For construction companies, finding the right asset tracking solution can be a massive step toward improving productivity.

Not only does it save the time and effort required to record equipment data, but it can also transform said data into valuable insight companies can use to further refine their processes.

However, every business is different, in terms of equipment type, volume, and work practices, among other things.

To help you find an asset tracking system that best suits your unique situation, this article will present seven common tracking types, explain how they function and give you the most prominent benefits and drawbacks of using each one.

To start, let’s explore QR codes.

In this article...

QR (Quick Response) Codes

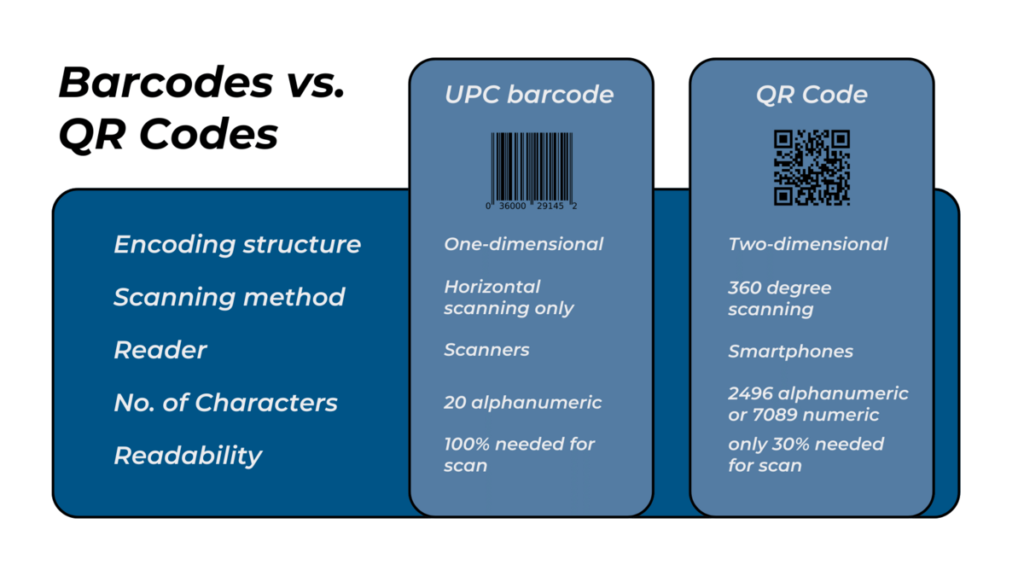

QR codes are a more advanced version of barcodes, and they first appeared in the Japanese automotive industry in the 1990s.

They’ve gained popularity in the recent decade with the widespread adoption of smartphones, which allowed QR codes to be used to display text, open websites, connect to a network, as well as a variety of other applications.

They offer improvements upon barcodes in almost every regard, making them an affordable and efficient tracking method for construction companies with lots of tools and equipment.

While offering more storage and enhanced functionality, their application in asset tracking is pretty much the same.

For a start, QR code tags are attached to assets. Scanning them with a smartphone reveals pertinent information about the asset, such as manufacturer data, maintenance history and schedule, users, etc.

From the mobile app, you can perform various actions, such as creating equipment maintenance tickets, uploading photographs, or performing audits.

The changes are instantly reflected in the cloud-based central database, which can be accessed anytime from any device.

As seen on the desktop screen in the image above, GoCodes Asset Tracking’ tracking system also has a GPS function that updates the location of an asset with every scan.

In case a piece of equipment goes missing somewhere on the site, pinpointing its last known location and users can be of great help in retrieving it.

For construction companies, it is crucial that tags remain attached and readable in rough conditions.

Consequently, GoCodes Asset Tracking offers durable, water-resistant QR code tags with extra strong adhesive, made from polyester or aluminum metal foil.

Their compact size and simple application make them a popular choice for tracking tools and inventory.

For heavy equipment, there is also the option of rugged aluminum metal tags up to 63mm thick, with optional screw holes for extra strong attachment.

Overall, using QR codes for tracking assets is an affordable, easy-to-use solution that can be applied to construction equipment of all shapes and sizes.

GPS (Global Positioning System)

One drawback of QR codes is they don’t support real-time GPS asset tracking.

In the modern era, GPS technology has become almost synonymous with navigation and location tracking.

This is primarily because of its widespread use in car navigation systems and, more recently, smartphones.

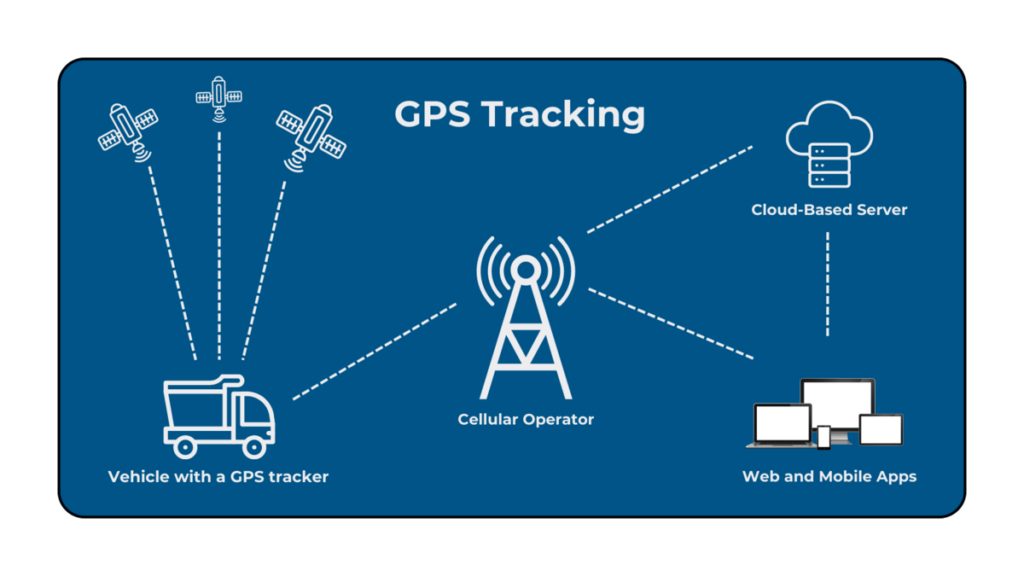

GPS devices can calculate their exact location based on distances from at least three satellites by a process known as triangulation.

The same technology is present in GPS trackers. The location data is then sent through a cellular network to the software, where it is continuously updated for users to follow.

It is the only tracking system allowing you to track assets in real time across the globe.

Providing valuable equipment with 24/7 visibility is especially useful in theft prevention.

Many systems include sending alerts when vehicles go outside a designated area, allowing for fast response and easier asset recovery in case of theft.

Transportation is another area where GPS tracking shines, as it allows you to track vehicle-related data such as speed, fuel consumption, and travel time.

However, there are also several downsides that ultimately limit the use of GPS tracking on heavy equipment and vehicles.

Firstly, as shown in the image below, the trackers are large and heavy.

This is because they contain the hardware needed to receive, calculate and send out data, as well as a power source or a connecting cable.

And secondly, they are expensive. The technology inside a GPS tracker is much more intricate compared to a simple QR code, not to mention the hardware and casing that go with it.

In addition, you have to pay for ongoing GPS service.

All in all, GPS asset tracking systems provide construction companies with unique capabilities such as real-time location tracking and telematics.

Although extremely useful for heavy equipment and vehicles, their size, energy requirements, and price point make them an inefficient choice for smaller and non-powered assets.

BLE (Bluetooth Low Energy)

Recently, there appeared a new asset tracking method that is finding more and more use in construction, and that’s BLE.

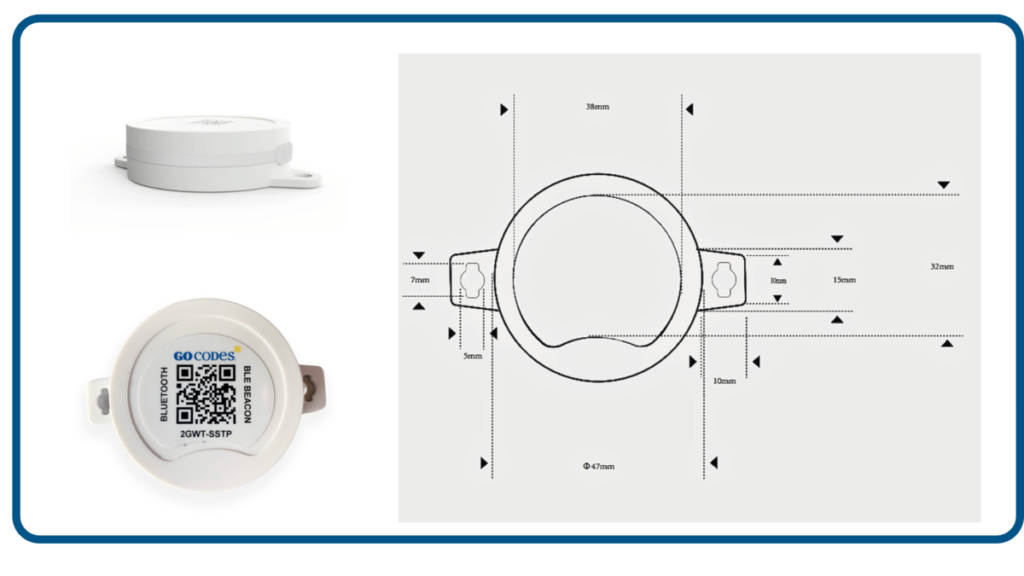

BLE beacons combine some benefits of QR code tags and GPS trackers to provide a low-energy, compact-size solution for precise location tracking and asset management.

The system uses radio waves traveling through the standard 2.4 GHz frequency used by Bluetooth devices and wireless networks.

The signal can be picked up by any BT-enabled device, such as smartphones and specialized readers, in a range of up to 300 feet.

GoCodes Asset Tracking’s BLE beacons continually broadcast asset data such as identity, distance from the device, and environmental information.

Their advantages over QR-code-based tracking include scanning multiple objects at once, greater range, and the possibility of location tracing.

In other words, you don’t need to go around the site or warehouse to scan every individual asset.

Instead, GoCodes Asset Tracking’ BLE tracking allows you to view the precise location of all assets in the vicinity of a reader.

This way, you can save a lot of time and resources in audits, inventory control, and pinpointing the location of hidden or misplaced equipment.

They are also more suitable for short-range location tracking compared to GPS trackers.

The latter have high energy requirements, which is why they usually need an external power source to function.

On the other hand, BLE beacons use low-power technology—hence the name—and batteries that last for months, or even years before needing replacements.

Furthermore, they are much more affordable, making them a viable option for a greater variety of equipment.

Finally, GoCodes Asset Tracking’ BLE tracking system comes with the Guardian feature.

It can be set to send out alerts if a tracker is removed from an asset in the vicinity of the Guardian mobile app, helping with on-site theft prevention.

Ultimately, the compact proportions of BLE beacons, their location tracking capabilities, and relatively low price make them a practical option for indoor tracking of heavy equipment and specialty tools.

RFID (Radio-Frequency Identification)

Just like BLE, RFID technology uses radio waves for communication. However, there are also some differences between the two tracking methods.

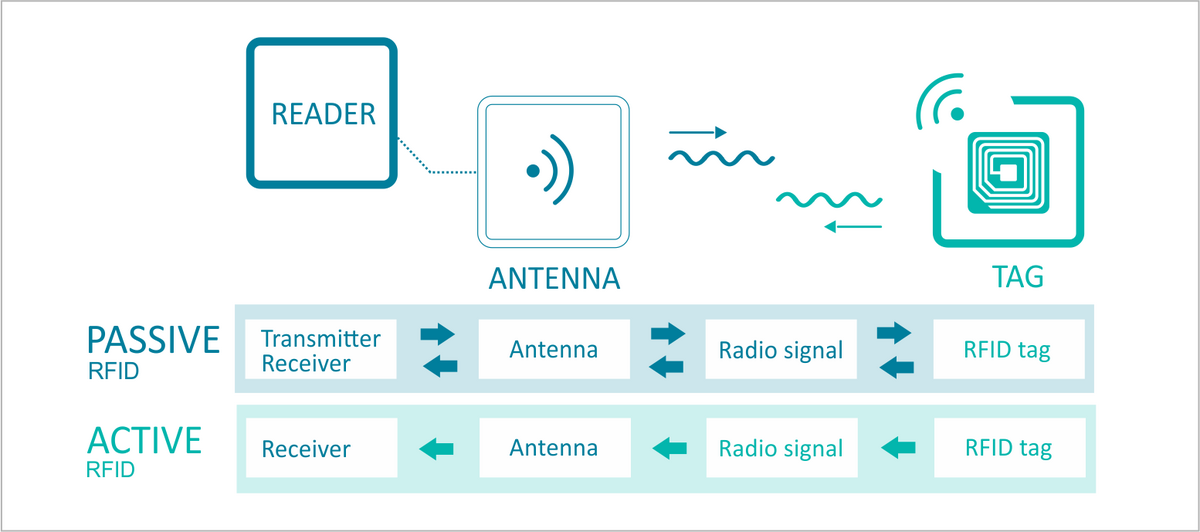

In this case, the system is comprised of RFID tags and RFID readers.

Passive tags don’t have their own power source. Instead, they are activated by a small electrical charge contained in a signal sent out by the reader.

The activation prompts a returning signal carrying the asset data.

As their name suggests, active tags have their own power source, usually batteries, and can send signals in intervals over much greater distances, up to several hundred feet.

Passive RFID tags offer some advantages over those with QR codes, like scanning out of the line of sight, reading multiple tags at once, and providing real-time data.

Active tags share the same benefits, but somewhat pale in comparison to BLE beacons.

When it comes to this technology, the main drawback is its higher price. According to RFID Journal:

active tags are $25 and up. Active tags with special protective housing, extra-long battery life or sensors can run $100 or more. A passive 96-bit EPC inlay (chip and antenna mounted on a substrate) costs from 7 to 15 U.S. cents. If the tag is embedded in a thermal transfer label on which companies can print a bar code, the price rises to 15 cents and up.

The same source estimated the price range for an average RFID reader to be between $500 and $2000.

With the amount of assets and workers construction companies usually have, these costs quickly add up to tens of thousands of dollars.

Additionally, RFID technology can suffer from interference issues. This includes interference from other radio signals, as well as physical barriers such as walls.

In summary, RFID tracking comes in two forms.

Passive tags are small and relatively inexpensive, providing expanded functionality compared to QR codes, and active tags are similar in size and function to BLE trackers, but come at a greater price.

NFC (Near-Field Communication)

NFC was created in 2002 as a subset of RFID technology. Today it is mainly known for its wide utilization in smartphones, specifically for contactless payments.

It is not commonly used for asset tracking, but still presents a viable option to explore.

Similarly to passive RFID tags, NFC labels are not powered. Instead, they are charged by the activating signal from the reading device.

However, the greatest distance they support is only around 4 inches. In addition, they can only read tags one at a time.

This makes them more secure, but also less effective for asset tracking.

However, NFC also has some features not present in RFID tracking systems. For example, NFC supports two-way communication, meaning you can both read and write information on the tags.

Furthermore, while RFID usually contains only identifying data, NFC tags can store up to 4KB of complex information, like URLs, text, and media.

And lastly, as most smartphones on the market come equipped with NFC technology, you don’t have to spend money on expensive readers.

That is one of the reasons German construction equipment manufacturer Hilti uses NFT as one of their primary tracking technologies.

As Jussi Silfver, Product Owner for Hilti Connect, says:

Moreover, smartphones can use their own GPS technology to report the location of the scan, allowing for limited location tracking.

Another rarely used technology, but for another set of reasons, is UWB. We go over it in the next section.

UWB (Ultra-Wideband)

UWB technology was developed as a low-energy solution to transmit large amounts of data over a short distance.

In terms of asset tracking, this means it can be used to track real-time location and any amount of other data in indoor or limited spaces.

It works somewhat differently from the other tracking methods discussed in this article.

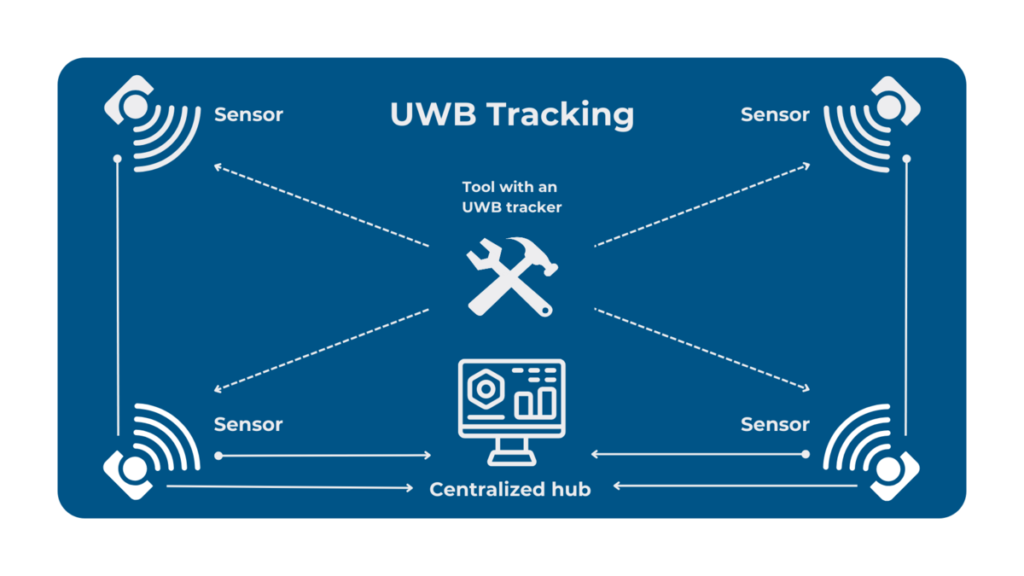

Three or more UWB receivers need to be placed on the periphery of the area you are overseeing.

These receivers interpret short-pulse RF transmissions from the tags and send data back to the centralized processing hub, which also supplies them with power.

Regarding the benefits of UWB technology, it is the only tracking method offering real-time 3D tracking, which requires a minimum of 4 receivers at different height levels.

It is also suitable for both indoor and outdoor tracking.

This is due to its short waveforms being much less susceptible to interference compared to RFID, and its low frequency allowing the signal to pass through walls and other obstacles.

The limitations of the system lie in its ultra-wide spectrum, which can interfere with and receive interference from other nearby systems, such as digital TVs, aircraft navigation, and radio equipment.

This can be avoided by carefully calibrating the receivers. However, the need for calibration can be seen as another drawback of the system.

UWB receivers need signal acquisition, synchronization, and tracking, all of which need to be done with very high precision.

Depending on the time your construction company spends on a site, this process can consume too much time and energy to be worthwhile.

IoT (Internet of Things)

The Internet of Things is a still-developing technology with considerable implications for the future of the construction industry.

Just like the internet itself, the IoT functions as an interconnected web.

Only, instead of websites, it is made up of tags and sensors which capture various data and automatically communicate it to the software through a wireless network.

The underlying technology of IoT has a familiar ring to it. However, the expanded capabilities make it a system well worth developing.

By utilizing asset tags in conjunction with sensors, the Internet of Things provides comprehensive tracking capabilities.

Firstly, it uses existing asset tracking systems such as QR code tags or Bluetooth beacons. However, IoT GPS trackers can also be used to track the real-time location of heavy equipment.

Furthermore, it includes video equipment that can be utilized for more robust on-site surveillance.

Secondly, sensor-driven data gives construction companies unparalleled insight into their assets’ performances.

Other than the already mentioned metrics, such as telematics, sensors can be used to track excessive vibrations and temperatures in machinery.

This way, you can catch symptoms of machine failures and send equipment to maintenance in time to prevent them.

Ultimately, the Internet of Things is a technology with significant potential for asset tracking.

It’s currently in development, which is why it is still rarely used today, but it’s something to keep an eye on in the coming years.

Conclusion

Congratulations, you’ve managed to reach the end. Hopefully, you did so knowing more about asset tracking methods than you came in with.

Of course, this is just one necessary step in researching the best asset tracking software for your construction business.

For now, take what you’ve learned and try to narrow down your choices based on what your company owns or needs.

This will determine the next step you need to take, eventually leading you to the optimal tracking solution for your tools and equipment.