Every piece of equipment you have invested in should serve to keep your company’s core operations working smoothly.

Everything from the heavy machinery and the power tools on the worksite to computers and copy machines at the office should contribute to that goal.

If you track your assets, you can ensure that your equipment doesn’t stand in the way of completing projects both on time and within budget. And the good news is that more and more contractors are starting to see the benefits.

So, what is asset tracking?

It is a part of an effective asset management process in which companies tag and track valuable equipment. It means knowing where your assets are located at all times and how they’re being used for fundamental construction tasks.

This gives companies a more complete understanding and control of their operations, enabling them to perform at peak efficiency. Ultimately, asset tracking helps construction companies grow.

This article will go over the most important benefits of asset tracking for construction companies. So, read on to find out more.

In this article...

Staying on Top of Maintenance Needs

You probably already have a maintenance process for your equipment in place, but asset tracking will help you take it to another level.

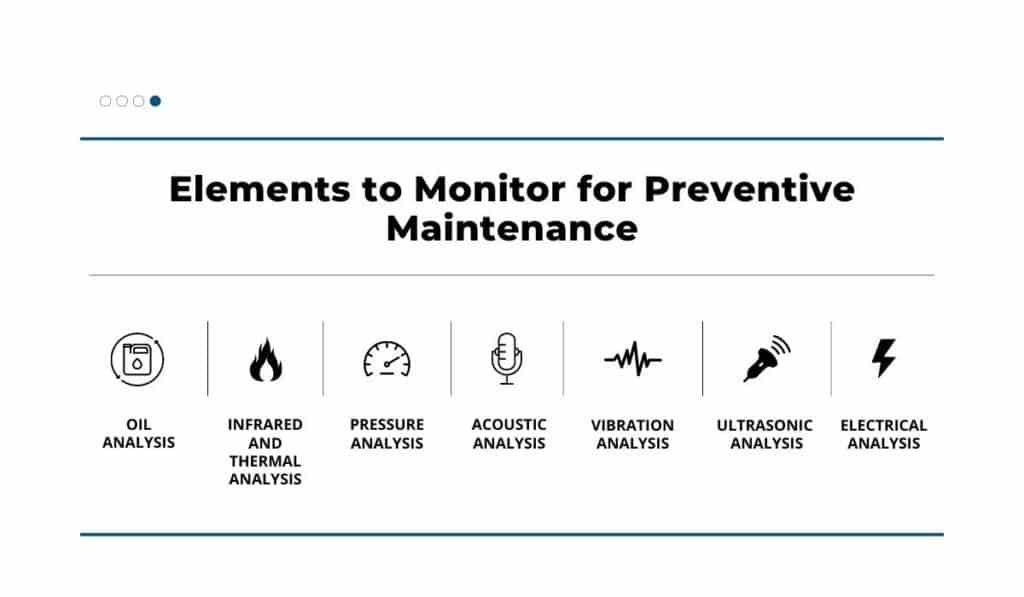

Asset tracking will show you exactly how your equipment is being used. You can even track different metrics that will indicate when your equipment is ready for a tune-up in the repair shop.

There’s nothing worse than starting a big construction project, only to have your essential equipment unexpectedly break down.

While unforeseen problems are always a risk, you must reduce downtime for your equipment as much as possible.

This means moving from corrective maintenance to preventive maintenance.

By carefully monitoring fuel levels or engine hours, you can determine the optimal time to send it for maintenance before an important part breaks or wears down.

The entire point of preventive maintenance is to keep your equipment in top working condition and to increase safety for your workers in the field. Malfunctioning machines can stop you from getting the job done and unnecessarily delay project completion.

For example, brakes are one of the essential parts of heavy construction machinery.

If you’re not on top of the maintenance regime for an excavator’s wheels and brakes, you risk injuring your operators if it rolls away.

Or even worse, if your heavy equipment is poorly maintained and you want to lift large cargo, the machine can collapse, posing a significant safety risk to your workers and the surrounding area.

So, if you want to reduce downtime and schedule key maintenance activities for all your assets better, using asset tracking is a great solution.

Improving Resource Efficiency

For now, we will focus on two areas where you can use asset tracking to improve resource efficiency.

The first one is keeping track of spare parts, and another is reducing idle time for your equipment.

Having backup resources on hand is a great way to speed up important construction processes and improve the company’s overall operations.

For example, keeping spare parts in stock allows your mechanics team to get your equipment back to optimal performance faster.

With asset tracking, you can get a comprehensive overview of your spare parts inventory and order new ones once they’re out of stock.

To illustrate the importance of it, let’s look at what can happen if you don’t have an inventory system for spare parts.

One company needed to replace a set of grate bars quickly. However, they didn’t have a spare on hand, so they ordered it and expedited the delivery.

They still had to wait, so on top of the already costly delivery, the production was halted for three days.

The production delay and additional expenses could have been avoided if the company had had an efficient asset tracking system in place.

On the other hand, reducing idle time has multiple benefits for your equipment and company.

According to experts, idling is not what the heavy equipment engine is designed to do, and it can cause significant damage in the long run.

In older machines, excessive idling can destroy cylinder packs by scarring rings and cylinder walls, resulting in compression loss into the crankcase and fuel dilution of engine oil.

Another important concern is preserving fuel. It goes without saying that fuel is an important resource for construction companies because it keeps the machines working.

So, as fuel prices skyrocket, you need to ensure that your equipment uses the fuel efficiently.

For example, a single mid-size excavator that works about 1000 hours per year can use a gallon of fuel per hour in idle time, and if it spends 40% of time idling, this can amount to wasting 400 gallons per year.

With asset tracking, you can keep a close eye on how much fuel your equipment uses and detect excessive idle time.

In the end, resource efficiency starts with properly monitoring your inventory and finding areas of improvement with great systems like asset tracking.

Keeping Employees Accountable

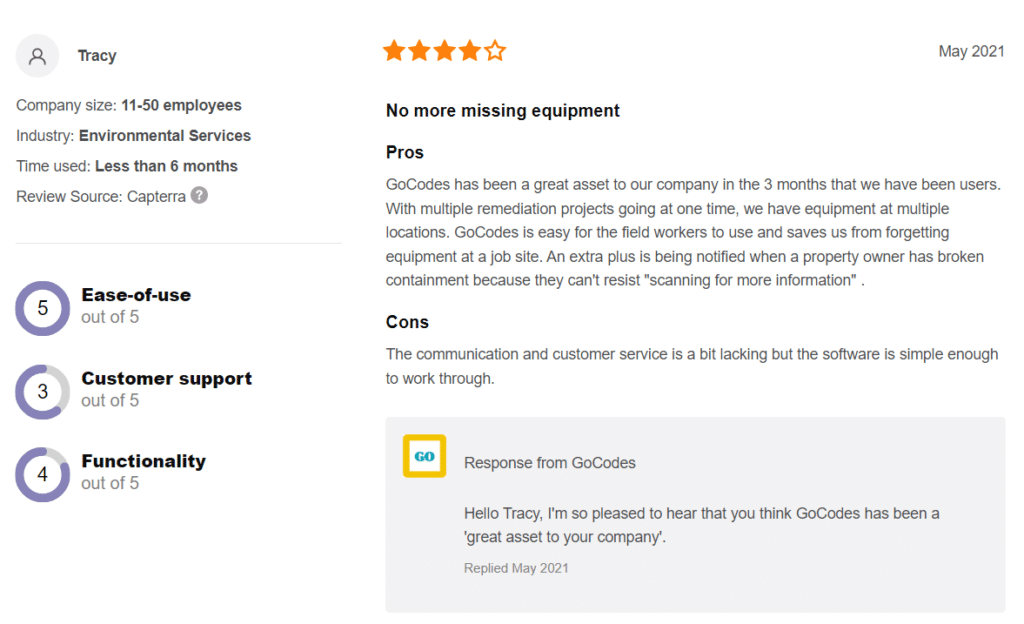

Do you have the same problem as this GoCodes Asset Tracking’ customer, of losing tools on construction sites?

This customer’s employees were always leaving tools and equipment on construction sites and misplacing them. Then, when they were supposed to continue work the next day, finding equipment was time-consuming and difficult.

Your employees are probably more focused on getting the job done, so taking care of the equipment itself is not very high on their list of priorities.

While they need the tools to complete projects, they often don’t consider taking care of them as part of their responsibility. After all, it is the company’s property, not theirs.

To nip any kind of misuse in the bud, asset tracking software helps keep employees accountable for the equipment they use.

Just take a look at how an entire city in Canada realized it could achieve savings by using asset tracking. They did a comprehensive review of their operations and found that avoidable damage to equipment and vehicles could be reduced by 50% that way.

The highest cost of damaged equipment was noted in the roadways department, rising from $256 000 in 2019 to $361 000 in 2020.

The city’s consultants projected that by using asset tracking on vehicles and equipment in different departments, they could save $284 000 per year.

Asset tracking will enable you to see where each asset is and which employee is currently using it. When workers know their name is attached to a tool, they’ll be more careful with handling it and putting it back where it belongs.

The easy check-in and check-out feature of most asset tracking software incentivizes employees to take care of the equipment they use so it’s available to everyone in the company.

They will no longer take the equipment for granted and even report more diligently about its condition.

What you want is to build positive habits in your employees and keep them accountable for the tools and equipment they use.

That way, you’re winning on three fronts: saving time, money, and improving organizational efficiency. So, use asset tracking to instill responsibility in your team.

Increasing Worksite Productivity

Increasing worksite productivity starts from making improvements in other areas first.

For example, if you’ve improved your maintenance process, you now have safe equipment in top working condition.

Then if you also made improvements with resource efficiency, your equipment is spending more time performing key construction tasks rather than idling.

But, another important way in which asset tracking boosts productivity is by improving asset utilization.

What this means is that you’ll be able to see which equipment is being used, send it to the closest construction site where it’s needed or make an informed decision about dealing with underutilized assets.

So your top-performing equipment will reach construction sites faster, and you’ll quickly address asset requirements for each project.

All of this contributes to the progress of your construction project and accelerates productivity on the worksite. This is good news for construction companies because it means a better turnover rate and increased profits.

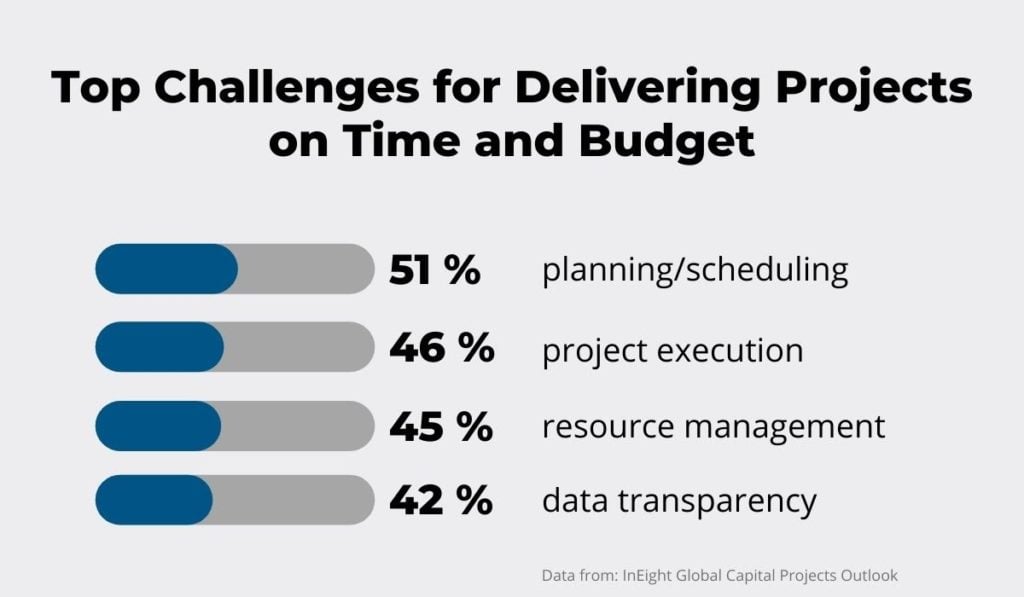

When you consider the fact that the top two challenges for contractors are project execution and resource management, asset tracking makes the future of the industry seem brighter.

In fact, almost 83% of construction professionals are confident that they’ll be able to complete future projects on time and within budget thanks to asset tracking.

And the best part is that asset tracking can help them turn this optimism into a reality.

Maintaining Accurate Asset Records

An important feature of asset tracking is enabling companies to collect relevant equipment data.

But it’s also important to keep that data accurate. This means regularly reviewing the status of all your assets, like whether you actually own the equipment that’s enlisted in your asset tracking system and removing stolen or ghost assets.

Bad data can significantly hinder your ability to make informed decisions about your assets.

For example, if a construction site urgently needs a forklift but the only ‘’available’’ forklift is the one that was stolen over a year ago, that can be a major setback for your project.

What’s more, such situations cost you money. According to recent research, bad data can cost the construction industry over $88 billion a year.

These expenses result from poor project outcomes that came with making decisions based on incomplete or inaccurate data.

It’s important to note that how you track your assets greatly impacts the accuracy of your data.

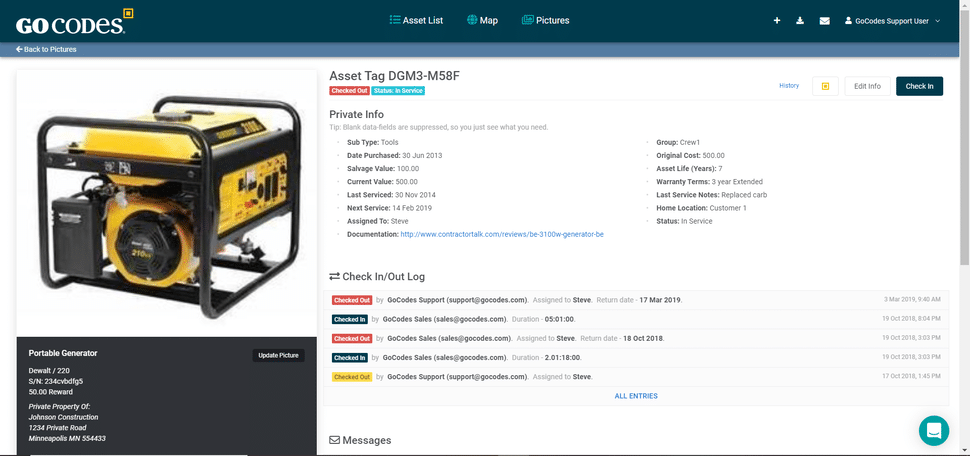

Keeping that information in spreadsheets or on paper drastically increases potential errors, while digital solutions like GoCodes Asset Tracking are more accurate and easier to manage.

GoCodes Asset Tracking is a complete tracking solution that will make your asset management easier using powerful cloud software and customized QR codes. You can access your tool and equipment data from the desktop or mobile app any time, anywhere.

When you have a centralized system to keep track of all your assets and gather information about them, you can standardize processes and create transparency within the company.

So, you’ll have all relevant asset information in one place that’s accessible to key stakeholders.

Most importantly, you can change that information any time and from anywhere to reflect the reality of your asset’s status.

Remember that asset tracking can give you a great overview of your assets, but to leverage these benefits, you have to do your part in maintaining quality data that reflects your current asset situation.

Only then will you truly be able to finish projects successfully.

Conclusion

Assets and equipment have a critical role in the success of project delivery. They are the backbone of your business, so it’s important to have a complete overview of their condition, location, and depreciation status.

Tracking valuable assets means you’ll be able to increase productivity, control resource allocation, and keep your construction teams accountable. All of this will ultimately result in cost reduction, streamlining operations, and long-term company growth.

Basically, if you aren’t already tracking your equipment with efficient methods, now is the best time to start.