Efficient construction operations hinge on successful equipment management, and the key to achieving this lies in using equipment management software.

In the dynamic construction industry, with many activities happening simultaneously on more construction sites, this tool prevents equipment misplacement, drives cost savings, and elevates overall operational efficiency.

In the following sections, we will explore precisely what equipment management software does to achieve these goals, so let’s jump right in.

In this article...

Enables Easy Equipment Tracking

In the bustling construction landscape, keeping tabs on your equipment is essential if you want to finish projects without delays and ensure the safety of your workers.

Equipment management software makes this task straightforward.

With this tool at your disposal, you can track the whereabouts of your equipment at any time, granting you a real-time overview of their locations.

And equipment tracking is essential in construction for a number of reasons:

- it ensures efficient equipment allocation by allowing you to know the exact location and status of each piece of equipment, preventing unnecessary downtime and delays

- it helps in preventive maintenance, reducing the risk of equipment failures and costly repairs

- accurate tracking enhances accountability and helps prevent theft or unauthorized use of equipment

But how does equipment management software do all this? It’s fairly simple.

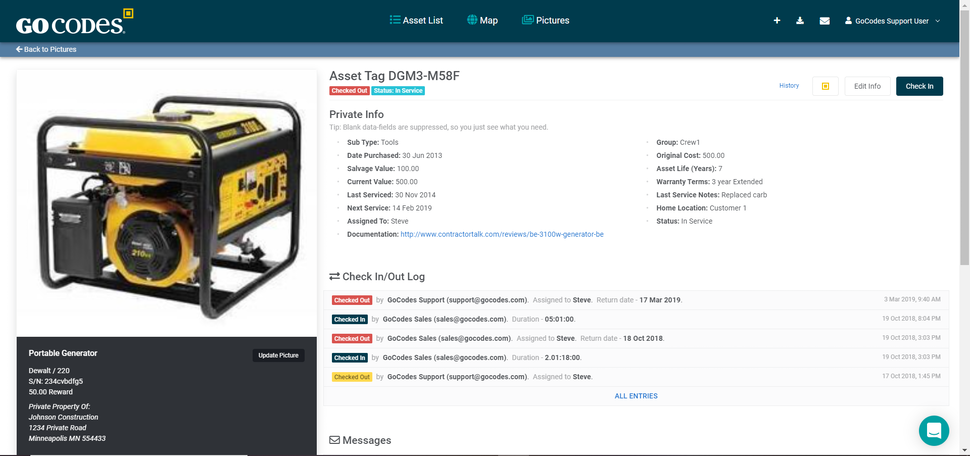

You have one centralized platform where you can manage and monitor all your equipment.

You can view details such as purchase date, size, value, location, who is responsible for the asset at the given moment, and even history of handling the equipment and maintenance history.

All this information, which you can access from wherever you are because it is located in the cloud, means you no longer have to waste time searching through spreadsheets to know what is happening with that piece of equipment.

Or even worse, running up and down the construction site to find where it is.

When you have all the data in one place, you simply access the system, locate the equipment, and direct your team accordingly.

More robust equipment management software, like our GoCodes Asset Tracking, apart from being a centralized platform where you can monitor and manage all your equipment, comes with rugged tags that you attach to your assets.

When these tags are scanned, employees can check in and check out equipment, and the software automatically updates information on who used the asset, when and where.

This enhances accountability but also allows you to allocate equipment optimally. We will explain how later on.

Ultimately, effective equipment tracking in construction contributes to increased productivity, time savings, and the successful completion of projects.

And it is equipment management software that enables you to track your assets easily!

Improves Equipment Allocation

Another important job this software does is improving equipment allocation.

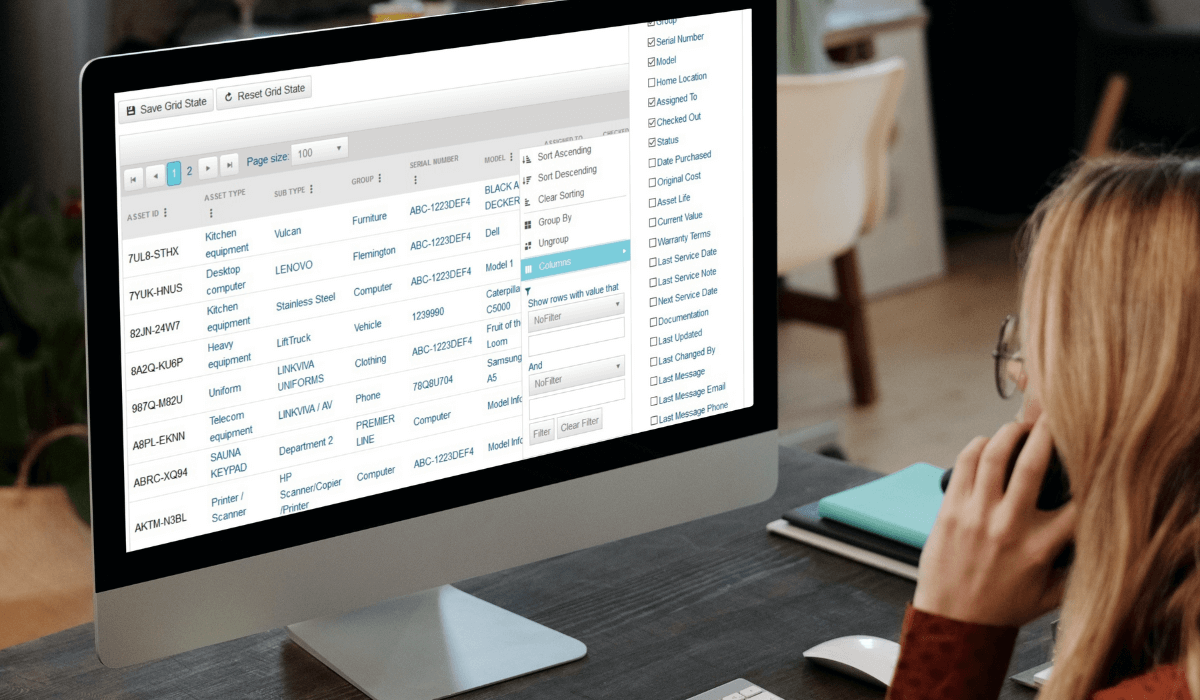

With equipment management software, you gain a clear and organized view of your entire equipment inventory, allowing you to allocate all those pieces of equipment to employees and various construction sites easily.

Let’s say you’re planning a new project and must decide which equipment to use.

The software assists you in this task by providing insights into the availability and utilization of each piece.

This streamlined process not only saves you hours and hours of time but also improves your overall decision-making.

When you have all available equipment in front of you (virtually, of course), and when you see the history data for each piece, you can allocate it more precisely and prevent overloading certain equipment while others remain underutilized.

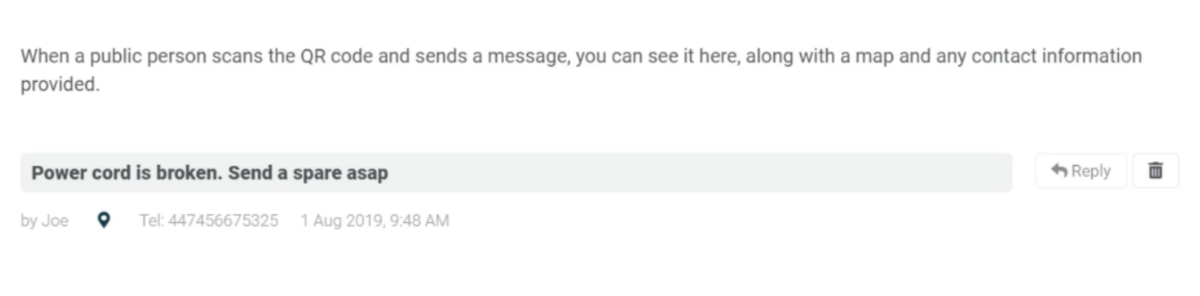

On top of that, when assets have tags on them, every employee who is using the equipment can scan it with their phone and write a message, which you immediately get notified of.

If an asset gets broken and the person needs a spare one, you can quickly provide assistance and allocate another piece of equipment. Because you know which equipment is available, you can quickly send it to the construction site.

This fast and easy exchange of asset information has a significant impact—it prevents delays, reduces downtime, and enables a more efficient use of your equipment fleet.

Bottom line, by enhancing equipment allocation, equipment management software becomes a valuable help in optimizing resources, saving time, and improving the overall efficiency of your projects.

Enables Higher Cost Savings

Achieving cost savings is a key aim for any business, and equipment management software can significantly contribute to this objective in many ways.

Let’s explore how.

Firstly, the software helps you minimize idle time by providing real-time visibility into equipment usage.

Idle time can creep up and be very costly. If you think that nothing will happen to your equipment because it’s not broken, but it’s just not being used, that’s false.

In fact, excessive idling could lead to premature engine failure due to lack of movement, corrosion and rust, moisture accumulation, clogged fuel injectors or fuel lines, and more.

If this happens, engine failure can cost you between $20,000 and $40,000, depending on the equipment type.

But with equipment management software, you can monitor the status and activity of each piece of equipment.

This enables you to identify prolonged idle time and take measures, such as optimizing scheduling or reassigning equipment to active tasks, to get equipment back into action and save yourself significant amounts of money.

The ability to record safety inspections, certifications, and training records for each piece of equipment is another vital feature of equipment management software, which also brings cost savings or at least cost avoidance.

When your equipment complies with regulations, and you have it all noted down in a system, you can prevent fines and legal complications that could impact your bottom line.

On top of that, with equipment management software like our GoCodes Asset Tracking, you can schedule future service tasks, like maintenance and repairs.

You can see how simple it is to set this feature in the short video below:

This ensures that preventive maintenance tasks are carried out promptly, reducing the risk of unexpected breakdowns and the associated high repair costs.

Lastly, the software’s tracking capabilities contribute to preventing redundant purchases.

When you know how much equipment you have and in what condition, you can make better decisions about when to repair or replace equipment.

This prevents unnecessary spending on new equipment when your existing assets can still be utilized efficiently.

Evidently, there are many ways in which you can save money by implementing equipment management software in your organization.

Not doing it would be a lost opportunity for better cost management and savings.

Increases Jobsite Productivity

Increasing jobsite productivity is a shared goal for every construction company out there, and implementing equipment management software helps you achieve just that.

With this software in place, your employees no longer need to waste valuable time searching for or relocating equipment across different sites.

The centralized tracking system ensures that assets are efficiently allocated, minimizing downtime and allowing your team to focus on the job at hand.

Furthermore, the ability to set up and schedule maintenance tasks directly through the software, as we explained above, prevents scenarios where workers arrive ready to start only to find that essential equipment is not functioning correctly.

Instead, workers can start with tasks without unexpected delays, optimizing their time and efforts.

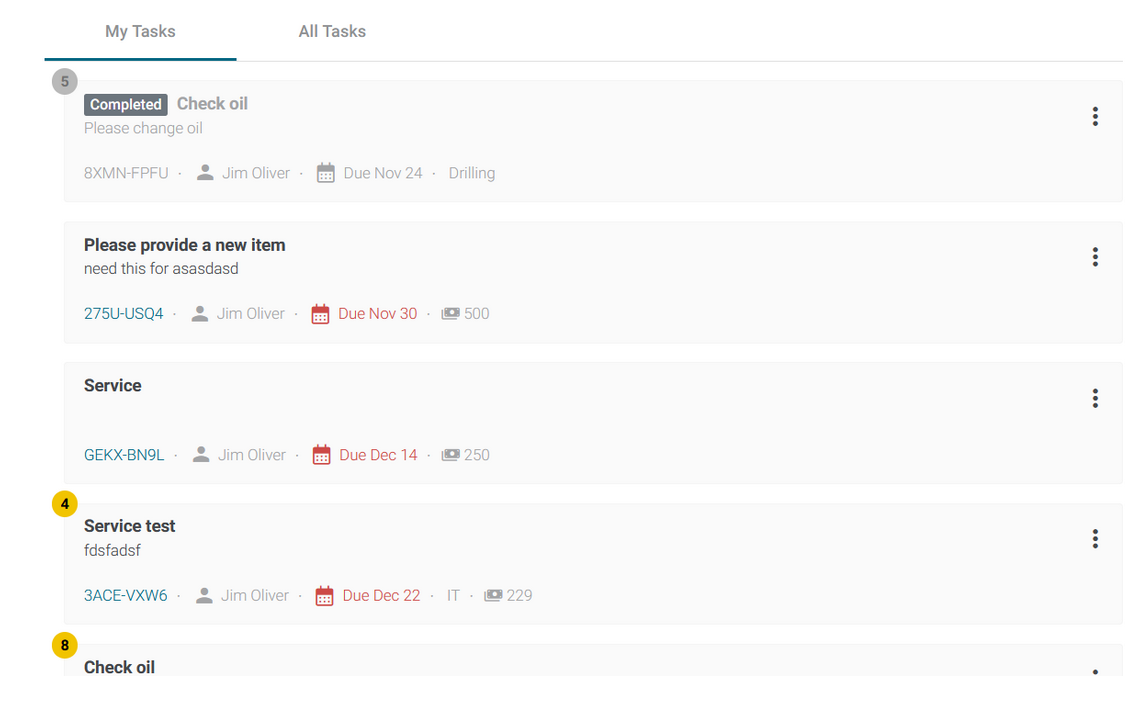

Beyond this, this software enables you to assign tasks directly to employees.

In GoCodes Asset Tracking, for example, you can schedule tasks for each piece of equipment and also assign the person responsible for it and the due date.

Then, when your employees come to the construction site and open the GoCodes Asset Tracking app on their phone, they can see which tasks have been assigned to them in the My Tasks section.

By assigning and tracking tasks through the system, you provide clear directives to your workers. They know what needs to be done and by when, fostering a more organized and efficient work environment.

What’s more, this also contributes to a sense of accountability and responsibility among your team members, which also affects their productivity.

In essence, equipment management software increases jobsite productivity by simplifying equipment allocation, preventing work disruptions due to maintenance issues, and fostering a structured workflow through task scheduling.

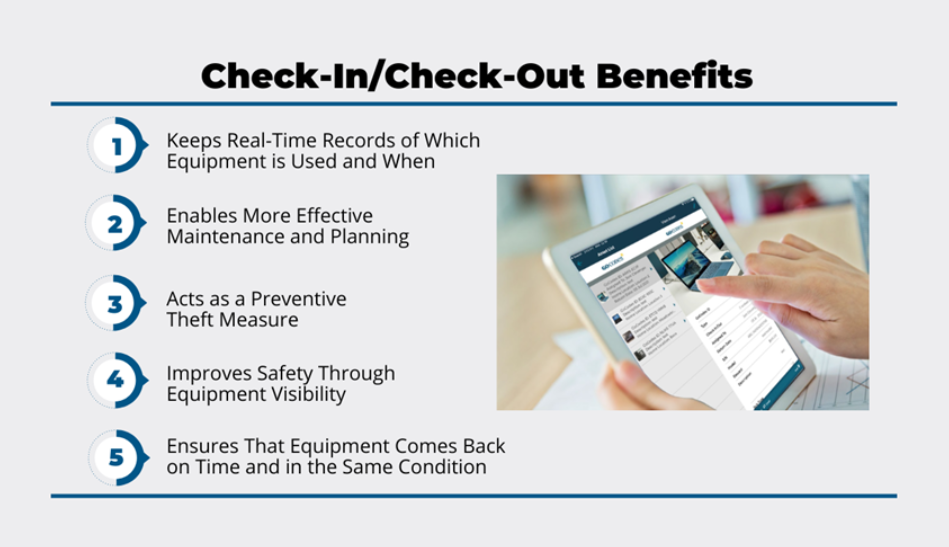

Enhances Worker Accountability

Improving worker accountability is essential for smooth construction operations and preventing equipment loss or theft.

Equipment management software does it seamlessly. Let’s see how.

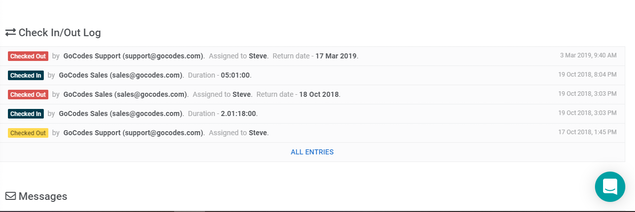

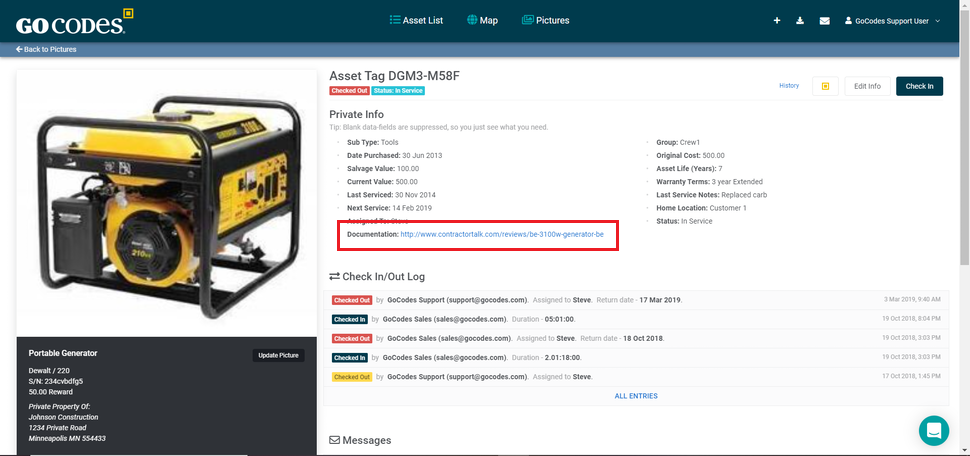

Every good equipment management software comes with a check-in and check-out feature.

This easy-to-use yet impactful functionality enables employees to check out equipment as well as check it back in when they finish work.

And the software automatically logs that information, as you can see below:

By documenting who used a specific piece of equipment, when and where, the system creates a clear trail of accountability and prevents misplacement and theft.

Also, because the software provides instant visibility into which employee is using a particular tool or machinery at any given moment, this fosters a sense of responsibility among your workers and prevents negligent equipment handling.

Moreover, equipment management software allows you to set permissions and access levels for different users.

You can control who can check out equipment, schedule maintenance, or generate reports by assigning specific responsibilities and access rights.

This hierarchical structure streamlines operations and ensures accountability is appropriately distributed within your team.

As you can see, investing in equipment management software not only safeguards your assets but also creates a culture of responsibility among your workforce.

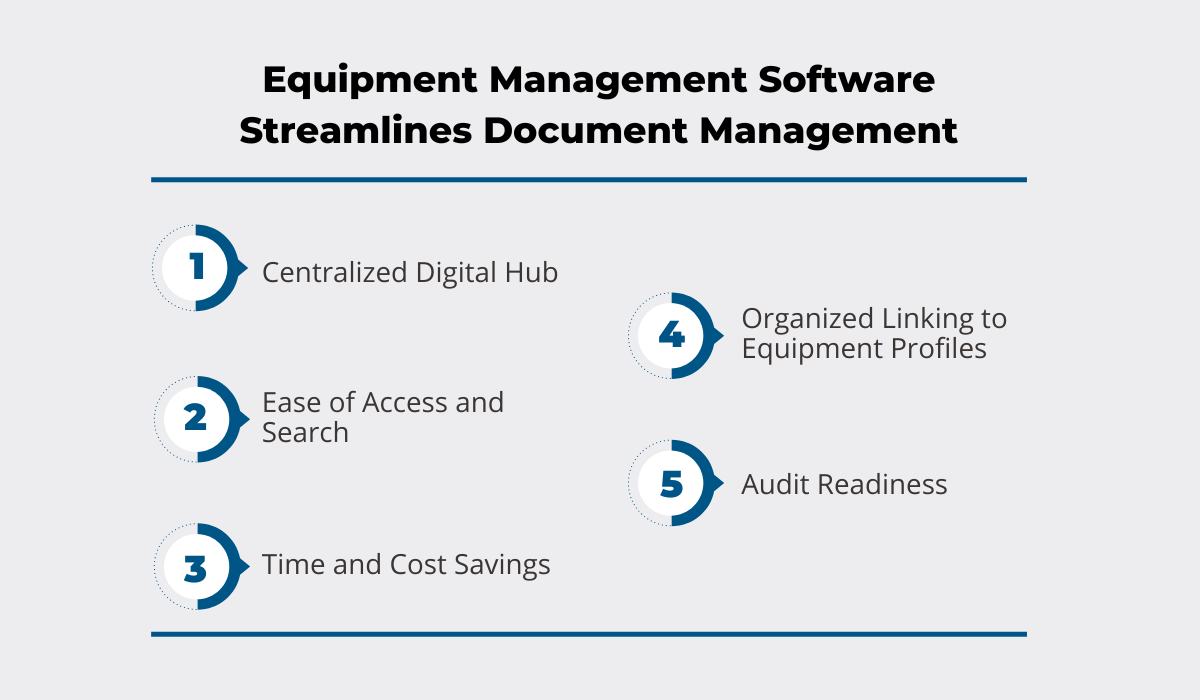

Streamlines Document Management

For a construction company owner like you, managing numerous equipment-related documents can be daunting.

Each piece of equipment needs its operator’s manual, maintenance records, inspection certificates, warranty information, insurance papers—you name it.

All these papers take up space and, truth be told, are easy to get lost.

However, equipment management software offers a solution by streamlining document management.

All your essential paperwork, from equipment manuals to safety certifications, can be centralized in one easily accessible digital hub.

You don’t have to search through stacks of paper or deal with misplaced documents—everything is just a click away.

Another key feature that simplifies document management is the ability to link documents directly to specific pieces of equipment.

Need the manual for that generator? It’s right there in the system, linked to the equipment profile.

This organized approach not only saves time (and space) but also ensures that crucial information is readily available when needed.

This proves its worth especially when it comes to audits and all your essential documents are neatly organized and easily accessible.

When you can showcase a comprehensive digital trail of equipment-related documentation, audits are much smoother. Also, you can avoid potential penalties and additional costs associated with non-compliance.

All in all, equipment management software streamlines document management, saving you time and potential costly errors.

Conclusion

And that concludes our exploration of what equipment management software does in construction.

As you have seen, this software is designed to help you with many areas of your business—from tracking equipment and better allocation of equipment in the first place, all the way to enhancing worker accountability and streamlining documentation.

The assistance and the benefits equipment management software brings to the table are indeed numerous and worth investing in!