Barcodes—the small black and white markings often found on retail products—are present in all facets of life, from stores and newspapers to hospitals and pharmacies.

Their compact design and ease of use make them the number one choice for companies that want to track and identify their products according to global standards.

This article will serve as your guide to barcodes as it will explain what barcodes are, their composition and purpose, and how they can help your company save time and money.

If you decide to start using barcodes in your business, the article will explain how you can implement them efficiently.

In this article...

What Are Barcodes

Barcodes are a globally recognized standard of business communication, developed and maintained by GS1 (Global Standards 1), the leading organization in this field.

These machine-readable symbols contain information about a product and help the owner or users track it while decreasing the risk of human error.

Barcodes are square or rectangular, consisting of black lines and white spaces that vary in width, with numbers underneath them. They are printed and applied to the product, packaging, or pallet of products, and they hold information about the product at hand.

After a quick, simple scan with a specially designed scanner or a smartphone, the user can access all the information the manufacturer has listed using the barcode’s parallel lines.

The encoded data includes:

- production and expiration dates

- country of origin

- manufacturer details

- product price

The barcode lines differ from item to item, making it a unique representation of a specific product.

This additionally speeds up the identification process and guarantees that the users get the correct information.

Nowadays, barcodes are found on many products in various industries as all industries strive to have the same standards.

More than a million companies use GS1’s products nowadays, and the number is only increasing.

Interestingly, the original barcode patent has existed since 1949, but the first successful use was recorded in the US in 1974 on a packet of Wrigley’s Gum.

Barcodes have come a long way since then.

They are used on products worldwide because they are easy to read, increase productivity, give less way to human error when it comes to product data, and save time.

It’s no wonder that users worldwide scanned barcodes an astonishing six billion times a day in 2019, proving how widespread and valuable they are.

Barcode Components

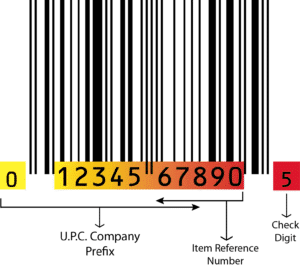

Barcodes consist of narrow and wide black bars and white spaces, under which there is a series of numbers representing the product information.

The bars and spaces represent the barcode height, which should be high enough for the scanner to read it easily. Optimally, the barcode height should be 15% of the barcode length.

Truncation—the shortening of something by removing a part of it—is not a good option for barcoding as the scanner might not be able to scan the barcode correctly with parts of it missing.

This would make the barcode useless.

Two quiet zones—blank spaces that make it easier for a scanner to read the code—surround the barcode symbol. Their color should be the same as the background color of the code, which is usually white, making it possible for the scanner to recognize it.

The minimal recommended quiet zone length is 2.5mm for optimal scanner reading, but in general, the quiet zone should be at least ten times bigger than the narrow bar.

The symbol itself begins with a start character and ends with a stop character. These values represent the code’s beginning and end and vary based on the barcode type.

The barcode data are the letters or numbers after the start character. These figures contain all the information about the product itself.

After this data, manufacturers include a check digit to ensure successful reading.

After a scan of the barcode digits, the scanner performs a check and calculates the value of the check digit using the preceding numbers. Finally, the device compares the calculated check digit with the one present on the barcode.

If they do not match, the scanner cannot read the barcode.

What Are Barcodes Used For

All businesses that have to identify or track their products or services should use barcodes since the technology is already helping many industries and organizations worldwide.

In Retail

It’s no secret that retailers use barcodes to be quicker and more productive. After all, you can see barcodes on any item you buy in stores.

When the cashier scans the barcode, they access important information on the item, including the item code, description, and price.

In fact, some stores offer the option of self-checkout, which would be impossible without the possibility of barcode scanning.

It lets the store know which items you are taking and how much you owe them for the item.

Retailers also use barcodes to optimize inventory tracking. Every sold item is recorded in the system.

They can use their tracking results to understand whether they need to stock up on certain things.

In Healthcare

Healthcare is another field that relies on barcodes. An essential part of it is the equipment that has to be available at all times.

Barcodes help the industry immensely as they make it easier to track assets and know where they are at all times.

Another important use of the barcode is the one on the patient’s wristband used in hospitals.

It eliminates human error and affirms that patients are getting the correct treatment and medication.

The personnel has to scan the barcode to get information on the patient, such as:

- their identity

- procedures they have to undergo

- the medication they need to take

- any allergies or complications they might have

As a result, this option helps avoid any accidental switches and ensures the patient is getting the correct medication and that this medication is in stock.

In the Public Sector

Similarly, governmental organizations use barcodes to guarantee that they can account for all their assets.

After all, public funds have paid for the equipment, so industries like the military, law enforcement, and even fire departments are responsible not only to their employer but to the public that funds them.

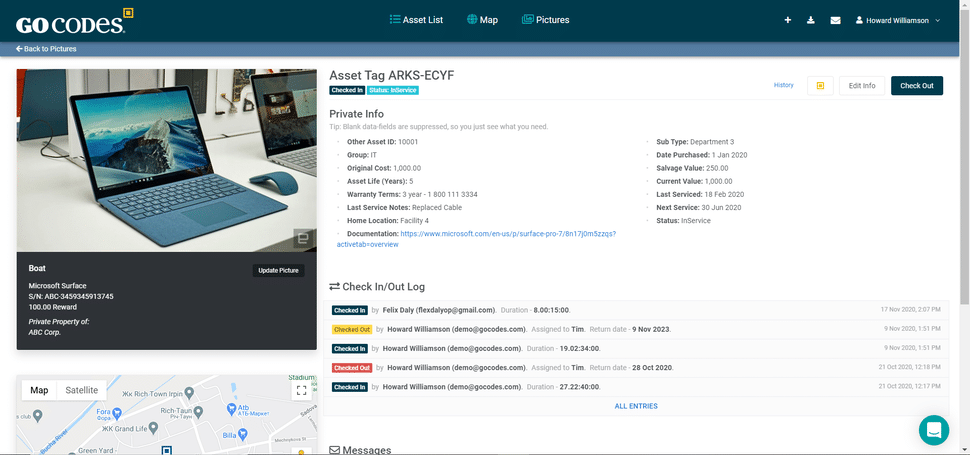

Since tracking equipment is crucial in such industries, they often use software to check equipment in and out and efficiently track it.

Tracking allows the user to understand who is using the asset, when they are supposed to return it, and when it’s due for maintenance.

Barcodes are used in many other industries as well, such as advertising, games, and education.

How Do Barcodes Work

Barcodes consist of numbers and black and white lines, which don’t give any specific information to the user when they simply look at the barcode.

However, the setup of the components makes it possible for an optical scanning device to read them and get the data translated into information that the user will understand.

The scanning process only takes a couple of seconds, making this type of technology fast and efficient. Once the user scans a barcode, they get more details on the product.

The typical scanner or barcode reader has a light source, lens, photoconductor, and decoder, all of which are necessary to read the code and understand it.

First, the scanner aligns with the barcode to be able to read it. The light source then assists in recognizing and reading the code while the lens scans it.

The photoconductor transfers the optical impulses into electrical ones, allowing the decoder to process and analyze the information, and send it to the system, typically a database.

Once the information is there, the scanner shares it with a computer, tablet, or smartphone connected to it, allowing the user to read the data.

Using Optical Scanning Devices With Barcodes

While they all work in pretty much the same way, optical scanning devices differ according to the type of engine they have.

Laser scanners use red lasers to read the standard black and white images, from a distance of a couple of inches to a couple of feet.

Such devices are widespread because of their cost-effectiveness, but they can only read the essential 1D barcodes.

Like laser ones, linear image scanners can only read the 1D type of images.

The difference between them lies in the way they scan.

Linear image devices capture a picture of the barcode and then analyze this image to get the necessary information. Their advantage is that they can get the needed data even when the label is not in the best state.

Similarly, 2D area imagers also take a picture of the barcode to analyze it, but they can scan the more advanced types of images, along with the basic ones.

The barcode position is not crucial for this type of scanner since it can read the barcode even if it is upside down, while the other two types can work only if the label is in a horizontal position.

Types of Barcodes

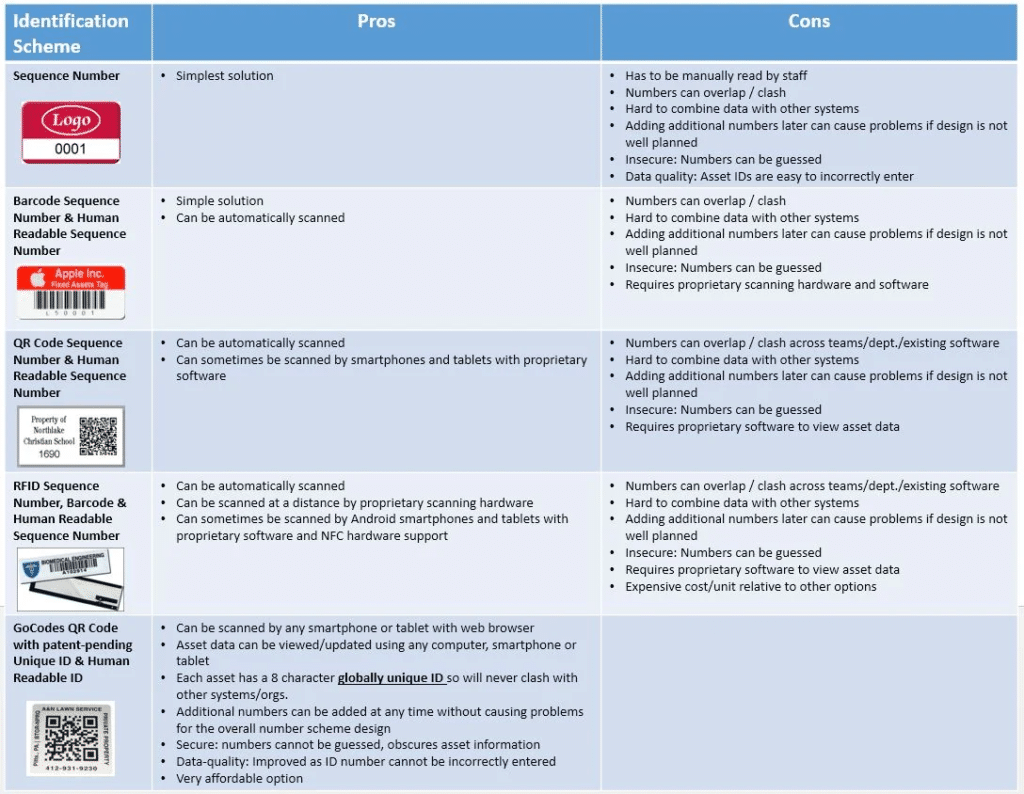

When deciding on the correct type of barcode for a business, owners should consider how much data they want to transfer through the barcode.

This will depend on the product and the label size, the needs of the company in general, and the country of use.

There is a distinction between basic and more advanced barcode types called 1D and 2D codes.

1D Codes

One-dimensional (1D) or linear codes are basic codes that hold standard information on the product’s type, size, and color and that the scanner reads horizontally.

The more information 1D codes hold, the longer they are, but they are nevertheless limited to 8 to 15 characters.

Some of the most common types of 1D codes are UPC and EAN codes.

Universal product codes (UPC) are present on consumer goods globally, most commonly in the US and Canada.

When scanned, these codes identify product features such as size and color, which helps with inventory tracking. They consist of a barcode and 12 digits.

European article number (EAN) codes are very similar to UPCs, and the main difference is their geographical use.

As opposed to UPCs, and as their name suggests, EAN codes are primarily used in Europe. They hold information on the product, packaging type, and manufacturer.

1D codes are used on products associated with information that is prone to changes, like retail prices. The code itself identifies the item’s static qualities, such as size and color, while the dynamic data associated with the product shows the price.

As a result, the barcode doesn’t include the pricing details, as those change quite often.

2D Codes

Two-dimensional (2D) codes are advanced options that carry both essential and additional information, ranging from price and inventory to voice data, websites, and images.

In addition to parallel lines, they use different patterns, such as hexagons, dots, and squares, but they remain smaller than 1D codes.

Such patterns allow them to have several times more characters and thus gather more data than 1D codes. The characters can be stored vertically and horizontally, making the reading easier.

Moreover, some of them can be read with 1D scanners and smartphones, additionally simplifying the process.

2D codes track a product and hold more information, while the codes themselves are smaller and easier to read.

The person scanning them doesn’t have to worry about their position since they can be read from either direction, speeding up the process.

The most prominent 2D code for consumers is the quick response (QR) code, consisting of black and white pixels in a small square.

QR codes are so popular that most smartphones have the option of reading them. For this reason, the industries of advertising and marketing often use them.

How Barcodes Help Businesses

Barcodes are prevalent in a variety of industries, from retail to medicine, but how can they benefit your business?

One of the key advantages of barcodes is accuracy, vital in most businesses.

Barcodes eliminate the risk of human error since the user only has to scan the barcode, and the scanner does all the work for them, showing them information stored in the code.

As a result, there is no need to enter or change data manually.

Likewise, barcodes eliminate the need for manual inventory management, thus improving inventory control quality.

They let users know which items were sold or shipped, and which ones are still available based on the scanning.

This knowledge helps businesses stay on track of demand and order in advance to avoid stockout without frequent manual checks of inventory.

Speed is why many companies opt for barcodes—scanning and analysis only take a couple of seconds, after which the data is readily available to the user.

They don’t have to enter the system and type in product data to determine its specifications, which usually takes time.

In addition, some scanners can read more than one barcode at once, with some achieving an impressive 480 scans a minute, which would be impossible without technology.

On top of that, barcodes are cost-effective, which is why they are so popular.

Creating and printing barcodes is relatively cheap, and so are scanners. There are scanners that you can simply plug into your computer to get the data on the scanned product.

Moreover, you will also save on training your team—barcodes and scanners are very easy to use, so the training doesn’t need to be extensive or frequent, and your team doesn’t have to do a lot of manual work.

Finally, barcodes such as QR codes can help you track your assets using the GPS tracking option.

Some QR codes have a GPS tracking device that lets you know the location of your equipment.

Tracking also comes in handy when you want to know which employee is currently using a piece of equipment, whether your product has left the company or warehouse, and if it’s been delivered, thus eliminating the risk of loss, theft, or misplacement.

How to Implement Barcodes

Once you decide to use barcodes in your business, you will have to start somewhere.

GS1 suggests adhering to the following steps to make the process as simple as possible.

1. Get A GS1 Company Prefix and Assign Numbers

First, get a GS1 company prefix from a GS1 Member Organization.

Before you can start creating barcodes, you need to get a GS1 company prefix from a GS1 Member Organization.

This will serve as an identifier in all your barcodes, consequently allowing users to associate your products with your company.

Once your company has a prefix, you can start assigning numbers to:

- your products

- the company as an entity

- locations

- assets

- logistic units

- any other part of your business that you wish to keep track of and label

The GS1 contact will let you know how many numbers you can assign based on your company prefix.

2. Choose a Printing Process

The next step is deciding on a barcode printing process by understanding whether your barcode will carry static or dynamic information, i.e., whether the data will change or not.

If the data is not prone to change, opt for printing directly on the product or a label applied to the product.

If the information is dynamic, you should use a digital printing process that allows later additions as changes happen.

3. Ensure Easy Access With the Right Scanning Environment

To ensure your barcode is easy to use, select a primary scanning environment. When you know whether stores, warehouses, hospitals, or offices will scan your product, you can decide on the positioning of the code.

Why does it matter?

Some codes can only be read horizontally, which slows the process down. Additionally, if warehouses will use your code, it needs to be large enough to be noticed by a warehouse scanner.

4. Select the Type and Size of the Barcode

The next step is to decide on the correct type of barcode.

UPC or EAN barcodes are primarily used in retail, so you should choose them if you intend to sell the product at points of sale. Opt for 1D codes if the product information can vary.

On the other hand, if you want to give the customer additional information when scanning, such as URLs or images, use 2D codes.

GoCodes Asset Tracking’ QR labels include randomized unique identifier numbers (RUID) that make sure each piece of labeled equipment has a unique barcode.

When you know who is going to use the barcode as well as where and what type of barcode you need, it’s time to choose the size, depending on where the scanning will happen.

Omnidirectional barcodes have a fixed height and width ratio. If you want to keep the data intact, you cannot change only one of the two without the risk of your code becoming illegible.

5. Be Mindful Of the Formatting

Formatting the text is an integral part of the process because the text becomes the main identifier if the label gets damaged and cannot be read.

It needs to be proportional to the symbol size, legible, and placed under the barcode. Its length depends on the type of barcode you chose.

6. Decide on the Color

When picking the color, stick to the original black and white barcodes, easily readable by scanners.

If you prefer a less traditional approach, go for darker shades for bars and lighter for backgrounds and quiet zones.

However, keep in mind that the bars shouldn’t be reddish since such colors tend to disappear under a red laser, making your barcode impossible to scan.

7. Consider the Placement

Think about the barcode placement and consider the packaging and printing process.

Your priority should be ensuring that the barcode does not get damaged. The barcode should be visible, and there should be enough room for the quiet zones.

8. Establish Barcode Quality

Once you’ve done all that, it’s time for a barcode quality plan.

An ISO-based verifier can help you determine the quality of the image, and you can then decide if you want that to be your company’s standard.

The program will let you know whether you have made mistakes in the previous steps as it will point out flaws in the contrast, measurements, scaling, and uniformity, among others.

For simpler barcoding requirements, applications like GoCodes Asset Tracking are viable solutions.

Conclusion

In short, barcodes are not only easy to use, but they save companies a lot of time and money, which is why you can see them practically everywhere.

In addition to that, the tiny black and white symbols give businesses the option to provide all necessary information to users through a small image that even smartphone apps can scan.

If you need to track your products and quickly identify them, consider using barcodes in your business.

An excellent way to start is following the GS1 recommendations and deciding which type of barcode suits your needs best.

GoCodes Asset Tracking Can Help

We use QR code labels with a unique visual code that you can scan with your smartphone. When scanned, GoCodes Asset Tracking tags provide GPS information about the item’s location, status, and use, making equipment tracking and management super easy. Sign up for a free trial here.