Supply chain issues are traditionally a challenge for construction products, but the perfect storm of the COVID-19 pandemic, rising inflation, and a universal labor shortage have conspired to create a logistics network nightmare.

Project managers and suppliers alike are scrambling to fill backorders and complete delayed projects.

Sometimes, meeting these demands might seem hopeless, but construction professionals can apply several strategies to soften the blow of the worldwide supply chain crisis.

Early planning can help, as long as time is invested in building strong relationships with suppliers.

Project managers can pre-order supplies as much as possible while also trying to work with alternative materials.

Finally, re-configuring project schedules will help manage client expectations and allow your team time to find what it needs to do the job right.

In this article...

Plan the Project Scope Early Enough

Unless your team is pitching in to address some sort of emergency, construction projects rarely appear with great suddenness.

The RFP process, negotiation period, and third-party contracting procedures all require time to develop, and most clients understand this, as long as they are informed of the time frame reasonably early.

However, when the supply chain is unpredictable, careful planning becomes especially important.

In the new supply chain reality, even construction professionals with decades of experience find themselves having to re-learn how to estimate project milestones.

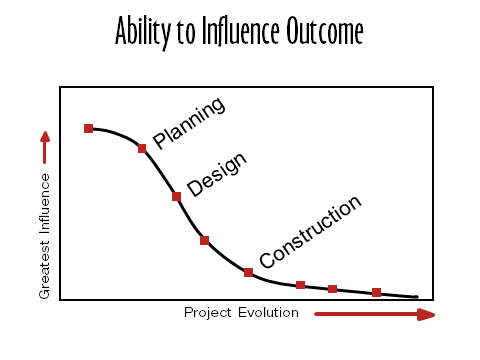

If you look at the graph below, you’ll see how early planning affects a project manager’s ability to influence the outcome of a project.

As you can see, “Planning” appears early in the process, as a critical point in the project.

By devoting time and resources to sensible early planning, your company might secure better prices and smoothly navigate supply chain challenges to ensure project success.

Build Good Relationships With Your Suppliers

In these unusual economic and post-crisis circumstances, suppliers and raw material providers wield a great deal of power in the construction industry.

Nurturing a healthy relationship with multiple suppliers benefits not only you, but your client and your employees as well.

Those performing the on-site work, after all, can only offer their best efforts when they are provided with the tools and materials they need.

A chaotic construction site with missing materials and overshot deadlines can produce distrust and increasingly low morale.

A major aspect of avoiding these potentially toxic environments is to remember that suppliers are struggling to meet their needs as well.

They are also negatively affected by government-mandated COVID protocols and a worldwide battle for affordable and reliable air transport.

Therefore, taking personal offense to delayed order fulfillments, or putting the blame for missed milestones on your suppliers helps no one and can even exacerbate your supply chain problems.

Project managers need lasting partnerships with construction businesses in order to keep deliveries arriving on time.

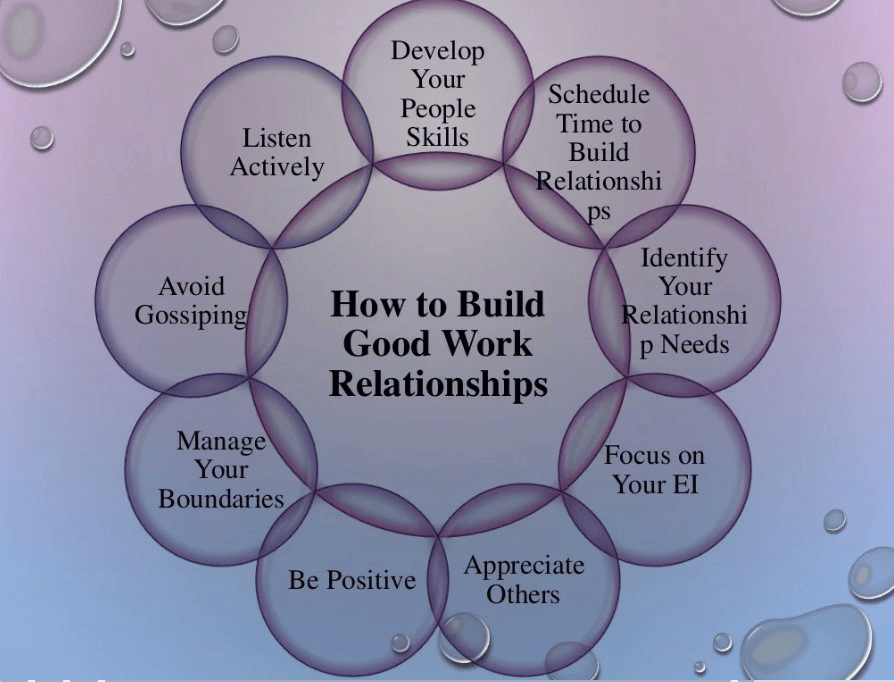

Focusing on “building good relationships” sounds easy enough, but in reality this is a multifaceted and long-term process that involves constant attention and upkeep.

Here are just a few aspects of industrial relationship-building, from paying attention to emotional intelligence to focusing on active listening:

Honest and early communication with suppliers bolsters these relationships.

It is also advisable to respond with flexibility and understanding as much as possible when circumstances outside the supplier’s control delay shipments.

Berating employees or publicly denouncing suppliers who cannot meet the needs of your project will not help you meet the next milestone.

In fact, burning bridges can only make matters worse.

In contrast, expressing appreciation for any extra assistance and last-minute accommodations will make the supplier feel appreciated, which will entice them to make a priority of your business in the future.

Pre-Order Supplies

One way to undertake effective project scope planning is to estimate demand as accurately as possible. Planning software and 3D modeling help speed this process along.

Moreover, encouraging clients to form decisions that balance their completion goals with supply chain realities benefits all parties.

Submitting precise quantity demands, complete with SKU numbers and plenty of lead time, can lead to better prices and more reliable delivery dates.

Letting your suppliers know exactly what you need and when you need it makes it easier for them to meet your needs.

Contributing to your suppliers’ headaches, such as causing them to store unneeded inventory or backtrack on an order, will not strengthen your relationship or induce the company to readily work with yours in the future.

Locking in rates and providing enough time for custom fabrication or overseas orders helps the client, design team members, and your supplier to adjust plans as needed.

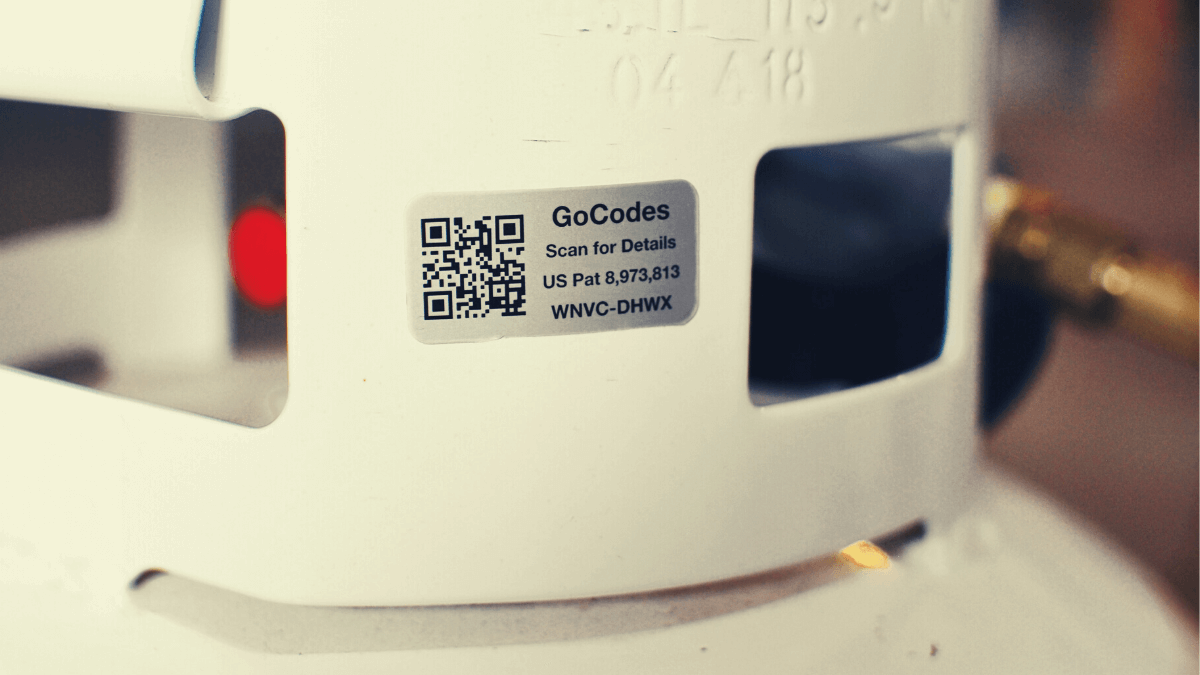

One way to help estimate supplies and inventory currently on hand is to rely on asset tracking.

Established and flexible systems such as GoCodes Asset Tracking can automatically track consumable quantities, provide customized reports, and even prompt re-orders when stock levels run below predetermined levels.

The advantages provided by this system can give your company the edge it needs in procuring the materials to complete your project on time.

Below is an example of the kind of information GoCodes Asset Tracking can provide instantly to any employee with authorization, regardless of whether your headquarters are open, adequately staffed, or even in the same time zone.

Making this sort of data available to a technician in the field, architect, or supply chain manager saves valuable time when attempting to assess stock or equipment levels:

Where delays are unacceptable, such as, for instance, when you’re meeting municipal contracts, consider buying hard in order to avoid having your work crews stand idle and the entire project grind to a halt.

While not an ideal solution, pre-purchasing materials and paying to store and secure them can forestall supply chain frustrations.

However, this tactic can easily backfire, so be sure to properly assess the cost of storage and security or shelf life of construction materials, and avoid hoarding, which would further congest your industry’s supply chain.

Try to Find Alternative Materials

While turning to custom or high-grade recycled materials might initially raise costs, sustainable options might save your clients money over time, especially when compared to conventional products.

In addition, becoming “certified green” might qualify the project for grants, exemptions, or tax credits.

In some cases, tear-downs or remodeling projects can serve as a source of usable materials. Some municipalities have even banned demolition to encourage careful deconstruction.

Turning to previously used materials might actually contribute to lower material costs while speeding up construction time, not to mention saving landfill space and contributing to declogging the supply chain.

Reclaimed materials might require specific cleansing standards, however, so it’s best to check with local authorities on rules regarding recycling.

Finding alternative materials can provide an exciting challenge for designers and material scientists.

Considering new ways to take on long-established building techniques can result in lower prices and more efficient buildings.

Here, for example, are a few items commonly used for insulation that you can source in this way instead of backordering:

Communicating with designers and clients about alternatives also helps address supply chain stresses.

For example, if a client has requested a common material that is in short supply, but still insists on a tight timeline, offer the alternative of a different product that might cost more but arrive much sooner.

Allowing the client to investigate and weigh these alternatives can help to increase a sense of agency while lessening feelings of helplessness and disappointment.

Adjust Your Project Schedule

Creativity with scheduling is another way to tackle a raw materials shortage.

Adjusting the schedule or investigating options such as off-site fabrication may extend the timeline of the project in the planning stages or result in certain inefficiencies that a project manager might usually attempt to avoid, but they also might serve as acceptable alternatives to simply hoping materials might show up before the client loses patience.

Moreover, keeping in mind that the supply chain will eventually recover and remaining open to new and possibly better solutions in the meantime can even benefit your organization.

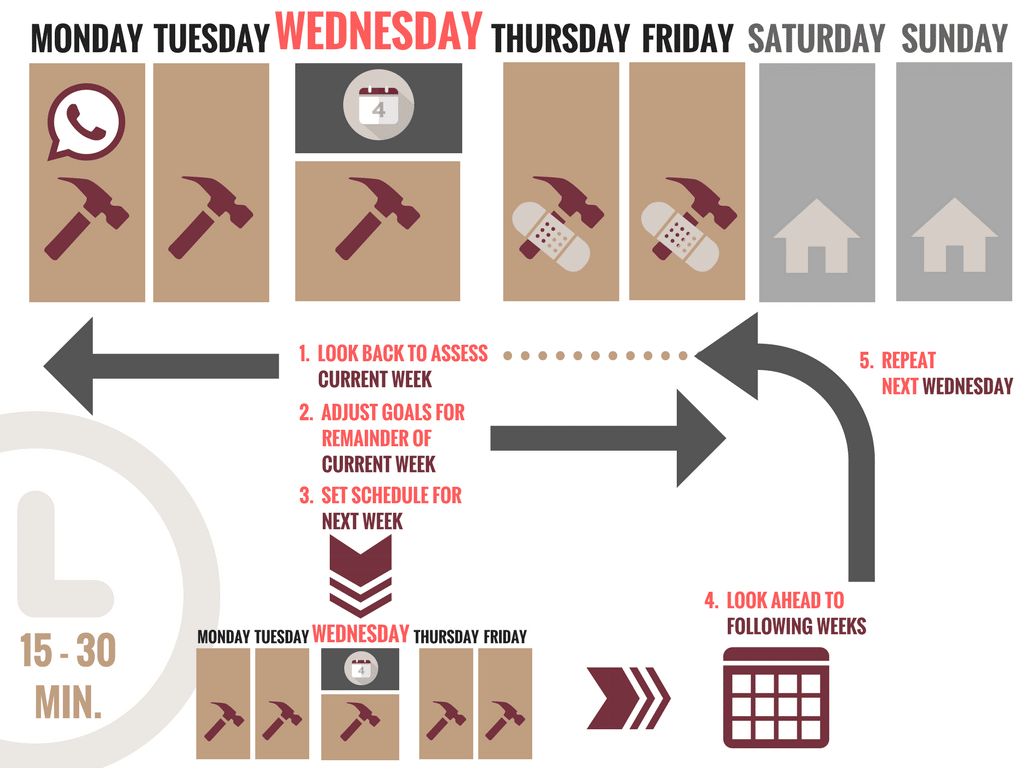

Consider using scheduling software or a “floating goals” approach to set schedules or explore time-blocking strategies that allow for changing construction order whenever possible:

In short, when other approaches are exhausted or unacceptable to the client, tweaking the project schedule is likely the best course of action.

Notifying the client of these changes as early as possible will help cushion potentially unwelcome news.

Combined with other tips from our list, such as inviting the client to consider unconventional materials or redesigned plans, these changes might even result in a project that meets the client’s needs better than the original one.

Conclusion

While every sector of the construction industry is facing struggles with the supply chain, avoiding a victim mindset can open new possibilities that might even save time or money.

Accepting that a new approach is necessary, rather than continuing to force old techniques into a world that no longer exists, will help your company remain forward-facing and better equipped to face future roadblocks.

By focusing on early planning, good relationships with suppliers, and openness to alternatives, this period of frustration might become a time of innovation and growth.