Buying an excavator can be a nerve-wracking experience.

First of all, excavators are one of the essential types of heavy equipment in construction. Their versatility allows contractors to handle any job, from landscaping to demolition. Basically, whatever your company needs, you’ll probably be able to find a suitable excavator for the job.

However, buying an excavator is not as simple as walking into a hardware store, placing an order, and driving out with a brand new machine.

Knowing what to look for in heavy equipment is a challenge, and the purchase has to result in improved productivity for your business.

So, we’re bringing you several important questions to ask yourself when you’re considering buying an excavator. In the end, you’ll rest easy knowing you’ve covered all the critical aspects of the purchasing process.

In this article...

What Size Machine Do You Need?

When it comes to choosing the right excavator, bigger isn’t always better.

Purchasing a large excavator to dig up a pool during home renovation might be considered overkill.

On the other hand, getting an excavator without the needed dig depth will result in performance issues and postpone the completion of a project.

So before you even start looking at different types of excavators, consider the following:

- Job site requirements and difficulties

- Lifting capacity

- Bucket capacity

- Transportation and access

- Dig depth

- Hydraulics

- Reach length

These are important factors determining exactly which type and size of excavator you’ll need for different projects. Once you find your exact requirements, you’ll be able to find the right machine for the job.

So let’s cover the three main size categories.

Mini or Compact Excavators

Small excavators that weigh under 6 tons are referred to as mini or compact excavators. Due to their size, they’re ideal for jobs in tight or small areas that don’t require too much power.

The best thing about them is that they’re easy to maneuver and transport, so you’ll usually find them on sites for sewer repairs, utility installations, or landscaping.

Midi Excavators

Excavators with greater power and capacity that weigh between 6 to 10 tons are called midi excavators.

They are used for more standard construction work. They have more lifting and digging capabilities while still being small enough to work in smaller spaces.

Standard Excavators

This category has the broadest range of available excavators. These machines can weigh between 10 and 90 tons, but those weighing from 19 to 24 tons are the most common.

The majority of them are full-sized with a range of features. This allows them to be used for most commercial construction where you need more power and capacity.

The only downside is that transporting them is quite tricky because you need trailers and trucks to move them from site to site.

In the end, getting the right size machine can mean the difference between job completion and job delay. So, you must find exactly what you need in terms of size and type. Otherwise, you can expect poor job efficiency.

Should You Buy Used or New?

After finding the right sized machine, price is one of the most significant factors in choosing the right excavator.

So, it comes down to deciding between new or used heavy equipment. Both have pros and cons, but the final decision rests on what’s in your company’s best interest.

Looking at brand new machines can be tempting and with a good reason. The main benefit of new excavators is they are easier to operate.

They’ll be able to work all day consistently, and you won’t have to worry about sudden breakdowns.

Furthermore, repair expenses are a lot lower, and you’re covered with a warranty should something unexpected happen.

But most importantly, the technology that comes with new excavators is cutting-edge, so you’ll get the features that ensure optimal productivity, comfort, and safety compliance.

Yet, even brand new excavators have their downsides.

The first one is that they incur high upfront costs. It goes without saying that the latest models cost significantly more than older machines, and not many companies are financially prepared for that investment.

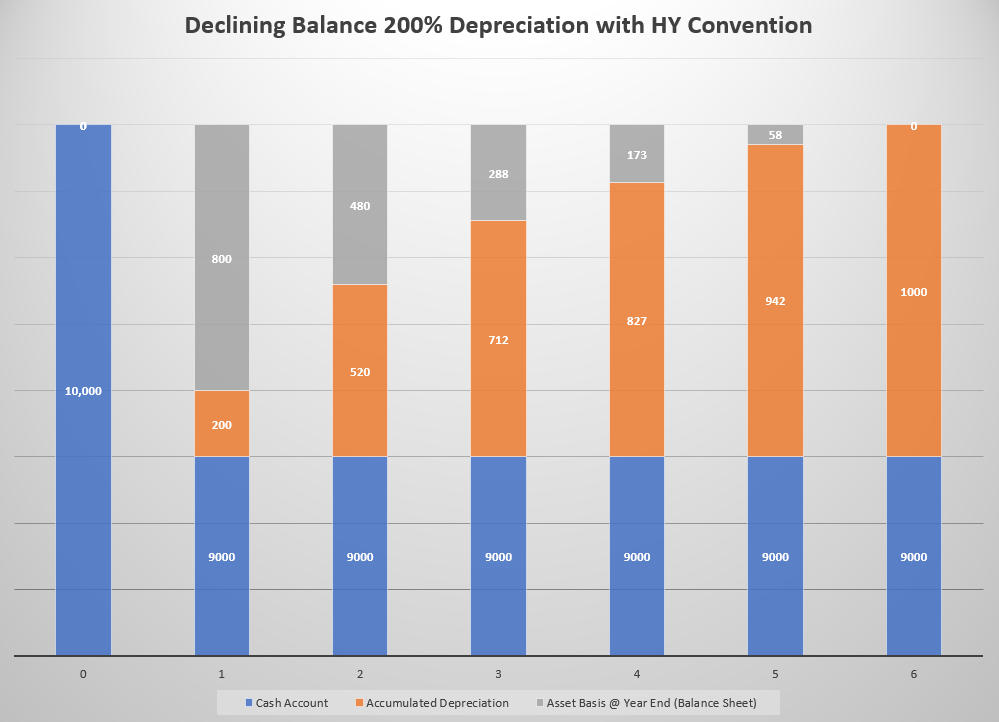

Another thing to consider is depreciation.

Everyone knows that the resale value of new machines drops faster than in older machines, and it’s the highest during the first few years of use.

This further impacts your return on investment down the line, should you ever need to sell the excavator.

On the other hand, if you’re not too fussed about the latest features and you want to get a good excavator for a lower price, then look into the used heavy equipment market.

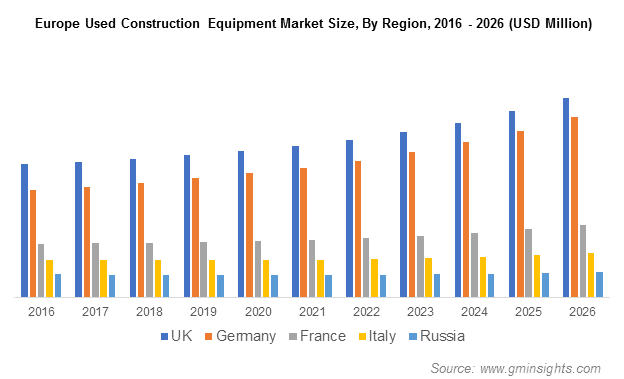

This industry is fueled by increasing investments in public infrastructure and the growth of small construction companies.

They demand cheaper heavy equipment to carry out their construction projects, so it’s no surprise that new research predicts the used construction equipment industry to grow to $142 billion by 2026.

But what are the exact prices of new and used excavators?

New excavators can cost between $100 000 and $500 000, which doesn’t include any extra buckets or attachments. Obviously, buying smaller machines will be significantly cheaper but still not as cheap as used machines.

For example, a new skid steer excavator will cost you anywhere from $70 000 to $125 000, while the price of a used skid steer ranges between $44 000 and $59 500. So, you’re looking at 25% savings with a used excavator.

While new excavators are costly, they have long lifespans, which means that you won’t have to make this investment often.

Also, because of the same reason, many used excavators are very reliable, and you’ll still be able to use them for many years to come.

In the end, the decision between new and used excavators depends on the available resources of your construction company.

What’s the True Cost of an Excavator?

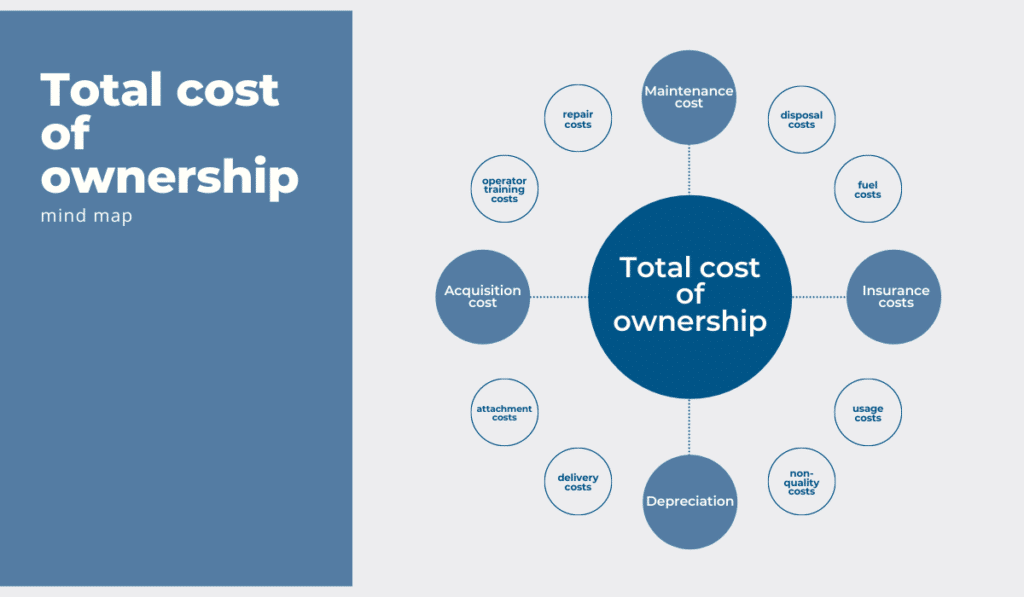

Your spending on an excavator doesn’t stop at the attached price tag. In fact, there are many other ‘’hidden’’ expenses that you need to take into account.

This is often referred to as the total cost of ownership. Companies use it as a framework to analyze their purchasing decisions.

They are looking at the short-term price (i.e., the dealer’s price during acquisition) but also long-term maintenance costs, depreciation, insurance, and fuel consumption.

So, to justify your buying decision, you have to account for all direct and indirect expenses.

To further emphasize what you should consider when evaluating the total cost of ownership, here’s the example of Irwin Post, a forest engineer.

He often used excavators for land clearing and digging in his professional and personal projects.

When he moved to a new property with his family, he carefully calculated how much he would spend on an excavator.

He estimated that he’d use it for at least five years for an average of 75 operating hours per year.

Post wanted a machine up to 7 tons and found a used one for $20 000 for his specific use case. But his cost calculations didn’t stop there.

He broke down his added costs on an hourly rate, so when he considered depreciation, insurance, and spare parts inventory, it amounted to $14 per operating hour.

His next step was to account for variable costs such as fuel, maintenance, and repair.

Diesel engines in excavators of his preferred size incurred a cost of $1.65 per gallon of fuel, which came to around $3 per hour.

Post took into account that his excavator wouldn’t operate at total capacity most of the time.

| Purchase price | $20,000 |

| Cost of owning and operating a used excavator – hourly | $34 |

| Approximate hours the excavator will be used | 375 |

| The total cost of ownership | $32,750 |

When it came to maintenance, Post knew his costs would be higher simply because the excavator was used.

If he bought a new machine for $80 000 with an expected lifespan of 10 000 hours, his cost would be $8 per hour, so he doubled the maintenance cost for his used excavator.

In the end, his final estimation of owning and operating a used excavator rounded up to $34 per hour.

So, in addition to the initial price, his total cost of ownership amounted to $32 750.

As you can see, there’s a lot to consider when buying used pieces of equipment besides the price dictated by a dealer.

For the investment to truly pay off, always think about the other expenses you’ll have to cover once you purchase an excavator.

Will The Operator Be Comfortable Using It?

Operator comfort is probably the last item on your list of considerations when you’re looking for an excavator.

However, while budget and job requirements often dictate what you end up buying, the well-being of your operators should be one of your top priorities.

Why?

Simply put, when operators sit in an uncomfortable chair for long hours, they can become fatigued or develop back problems.

Fatigue is concerning for excavator operators, because it reduces their mental abilities, making them less productive and motivated.

Not only that, in those circumstances, their reaction time is slower, so they could potentially harm other workers.

Almost 80 000 non-fatal injuries were reported in construction in 2019, and nearly half of them included overexertion or contact with equipment.

In the end, this costs employers $1 100 per worker (the calculation only takes wage and productivity losses into account). So you’re not just harming your workers. You’re harming your business too.

Luckily, manufacturers are increasingly designing excavator cabs with operator comfort in mind. Design improvements are focused on accommodating different needs to keep operators satisfied and efficient.

So if you want to minimize the potential losses in labor and time, look into several key elements that contribute to making your excavators more comfortable to operators:

- Plenty of room

- An ergonomic chair

- Adjustable seats

- Good air conditioning and heating system

- Easily accessible controls

Remember, investing in an excavator that will enhance operator comfort will pay off in the long run.

You will have fewer expenses due to injuries and medical absences, and you’ll maintain peak performance from your workers.

How Will You Manage Your Excavator Use?

Excavators, like any other piece of heavy equipment, require ongoing management for optimal use. Knowing where your excavator is and in what condition is important to lower your cost of ownership.

But it also ensures better productivity and business operations.

Keeping that in mind, you need to have a plan for heavy equipment management.

Among other things, proper management includes conducting inspections after use, performing routine maintenance, and controlling access to your heavy equipment.

The first step in this process is to invest in quality equipment tracking software. This provides you with real-time updates on productivity, maintenance, and utilization of all your assets.

You’ll have the right information at all times, so you’ll plan repairs, check warranties, and respond to alerts faster.

Why is this necessary?

You must be aware that any downtime in construction seriously affects project outcomes and workflow.

When you implement systems that enable you faster task completion and preventive measures (such as scheduled repairs), you’ll severely save time and money.

So, the most important benefit of tool tracking software is enabling preventative servicing. This can save you up to 25% on repairs.

There are only so many things that you can control to ensure better productivity, and preventative maintenance is one of them.

On the other hand, while you might not be able to eliminate all breakdowns, you’ll significantly reduce their number. That way, your excavator can spend more time on the construction site and not in the repair shop.

Unexpected machine failures and equipment misuse will not be as much of a problem because you’ll be able to monitor your excavator better with a good tool tracking system.

Conclusion

A powerful excavator is a great tool to get any job done on time. But not all excavators are the same, so there are crucial questions you need to answer before you buy your next excavator.

Think about the type and size of the excavator that will suit your needs. Then you can properly compare prices of the used and new machines but don’t forget about the hidden costs.

Furthermore, maintaining the excavator and keeping track of its use is crucial to ensure the longevity of any heavy equipment.

So, if you carefully consider all the factors in this article, it will be easier to find the best excavator for the work you’ll be doing.