Construction technology has advanced to previously almost unimaginable levels. What is more, changes seem to come about so quickly that keeping track of the latest developments can be quite a challenge.

To help keep you current, we’re here to provide you with an overview of top technological trends affecting the construction industry.

In this article...

Mobile Apps

Mobile apps provide an efficient way to keep track of construction tools across your company, but that is only one of their many uses on the construction site.

Such apps are cloud-based, which means the information that workers enter is available to all necessary employees and securely uploaded. This cuts down on storage needs and costs for physical records, organization, and maintenance.

Best of all, mobile apps rarely require extensive training for employees.

Since the vast majority of people have become accustomed to using tablets and smartphones, they will likely already have at least some familiarity with using an app solution for digital collaboration and mobility.

This often speeds training programs and aids in inventory accuracy.

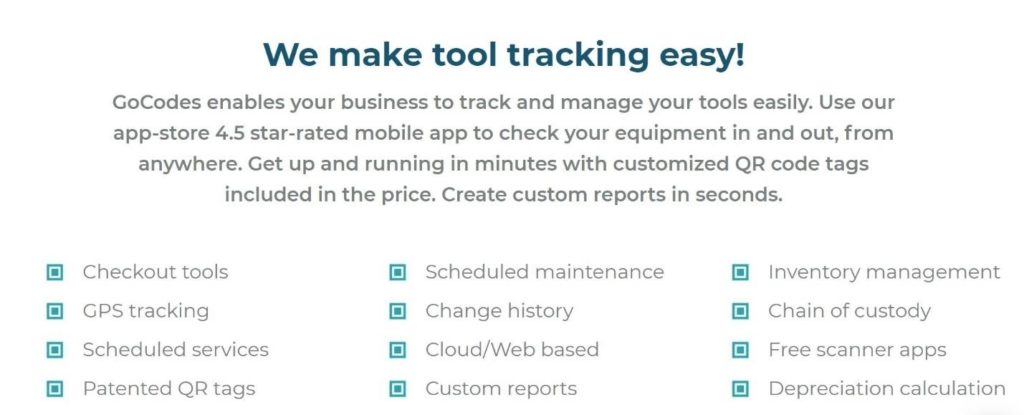

For instance, the GoCodes Asset Tracking app is an easily adaptable solution that updates instantly on job sites. It loads quickly and is compatible with major mobile systems.

Here are just a few of the applications for tool tracking that the GoCodes Asset Tracking app offers:

Even if your company has invested in its own app, using a dedicated tracker and coordinator like GoCodes Asset Tracking’ is a plug-and-play solution for maintenance alerts, GPS tagging, and much more.

Artificial Intelligence (AI)

Artificial intelligence isn’t just for computer labs and virtual reality games. AI has made important inroads in construction technology. It’s affecting office interaction, planning, and activity on site.

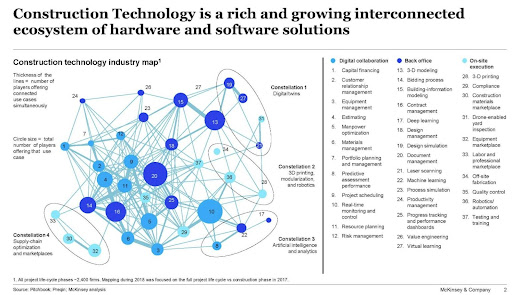

Here’s a visualization of the many ways in which hardware and software interconnect in the construction industry:

As you can see, the impact of information technology reaches areas that you might not expect. However, each of these presents new potential areas of growth and monetization.

In the construction industry, some of these areas include:

- Laser scanning

- 3D modeling

- Design simulation

- Process simulation

- Virtual learning

Therefore, the application of artificial intelligence to construction is nothing to fear. Embracing it can assist crews and project managers with advanced calculations and simulations.

AI can work with volume predictions, safety monitoring, and design animation. It also helps with planning maintenance and downtime, and even risk and weather projection.

All of these applications improve efficiency and help identify design alternatives.

In the most immediate future, AI could be most useful in stemming labor shortages. The ability to process vast amounts of information in real time can lead to more effective workforce distribution and schedule prediction.

Some programs can even analyze worksites to discern which areas are showing progress and which are behind schedule. This allows project managers to check on developments in the field from remote locations.

Internet of Things and Construction Wearables

The term Internet of Things, or IoT, describes any physical object that is enhanced with advanced technology such as software, sensors, recording capabilities, and so on. These items might function with a Bluetooth or WiFi connection to a larger network.

The data this system generates provides valuable information about object usage, GPS location, and much more.

For example, library books equipped with tracking stickers are easily stacked on a “smart mat” that checks out all of them at once, which increases record accuracy and saves patrons and staff the time of scanning each item individually.

In construction IoT, this same concept is expanded to the ability to count, price, and log entire pallets of materials in an instant.

Materials and simple construction tools are easily outfitted to become part of the Internet of Things.

As you can see in the graphic above, safety and resource administration aren’t the only ways IoT affects the industry; waste and daily remote management can also benefit from this ever-evolving technology.

Wearables are also part of this technology. The most widely known example of an IoT item is a fitness tracker that connects to a phone or laptop; in real time, the tracker might count steps, monitor heart rate, and reflect calorie burn.

However, this same technology is used in the construction world in the following ways:

- Alerting workers to environmental hazards or fall risks

- Real-time training feedback

- Reporting sudden impacts in machinery

- Tracking for ease in finding location

- Calling for assistance in the event of injury

The information gathered by wearables and other objects integrated with IoT is easily stored in the cloud and, over time, can provide valuable data concerning efficiency trends and project modeling.

Drones

In the construction industry, drones are a tremendous advantage. Their most popular use is to provide an overview of remote construction sites.

A drone represents a safe and relatively inexpensive way of seeing a site from above. They enable operators to get a closer look at specific areas on a particular location, offering improved security, real-time data, and proof of progress.

Even before the digging and construction begin, drones allow you to inspect the intended building site.

You can see how drones provide valuable and otherwise to tall and complex structures, as well as sprawling work areas that would otherwise be difficult to access in the graphic below:

As long as employees use drones responsibly and operate them only after licensing, the devices are a valuable addition to a construction venture.

They can quickly arrive at specific GPS coordinates, giving exciting updates to clients and rapid overviews of sites affected by weather, dangerous areas, or condemned sites.

Drones are also useful in the production of three-dimensional maps and virtual walk-throughs.

Construction Robots

Unlike drones, construction robots tend to stay close to the job site in order to perform autonomous tasks.

Have you heard of autonomous or self-driving cars?

Consider the possibilities presented by autonomous excavators, dump trucks, jackhammers, and backhoes.

In fact, Built Robotics CEO Noah Ready-Campbell predicts that such equipment will appear on American roads before driverless cars.

Driverless trucks, trains, and delivery fleets might become common sights on construction sites and the roads leading to them.

This modified map of the United States shows the states in which autonomous vehicles are currently legal. Notice that in many Southern states, where warm weather makes for a long construction season, these vehicles are already permitted:

Relying on robotic solutions contributes to lowering cost overruns, while allowing you to create a safer work environment, particularly in road construction projects and tasks that pose great risks to humans.

Just as wearables and IoT can help project managers distribute a stretched-too-thin workforce more efficiently, construction robots can address a post-pandemic labor shortage.

Workers will then concentrate on remote operation and work verification. Although widespread adoption hasn’t yet taken place, construction robots could shrink project completion timelines and provide a safer, more precise worksite.

Building Information Modeling (BIM)

The practice and process of Building Information Modeling (BIM) includes the planning, production, and studying of digital models of structures.

BIM involves many different disciplines and forms of construction. It is a collaborative undertaking that can involve contractors, architects, engineers, manufacturers, real estate developers, government officials, and project managers.

BIM has, in essence, replaced blueprints and even CAD (Computer-Aided Design) models. BIM representations carry much more data than a mere 3D rendering of a project, however.

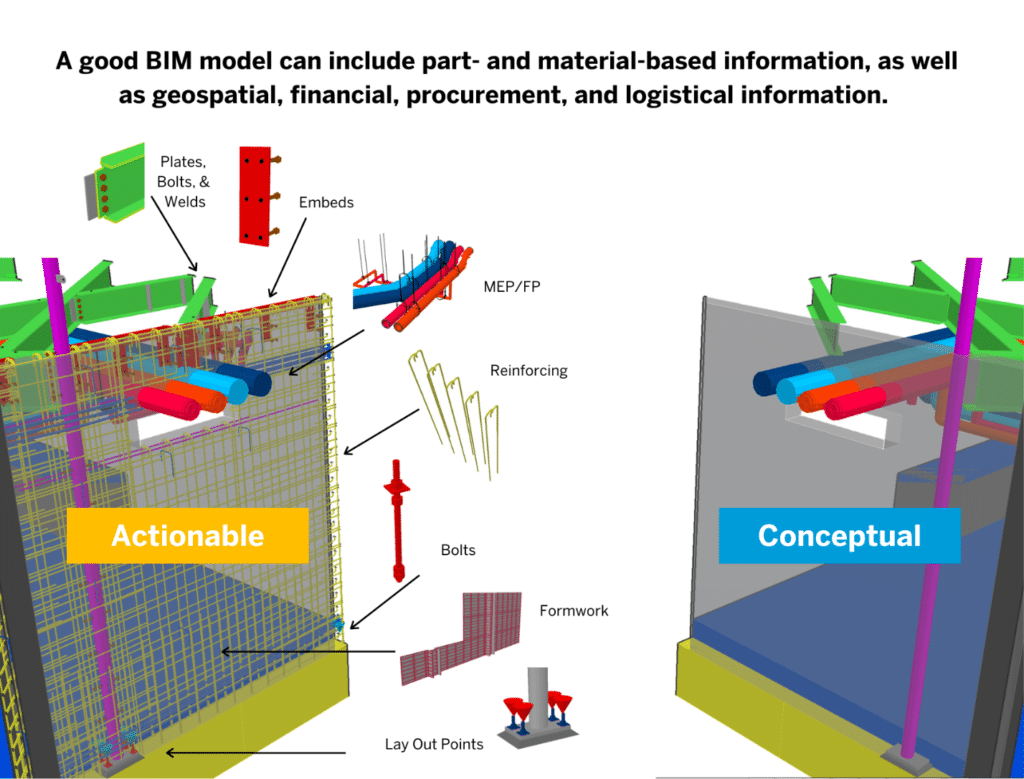

As the graphic below shows, Building Information Modeling is actionable as well as conceptual. It communicates step-by-step information in addition to artistic and visual depictions:

Many BIM projects begin in the traditional way: as a drawing on paper from a rough client sketch, architect rendering, or engineering projection. Software then layers more information through various dimensions.

BIM takes advantage of cloud storage and advanced computational abilities to reflect real-time updates.

For example, if collaborators input a change in any part of the project, the BIM program adjusts for this alteration throughout the model.

The data then becomes available to project associates in a collaborative online environment called a CDE (common data environment) so that interested parties can view the project and add comments or ideas.

Because of this, advanced BIM offers energy consumption projections and streamlined cost analysis. It can give you cost estimates, goal visualization, and even determine the impact of the weather on the completed project over time.

3D Printing

The advent of 3D printing has revolutionized many fields, from medicine to the arts, and quick innovation means that 3D printers are domestically available.

In the construction industry, the impact of this technology has already been profound, with room for even further development.

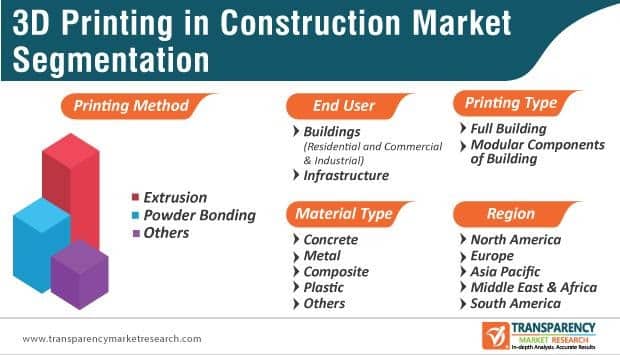

This visual aid illustrates how 3D printing has disrupted and changed various segments of the construction market:

Thanks to 3D printing, prefabricated construction has become more widespread and affordable.

Building components are produced at a plant with a 3D printer, then shipped to the building site for rapid assembly. In some cases, crews build smaller structures entirely inside a warehouse before transporting them to the location.

Advances in BIM and 3D printing have helped to increase the popularity of tiny homes and prefab in the housing and building market.

This development has been concurrent with the decline in traditional construction that stems from supply chain and labor disruptions.

Here’s a short list of recent construction projects using 3D technology:

- Plastic footbridges in China

- Lightweight cement pipes in Munich

- 3D printed homes for disadvantaged populations in Mexico

- Elements of the International Space Station, with the future potential to build habitats in space

3D printing is also applicable to quickly and cheaply produce replacement parts for rare and heavy machinery. That results in lower maintenance costs and less downtime.

While the construction industry is yet to take full advantage of all the potential of 3D printing, sustainability and efficiency goals continue to accelerate its adoption.

Conclusion

Technological developments might first become widespread in the popular market before reaching the construction industry, as was the case with apps or wearables, but their effect is undeniable.

Construction technology trends might also affect other markets, as with the use of autonomous vehicles. In any case, staying attuned to the latest innovations in construction technology allows companies to pivot quickly and become increasingly efficient.