Key Takeaways:

- GPS tracking allows you to monitor and receive real-time updates on your trucks’ whereabouts.

- Route planning is a feature that is going to help you map out the safest and most efficient routes for your drivers.

- Your truck fleet telematics system should also have maintenance scheduling features.

Looking to get a telematics system for your truck fleet, but don’t know where to start?

You’ve come to the right place.

In this article, we’ve compiled a list of six super useful features you should be looking for when researching your new fleet tracking solution.

They can all be real game-changers when it comes to streamlining your processes, safeguarding drivers and vehicles from different risks, reducing fleet management costs, and maximizing your trucks’ utilization in general.

Let’s see what they are.

In this article...

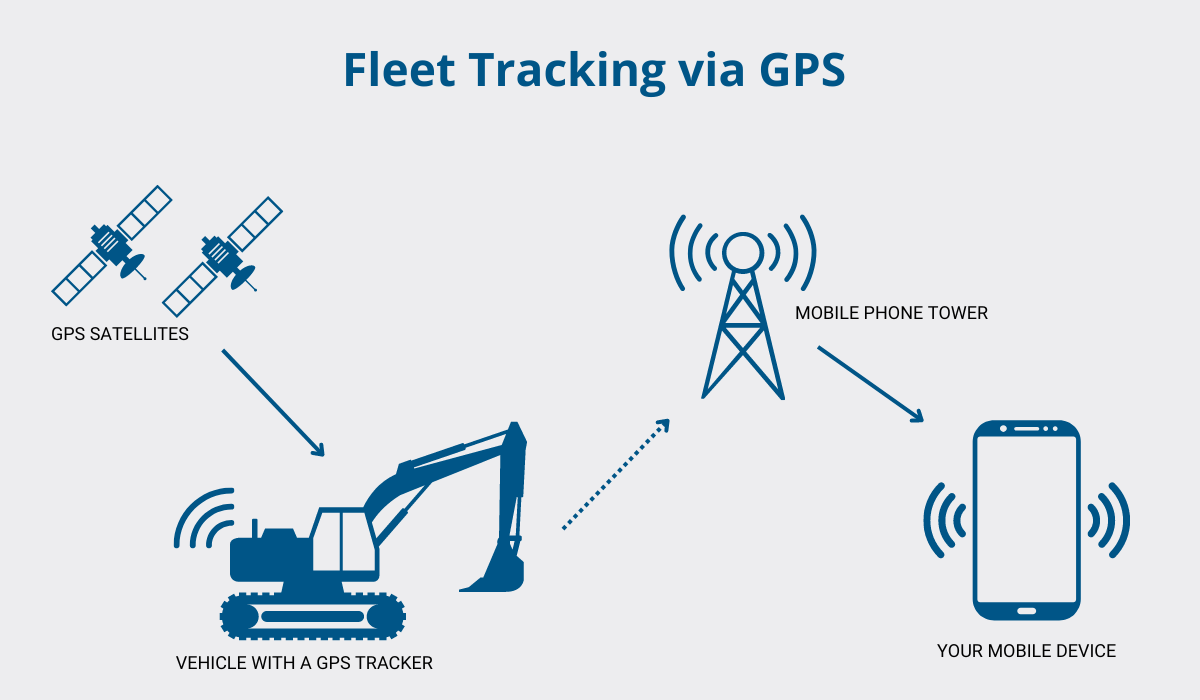

GPS Tracking

If there’s one telematics feature you can’t afford to miss out on, it’s this one.

GPS location monitoring is the heartbeat of fleet tracking, making it an indispensable feature to look for in your new telematics system.

It provides real-time updates on your trucks’ whereabouts, enabling you to constantly have your eye on every movement and route they take.

Now, to activate this feature, alongside the software, you’ll need to install GPS trackers in your vehicles.

As you can see in the image below, these devices are really the core of the system.

Using signals from GPS satellites and mobile phone towers, they calculate their location and transmit this data to your software, which then translates it into a visual representation on a map.

Simple, yet highly effective.

Below, you can see the GPS trackers developed by us at GoCodes Asset Tracking.

Staying true to our mission of helping companies maximize the visibility of their assets, we’ve created these compact yet powerful devices that provide real-time location updates for your valuable vehicles, whether stationary or in motion.

But what do you get out of all this?

Quite a bit, actually.

This ability to continuously monitor your trucks offers numerous perks:

- More efficient route optimization

- Increased security

- Improved driver safety

- Decreased risk of theft

- Enhanced compliance and accountability

Bottom line?

This feature is at the top of our list for good reason.

If you’re serious about running your truck fleet like a pro, you absolutely need a software solution armed with this game-changing capability.

It’s easy to get a hang of, highly efficient, and, most importantly, boosts your fleet’s visibility like no other tool.

Route Planning

The route planning feature automatically maps out the safest and most efficient routes for your drivers, either in real-time as the driver is en route or in advance.

It does so by analyzing:

- Traffic conditions

- Road closures

- Weather forecasts

- Delivery schedules

- Vehicle capacity

- Specific constraints and priorities set by you

Some solutions even maintain records of past trips, using them as a reference to deliver better results in the future.

This technology ensures your drivers always take the best possible routes, significantly improving overall operational productivity and cost-efficiency by reducing travel time, fuel costs, unplanned stops, vehicle wear and tear, and even the environmental impact of your fleet.

Essentially, a win on all fronts.

At Axis Europe, a construction company specializing in the repair, maintenance, and refurbishment of housing, commercial, and public properties, they would certainly agree.

According to them, this technology “is a key solution to enable the performance of [their] field force.”

Simon Spriggs, senior sales & partnership manager at FLS, the company providing Axis Europe with their route optimization systems, emphasizes that manual route planning simply doesn’t cut it anymore, given the complexity of fieldwork today:

“There are a possible 3.6 million different route sequences for a single field operative with 10 visits in their shift. Add in the complexity of emergency orders, cancellations, and sick days and it quickly becomes evident that manual optimization is time-consuming and ineffective.”

Automated route planners, on the other hand, are far more efficient, faster, and accurate, ensuring your drivers arrive at their destination safe, sound, and right on schedule, every single time.

That’s precisely why this feature is another must-have for all fleet managers aiming to enhance the efficiency, safety, and profitability of their fleet.

Custom Alerts

This feature enables you to set up notifications that warn you about certain events or behaviors that could pose risks to your drivers, vehicles, or transported cargo.

These warnings occur in real time, as risky behavior unfolds, allowing for immediate corrective action.

Below, you’ll find examples of common alerts:

| Unauthorized vehicle use alerts | prevent theft |

| Speeding or harsh braking alerts | ensure driver safety |

| Due maintenance alerts | reduce wear and tear and increase vehicle lifespan |

| Route deviation alerts | reduce theft and optimize fuel efficiency |

| Temperature, or shock and vibration alerts | preserve the integrity and quality of transported goods |

As you can see, with this feature, managing daily tasks, particularly maintenance-related ones, becomes much easier.

There’s no need to mull over whether that oil change was done or not—the software makes sure it gets done, every time.

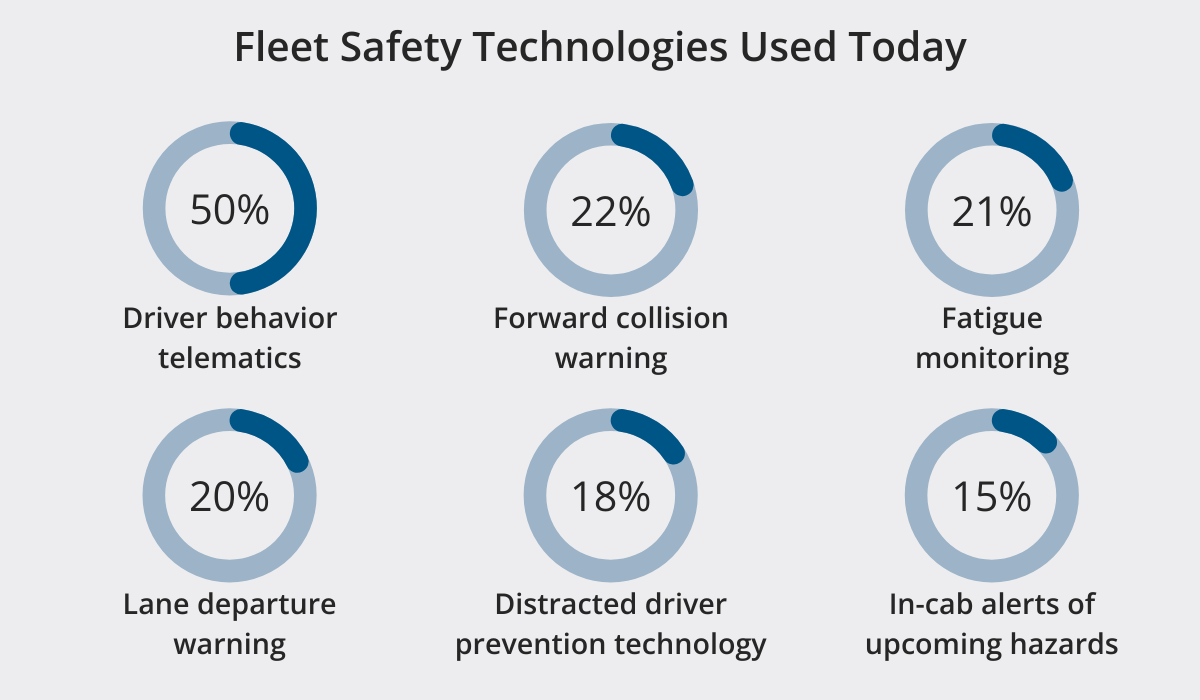

However, the area where alerts prove to be most impactful is definitely driver safety.

A report from GPS Insight backs this up, indicating that the majority of technologies fleet managers use to ensure the well-being of their drivers are alert-based.

These technologies include driver behavior telematics that warn about speeding, hard braking, or seatbelt use, forward collision warning systems, fatigue monitoring, lane departure warnings, distracted driver prevention systems, and in-cab alerts for upcoming hazards.

All in all, managing fleets is no easy feat, that’s for sure.

But luckily, with the automated alert feature, you can breathe a sigh of relief knowing that your assets and drivers are closely monitored and protected.

Even if anything goes off course (either figuratively or literally), rest assured, your telematics system will have your back and let you know about it.

Real-Time Reporting

Your telematics system should go beyond just passively observing your vehicles; it should also be able to analyze relevant fleet information and generate actionable reports in real time that empower you to make better informed, data-driven, and timely decisions.

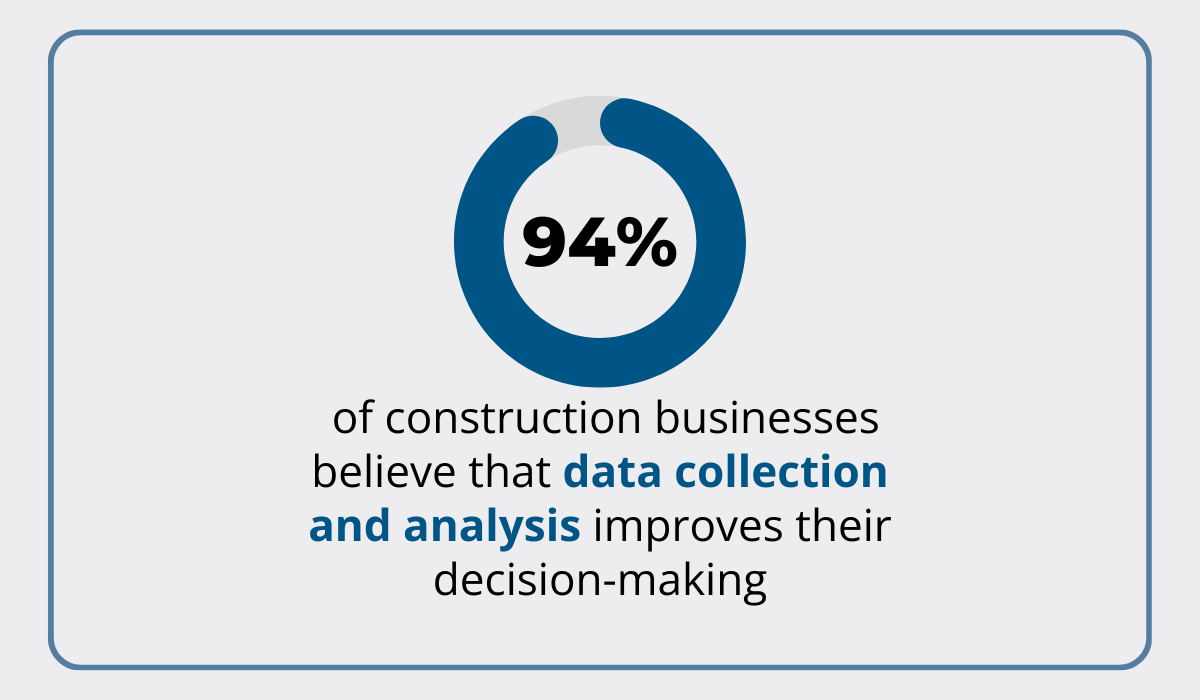

Did you know that, according to a survey conducted by Deloitte and Autodesk, a staggering 94% of construction businesses already recognize the need for data analysis when it comes to efficient decision-making?

In other words, robust reporting isn’t a nice-to-have feature anymore, but an industry standard.

So make sure your new telematics solution is empowering you to keep pace with your competitors and can deliver real-time reports covering various aspects of fleet management.

Think reports on fuel efficiency, driver behavior, environmental impact, compliance, maintenance history, and more.

They lay all vital information right in front of you, often using graphs and charts for easier visualization.

You can then compare these insights against your KPIs, industry standards, or competitors’ performance to optimize your processes and drive efficiency.

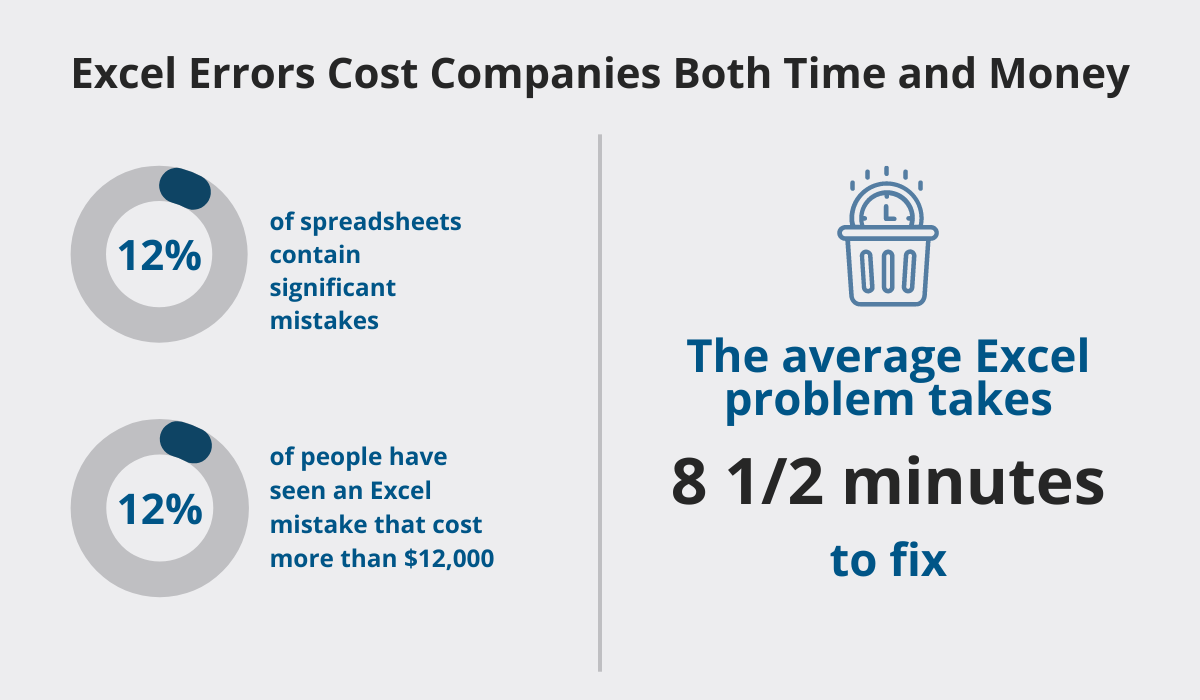

Let’s face it, manually tracking and analyzing such vast amounts of data only invites trouble.

Why waste time on spreadsheets that are highly labor-intensive and prone to human error when you can use a system that examines and interprets data in seconds?

Just take a look at research from the Acuity Training on Excel use.

It only goes to show how much time and money companies can spend on inefficient processes.

Automated real-time reporting is, without a doubt, a far more precise, accurate, and up-to-date alternative.

Robert White, operations manager at Maple Hill Lawn & Garden agrees, saying that before automation, they were practically operating blindfolded, relying on intuition rather than cold, hard data:

“Before using a fleet tracking solution, things were a big mystery. A lot of it was crossing your fingers and hoping to goodness that the bottom line panned out the way you wanted it at the end of each day, month, and then year. We did the best we could with paper documentation, but there was a lot of chance for error and dishonesty.”

As a result, they had no real insight into what was going on with their fleet and were never truly aware of how it was impacting the business’s bottom line.

All in all, don’t make the mistake of looking at this feature as a glorified calculator—it does so much more than crunching numbers.

In fact, if used correctly, it just might be your key to unlocking improved decision-making, smoother operations, and greater profitability.

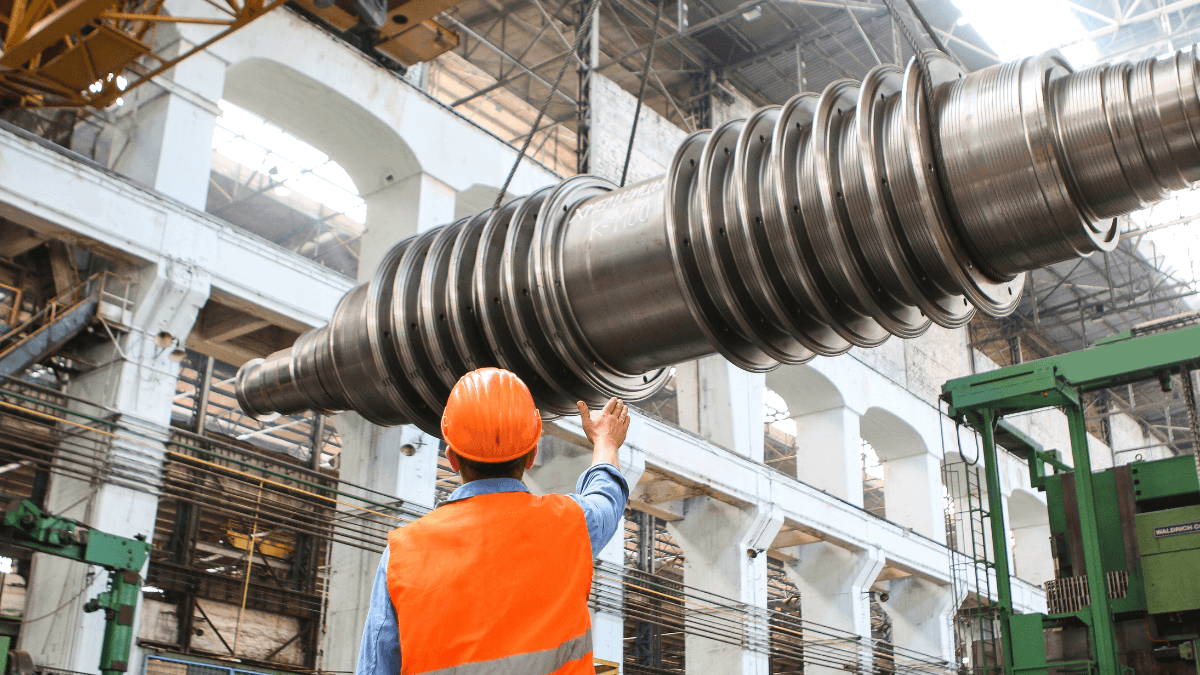

Maintenance Scheduling

Telematics solutions featuring maintenance scheduling capabilities help you manage and optimize fleet maintenance activities and schedules.

More specifically, this feature allows you to assign various service tasks and inspections to workers, monitor their progress, and even track your fleet’s health in real time.

With maintenance scheduling, vehicle maintenance never takes a backseat, keeping your trucks in top-notch condition and extending their service life.

As Bryan Bieschke, head of community and partnerships at UpKeep, underscores, neglecting proper inspections and service task scheduling is one of the main causes of unplanned asset downtime:

“Teams struggle to this day to control asset downtime for 2 core reasons. 1. We still have trouble with implementing and applying the basics of structured machine inspection and repair. 2. We […] do not build an asset-based maintenance strategy that looks at context, environment, or age to name a few. Planning and scheduling is a misunderstood process and it’s often put on the back burner for today’s downtime.”

But why is that?

Well, if you fail to organize your maintenance process effectively, there’s a significant risk that you and your team may miss a potential vehicle issue.

If left unaddressed, the issue may escalate and worsen over time, potentially leading to complete failure, right in the middle of the job.

This not only jeopardizes project timelines and causes delays, bear in mind, but also compromises driver safety.

So, to mitigate such risks, look for a system that makes maintenance planning easier because, ultimately, simplifying the process is what ensures upkeep tasks actually get done.

And the result?

A myriad of benefits regarding your budget and operational efficiency, says Fred Paul, manager at Wacker Neuson University:

“If a machine is equipped with the deluxe telematics version, and the machine alerts the operator with a problem, that same alert will be visible to the owner or mechanic at the same time. This provides valuable diagnostic assistance early and can help the mechanic determine a course of action. Often this can save time and money on repair or maintenance costs and keep the machine operating at top performance.”

Since maintenance scheduling enables timely diagnosis and resolution of vehicle problems, this proactive approach results in fewer defects and extends vehicle lifespans, saving you quite a bit of money on costly replacements and repairs in the long run.

Not bad for a single telematics system feature, right?

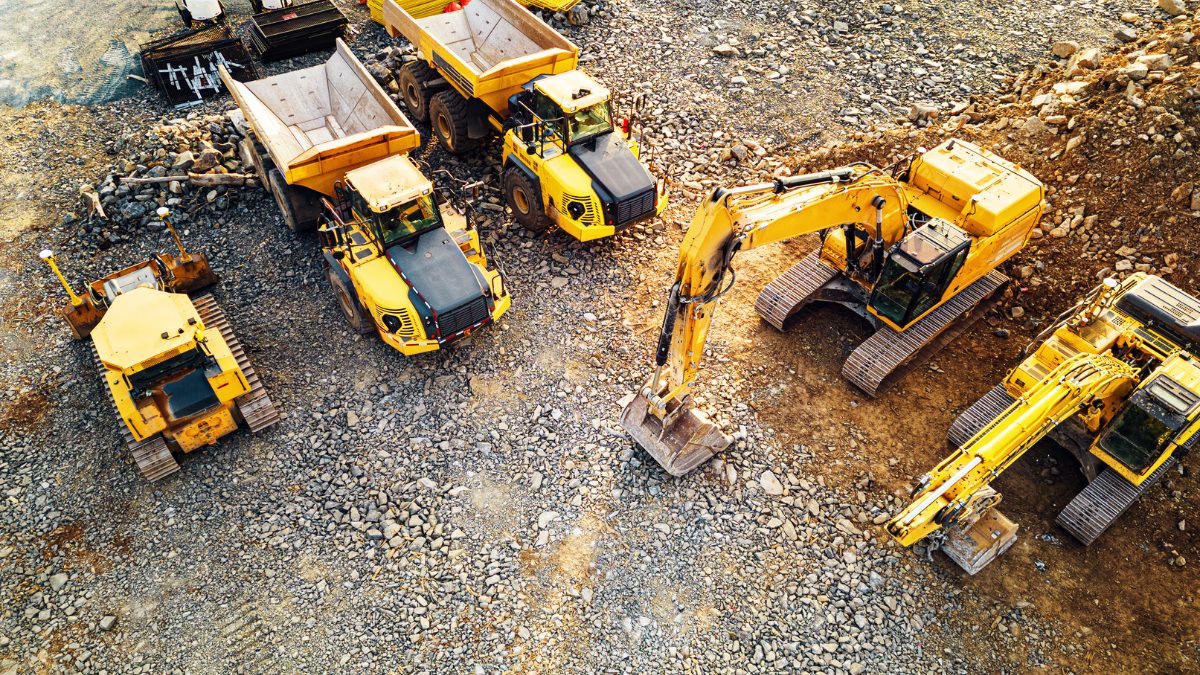

Utilization Monitoring

This feature allows you to monitor different aspects of vehicle utilization, granting you a comprehensive insight into the operational dynamics of your equipment: how it’s used, how often, and for how long.

It does so by keeping track of several metrics, such as:

- GPS location

- Vehicle speed

- Mileage

- Fuel consumption

- Driver behaviour

- Tire pressure

- Idle time

- Driver hours

With such a wealth of data at your fingertips, you get to know your fleet inside out, pinpointing areas for improvement with greater precision and taking resource allocation and utilization to the next level.

Are certain trucks being overutilized?

Expand your fleet to distribute workload evenly and minimize wear and tear.

Are others being underutilized?

Explore options such as reallocating them to another project or downsizing your fleet to cut maintenance, fuel, and insurance costs.

With utilization tracking, you don’t have to speculate about the next course of action—the system provides you with data-backed answers.

After all, your trucks are too expensive to just idle on the sidelines.

Lonnie Fritz, senior market professional at Construction Industries at Caterpillar Inc., agrees:

In construction, there’s a saying “More uptime, less downtime” for a reason.

You want those vehicles to be put to work as much as possible to ensure they are actually making you money, instead of just wasting it.

Utilization monitoring enables you to do just that.

It lets you measure every aspect of your fleet’s use, thus empowering you to control it better, smarter, and with more efficiency, ultimately unlocking its full potential.

Conclusion

At the end of the day, there is no single list of features that suits absolutely everyone’s fleet management needs.

However, we consider these six to be the most important ones to look out for.

Some of them are fleet tracking staples, while others are sometimes unrightfully overlooked, but overall, they are all super efficient in getting your fleet to that next level.

So, as you dive deeper into your research and product comparisons, keep these features in mind.

And if a vendor offers a free trial, take full advantage of the opportunity to experience firsthand how they can revolutionize your fleet’s performance.