Have you ever found yourself unable to begin a project as planned because of shortages in your inventory?

If so, you are not alone.

The dynamic environment of a construction company requires good organization and even better inventory management.

It’s no secret that keeping track of all the materials and supplies at your disposal can be a daunting task, especially when your work involves covering more construction sites at once.

One small mistake could delay your project timeline, increase costs, and bring unhappy clients.

But there is a solution to these issues—inventory control systems.

In this article, we’ll introduce you to inventory control systems and explain how they can help you overcome the challenges of managing the inventory of your construction company.

We’ll start by explaining what inventory control is and how it differs from inventory management.

So, let’s dive in!

In this article...

What Is an Inventory Control System

Inventory control refers to tracking and managing the material and supplies used in construction projects and ensuring they are available when needed, without overstocking or understocking.

We’ll go into the types of systems that exist for carrying out inventory control and how they work, but first, some disambiguation is in order.

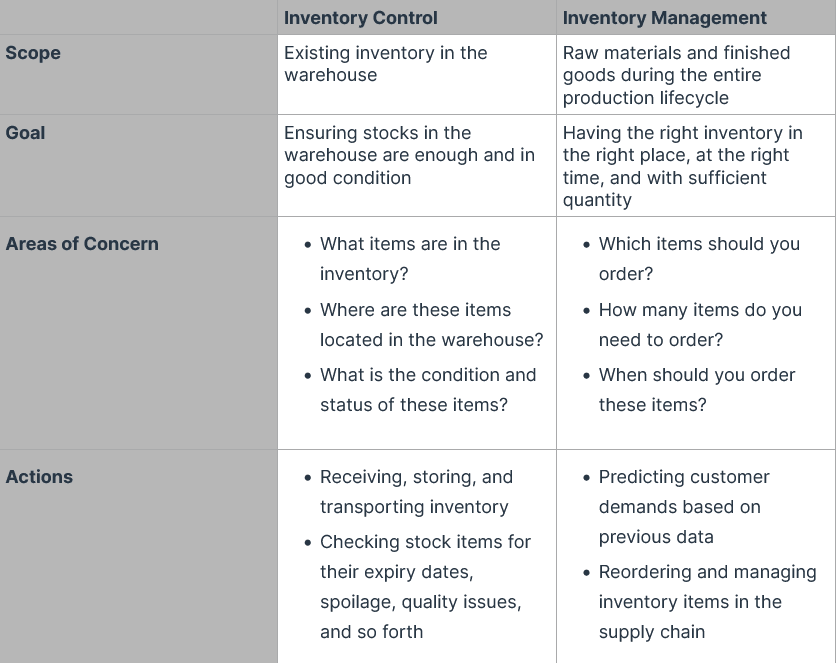

Although inventory control is often confused with inventory management, the latter is actually a broader term.

Inventory management encompasses all activities associated with managing inventory, with inventory control being a key segment of it.

It includes ordering, receiving, storing, and distributing material and supplies, managing inventory records, and predicting customer demands based on previous inventory data.

To better understand the differences between these two terms, check the table below.

To summarize the table, inventory control focuses on ensuring that your company has enough stock in storage and that those items are in good condition.

On the other hand, inventory management ensures moving a sufficient quantity of the proper inventory between the warehouse and one or more job sites you are working on.

It also deals with the reordering of materials and the movement of inventory through the supply chain.

Now that we know the difference between inventory control and management, let’s see what an inventory control system is.

In construction, inventory consists of building materials, maintenance, repair, and operations supplies.

The inventory control system monitors inventory levels of those materials and supplies in real time by automating manual processes.

It reduces waste, minimizes delays, and improves your company’s cost management.

In the next section, we will explain this more extensively.

Why Are Inventory Control Systems Important

If you work with lots of materials and supplies, inventory control systems are essential for your business to thrive.

In fact, they can be a game-changer for your organization, particularly if you’ve encountered the all-too-familiar issues highlighted at the beginning of this article.

Let’s see why inventory control systems are important and why you should implement them in your company.

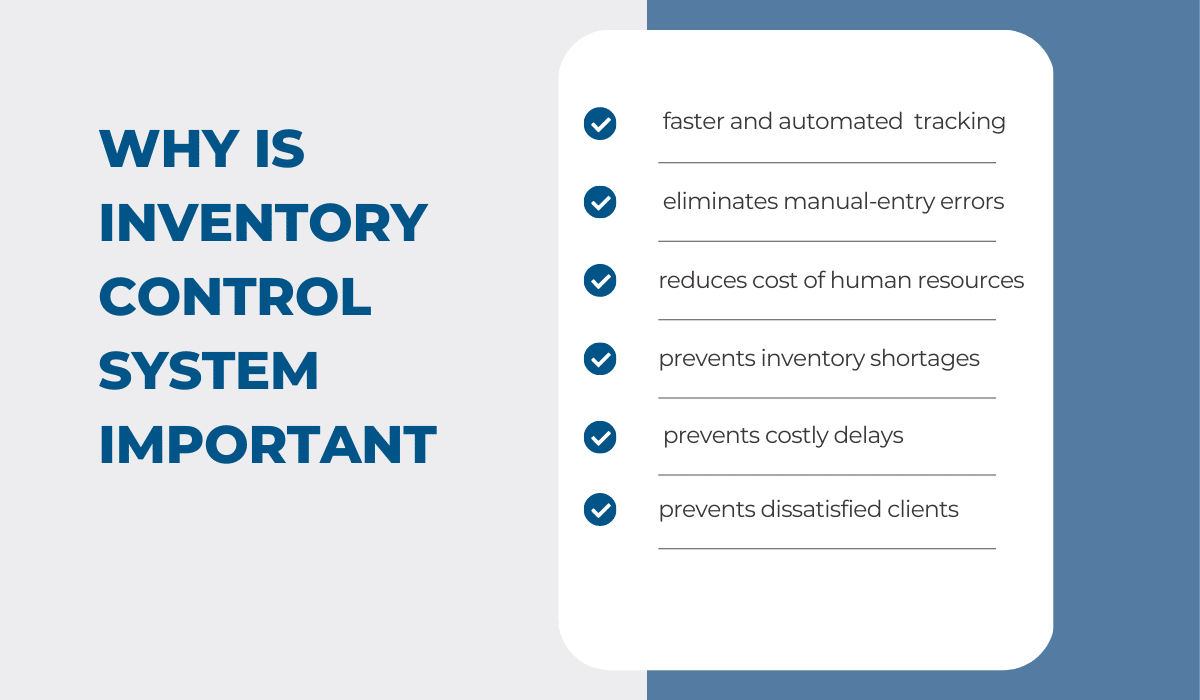

First, a sound inventory control system will help you track your inventory faster.

This is possible because a barcode is attached to every piece of the stock. When the barcodes are scanned, the system instantly updates the counts, making the process much faster.

Moreover, automatically tracking inventory with barcodes eliminates errors that could result from manual data entry.

Automating the process also reduces the need for human resources, parallelly reducing human management costs.

Furthermore, by using an inventory control system, you will always know how much inventory you have on hand and when to order new materials and supplies.

This will prevent you from running low on inventory or, conversely, being overstocked and wasting material and supplies.

As you already know, experiencing inventory shortages typically results in costly project delays and dissatisfied clients.

Our inventory management software GoCodes Asset Tracking, for example, has a feature that enables low inventory item quantity alerts.

With that, you will rest assured that no shortages will happen in your inventory, and you will have happy clients, no delays, and no additional costs.

Let’s back up these reasons with some practical examples.

For instance, the American retail corporation Walmart was one of the first adopters of barcode inventory control.

The system allowed Walmart to track its inventory in real time, reducing out-of-stock situations and overstocking of slow-moving items.

It helped the company achieve greater efficiency, reduce costs, and improve customer satisfaction by ensuring customers’ desired products are always in stock.

Another excellent example of implementing an inventory control system is the Toyota manufacturing company.

Toyota pioneered the Just-in-Time (JIT) inventory system, which is now widely used in manufacturing and other industries.

The JIT system involves producing and delivering products just in time to satisfy the demand from customers without holding excess inventory.

This way, Toyota could significantly reduce its inventory carrying costs, reduce waste and improve the efficiency of its production processes.

As we have just seen, inventory control systems are not only applicable to the construction industry but to any industry working with large amounts of inventory, such as retail and manufacturing.

What Are the Types of Inventory Control Systems

Now that we understand what inventory control systems are and how you can benefit from them, we will discuss the two main types commonly used across industries: periodic and perpetual inventory systems.

Let’s start with the former.

Periodic Inventory System

A periodic inventory system relies on counting inventory physically at specific time intervals.

For example, you can carry out inventory counting monthly, once per four months, or yearly, depending on your company’s needs.

This system is simple and works on the formula:

The process consists of counting the inventory physically and shifting the balance in the purchase account to it.

In the end, you adjust the inventory account to match the cost of the ending stock. This new balance is then applied to the beginning of the new period.

Due to simplicity, this system is easy to manage for smaller businesses with small amounts of inventory and doesn’t require any implementation of software or technology.

On the other hand, the periodic inventory system is not appropriate for big companies with lots of inventory. Let’s see why.

First, this type of counting inventory is highly time-consuming and, most of the time, cannot be done within the company’s regular working hours.

Everyday business activities must be suspended during inventory counting, or the employees must work extra hours. In both cases, it increases the company’s costs.

Furthermore, it requires much workforce, which is highly prone to human error as the counting is done manually.

Another disadvantage is that inventory with this system is rarely up to date.

It is much more challenging to notice discrepancies in inventory levels when you count your inventory only once every couple of months or once a year.

In summary, periodic inventory systems are best for smaller companies with less inventory at one location.

Bigger companies with lots of stock should implement the perpetual inventory system that we will talk about in the following section.

Perpetual Inventory System

As its name suggests, a perpetual inventory control system tracks the inventory level perpetually.

That means it continually provides an accurate count of inventory levels in real time, and inventory information is immediately accessible.

That is possible because the system uses technology like barcodes or Radio Frequency Identification (RFID) tags to count the inventory.

For example, when you sell a product and scan its barcode, the system immediately removes the product from the inventory database and updates the information.

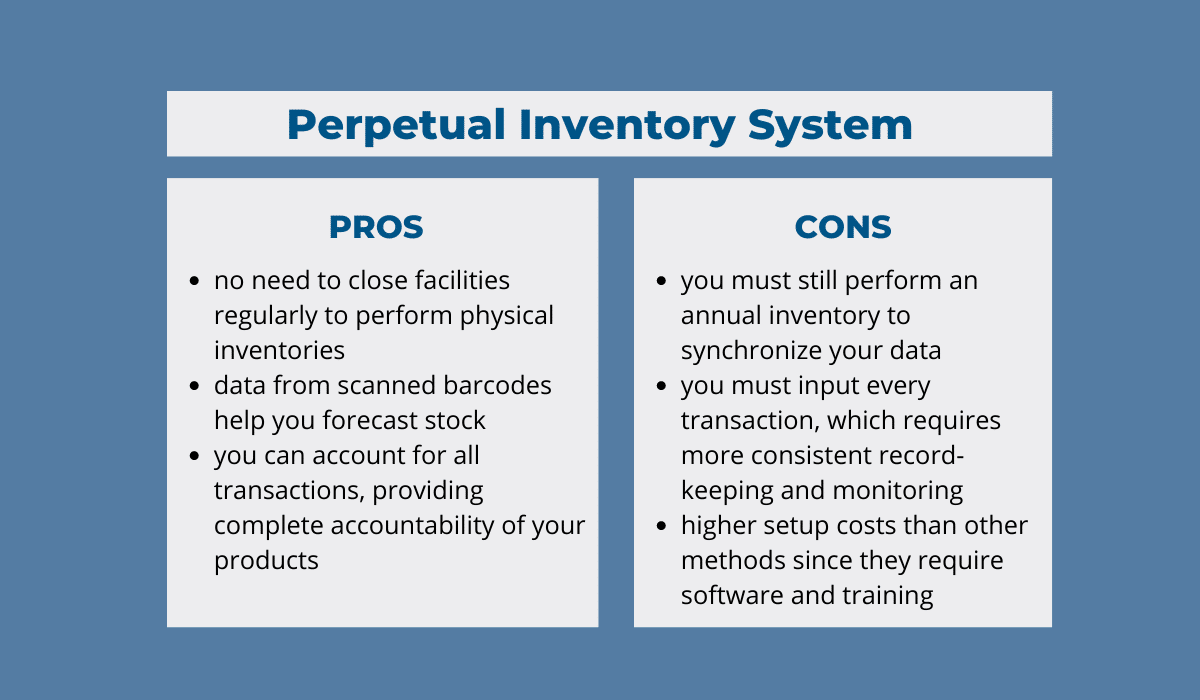

This system, like every other, has its advantages and disadvantages.

Let’s see which.

Advantages of the perpetual inventory system include continually updating inventory levels and providing information about stocks without counting the inventory manually.

This saves lots of time and money, and there is no need to suspend normal business activities or close the facilities to perform physical inventory.

Another great advantage of the perpetual system is the accountability it fosters.

With this system, you can make sure that every transaction is logged in the system, so when the time for financial audits comes, you will have the data easily accessible and in one place.

However, even though this system has some significant advantages, it is pretty costly because it requires software, continual maintenance, and training for the employees.

Moreover, this system might not capture discrepancies resulting from theft, loss, damage, and scanning errors, so you will still have to perform an annual physical inventory to synchronize the data.

Despite certain downsides, the perpetual inventory control system is crucial for companies of all sizes with large volumes of inventory or multiple locations, such as construction companies, because it significantly reduces the costs of counting inventory.

In the next section, we will explain how inventory control systems work and suggest what to be careful about when choosing the right one.

How Do Inventory Control Systems Work

Until now, we have talked about inventory control systems and their types, but we haven’t mentioned how they work. Let’s fix that.

An inventory control system for identifying and tracking construction inventory works through software and apps paired with one of the two following ways of monitoring inventory:

- Barcodes

- Radio Frequency Identification (RFID)

We will explain them one by one and see how they differ.

Barcodes

A barcode inventory control system works by assigning a unique barcode to each item in the inventory.

These barcodes can be scanned using a handheld scanner or a mobile device, and the information is instantly uploaded into the inventory management software.

This allows for real-time tracking of inventory levels and the ability to locate specific items when needed quickly.

The barcode system also makes it easy to track inventory movements between multiple locations and enables more accurate reporting and analytics, which is a significant benefit for the construction industry.

Radio Frequency Identification (RFID)

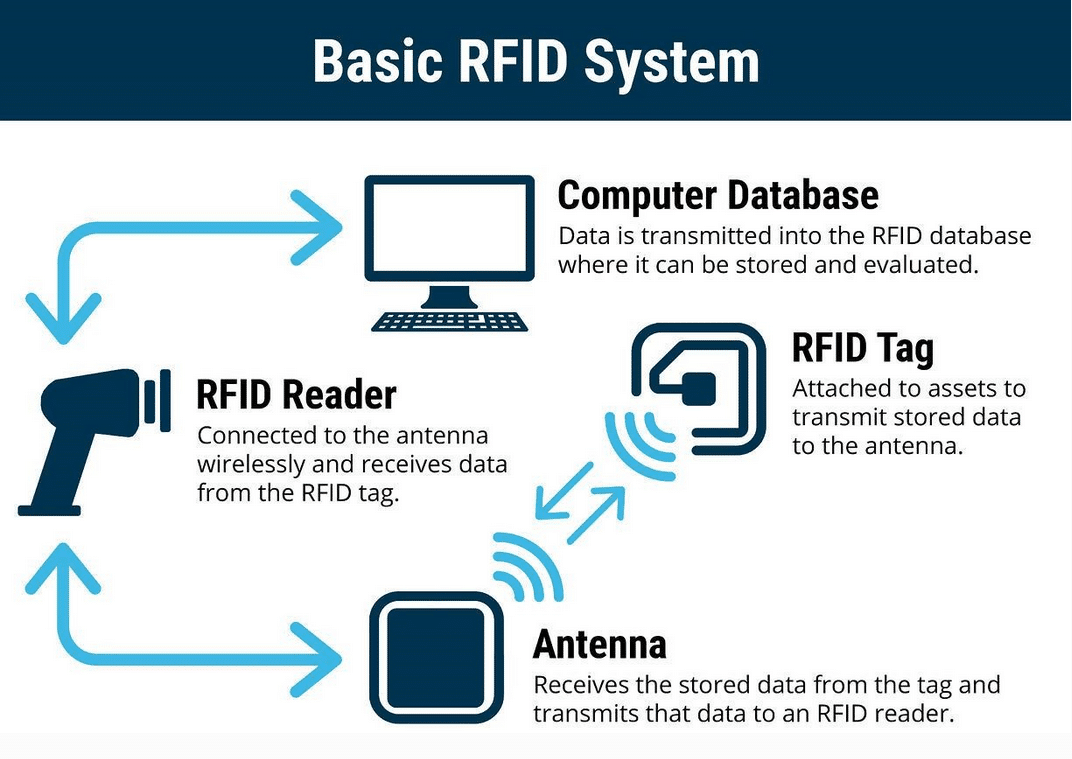

RFID systems offer many of the same benefits as barcode inventory control but use a different technology.

In this system, RFID tags are placed on items, and inventory control software records information each time the tag is tracked.

This allows for the quick and accurate tracking of inventory levels and the location of specific items.

However, there are downsides to RFID tracking, including higher costs compared to barcode tracking. Therefore, RFID is typically used only for high-value items.

Additionally, RFID tracking has some range limitations and can experience interference issues.

The use of radio waves means that the signals can be disrupted or blocked by other electronic devices, such as metal surfaces or other RFID readers operating on the same frequency.

Objectively speaking, when choosing the inventory control system for your company, keep in mind that barcodes are inexpensive to print, easy to apply, quick to scan, and not susceptible to interferences compared to RFID tracking.

Our inventory management software, GoCodes Asset Tracking, works with patented and customizable QR code tags, a type of barcode, and offers easy inventory tracking through your smartphone.

Here is one review from a satisfied customer who emphasizes how easy it is to use our inventory tracking.

If you want to implement an inventory control system into your business, get your GoCodes Asset Tracking free trial today.

Conclusion

We hope this article has given you a better understanding of what inventory control systems are, how they work, and how they can help you maintain proper inventory levels.

To summarize, a quality inventory control system will streamline your construction company’s operations and avoid costly mistakes.

With the ability to track your inventory in real time, you’ll always know what supplies you have and where they are located, ensuring that your projects run smoothly and efficiently.

Invest in an inventory control system and take the first step towards a more organized and successful construction business. It will pay off.