Asset monitoring has come a long way in the past couple of decades.

As a result, construction companies that take advantage of new technologies stand out from competitors who rely on outdated monitoring techniques.

Nonetheless, choosing the right asset monitoring technology is not an easy task. Therefore, before you make a decision, it would be wise to explore the landscape first.

At the very outset, you should focus on reviewing your company’s current needs, as well as the number, and the value of your assets, as that will determine what sort of features you’ll require from your tech stack.

Then, take a moment to learn more about the different technologies used to monitor assets, and assess their pros and cons.

This article will provide an overview of the six most widely used technologies for asset monitoring, outlining some of their benefits and limitations and explaining how you can best match them to your needs.

In this article...

QR (Quick Response) Codes

Let’s start with QR codes, square-shaped black-and-white digital markings that store information, allowing people to access different types of content by scanning them with their smartphones.

QR codes allow fast information retrieval without special scanning equipment, which makes them a practical and easy-to-use tool.

Even though the construction industry has only recently adopted QR codes, their potential on outdoor worksites is vast and growing rapidly.

One of the most effective applications of QR codes is in tracking a company’s assets.

They enable managers and workers to instantly share and access important information and track and manage construction materials, tools, equipment, and inventory.

By attaching QR code labels and tags to assets, workers can easily scan them to quickly access relevant information about the item that interests them, including the asset’s location, availability, manufacturer data, maintenance history, etc.

The supporting software allows workers to view and update asset information and, most importantly, check the assets in and out.

Checking out equipment makes a record of which employee has taken a tool or a piece of equipment, and when he or she is expected to return it, helping to reduce the risk of lost or misplaced items significantly.

The information collected at check-out also provides a valuable source for tracking equipment utilization by project, thus facilitating asset life cycle management and planning.

By scanning the QR code through the mobile app, workers can also access the asset’s maintenance history, schedule maintenance, or request a field service if equipment or machinery malfunctions.

The asset tracking software solution provided by GoCodes Asset Tracking also includes a feature that allows workers and other employees to assign work orders and perform audits.

With every scan and input, changes are directly uploaded to a cloud-based database, which any authorized employee can access at any time.

QR codes can be a cost-effective way to manage construction companies’ assets, significantly improving workflow and efficiency.

They are simple but mighty tools that make asset monitoring and sharing information between the office and the worksite seamless.

However, there might be better solutions than QR code technology if real-time asset tracking is a must for you.

Additionally, since QR codes require manual scanning, they may be less efficient for large-scale asset monitoring.

Nevertheless, this technology has the potential to make it easier to handle everyday tasks and help you avoid misplacement of tools and equipment, while also making bulky paper documentation a thing of the past.

GPS (Global Positioning System)

GPS is a technology widely used as a navigation system for vehicles.

This US military technology, which became publicly available in 1983, is used to pinpoint the exact location of a moving object anywhere on the planet.

But its use doesn’t end there, on your car’s dashboard.

GPS has surfaced as a valuable tool for tracking and managing expensive construction machinery, from mobile cranes and heavy trucks to service vehicles, generators, and compressors.

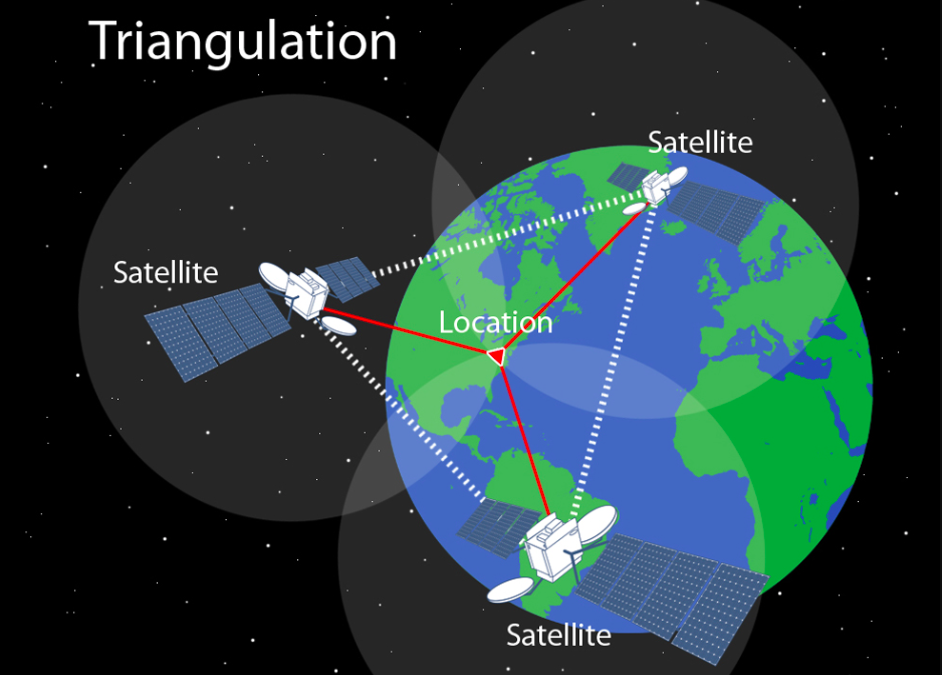

The GPS tracking system includes satellites, ground stations, and receivers.

The receiver—a phone, car navigation, or a GPS tracker installed on a vehicle—confirms the exact location using the signal from at least three satellites.

This process is called triangulation.

This enables GPS to achieve a high level of precision of about 16 feet in radius.

The tracking device is usually easily installed and connected to the equipment’s power source.

It’s pretty rugged and can withstand rough working conditions and extreme temperatures.

A leading advantage of GPS tracking is the power to communicate across distances and provide real-time monitoring of your movable assets.

This technology is particularly advantageous if your construction operations are dispersed in many locations, coast-to-coast or internationally.

An asset monitoring software based on GPS will also allow you to track other vital metrics, such as driving routes, fuel consumption, detours, speed, and transportation time.

However, one drawback of GPS worth noting is its susceptibility to obstructions.

High buildings and mountains, atmospheric conditions, indoor or underground use, or radio interference can hamper signal strength and reduce GPS precision.

Additionally, GPS trackers are relatively large and unfitting for smaller items, like tools or hand drills. In this case, QR code tags will do the job.

Nonetheless, GPS has revolutionized modern-day asset-tracking methods and is still the only technology that can track your assets globally.

BLE (Bluetooth Low Energy)

Bluetooth is a secure and simple wireless technology built to communicate and exchange data over short distances.

Bluetooth Low Energy is an energy-efficient version of Bluetooth that provides accurate real-time information to users and is suitable for devices that need to run for extended periods of time.

Although BLE has lower data capacity than the standard Bluetooth technology, its low power consumption provides a longer battery life.

Additionally, a Bluetooth beacon is a battery-powered small radio transmitter that emits signals within a given range using Bluetooth technology.

These radio signals are detected by a mobile device—usually a smartphone—that can determine their proximity.

This feature enables BLE beacons to facilitate location-based tracking of assets, even if they’re hidden from view.

Bluetooth beacons come in many shapes.

Here’s an illustration:

Most industries, including construction, frequently use Bluetooth beacons and tags to identify, track, and manage valuable assets.

They are flexible, reliable, and small enough to attach to tools and other equipment easily.

A nearby BLE-enabled device can detect their signal, allowing companies to locate their assets on-site in real time but also maintain an accurate inventory.

In addition, companies can also use Bluetooth beacons to monitor equipment utilization rate—how often and how long a piece has been in use—thus helping management to schedule regular servicing or replacement.

Moreover, BLE beacons are durable, meaning you can transfer them from one piece of equipment to another or between construction sites. In other words, a company can use them over many years.

On the downside, BLE has a limited range of 100-300 feet, which makes it unsuitable for tracking movable assets, such as construction machinery or truck fleets.

Also, if the beacon is blocked by metal, water, or the human body, its signal will be lost unless positioned on a higher spot.

Despite its limitations, BLE technology brings a variety of benefits to asset monitoring, one being the opportunity to gather vital information about a company’s assets.

It also helps reduce worksite theft or loss of equipment and tools and allows for proactive and timely maintenance.

RFID (Radio-Frequency Identification)

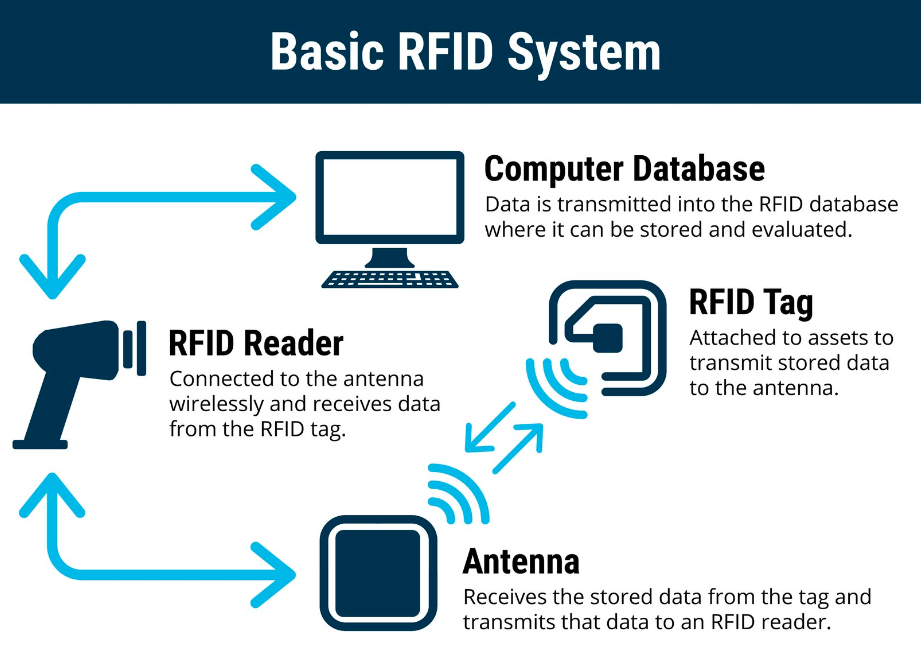

RFID is a wireless, contactless communication technology that uses radio waves to locate and identify objects through asset tagging.

It contains an antenna, a handheld reader, and a tag. The reader receives signals from the RFID tags attached to assets and converts them into digital data on a computer database.

The construction industry utilizes RFID technology in various ways. Initially, its purpose was to monitor thousands of high-value assets their employees use at construction sites.

By using this technology, companies can keep track of their assets’ location at all times, thereby avoiding purchasing new or renting replacements for equipment that cannot be found.

In other words, RFID provides improved inventory accuracy and reliable monitoring of tools and equipment.

In practice, RFID tags are placed on each tool and linked to a digital inventory of tools and their locations.

An employee who needs a tool at a specific worksite can check it out by scanning the RFID tag.

Once the tool is returned to the warehouse, the employee will scan the tag again, indicating it is no longer used.

This kind of system prevents theft and loss of tools and equipment by ensuring that all of them are accounted for, no matter the location.

One of the most significant advantages of RFID monitoring technology is that hundreds of tags can be read within seconds simultaneously, verifying the on-site presence of tools.

Also, the RFID reader does not require a direct line-of-sight, allowing tags to be read from a distance and in different environments, including when tags are on assets covered in mud, dust, or snow.

Lastly, RFID tags can be rewritten and reused and can hold more data than other types of tags or labels, including manufacturer, maintenance logs, inspection date, location, and usage.

However, the system has a major shortfall, and that is the pricing. According to RFID Journal, an estimated price range for an average RFID reader is between $500 and $2,000.

Additionally, RFID technology can encounter interference problems from other radio signals or physical barriers such as walls.

NFC (Near-Field Communication)

NFC is a subset of RFID technology that allows contactless data transfer using tags or cards that store data.

A prerequisite for the data transfer to function is that both devices are equipped with NFC tags and are within a close range.

Unlike RFID, which can operate from a distance, the maximum separation between devices for NFC to work is around 4 inches.

This makes NFC less effective for asset monitoring and tracking.

The way to access the information that is carried by the NFC tag is to read it with a mobile device placed in the vicinity of the tag.

The good thing is that an internet connection is not necessary for the system to work.

NFC tags have the potential to track materials, equipment, construction site activities, and deliveries.

Each time an employee interacts with an item by scanning or tapping the associated NFC tag, this information is digitally stored and can be traced whenever needed.

This way, using NFC tags significantly simplifies the sharing of essential information on worksites, making the construction process more efficient and cost-effective.

This technology helps save money, time, and resources, ensuring at the same time that everyone involved in a project has access to accurate, up-to-date information.

However, compared to RFID, which allows for the simultaneous scanning of hundreds of items, NFC works on the principle of “one tag at a time”.

Nonetheless, NFC can have diverse implementations on a construction site – from monitoring tools and equipment to ensure they have been properly handled to placing tags at key points around the worksite to share critical information among crew members.

Additionally, most modern-day smartphones are fitted with NFC reading capabilities, significantly reducing the cost of implementing NFC tags.

NFC tags have a lot more potential use in the construction industry. As the technology evolves, NFC will likely find a more comprehensive application.

UWB (Ultra-Wideband)

Ultra-Wideband Internet is a newcomer in the company of tested and proven asset monitoring technologies.

It is a wireless communication technology capable of transferring large amounts of data over a relatively short distance.

With its ability to spread radio energy over a very wide frequency band, UWB tracking technology can achieve notable location accuracy.

UWB tags are typically battery-powered; however, thanks to their low power requirements, their batteries can last for years.

An outstanding feature of UWB is its ability to perform with remarkable accuracy in the most demanding environments and its suitability for indoor and outdoor tracking.

Another aspect of UWB communications systems is their inherent capacity to remain undetected and resilient to interception, which makes it a highly secure tool with a broad future application.

Regarding its application in construction, Ultra-Wideband has an enormous utilization potential, mainly for its capacity to transfer significant volumes of data with lightning speed.

It is the only asset monitoring method that can offer real-time 3D tracking. That, however, would require no less than four receivers, situated at different heights.

With all these advantages and many possibilities for utilization, it is likely that UWB will very soon find its place in the construction sphere.

Conclusion

The benefits of using new technologies in construction become quickly evident, and the asset monitoring process is rapidly evolving.

By now, you probably already know which particular technology, or a set of technologies, will best suit your company’s needs.

In any case, keep in mind that this is an important step you have to make. So, take things slow but in the right direction.

The use of technology in the construction sector shows no signs of slowing down.

That’s why it’s crucial to keep up the pace, so that you can be there when the time comes to reap the benefits.