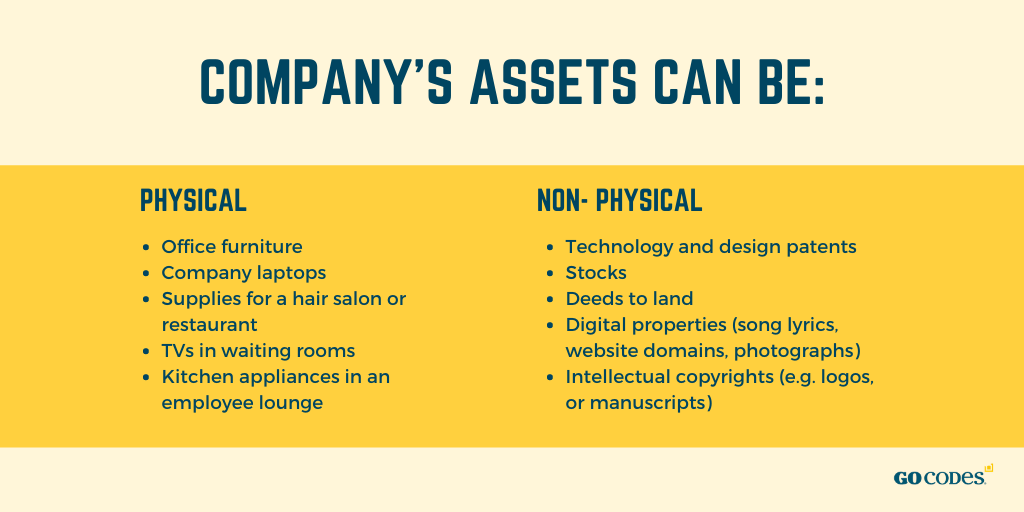

An asset is any item the company owns. This is a broad definition for a reason, because an “item” can be physical or non-physical.

Here are some examples of physical assets:

- Office furniture

- Company laptops

- Supplies for a hair salon or restaurant

- TVs in waiting rooms

- Kitchen appliances in an employee lounge

These are non-physical assets:

- Technology and design patents

- Stocks

- Deeds to land

- Digital properties (song lyrics, website domains, photographs)

- Intellectual copyrights, such as architectural plans, manuscripts, and logos

As you can see, assets are not always items for sale. They include objects necessary to conduct business properly.

They also function as contributors to the financial stability, diversity, and health of the organization.

All businesses can benefit from at least some form of asset tracking, even if it consists of a one-person sewing operation selling handmade masks to friends. In this scenario, there are still materials, transactions, orders, and quantity counts to keep track of.

It’s no different for major international corporations.

What Is Inventory?

For the purposes of this post, inventory refers to the items a company is selling. They can either be produced by the company or purchased from suppliers for resale.

Inventory can also refer to raw materials required to produce a product.

In short, inventory items are assets, but not all assets are inventory.

These materials might include:

- Sporting goods

- Consumer electronic equipment

- Airplanes

- Food packages

- Clothing items

The service industry has a different understanding of inventory. Its goods are intangible, and can include offerings such as a manicure, a hotel stay, athletic training, or consultant services.

However, these items are not physical, and therefore do not require storage or tracking through the supply chain.

All kinds of inventory, however, require organization and active, real-time data streams for optimization.

Key Differences Between Asset and Inventory Management

Since assets and inventory are fundamentally different, they required tailored management approaches.

The management of inventory involves a company’s techniques in shipping, organizing, storing, and deploying its inventory.

On the other hand, asset management refers to a company’s management of its non-inventory property throughout its life cycle. It includes maintenance, design, procurement, disposal, operation, and upgrading.

Inventory management requires quick action and a flexible approach for the best results.

A company that manufactures Christmas ornaments has different needs and income in December than it does in April.

An organization that sells oranges can closely track its product as it moves through the supply chain so that its perishable properties do not limit income potential.

Similarly, service industries can use inventory management to ensure that functional needs are met. For example, a four-season resort might require paddleboards in July, but ski gloves in January.

The short shelf of inventory calls for a different type of handling than do assets.

Asset management is deployed over the long term.

Since assets usually involve major investments that depreciate and pay for themselves over many months or years, such as a conveyor belt system, they require regular maintenance, inspection, and perhaps software upgrades.

Some assets, such as medical or technological equipment, tend to move throughout a building or across job sites; these items also benefit from location tracking and check-in/check-out systems.

Even if the asset does not move from its installed location, asset tracking is still necessary so that managers and stakeholders can monitor its performance and health.

Deciding Between Asset Management and Inventory Management

Having a strong grasp on the differences between asset management and inventory management helps decision makers discern which of these options is best for their company.

Some organizations benefit from using both.

The Purpose of Inventory Management

The role of inventory management and control is vastly different from asset management.

The proper management of inventory enables businesses to streamline the movement of salable articles from pre-production to manufacturing and assembly to sale and delivery.

In the case of companies that only deal in resale, it allows for a disciplined organization of the supply chain.

Inventory management arms each sector of a company with valuable data and up to date information on which items are selling, as well as when.

Having too much inventory on hand is a burden on employees, storage costs, and those in management roles who are eager to stock a more profitable item.

The inverse, a shortage of a stock item, is just as costly.

It contributes to customer frustration, damage to reputation, revenue lost to rush shipping, and even an eventual overstock due to panic ordering.

In the event the demand is short-lived or cyclical, the company might find a costly surplus on its hands if it doesn’t plan carefully.

Production systems work best with smart inventory management. Costs plunged into raw materials are then balanced with revenue to form a dependable ebb and flow of income.

Inventory Management Benefits

Properly managing inventory means that businesses can restock shelves at a reasonable rate and plan for fluctuations in the supply chain.

When inventory is kept from an overstock or an understock status, a company can more effectively set prices, negotiate with suppliers, plan for storage needs, and meet consumer expectations.

Cash flow becomes more predictable and manageable as a result of well-managed inventory for a number of reasons.

Good inventory management has the following benefits:

- Ability to plan for having the correct amount of inventory at critical moments

- Avoidance of wasting storage space on overstock

- No overselling

- Less theft

- Increased customer satisfaction due to fulfilled expectations on delivery times

- Reduced employee stress levels and increased job performance

- Minimized spoilage on perishable items

- Lowered prices on supplies or stock due to the ability to buy in bulk

- More accurate order fulfillment, which translates to fewer costs sunk in returns

- Product tracking results in acquiring valuable information for marketing data and trend spotting

Companies which sell their own products might become involved with a product recall.

This logistical, economic, and public relations nightmare is far less damaging with an efficient in-place inventory management program.

With inventory management, a business can quickly and easily trace which products are affected, provide tracking information, contact customers and suppliers, and provide transparency to overseeing agencies to verify compliance.

Cutting inventory and stocking costs while improving relationships with suppliers and consumers is the goal of inventory management.

Using a single system to standardize inventory management yields all these benefits and more. The right system makes this possible.

Technologies Used in Inventory Management

Implementing the same system for asset tracking and inventory management results in an easily scannable and scalable arrangement.

However, for businesses that best benefit from only inventory management, several forms of tracking are available.

Warehouse Management System

A warehouse management system varies widely. It simply means that a company has implemented a form of inventory tracking, no matter how rudimentary.

Some involve no more than a pen and paper or a spreadsheet. Others might stand alone or become integrated with another form of tracking.

Warehouse management systems help employees keep track of receiving, shipping, and picking.

Smaller businesses might use warehouse management system software in-house, some of which are built within the company. They are primarily focused on recording the action of the supply chain.

Light Fidelity (LiFi)

LiFi is optimized for wireless connections within a single indoor environment.

It involves the transmission of data across short distances using light, usually LED lamps.

It is especially useful in environments in which drones, robotic equipment, and automated systems are prevalent.

Barcodes

Barcodes, which involve the use of a handheld scanner, debuted several decades ago and represent one of the oldest, cheapest, and most reliable inventory management systems.

Barcodes use spaces of lines and blank areas to communicate information.

These technologies are especially useful when an organization has a great deal of stock and inventory in house.

They help track which items are moving when, and provide information about stock levels on a regular basis.

The Purpose of Asset Management

Why do businesses manage assets if customers rarely, if ever, see them?

Assets are major investments. They can include vehicles, machinery, and even the building in which the business itself is located.

Managing assets wisely leads to lower prices for the consumer, as well as clarified relationships with suppliers.

When decision makers have a comprehensive understanding of their business’ assets, they are far more wisely leveraged.

The ability to anticipate the major phases of an asset’s life cycle impacts inventory-related decisions and has a ripple effect on hiring and training employees, scalability projections, as well as the prediction of business cycles.

It allows businesses to keep track of their assets’ current market value and calculate their depreciation over time.

With proper asset management practices in place, businesses can maintain a central record of all their fixed assets, schedule regular maintenance in a timely manner to prolong their useful life, and track the use of assets for better accountability and control.

Well-informed asset management helps a company to tend to its own needs first. This prevents it from constantly attempting to shore up its own structure in addition to seeing to the requests of its clients.

After all, who would want to hire a plumbing repair company which is forever suffering burst pipes in its own office building?

That’s why when it comes to asset management, investing in the right technology and software is vital.

Asset Management Benefits

Asset management is primarily internal, but its benefits are quickly recognized by clients and competitors. Here are just a few:

✔ Burnished Reputation: A well-organized business projects confidence and competency to customers. With no chaos behind the scenes, management is better able to focus on marketing and consumer research, data analysis, as well as asset life projection.

✔ Seeing Gaps in the Competition: Asset management allows decision makers to adjust for seasonal changes, consumer trends, and supply chain bottlenecks. It enables them to see where the blind spots in their competitors’ activities and fill that space themselves.

✔ Streamlined Workflow: When an organization knows where an item is, as well as what its condition is, team members and third-party contractors are better equipped to foresee breakdowns, arrange for preventive maintenance, and identify any potential areas of growth.

✔ Decreased Overhead: The ability to plan for in-house upgrades means that panic buying is avoided, assets are used to the natural end of their life cycles, and equipment downtime is optimized.

When assets are managed from the beginning of their design or procurement, stakeholders are better informed.

Accurate, up-to-date information gives them the ability to make more leveraged decisions about the future direction of the organization.

Technologies Used in Asset Management

Asset management technologies are generally more advanced than inventory management technologies.

Since many of them involve instant communication and real-time tracking, some are reliant on Bluetooth or satellite systems.

QR Codes

Unlike barcode scanners, QR codes are usable with any smartphone or tablet, and store much more data. Employees or contractors can access operator manuals, manufacturer suggestions, schematics, and maintenance history, instead of just tracking or inventory data.

GPS

Global positioning satellites enable the tracking of items from place to place across wide distances. This is useful for vehicles, items in a far-flung supply chain, or assets involved with fieldwork.

Cloud Data Storage

The ability to keep archival information in the cloud drastically reduces storage costs and provides real-time information across time zones and geographical locations.

Asset management technology occasionally requires updating, but with a well-constructed system, these changes take place automatically and as part of an agreement with a third-party contractor.

Conclusion

Assets and inventory are quite different; so are asset management and inventory management. While some of their characteristics and requirements run parallel to one another, understanding the difference between them creates an opening to better management of both.

GoCodes Asset Tracking Can Help

We use QR code tags with a unique visual code that you can scan with your smartphone. When scanned, GoCodes Asset Tracking tags provide GPS information about equipment location, making asset tracking easy.

Sign up for a free trial here.