As you probably know, construction companies use Bluetooth beacons and QR codes to track their assets, such as heavy machinery, equipment, and tools.

While these are two distinct technologies whose methods differ, the outcome of implementing them is often the same: minimized asset theft, streamlined asset management, and optimized operations.

In this article, we’ll explore how Bluetooth beacons and QR codes are used in construction asset tracking.

By highlighting their unique advantages and key differences, we’ll help you decide which technology better aligns with your company’s asset-tracking needs.

In this article...

Advantages of Bluetooth Beacons for Asset Tracking

Bluetooth beacons are small, battery-powered devices that are attached to tools and equipment for asset-tracking purposes.

Each beacon (tag) frequently emits short-range radio signals that can be detected by nearby Bluetooth-enabled devices like smartphones and tablets (and/or stationary Bluetooth signal receivers).

These signals are then relayed to the central database and processed by tracking software that converts them into user-friendly information.

You can see the described process below, courtesy of Comparesoft:

When you implement a Bluetooth Low Energy (BLE)-based tracking system in a warehouse or jobsite, you benefit from real-time monitoring of asset locations and automated alerts if an asset is moved out of range.

Now let’s turn to more specific advantages of using BLE beacons for asset tracking: the coverage area, positioning accuracy, operational efficiency, and asset loss prevention.

Wider Coverage Area

Compared to asset-tracking methods that require a direct line of sight between the asset and a reading device (e.g., QR codes and NFC tags), Bluetooth beacons can be tracked regardless of whether an asset is packed in a box or hidden behind other assets.

In other words, if an asset has a beacon, Bluetooth-enabled devices will be able to detect its signal within a range of about 300 ft (close to 100 meters).

This means that a BLE-based tracking system provides a wide coverage area where assets can be automatically tracked.

Naturally, the actual range of such systems depends on many factors, like the capacity of the beacon battery, the number of mobile/stationary Bluetooth receivers, and signal-blocking barriers.

Greater Positioning Accuracy

When it comes to how accurately a Bluetooth tracking system can pinpoint an asset within its range, this technology outperforms even GPS tracking.

In other words, when GPS is used, assets can typically be located within 16 ft (about 5 meters).

As for Bluetooth, beacons can generally be located within 10 ft (3 meters), while some high-accuracy positioning solutions achieve accuracies of less than 1.6 ft (0.5 meters).

Moreover, Bluetooth is better suited for accurate positioning in indoor environments where GPS signals are often distorted or lost.

Improved Operational Efficiency

In essence, the main purpose of any asset-tracking system is to improve operational efficiency, and Bluetooth beacons are no exception.

In fact, the versatility and affordability of BLE beacons make them the prime candidate for real-time tracking of construction assets.

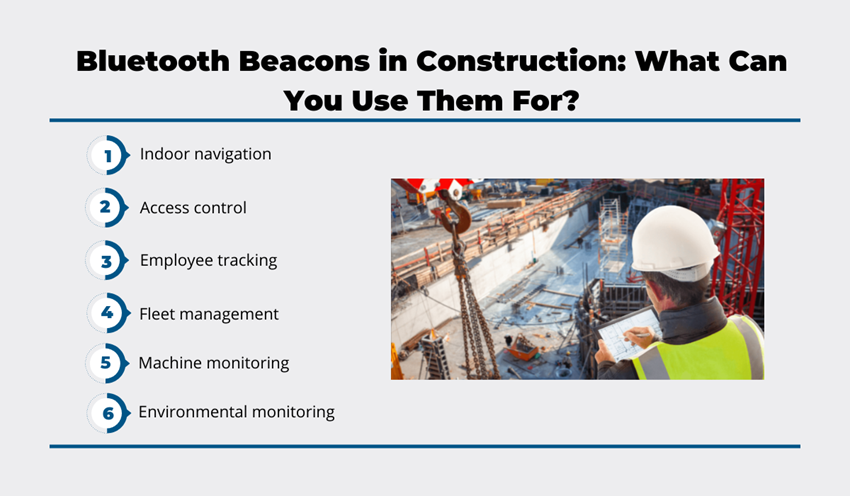

Moreover, there are many beacon applications other than asset tracking that can increase overall productivity.

Here are the six top ones.

As you can read more about specific beacon uses in our article here, we’ll just say that each can, alone or combined, be used to improve your company’s operational efficiency.

For example, beacons with sensors can monitor internal machine conditions (e.g., temperature, oil level, acceleration) or external environmental conditions (e.g., extreme heat or cold, and humidity).

In other words, sensor-enabled beacons can help prevent breakdowns, delays, and cost overruns, which would otherwise negatively affect jobsite productivity.

Even without sensors, Bluetooth beacons provide real-time updates of asset locations, allowing construction companies to improve asset maintenance, allocation, and usage and thus enhance their overall efficiency.

Reduced Asset Loss

Again, it could be said that all asset-tracking solutions—beacons and QR codes included—are aimed at reducing asset losses caused by poor maintenance, negligent behavior, or theft.

However, Bluetooth beacons are ideal for:

- quickly locating assets within a limited area (i.e., construction site or warehouse)

- real-time monitoring of assets moving or situated within that area

- alerting the site manager (or any other authorized user) if a tracked asset moves out of the system’s detection range

A practical example of how beacons help reduce asset loss is the GoCodes Asset Tracking Guardian feature.

Simply put, one or more phones with the GoCodes Asset Tracking Guardian feature activated and Bluetooth turned on will detect all beacon-tagged assets within their range and notify you if an asset goes out of range, allowing you to take appropriate action.

Overall, Bluetooth beacons help minimize asset theft and loss by monitoring the movement of assets within one restricted space in real time.

Having covered what advantages beacons coupled with tracking software provide when used for asset tracking, let’s turn to QR codes.

Advantages of QR Codes for Asset Tracking

Quick response (QR) codes are more advanced, two-dimensional versions of barcodes that provide a fast, simple, and cost-effective way to track assets and inventory.

Given the simplicity and affordability of establishing a QR code-based tracking system, they’re widely used in the construction industry.

To start tracking your assets, all you need are QR code tags and cloud-based tracking software with an in-app scanner installed on mobile devices like smartphones and tablets.

As you can see, workers can use a smartphone or tablet to quickly scan the QR code tag and instantly access the asset data via the tracking software.

In other words, after QR code tags are affixed to assets, and the software’s database is populated with initial asset data (e.g., serial number, manufacturer, purchase date, etc.), the tracking system is established.

Once it’s up and running, the QR code tracking system will provide specific advantages for construction companies discussed below.

Faster Asset Identification

Since all it takes for the tracking system to identify an asset is a simple scan, QR codes are the easiest and fastest way to minimize time-consuming manual data entry and reduce record-keeping errors.

For example, a worker who scans an asset will be immediately taken to the asset’s info page, where they can view and update relevant asset data we mentioned, thus saving time and minimizing errors.

This instant accessibility is why QR codes are often used as the primary tracking method for all construction assets, including those tracked by methods like Bluetooth beacons.

Overall, QR codes (and cloud software with an in-app scanner) provide construction companies with a quick and easy way to identify and track assets and inventory.

Complete Asset Visibility

In addition to fast and easy asset data retrieval, a QR code-based tracking system provides construction companies with comprehensive asset visibility.

More precisely, when a QR code tag is scanned, the tracking software will record the identity of the person who scanned the asset and allow them to enter relevant data (e.g., the asset’s location).

However, some tracking software will use the GPS function of the scanning device, such as a smartphone or tablet, to automatically record the asset’s GPS location, which can be viewed on a map.

When current locations and users of assets are tracked, the ability to access this data in real-time ensures that companies have an up-to-date and complete view of their assets.

Finally, the low price of QR code labels allows companies to track an unlimited number of assets, which also increases overall asset visibility.

Ease of Asset History Tracking

By scanning a QR code tag or accessing the software’s database on any device, managers and workers can view the asset’s complete history, including maintenance records, previous locations and users, and any relevant updates.

This historical data is crucial for various aspects of asset management, such as asset procurement and allocation, maintenance planning, compliance audits, lifecycle management, and insurance claims.

Simply put, asset history is easily tracked because all relevant information is safely stored and readily available whenever needed.

Lower Risk of Label or Tag Damage

Last but not least, QR codes can be engraved or printed directly on sturdy materials (metal, plastic), avoiding the risk of label or tag damage in often harsh construction environments.

When affixable QR code tags and labels are concerned, they should be made from durable materials (preferably also tamper-proof).

The readability of QR codes when damaged and the choice of label or tag material to prevent damage minimize the risk of asset information loss due to label or tag damage.

To sum up, QR code-based asset tracking is a fast, simple, and cost-effective method that allows construction companies quick asset identification and provides complete asset visibility and easy history tracking with reduced risk of damage.

Bluetooth Beacons vs. QR Codes: Key Differences

When key differences between Bluetooth beacons and QR codes are concerned, the biggest one is the tracking technology they use to track assets.

As mentioned earlier, Bluetooth beacons emit radio signals, which enable automatic and continuous real-time updates of asset locations within the range of mobile as well as stationary signal receivers.

Conversely, QR codes do not emit anything; instead, they must be manually scanned to record asset users and locations and retrieve asset data from cloud-based tracking software.

As such, QR codes do not provide real-time tracking but, when assets are regularly scanned, can ensure near real-time asset visibility.

Moreover, they enable construction companies to establish an automated check-in/check-out system where the software records who uses an asset and whether they returned it.

This creates a transparent chain of custody, increases worker accountability, and minimizes asset theft.

Other differences between Bluetooth beacons and QR codes include:

- beacon/label size: some small assets can’t be fitted with beacons

- price: beacons involve higher upfront costs due to more complex hardware and installation requirements

- power: QR codes require no power, beacons are battery-powered

- reusability: beacons can be transferred to other assets, while QR codes can’t

The effective range of a BLE-based tracking system will depend on the number of mobile and stationary BLE receivers present within a designated area, beacon settings, battery capacity, and other factors.

The range of a QR code-based tracking system is essentially unlimited since the tracking software can use the scanning device’s GPS function to capture the asset’s location anywhere in the world.

Having highlighted the main differences between Bluetooth beacons and QR codes, let’s try to answer which method is better for construction asset tracking.

Bluetooth Beacons or QR Codes: Which Is Better

In essence, Bluetooth beacons and QR codes are two distinct technologies that can complement each other and allow construction companies to establish a multilayered asset-tracking system.

As such, neither is inherently better, and despite some overlaps and shared goals, they are ultimately used for different purposes.

For example, your company can use QR codes in tandem with tracking software to:

- minimize manual data entry

- maintain accurate and up-to-date asset records

- establish an automated asset checkout system

- enable fast asset identification and data retrieval

Concurrently, you could use Bluetooth beacons to automatically track assets in real time, prevent asset theft, and monitor workflows to improve operational efficiency.

However, QR codes also contribute to these aspects of asset management by, for example, enabling asset tracking beyond the range of Bluetooth beacons.

So, the point is to find a solution that combines the benefits of both technologies in a single, integrated tracking system.

One such solution is our asset-tracking software, GoCodes Asset Tracking.

By using a tracking solution that provides both QR codes and Bluetooth beacons, your company can establish an easy-to-use and affordable primary asset-tracking method (QR codes) and complement it with beacons affixed to high-value assets for additional security.

Therefore, neither beacons nor QR codes are categorically better than the other.

The point is to find the right combination of both technologies that will meet your company’s specific tracking needs and budget considerations.

Conclusion

Having covered the advantages of beacons and QR codes, it’s clear that these technologies are each suited to different asset-tracking scenarios but also that they complement each other.

So, whether you decide to make your tracking system QR code-based with beacons in a supporting role or vice versa, the outcome should be minimized asset theft and loss, improved asset management, and streamlined operations.