The value of an efficient asset tracking solution cannot be overstated. It’s indispensable for businesses that want to reach their peak efficiency and take their organization to another level.

That’s why today, we see so many different types of asset management systems on the market.

The two most well-known and very commonly used ones, however, are barcodes and Quick Response (QR) codes.

The two are, in fact, related, with QR codes being the newer, more advanced version of barcodes.

But despite being older, barcodes are by no means obsolete. Many still use them for asset tracking and management today.

So which one’s actually better?

In this article, we answer that question. But first, we need to explain what each of these systems is and what the main differences between the two are.

In this article...

What Are Barcodes

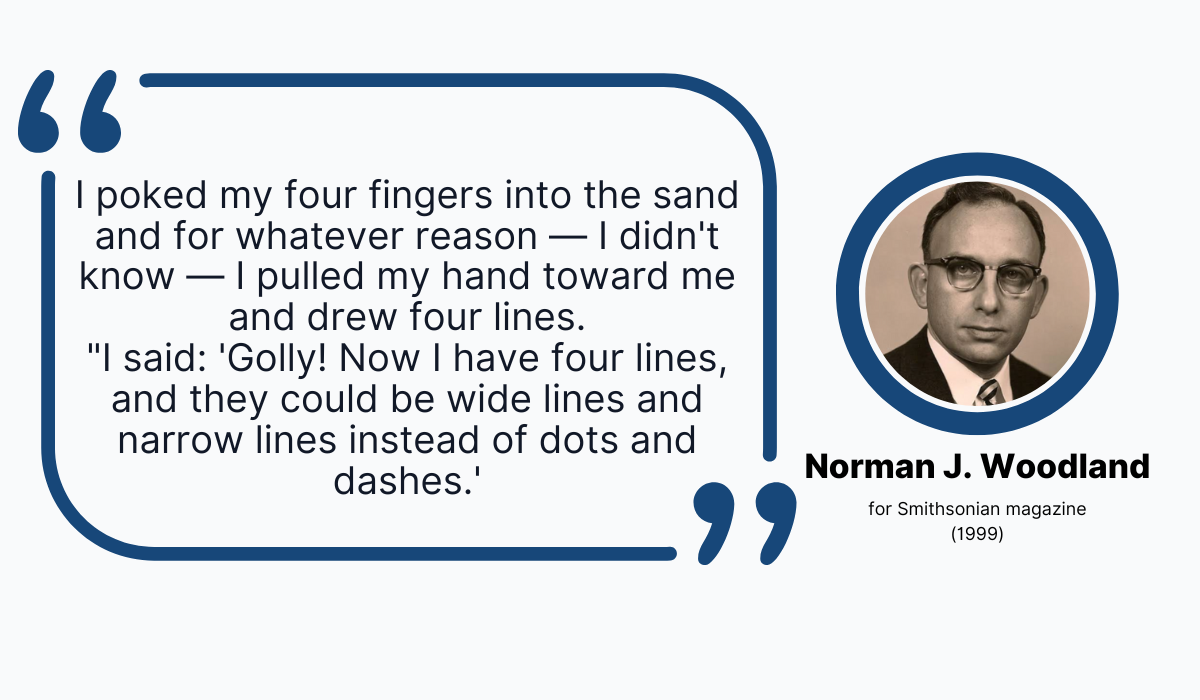

Inspired by the Morse code, Norman J. Woodland and Bernard Silver got the idea for barcodes and applied for a patent for the invention in 1949.

However, the technology didn’t catch on immediately.

It wasn’t until the 1970s that the use of barcodes became more widespread.

This was when grocery stores started implementing them, and the National Association of Food Chains (NAFC) standardized the use of barcodes in retail.

Today, on the other hand, it’d be very hard to find someone who wasn’t familiar with these boxes with black and white vertical lines.

But how exactly do they work?

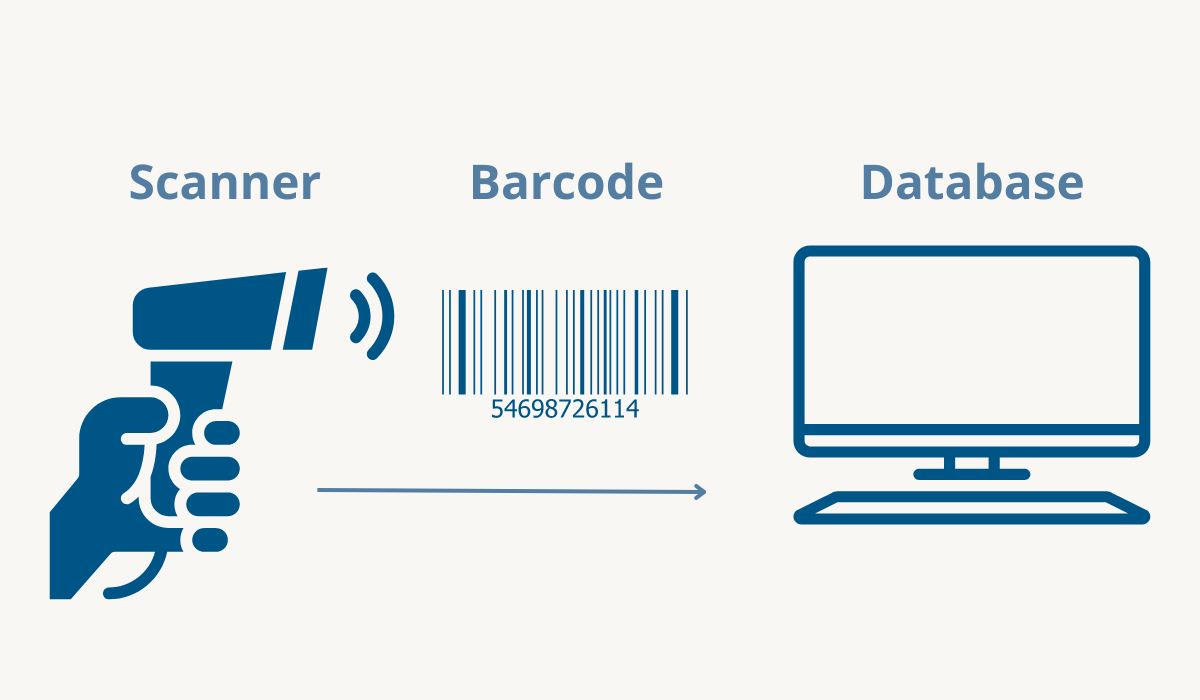

Essentially, there are three components you need to get started with barcode asset tracking: barcode labels, barcode scanners, and a central database.

The thickness of each black bar on a barcode label varies and signifies the numbers 0 or 1, while the bar sequence represents a number between 0 and 9.

Although looking at these lines might not tell you much, the computer connected to the barcode scanner knows and understands which item is associated with each unique combination.

In essence, the barcode contains data, the scanner reads it, and the database connects the data with products.

For instance, barcodes used in retail might contain the name of a product and its price, which are shown on the store’s cash register after the barcode is scanned.

Overall, barcodes were a massive advancement in asset management compared to their predecessors—pen and paper—and a first step towards the automation of the asset tracking process.

What Are QR Codes

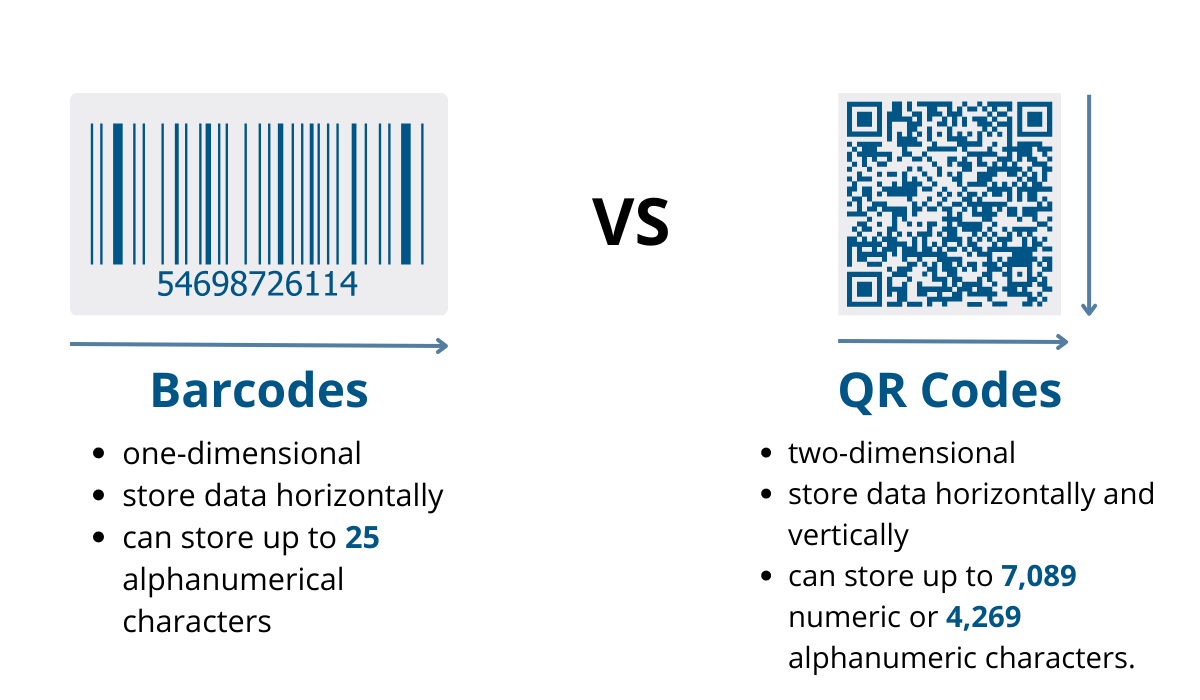

The more barcodes became widespread, however, the more their limitations became apparent. They just couldn’t hold larger amounts of data, only up to roughly 25 alphanumeric characters.

So naturally, it was only a matter of time before a more advanced solution appeared.

This finally happened in 1994 when a team led by Masahiro Hara developed Quick Response (QR) codes for the Japanese company Denso Wave.

Interestingly enough, the company never exercised its pattern and released the QR code system for free.

Similarly to barcodes, QR code asset labels store data that’s readable by scanners, although nowadays, most people use their own smartphones to scan them.

In fact, this is precisely what contributed to their widespread use in the first place. With the rise in the popularity of smartphones, QR codes have become more commonplace, too.

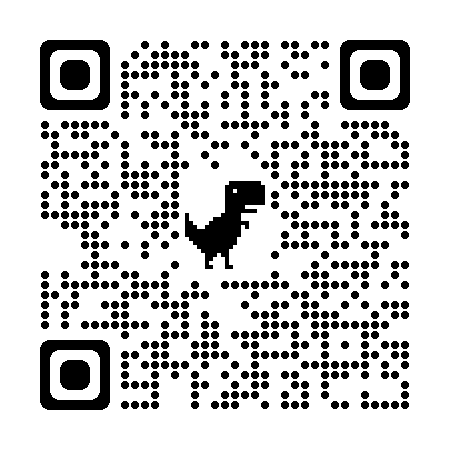

These now widely recognizable black-and-white squares can contain many different types of data: website URLs, email addresses, text, media—you name it.

Thanks to that kind of flexibility, we see them used in so many different and creative ways.

For example, if you scan the QR code below, it’ll lead you to our article about the benefits of effective asset tracking.

All in all, the versatility of QR codes is undeniable.

From retail, restaurants, and bars, to museums, libraries, and parks—QR codes are virtually everywhere, so it really comes as no surprise they found their way into asset tracking as well.

Barcodes vs. QR Codes: Key Differences

Despite a great proliferation of new technologies on the market, both barcodes and QR codes are still popular choices for asset tracking.

But what’s the difference between the two anyway?

Besides the most obvious one— their appearance—there’s a great deal of them, in fact.

The main difference is in the way they store information. Barcodes store the data in one dimension, in the horizontal direction.

Meanwhile, QR codes can store information horizontally and vertically, i.e., in two dimensions.

So what exactly does that mean?

It means that QR codes are able to store significantly larger amounts of data. We’re talking hundreds upon hundreds of characters more than barcodes.

QR codes are also much more easily readable because, unlike barcodes that have to be in line with the scanner, they can be read from any angle.

This might not seem like a big deal at first glance, but when you have many assets to scan, this becomes a huge life-saver.

Plus, QR codes can be up to 10 times smaller than barcodes, and you’d still be able to read them.

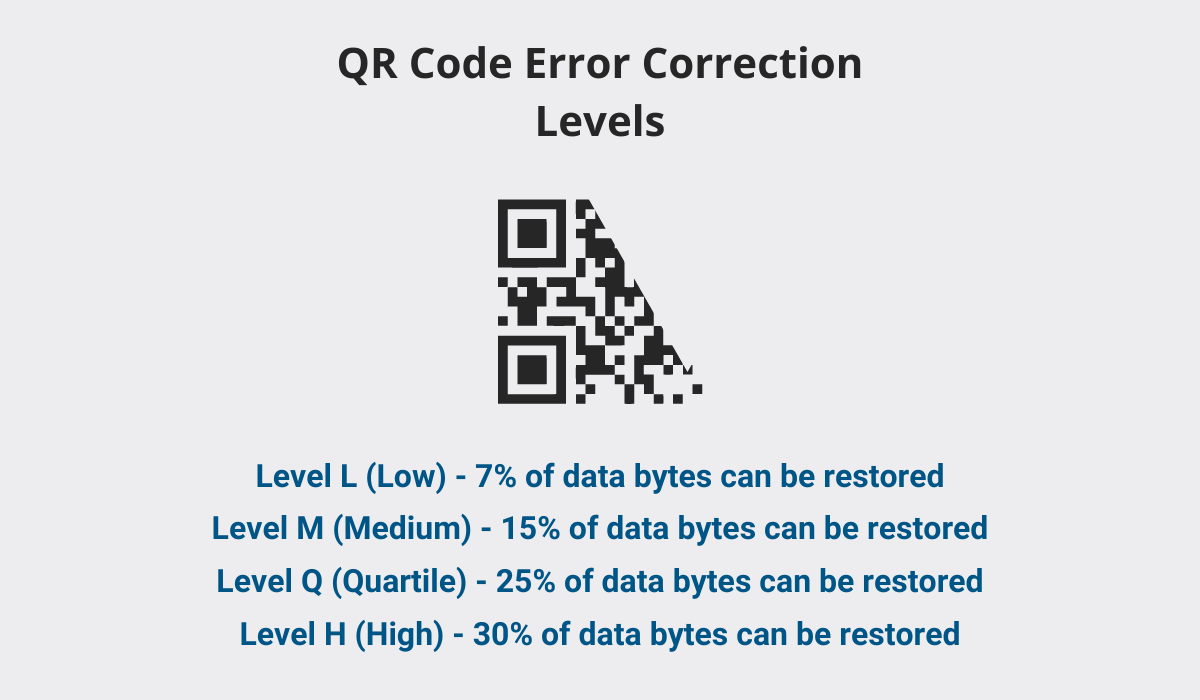

Another attribute of QR codes worth mentioning is the fact that they work even when damaged, dirty, or printed poorly.

They can sustain anywhere from 7% to 30% damage, depending on their error correction level, and still be scannable.

So finally, we arrive at the most important question. Which is better —barcodes or QR codes—and which should you use for asset tracking?

Barcode or QR Code Tracking: Which Is Better

Taking what was just said in the previous section, it’d be easy to conclude that QR codes are a far superior asset tracking solution.

But is that really always the case?

The answer might not be as clear-cut as it may initially seem.

It all depends on your own circumstances. If you’re already using the barcode system and it’s working great for you, there’s no need to make the switch to QR codes now.

In fact, making that change might even be too expensive, time-consuming, and labor-intensive for it to be worth the hassle.

Moreover, the choice of asset tracking solution also somewhat depends on the type of assets you want to track.

Take, for instance, cables. QR codes are really hard to read on thin and round objects, so in this case, it would be better to use barcodes.

That being said, QR codes win over barcodes on several fronts.

First, they can contain so much more data while being able to fit on almost any asset, which is important for asset tracking in the construction industry, where asset management is becoming increasingly sophisticated and complex.

What’s more, construction sites are notoriously hectic and dirty, with heavy machinery working nonstop and everyone always on the move.

That’s why for construction professionals, a more durable solution is necessary. QR codes are exactly that.

Conclusion

So which is better—barcodes or QR codes?

Ultimately, that’s up to you.

If you’re already using a barcode asset tracking system and don’t really see the need for change because it fits all your needs, there’s nothing wrong with that. Keep using it.

However, there’s no denying the effectiveness of QR codes. More data storage space, more durability, more versatility—they have it all.

So, take what you’ve learned from this article and use it as a starting line for your research. Whatever you decide, it’ll undoubtedly take your asset management to whole new heights.