If you’re here, you’re probably wondering whether your construction company should use Bluetooth beacons to track tools, equipment, and other assets as they move across a jobsite or warehouse.

That question is not without merit.

Despite all the hype about seamless, foolproof Bluetooth-based tool tracking solutions, using this technology does present some practical challenges, especially in construction.

In this article, we’ll explore the top three challenges of tool tracking with Bluetooth beacons and suggest possible solutions and practical workarounds for each of them.

In this article...

Time-Consuming Beacon Application

Setting up and attaching Bluetooth beacons to a large number of tools can be time-consuming, impractical, and—in some cases—impossible.

To illustrate our point, let’s first briefly explain how Bluetooth tool tracking works.

Bluetooth beacons are small, battery-powered devices that are attached to tools, equipment, and other assets that need to be tracked.

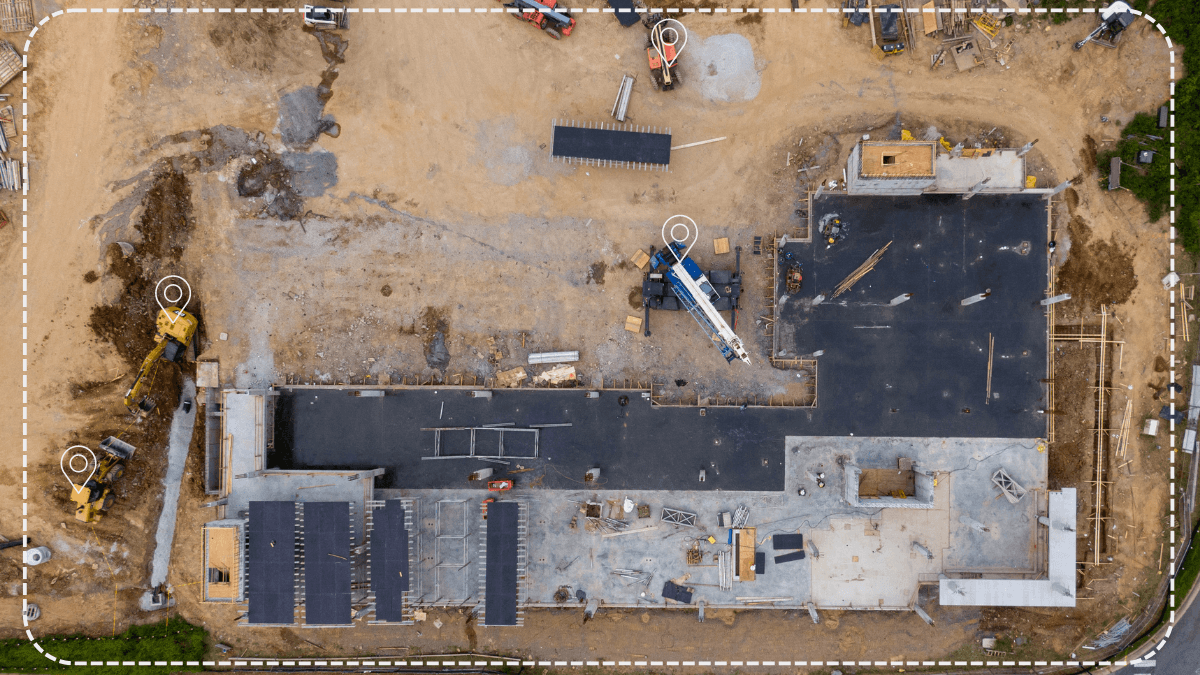

They transmit short radio signals at regular intervals, which are detected by nearby Bluetooth-enabled mobile devices (smartphones, tablets) and sometimes stationary Bluetooth receivers strategically positioned around the site.

All these beacon signals are routed to and analyzed by a cloud-based tracking app, which provides real-time location updates for the tracked assets through an intuitive user interface.

This, in turn, generates benefits like improved resource management, better theft prevention, and increased jobsite productivity.

Here’s how the system works, courtesy of Comparesoft:

Mind you, stationary Bluetooth receivers are optional, and some beacon-based tracking applications can be used with a single smartphone (e.g., the Guardian feature from GoCodes Asset Tracking).

Now that we’ve explained how Bluetooth asset tracking works, let’s focus on the challenges a company will face when it wants to attach beacons to many construction assets.

First, the beacon’s dimensions.

Although relatively small, most externally attached beacons are still too large to be fitted on some smaller power tools, specialized testing instruments, or advanced surveying equipment.

For example, Bluetooth beacons are usually round, with a diameter of about 2” (5 cm) and a height of about 0.6” (1.5 cm).

This means that, although suitable to be affixed to most larger tools and equipment, there are still some often-valuable assets that can’t be effectively tracked (nor protected) using a Bluetooth-based tracking system.

Then there’s the issue of the number of assets a company wants to track and the time and effort required to install (screw, glue, strap, etc.) all the beacons.

Finally, managing beacon settings, updating firmware, and monitoring battery levels can also become time-consuming for equipment managers.

Now let’s see what solutions are available to address these challenges.

As for beacons being too large to track an array of smaller hand and power tools, accessories, equipment spare parts, etc., you should employ another asset-tracking method that tracks worker accountability and ensures automatic location updates.

For example, our tool-tracking app, GoCodes Asset Tracking, uses rugged QR code tags that can be quickly attached to tools of any size.

Once the tools are tagged, and the cloud-based tracking system is set up, workers can scan tags using smartphones or tablets and use the tracking app to assume/release responsibility for the tools they’re using (check-in/check-out system).

In parallel, every time a tool tag is scanned, GoCodes Asset Tracking will automatically record its current location using the mobile device’s GPS function.

By using QR codes as an affordable and easy-to-use tracking solution and pairing them with Bluetooth beacons, GoCodes Asset Tracking enables companies to:

- track and protect all tools by establishing a transparent chain of custody and an official record of tool locations and users

- reduce the number of tools needing Bluetooth beacons (QR tags are cheaper and easier to install, which saves time and money)

- use Bluetooth beacons on size-suitable, high-value tools and equipment for additional security (and workflow tracking, if necessary)

Additionally, since Bluetooth beacons come preprogrammed to be used with the GoCodes Asset Tracking app, beacon settings, and the system setup are much easier and come with dedicated training and user support.

Therefore, using the right combination of tool tracking methods integrated into one tracking solution can seriously cut down the time and effort needed to deploy beacons.

Varying Signal Range and Reliability

Another common challenge of tracking tools with Bluetooth beacons is the varying signal range and reliability.

In other words, numerous factors can affect the range and reliability of beacon-emitted signals, such as:

- the beacon’s signal strength (longer range, shorter battery life)

- physical obstructions (thick walls, large metal objects, etc.) that weaken or even block the signal

- devices or networks using the same frequency range as Bluetooth (e.g., Wi-Fi routers, other Bluetooth devices, microwaves in use) causing signal interference

- environmental factors like the signal reflection in indoor environments and severe weather conditions in outdoor environments

Given all these factors, it’s not surprising when a beacon-tracked tool is not detected by your phone or tablet, although the tool is actually within its signal detection range.

Likewise, when tools are detected, their location may sometimes not be as accurate as expected.

Therefore, although the maximum transmission range of a Bluetooth beacon is most often cited as being around 300 feet (100 meters), its actual range can vary widely depending on the abovementioned factors.

Or, to quote Mapsted, an indoor positioning system company:

Most Bluetooth beacons can reliably transmit up to approximately 30 meters without any physical obstructions.

Okay, so how can a company avoid/minimize these issues?

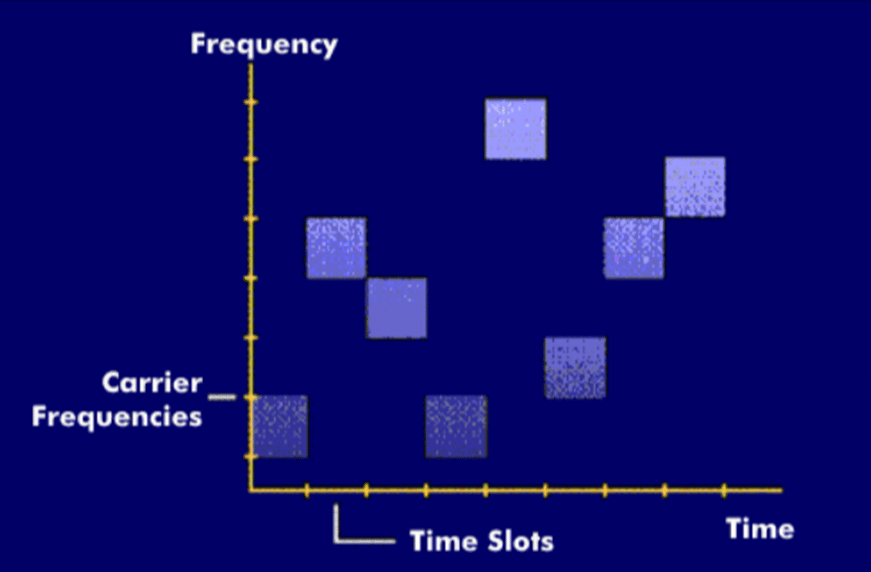

For starters, interference with other devices operating within the same frequency range (2.4 GHz) is minimized by beacons using the frequency-hopping spread spectrum (FHSS) shown below.

In essence, beacons emit short signals with rapidly changing frequencies, thus reducing the chances of interference.

As for physical obstructions and other factors affecting signal range and reliability in construction environments, these issues can be addressed by having more BLE-enabled mobile devices, i.e., moving Bluetooth receivers, on-site.

In more complex environments, strategically positioning portable Bluetooth receivers across the jobsite or warehouse is the best option.

These devices (sometimes also called beacons, to make matters more confusing) act as stationary hubs or gateways that receive beacon signals within their range and relay that data to a central cloud database, enhancing tool tracking coverage and accuracy.

Of course, procuring and installing a sufficient number of Bluetooth receivers positioned at the right places to provide maximum signal reliability makes the tracking system more expensive to implement.

Therefore, it’s worth considering practical tool-tracking solutions that do not rely solely on Bluetooth, such as the GPS-enabled QR code tags we mentioned.

All in all, signal range and reliability issues can be efficiently addressed using Bluetooth-enabled mobile devices and/or well-positioned, stationary Bluetooth receivers.

High Power Usage and Battery Drain

All Bluetooth tool tracking system components—beacons, mobile devices like smartphones and tablets, and potential stationary receivers—are typically battery-powered.

And, as we know, batteries run out.

When it comes to beacons, they usually come with energy-efficient, long-lasting batteries with a lifespan of anywhere between several months to several years.

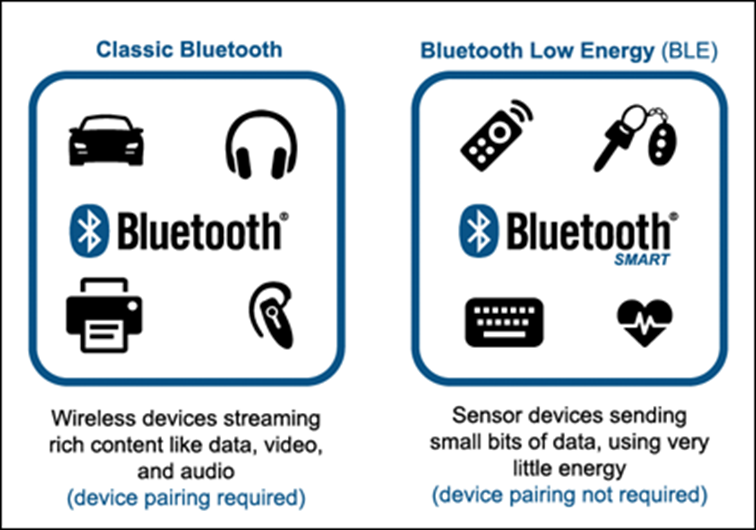

Moreover, beacons use Bluetooth Low Energy (BLE) technology, which consumes about 50% less power than Bluetooth Classic and provides a faster beacon-device connection.

Here are the basic differences between these two technologies, courtesy of OneTemp.

Despite low energy consumption, the beacon’s battery life will still depend on a host of factors, starting with the battery capacity and usage optimization features (sleep mode, adaptive signal transmission intervals, etc.).

Then there is the relationship between the beacon’s signal transmission power and range.

Simply put, higher power gives beacons extended range but shortens their battery life.

Other battery-draining factors include:

- frequency of beacon transmissions (i.e., advertising interval)

- environmental conditions like extreme temperatures

- sensor usage

As for the last one, it should be noted that some beacons come equipped with additional sensors, such as motion, temperature, and humidity, as shown below.

As you can see, these additional sensors do not significantly affect beacon design, but frequent sensor readings can impact their battery life.

Now let’s move to BLE signal receivers and first quickly cover potential stationary hubs/gateways positioned around the jobsite/storage.

They are usually battery-powered and, therefore, susceptible to more or less the same factors as beacons (but can have larger, higher-capacity batteries).

For example, if they’re set to scan for beacons at their maximum range, you might need less of them to cover a specific area, but their batteries will run shorter.

As for mobile beacon signal receivers, namely smartphones (or tablets), their battery is drained by many more processes than just keeping Bluetooth turned on.

In fact, according to Android Authority, leaving Bluetooth on an entire day consumes less than 4% extra battery life.

Therefore, the main battery-draining factors are other smartphone functions, primarily keeping the device connected to the internet and running all the apps, including the tracking app, in the background.

The solution to these issues is, for beacons, careful configuration of the beacon’s signal strength and range as compared to the number of mobile/stationary receiver devices, site layout, and other relevant parameters.

As for smartphones and tablets, utilizing power-saving mode, optimizing battery usage, and closing unused apps to remove unnecessary background processes can be effective battery savers.

Overall, high power usage and battery drain shouldn’t be an issue when the beacon-based tool tracking system is correctly configured and battery life optimized.Conclusion

Long story short, while using Bluetooth beacons for tool tracking can bring many benefits, the practical implementation of this technology does present some challenges we explored in this article.

For instance, the time-consuming implementation of beacons can be addressed by selecting the right tool-tracking software that will combine BLE beacon tracking with other easy-to-use and affordable tracking methods based on monitoring workers’ accountability for tools and tool locations.

This will enable you to limit the number of beacons and focus your Bluetooth tracking on more valuable tools and equipment as an extra security measure.

At the same time, careful planning, configuration, and setup of the beacon-based tracking system will allow you to overcome the technical hurdles related to varying signal range and reliability, high power usage, and battery drain.